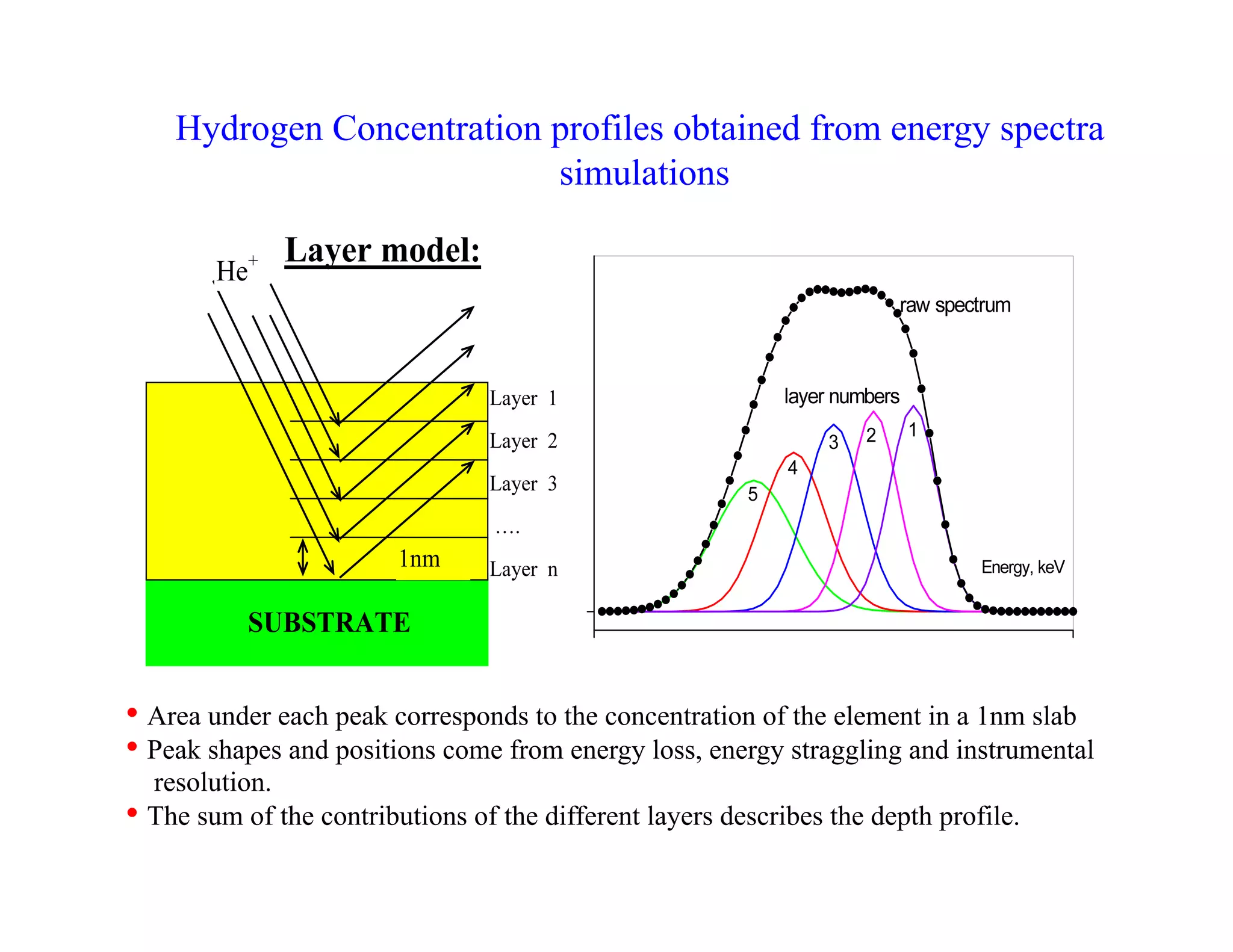

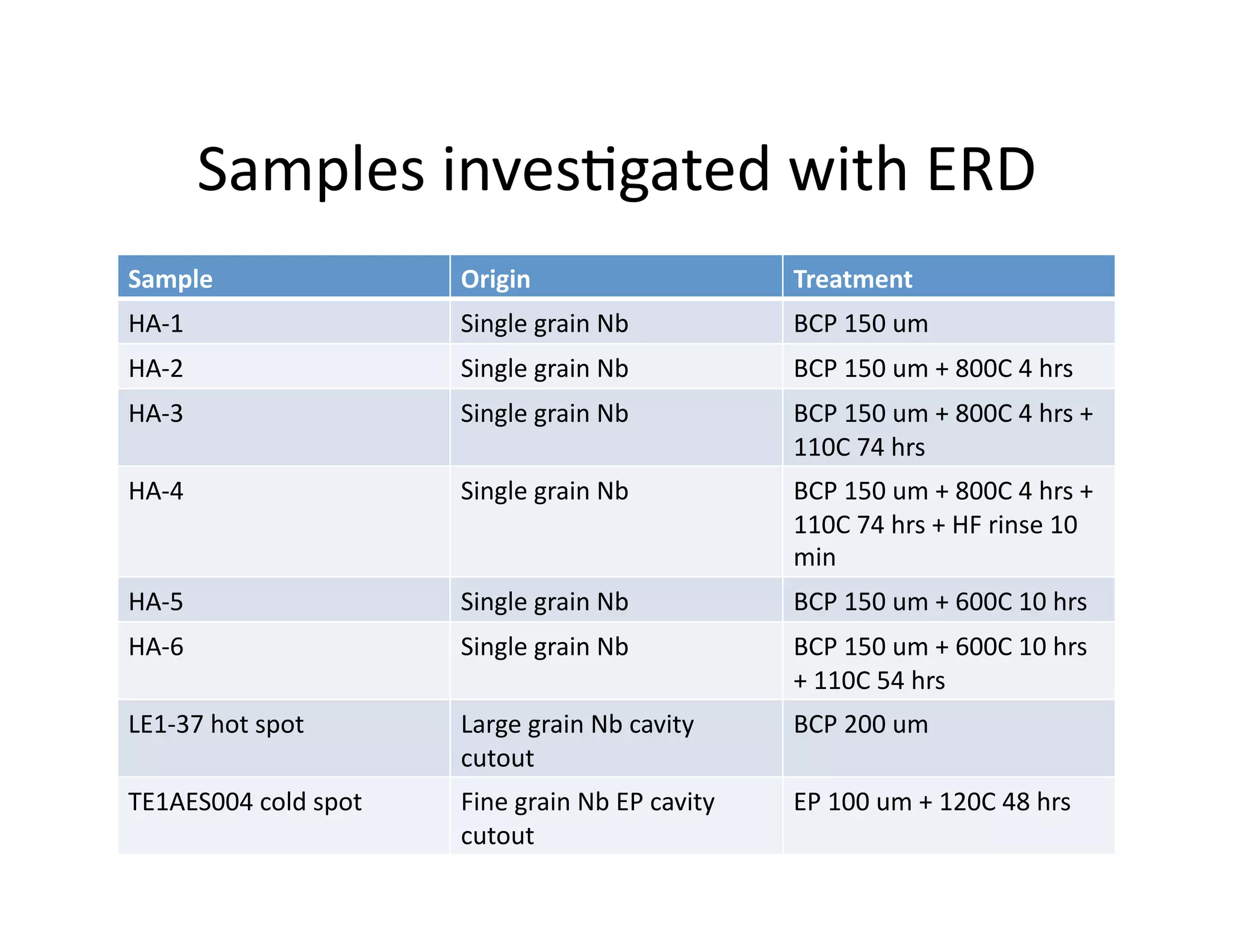

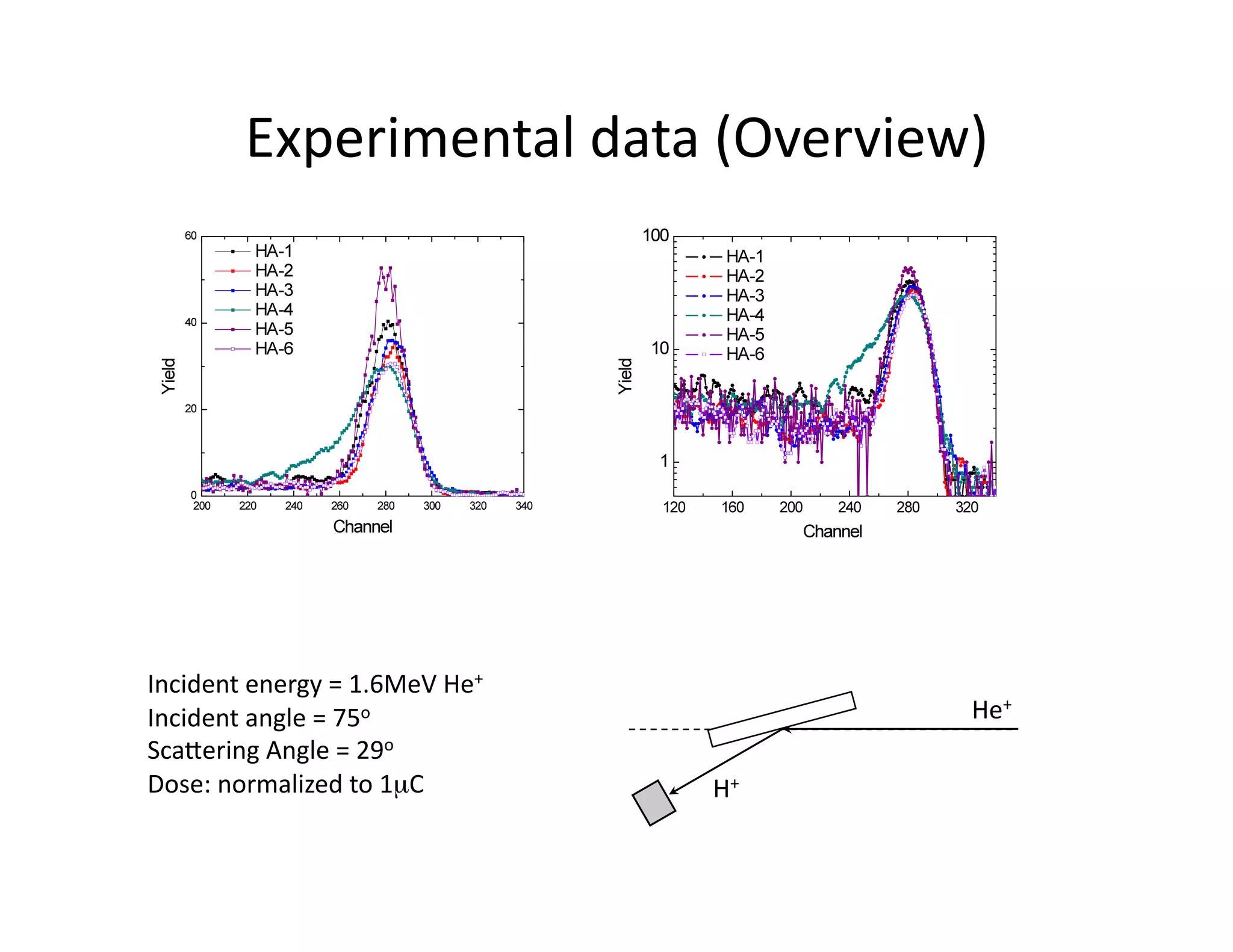

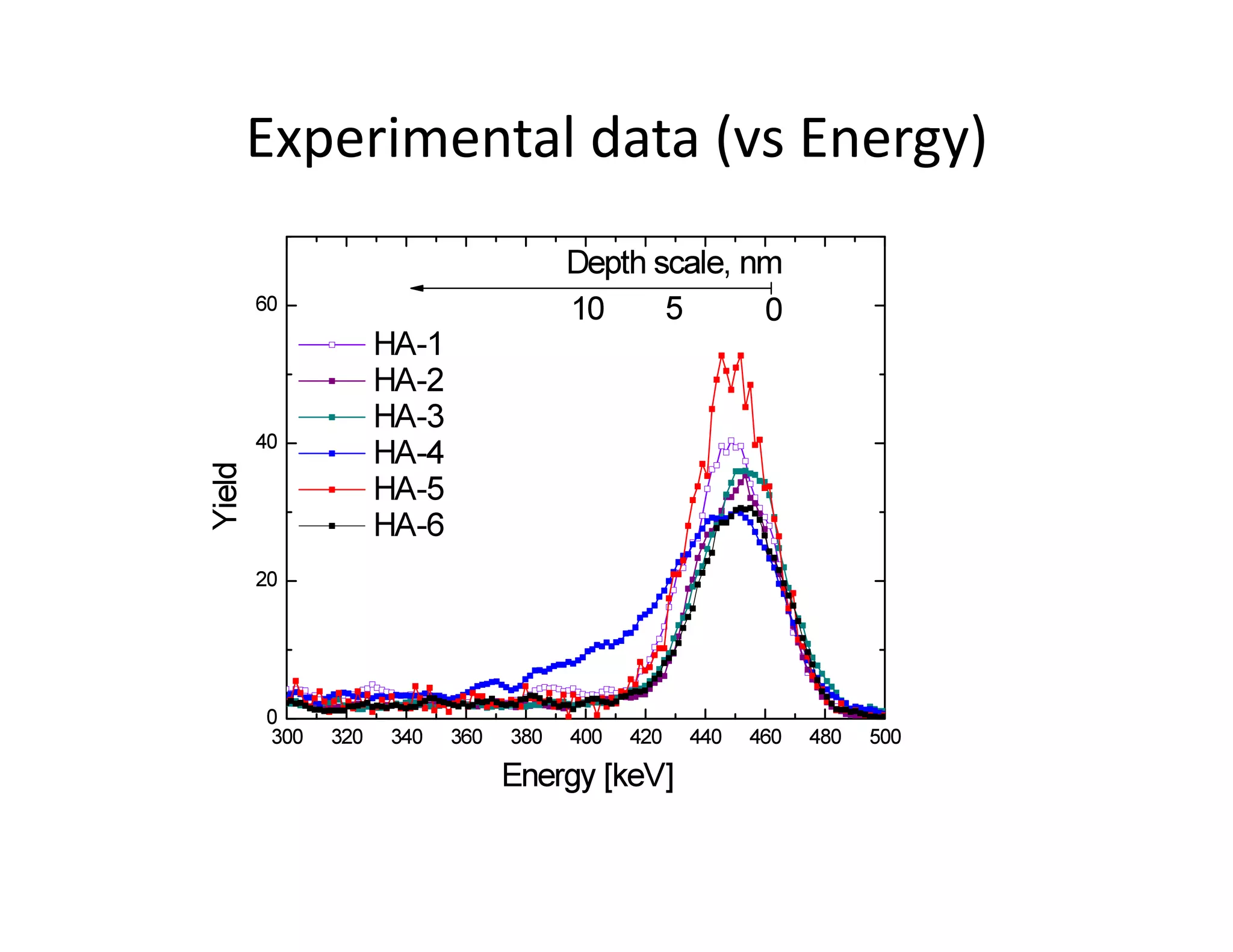

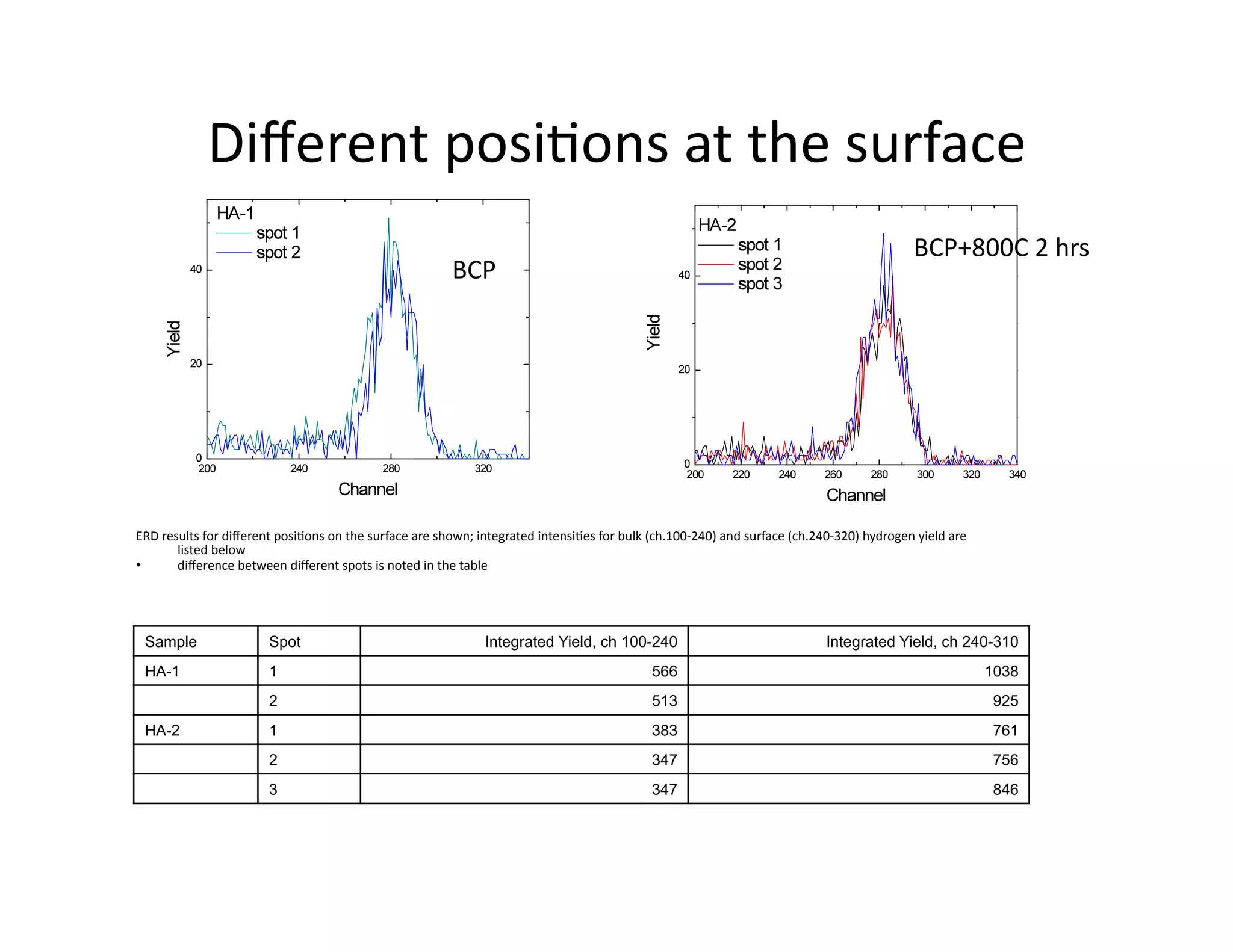

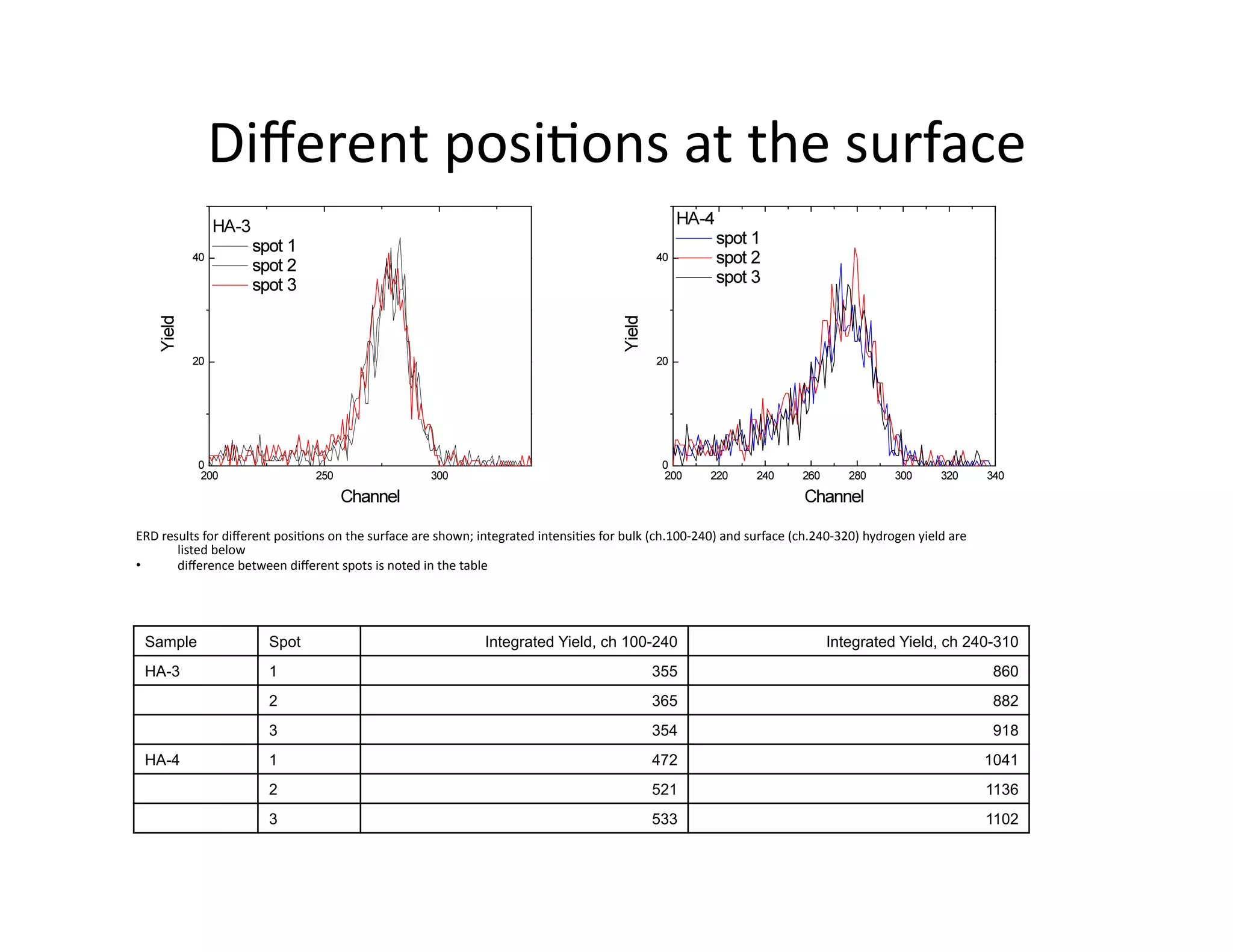

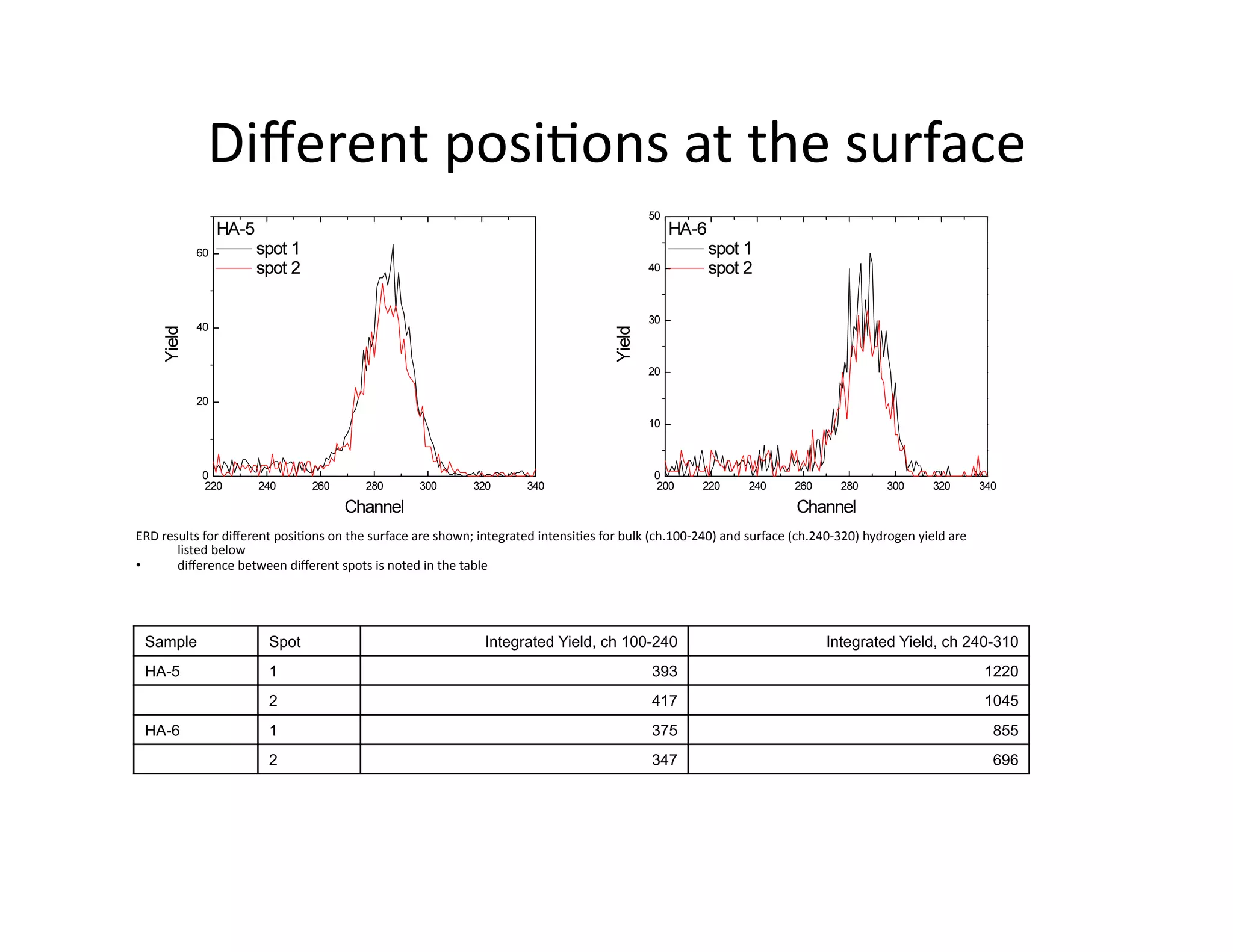

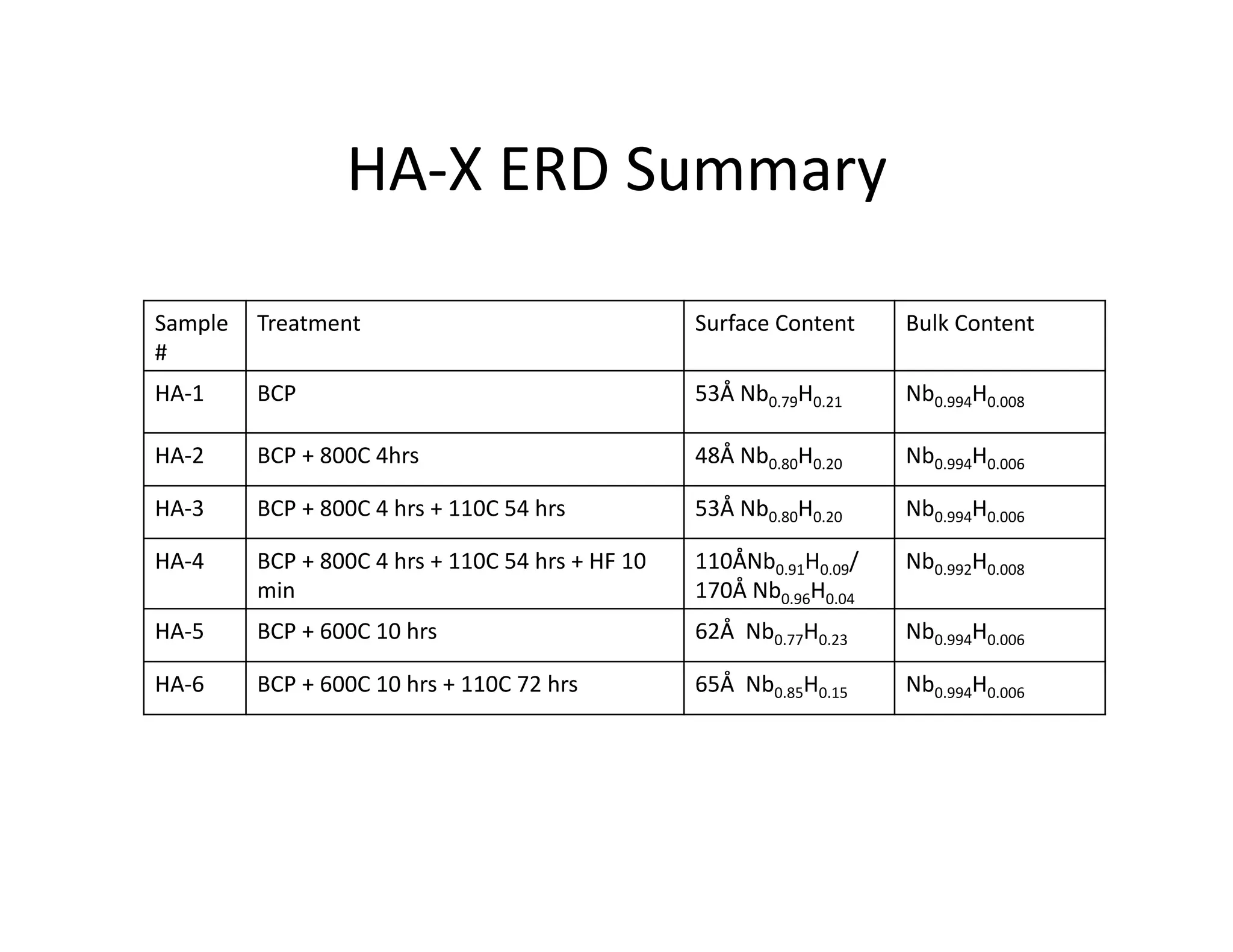

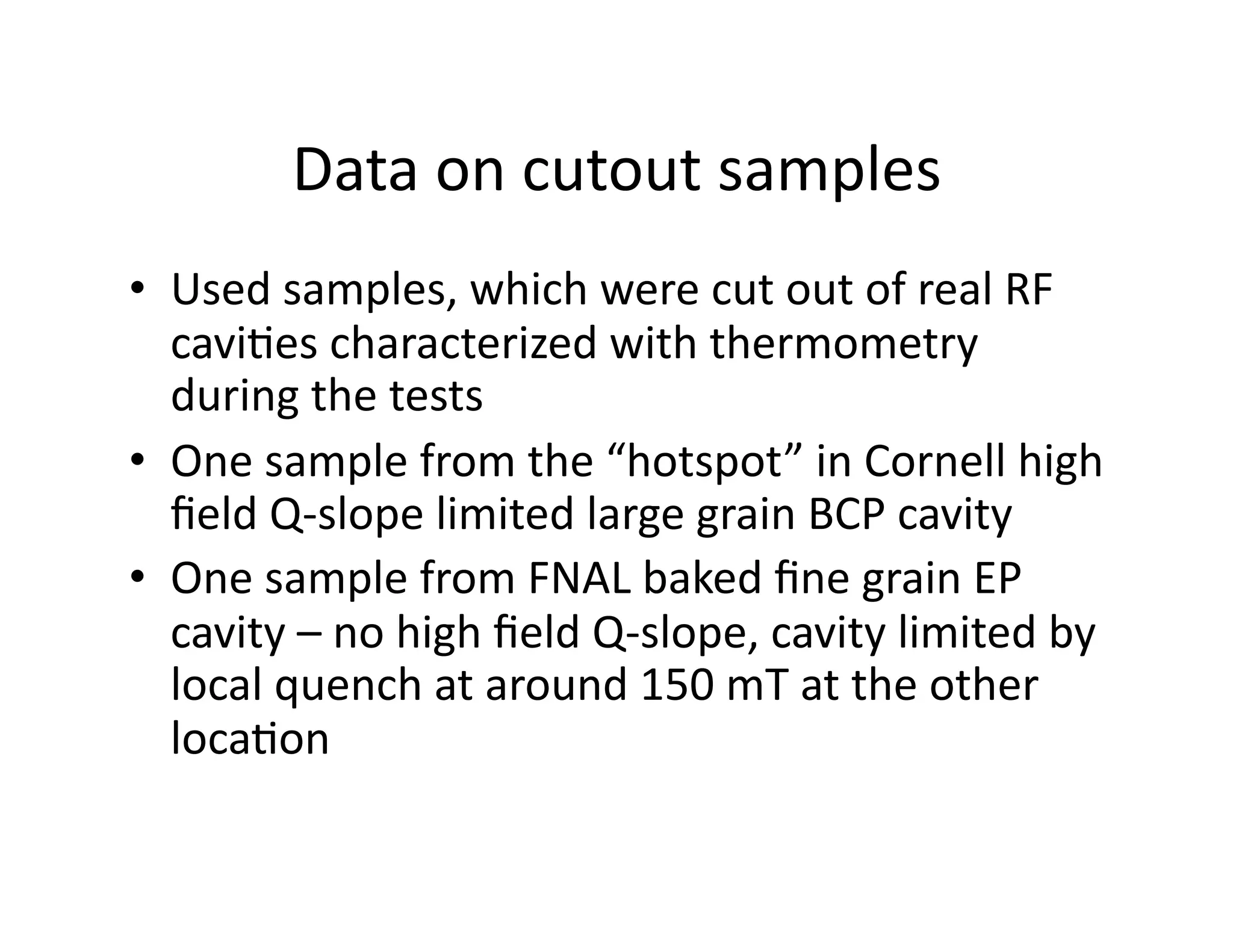

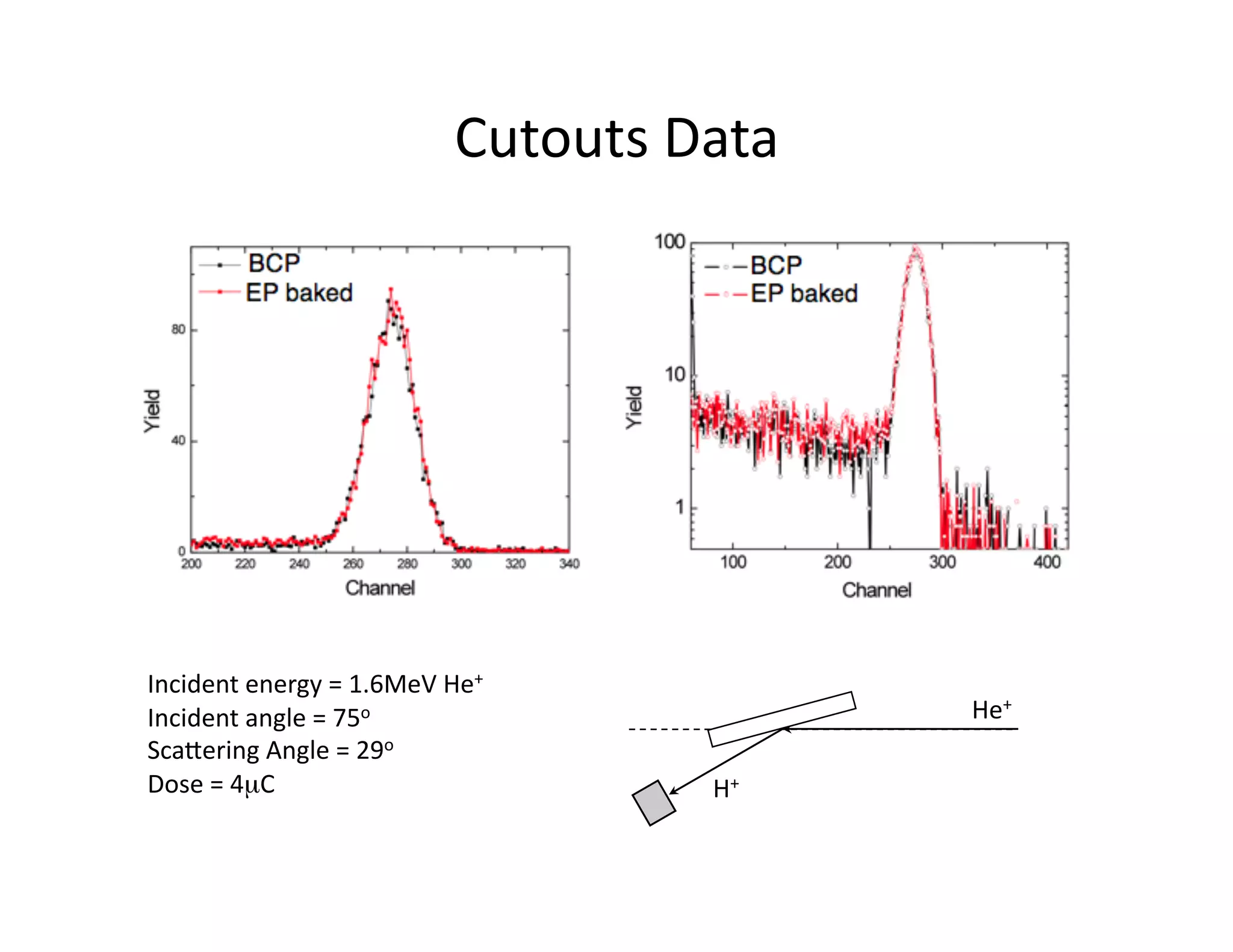

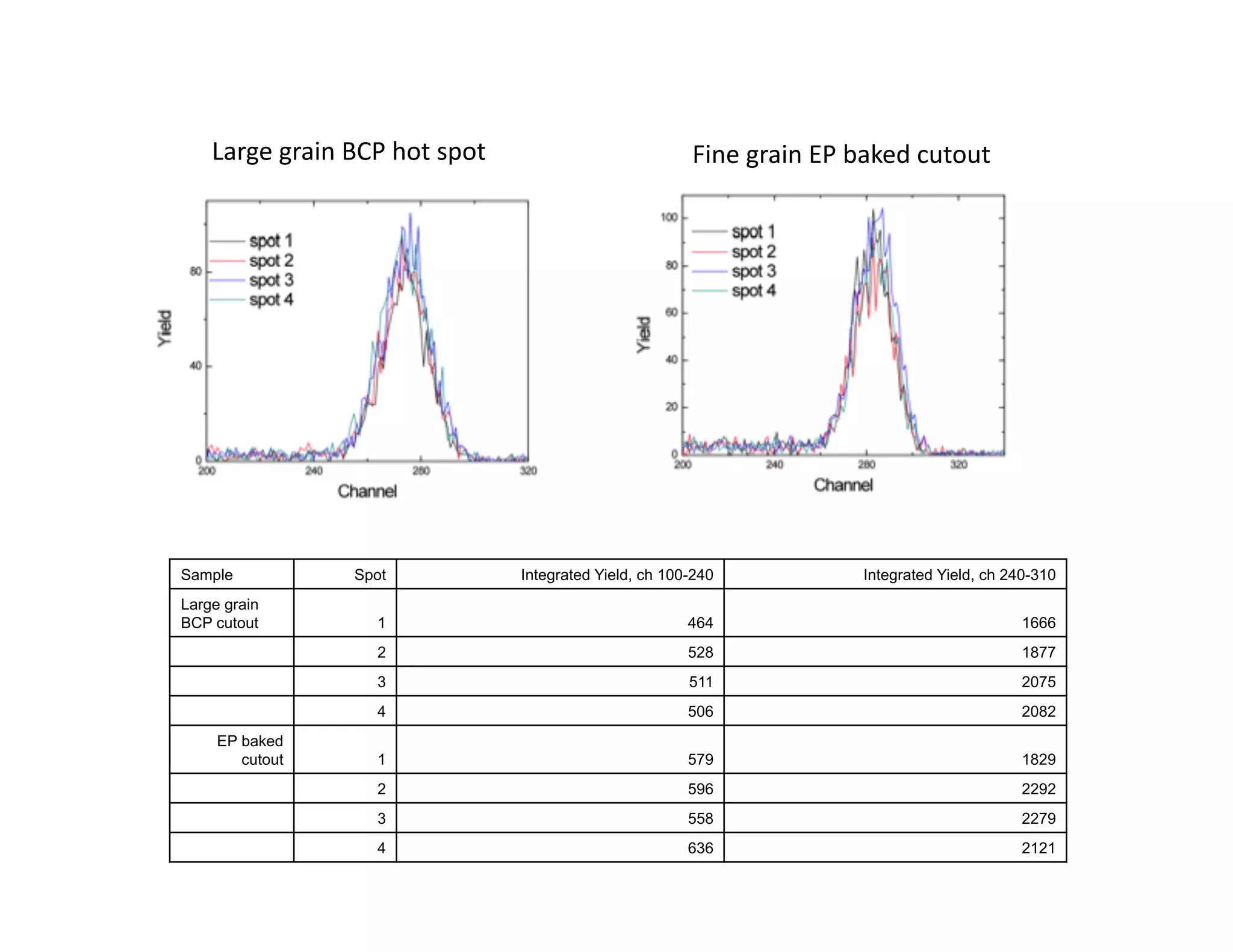

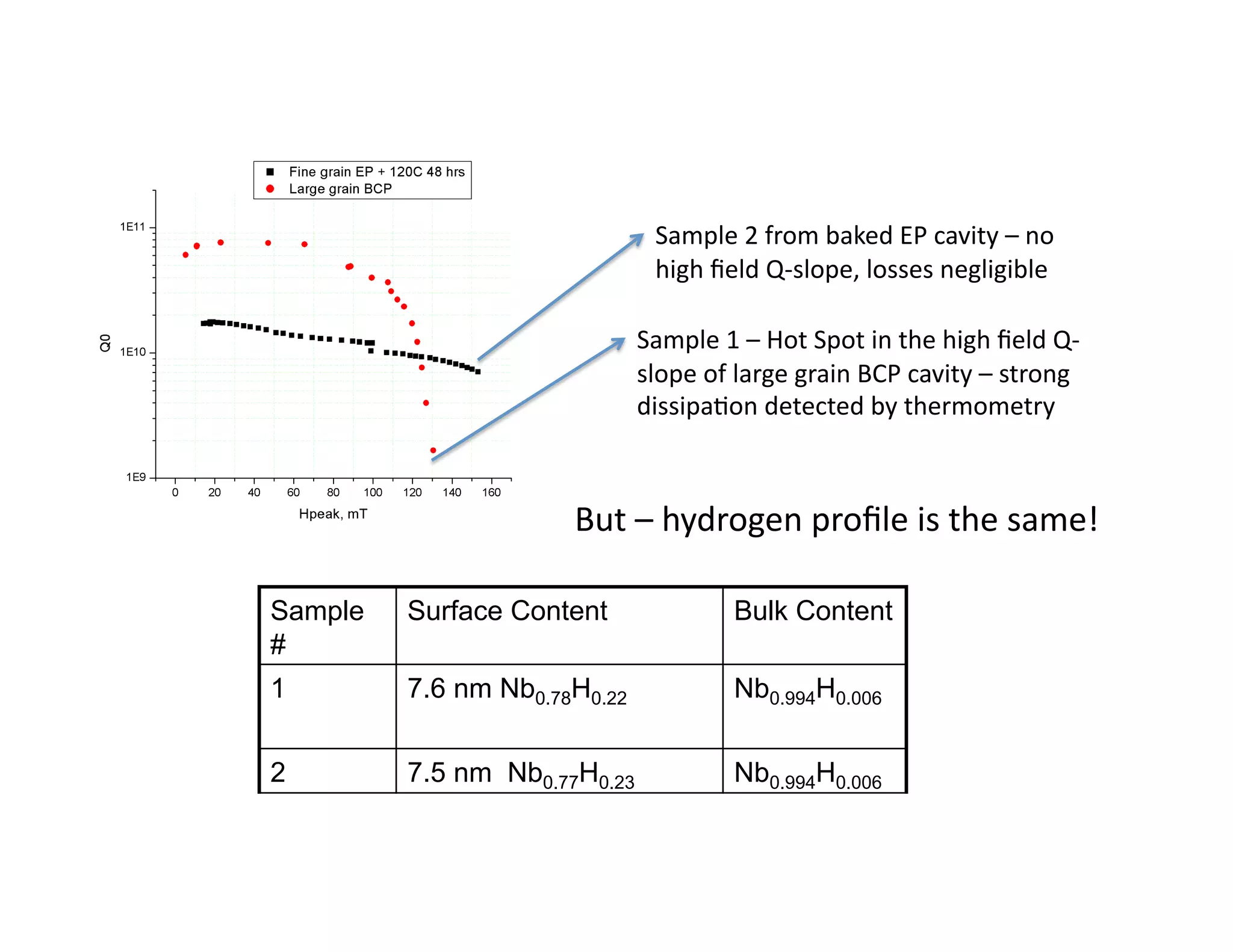

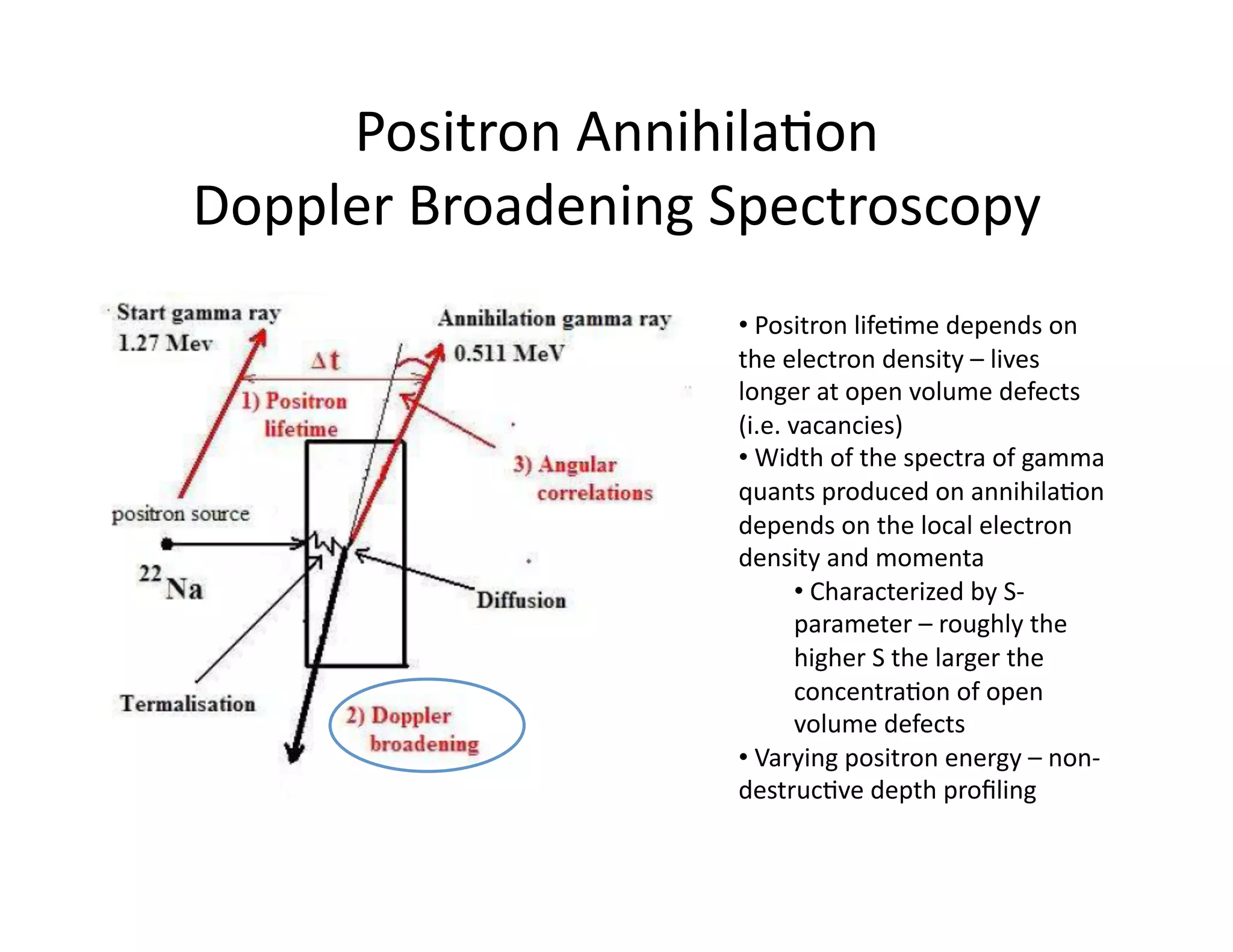

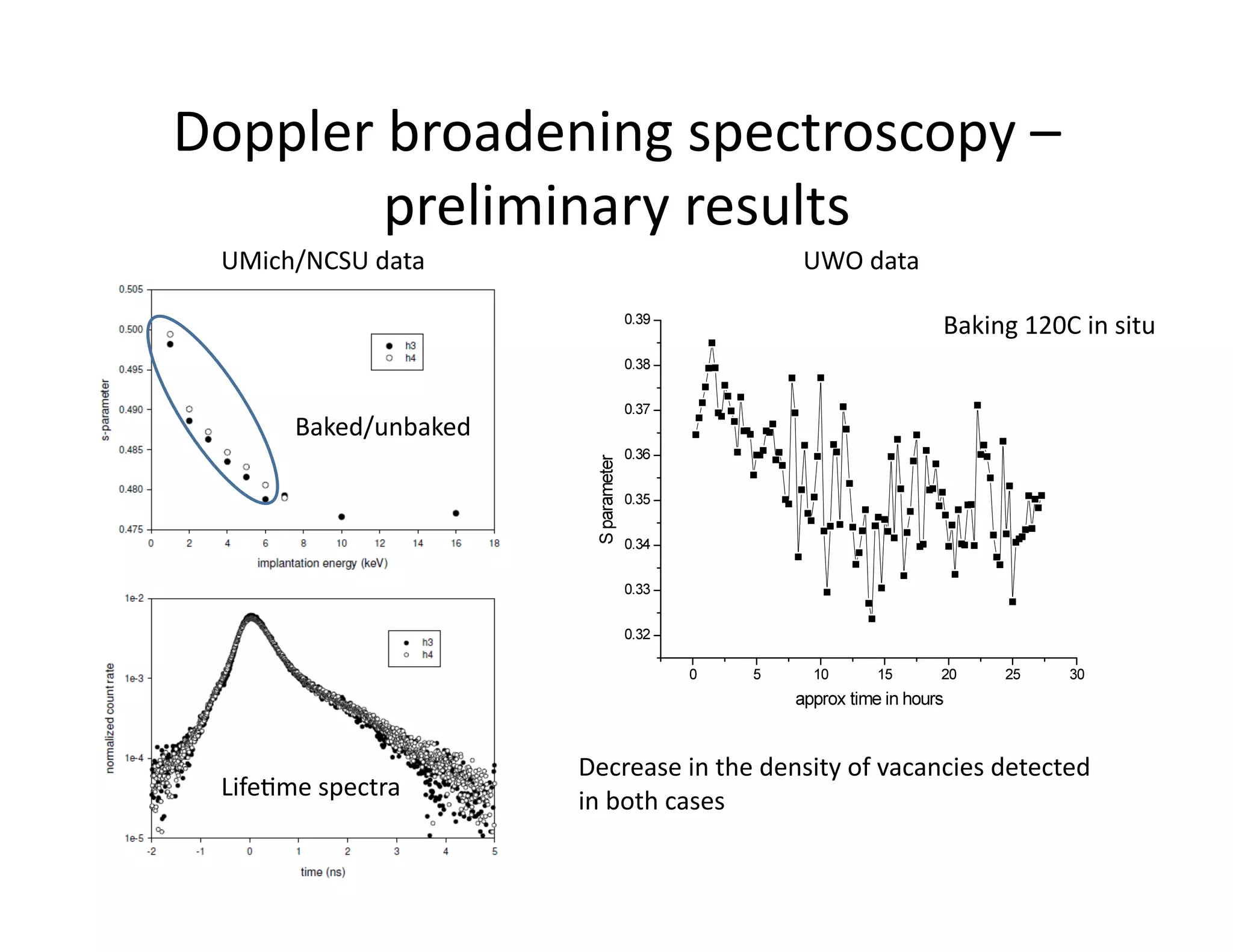

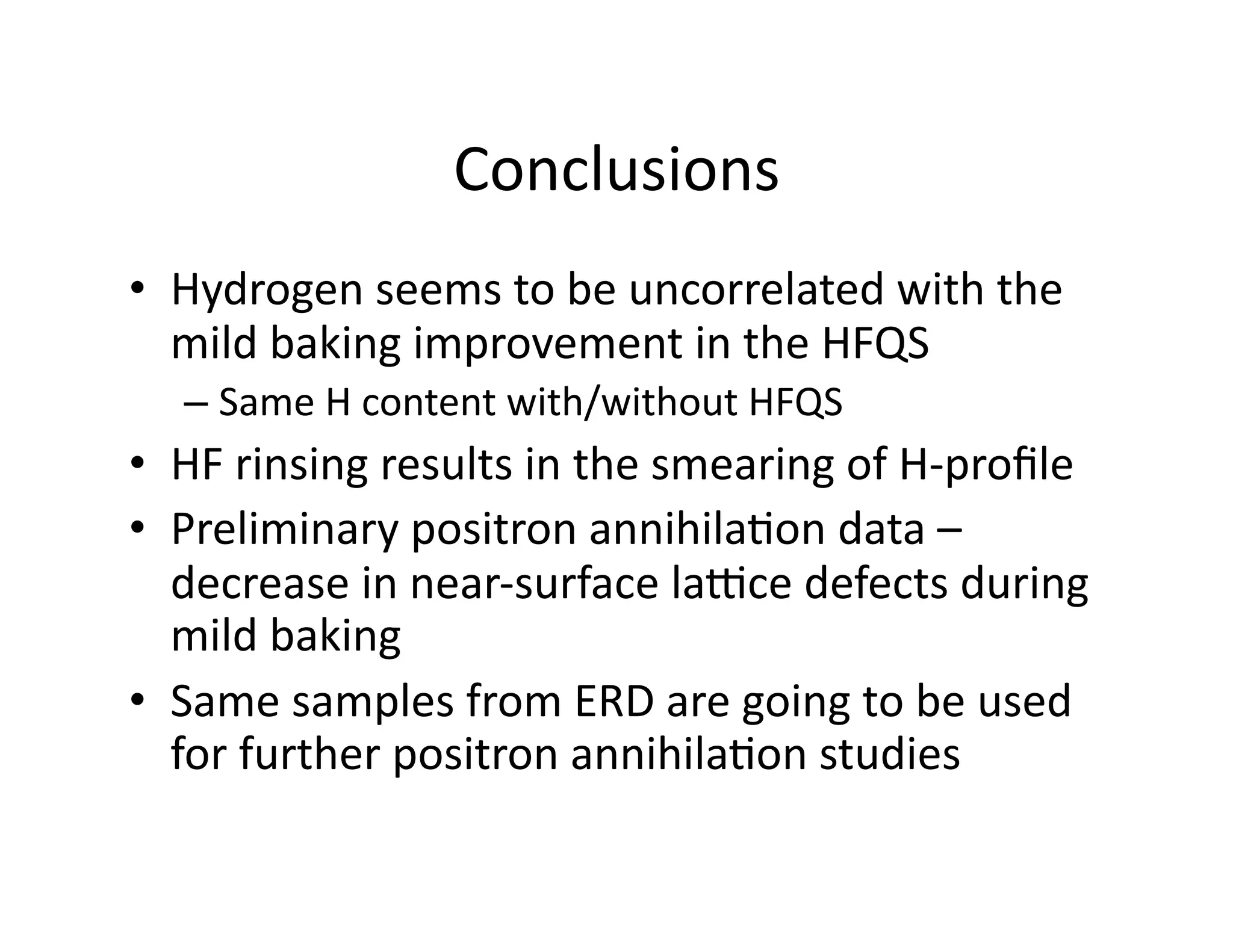

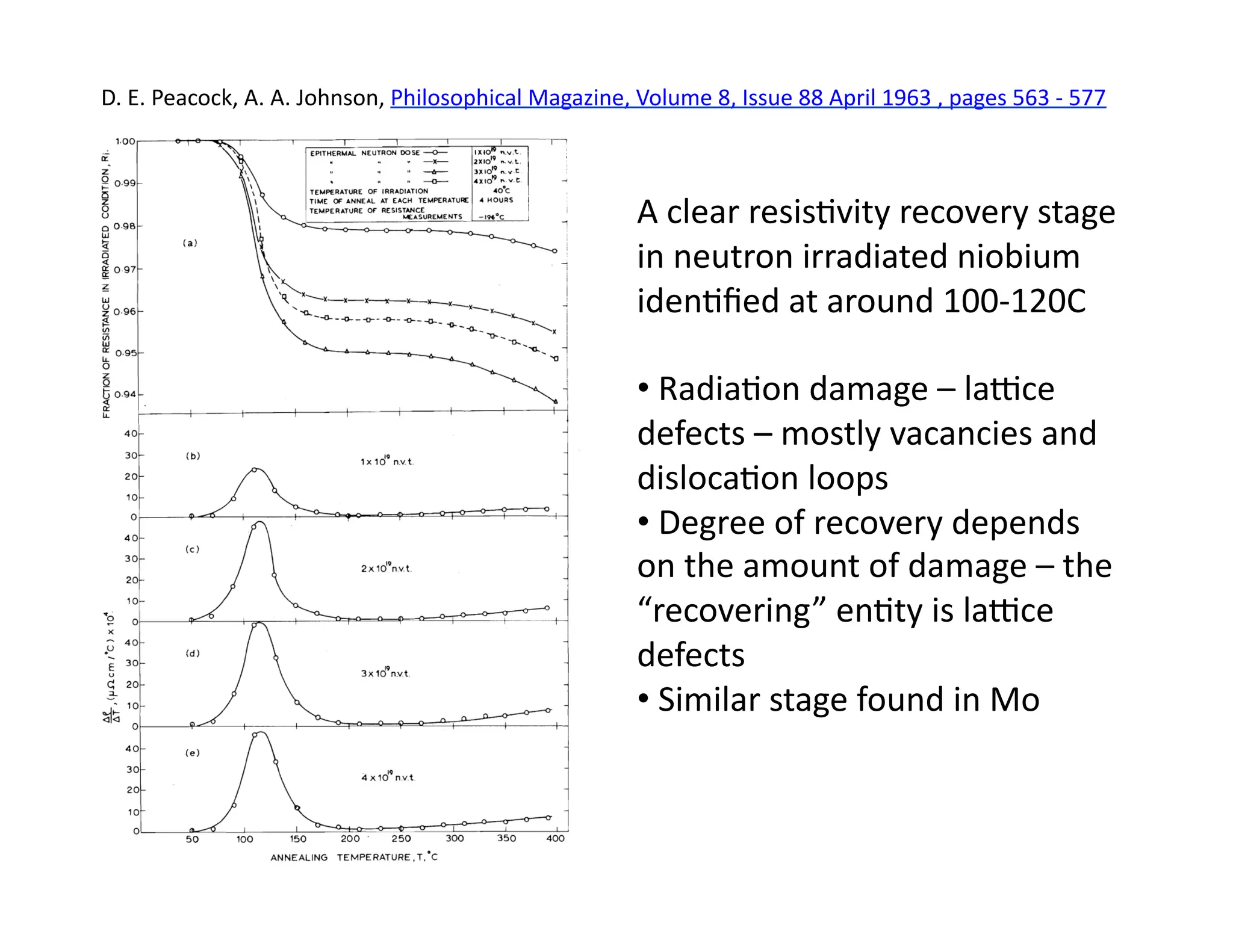

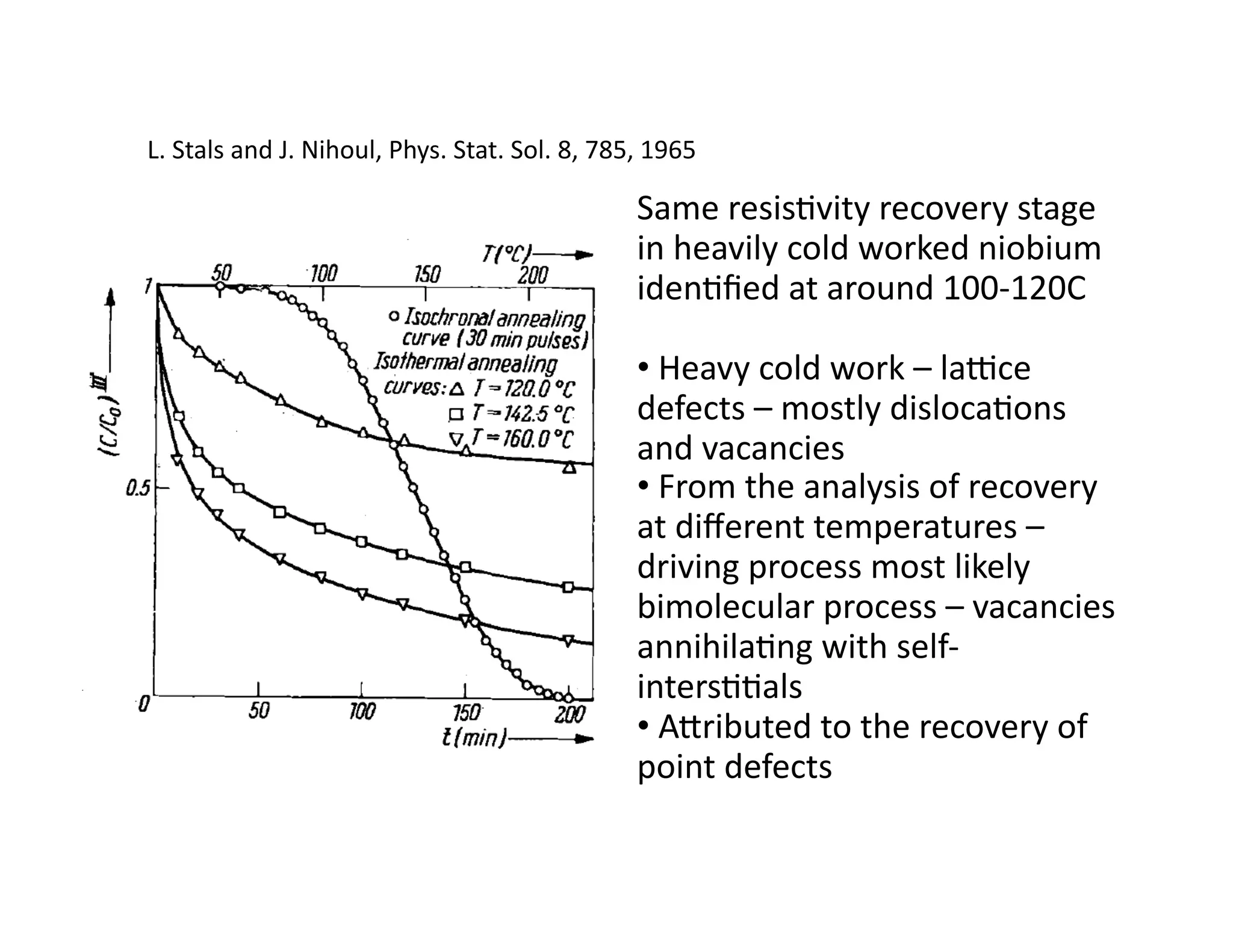

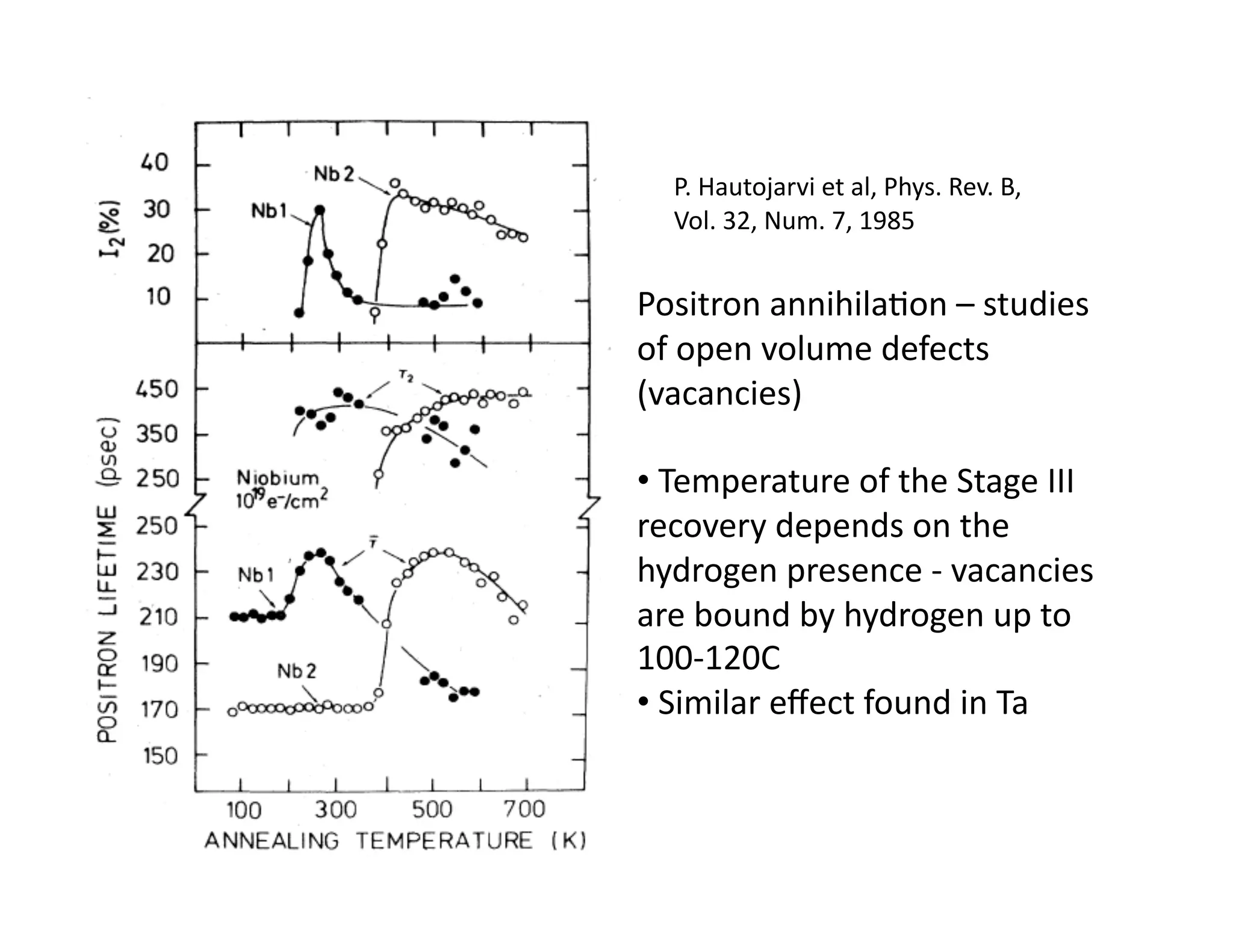

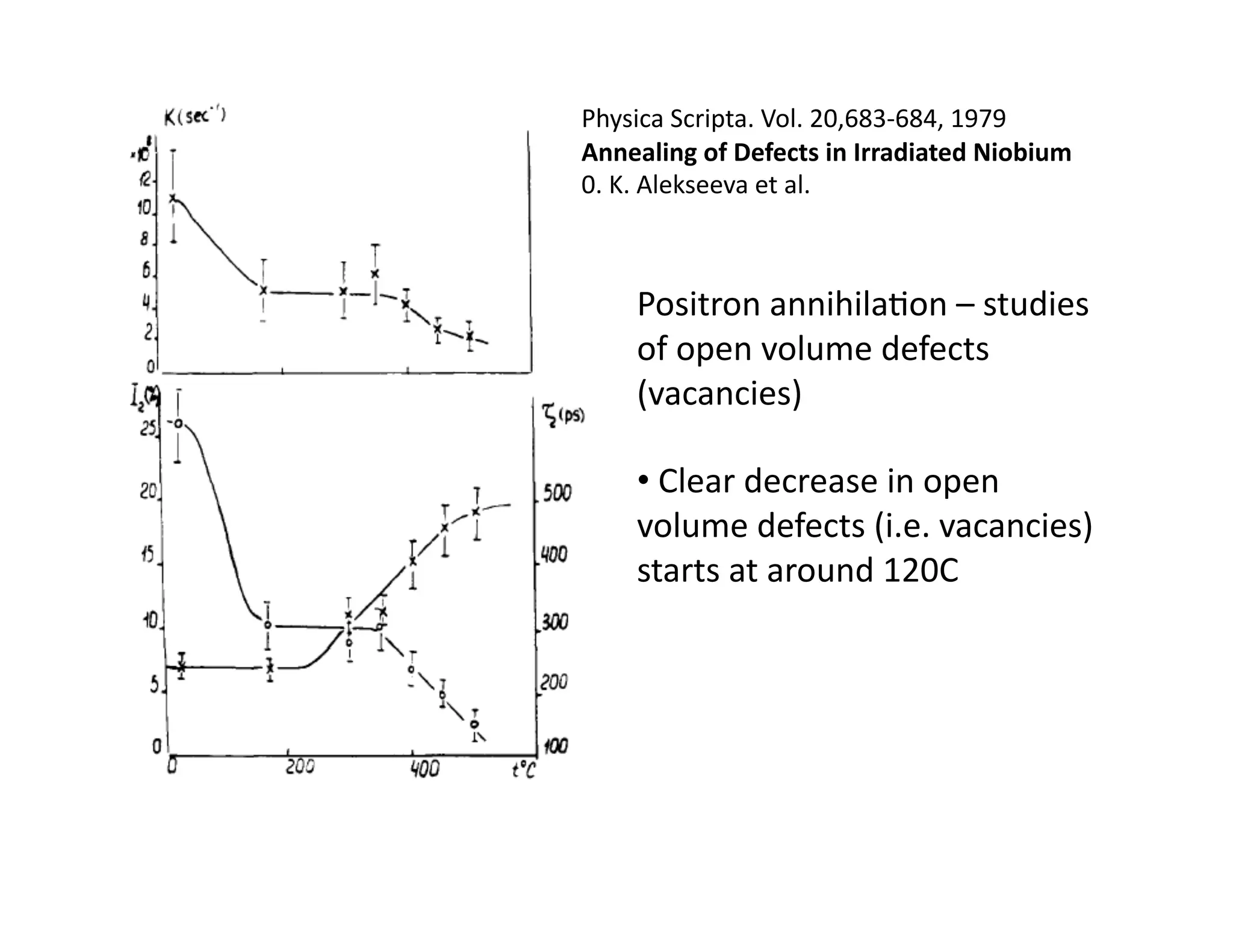

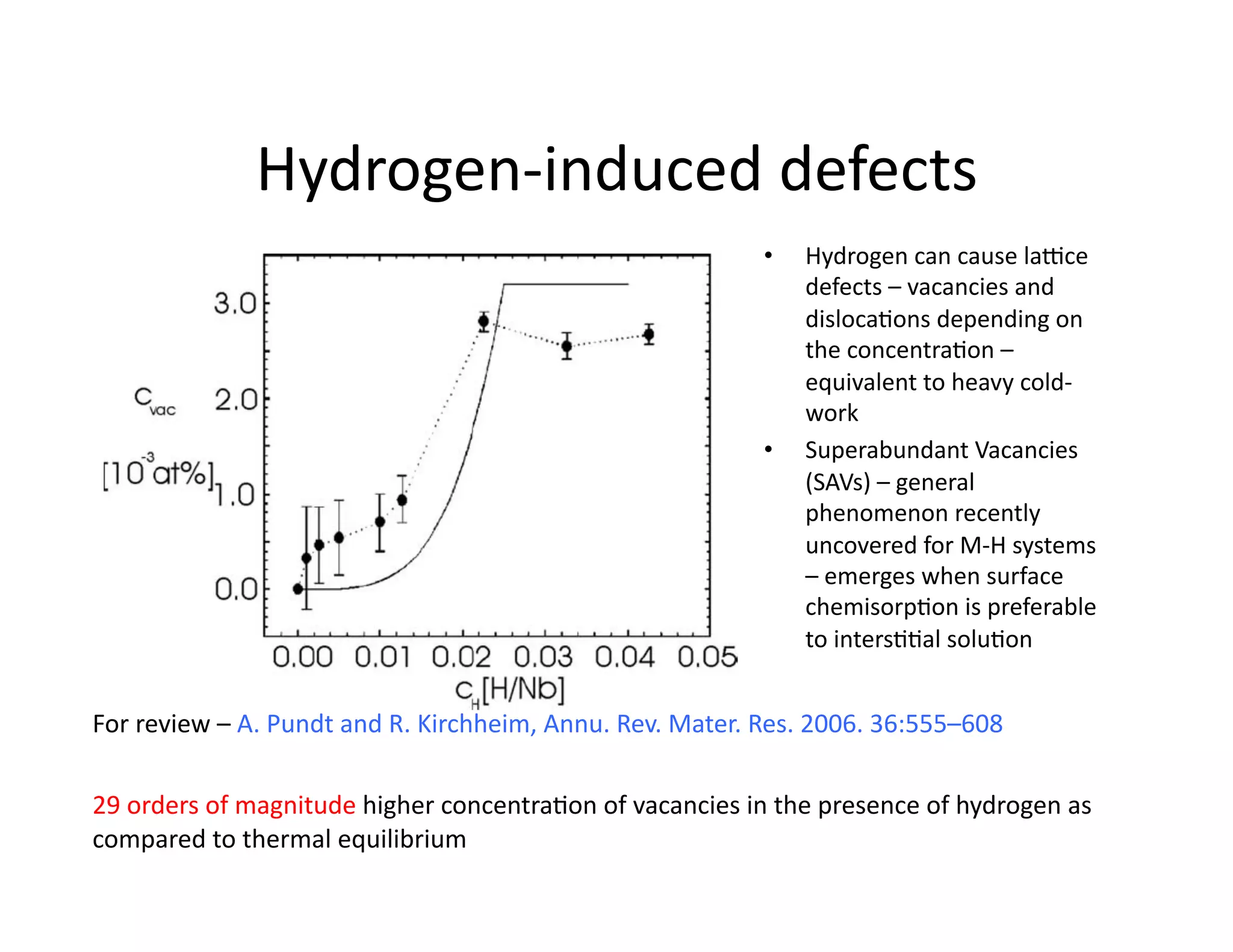

This document discusses the historical context of the "Stage III" phenomenon observed in metals like niobium and molybdenum, where resistivity suddenly decreases upon heating around 100-120°C. Previous studies using techniques like positron annihilation and elastic recoil detection showed this is due to the recovery of lattice defects like vacancies. More recent work suggests the presence of hydrogen plays a key role by binding to vacancies up to 100-120°C, above which the vacancies dissociate from hydrogen. The document then describes an elastic recoil detection study of the near-surface hydrogen concentration in niobium samples subjected to different baking treatments.

![Inves%ga%on

of

near-‐surface

hydrogen

• Mo%vated

by

the

possible

driving

mechanism

for

the

mild

baking

effect

–

Vac-‐H

complexes

dissocia%on

occuring

around

100-‐120C

• Leading

to

the

elimina%on

of

the

HFQS

by

– LaJce

defect

density

reduc%on

in

the

near-‐

surface

layer?

[A

Romanenko

and

H

Padamsee

2010

Supercond.

Sci.

Technol.

23

045008]

– Or

hydrogen

concentra%on

decrease?

-‐

inves%gated

by

Elas%c

Recoil

Detec%on

(ERD)](https://image.slidesharecdn.com/erdromanenkotf2010-101005090658-phpapp01/75/Romanenko-Elastic-Recoil-Detection-and-Positron-Annihilation-Studies-of-the-Mild-Baking-Effect-9-2048.jpg)