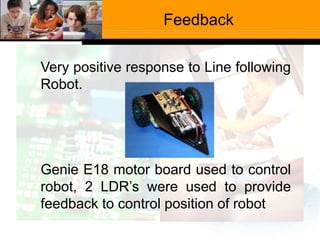

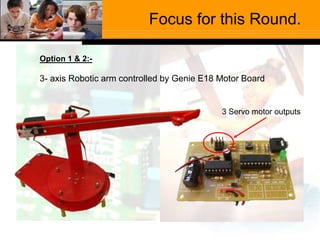

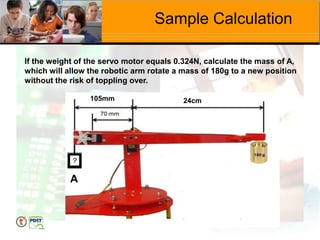

This document provides information about developing a 3-axis pick and place robot project for a technology class. It outlines three options for the project, and focuses on Options 1 and 2 which involve building a 3-axis robotic arm controlled by a Genie E18 motor board and 3 servo motors. The document lists required materials, health and safety considerations, example end effectors, a sample calculation, and suggestions for assessment.