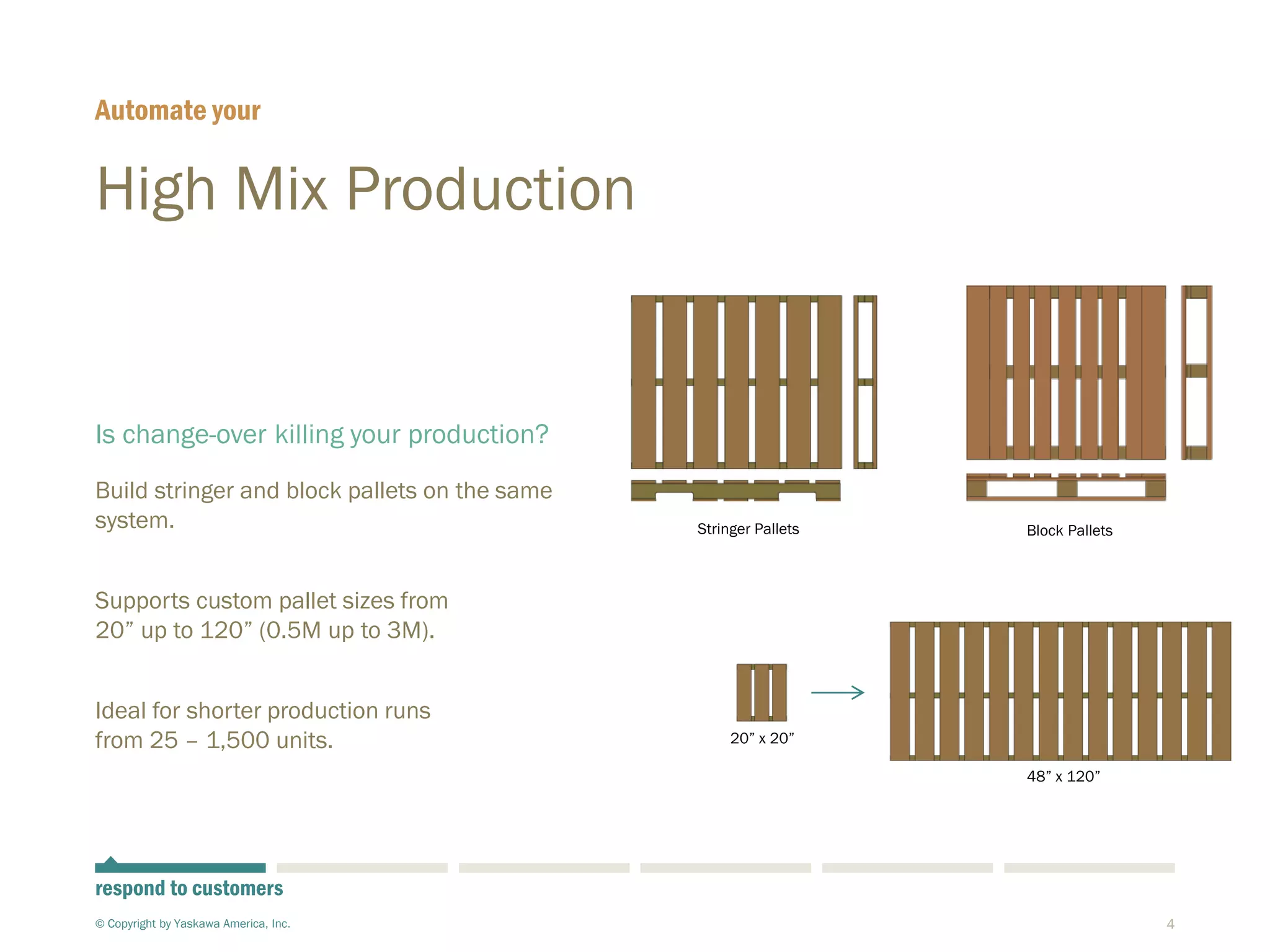

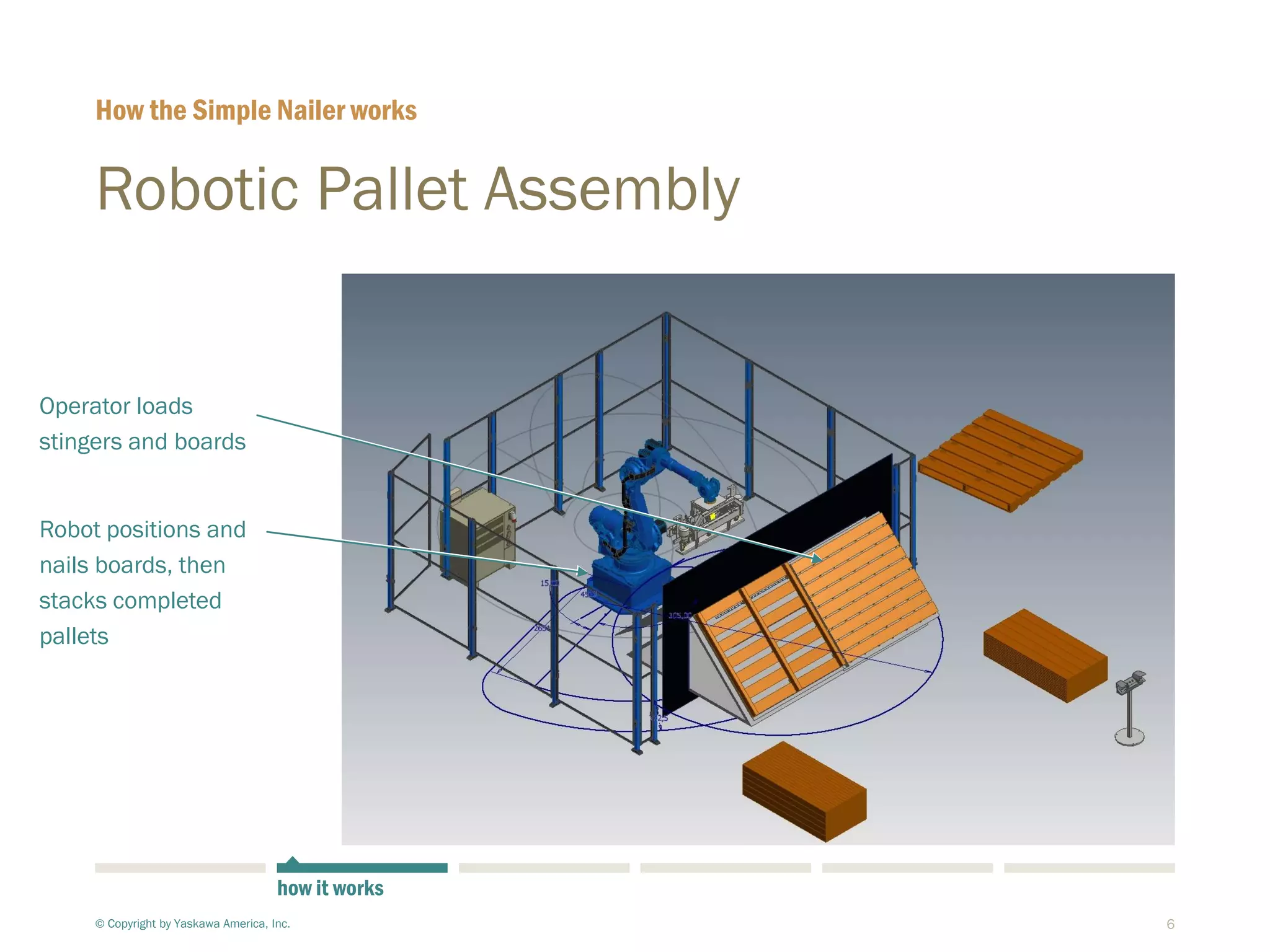

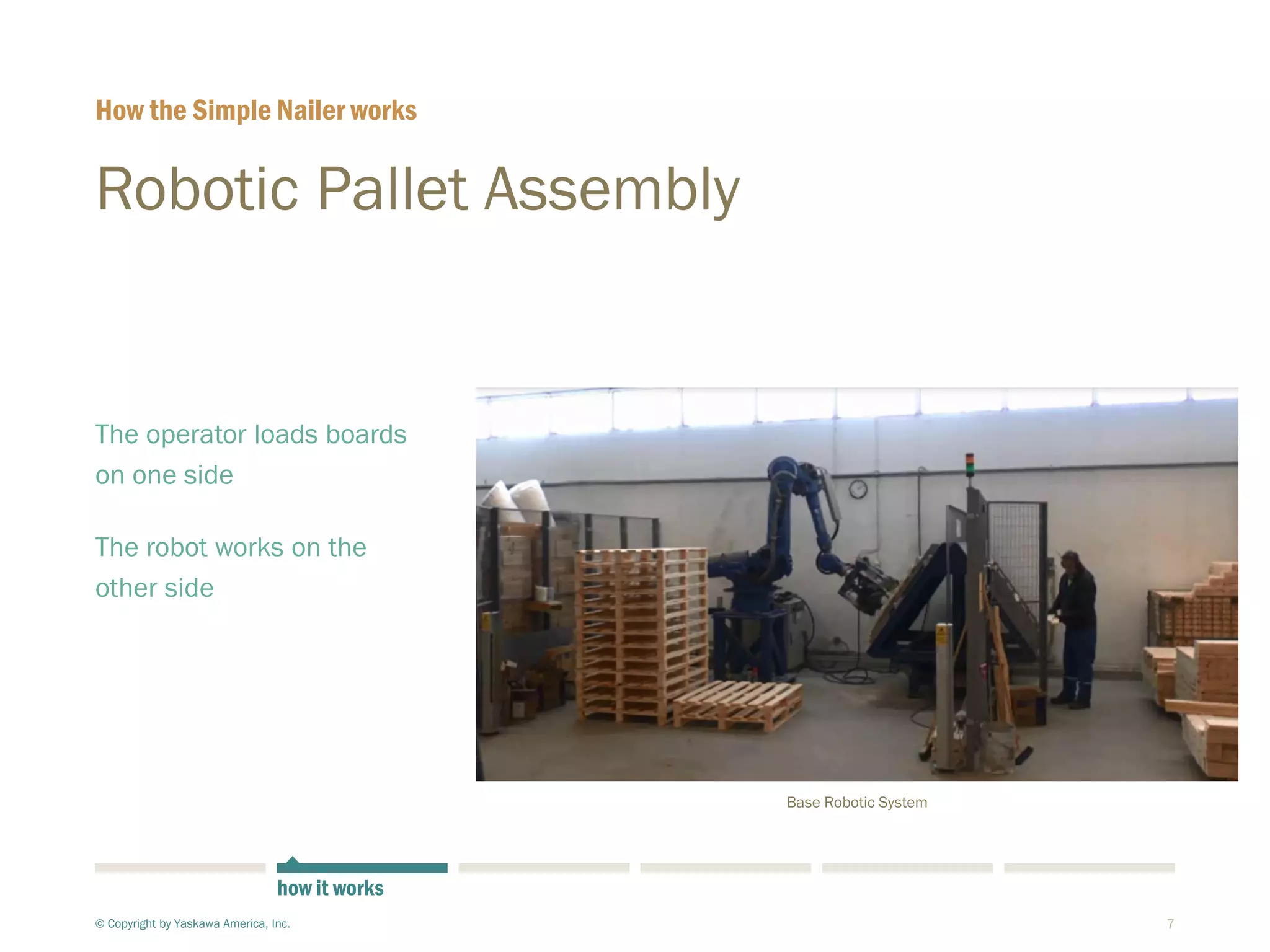

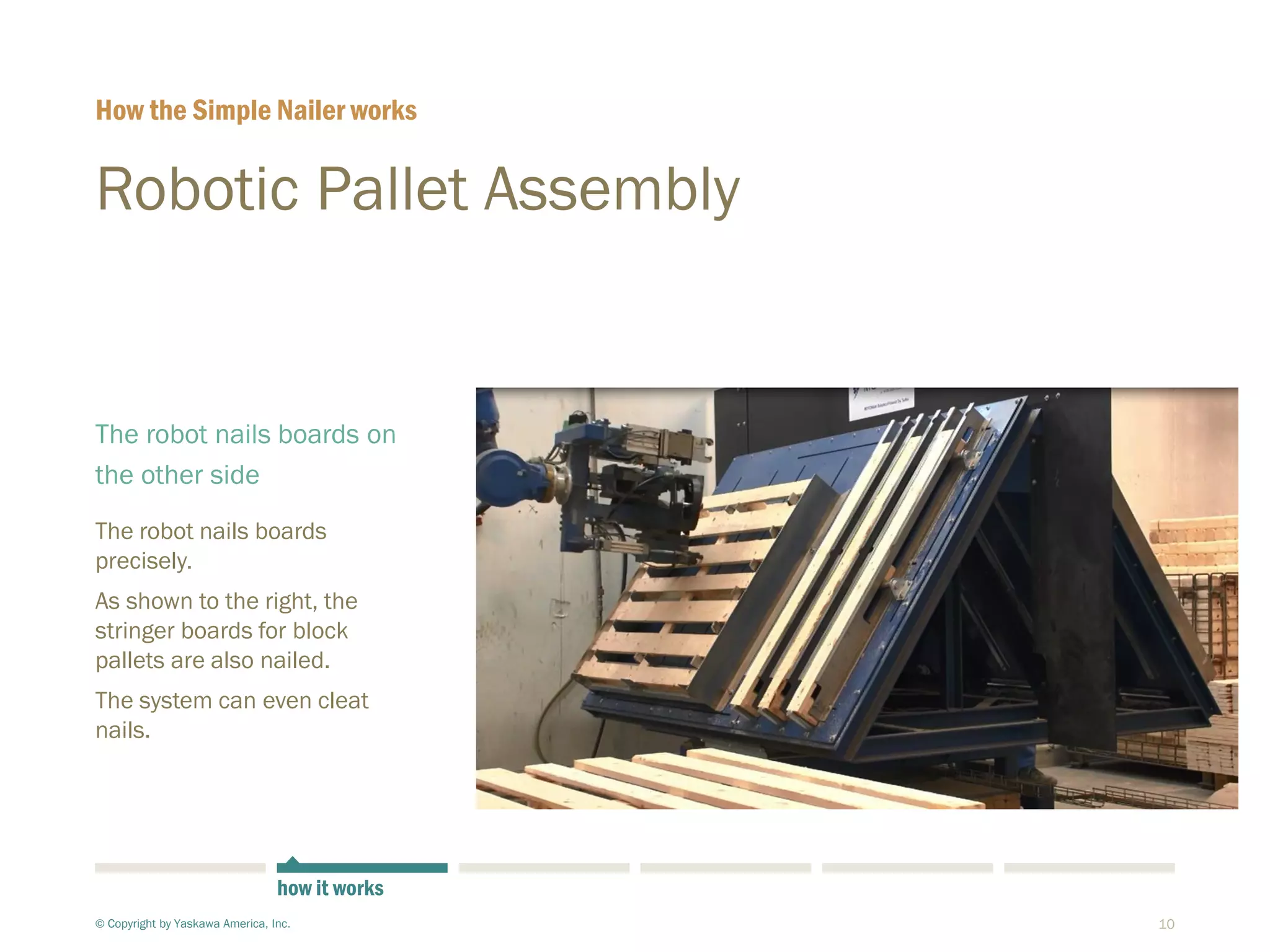

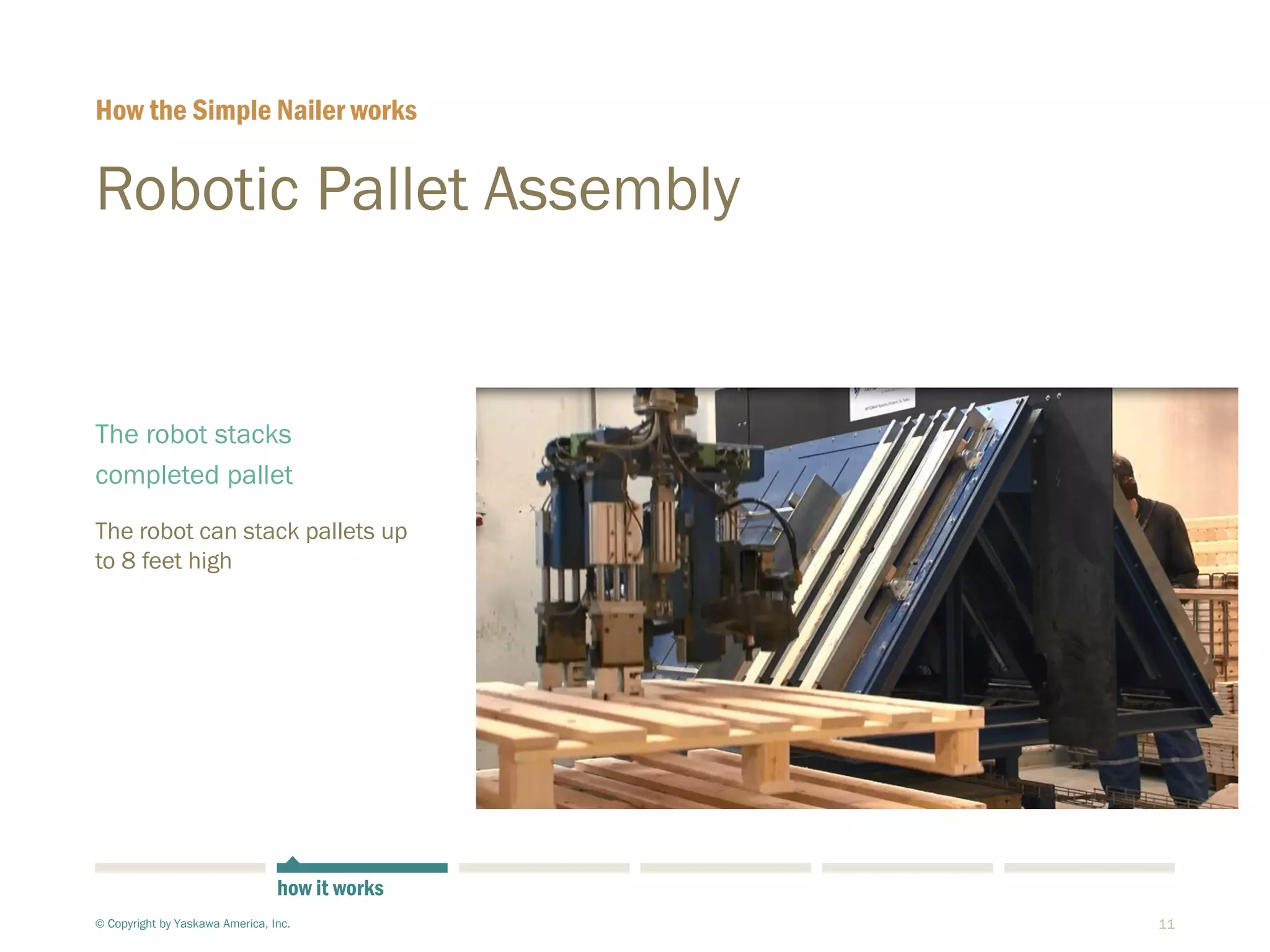

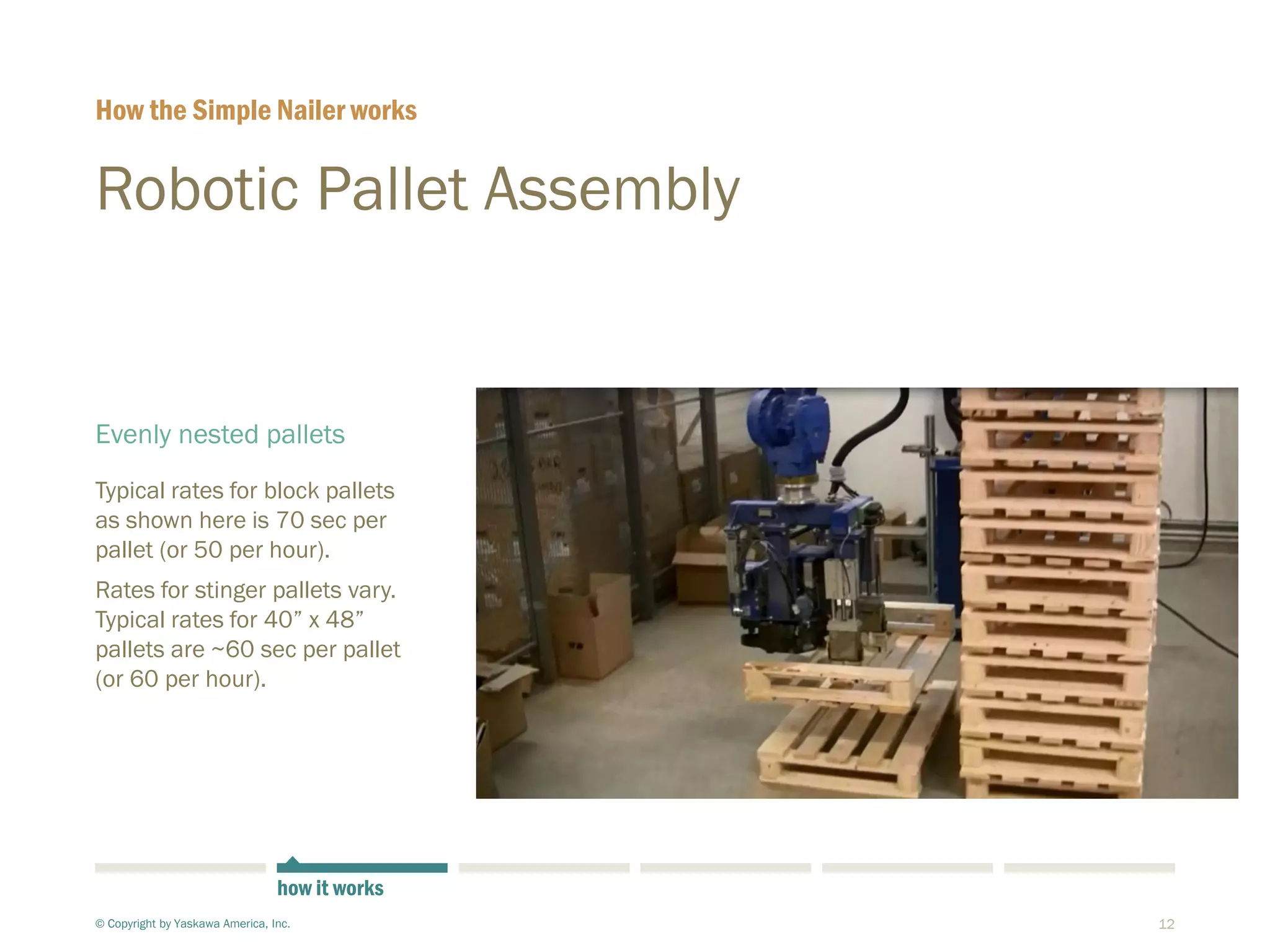

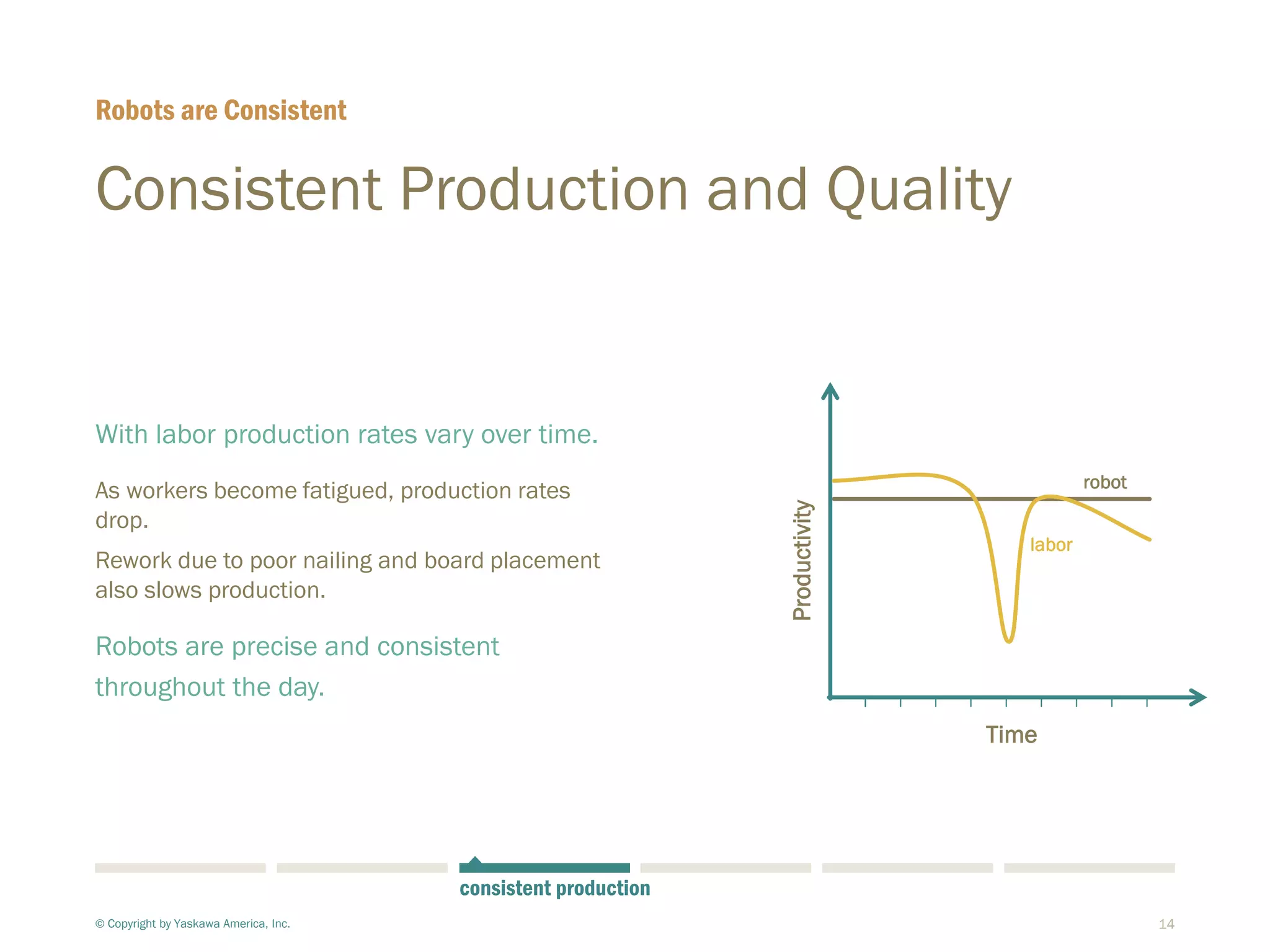

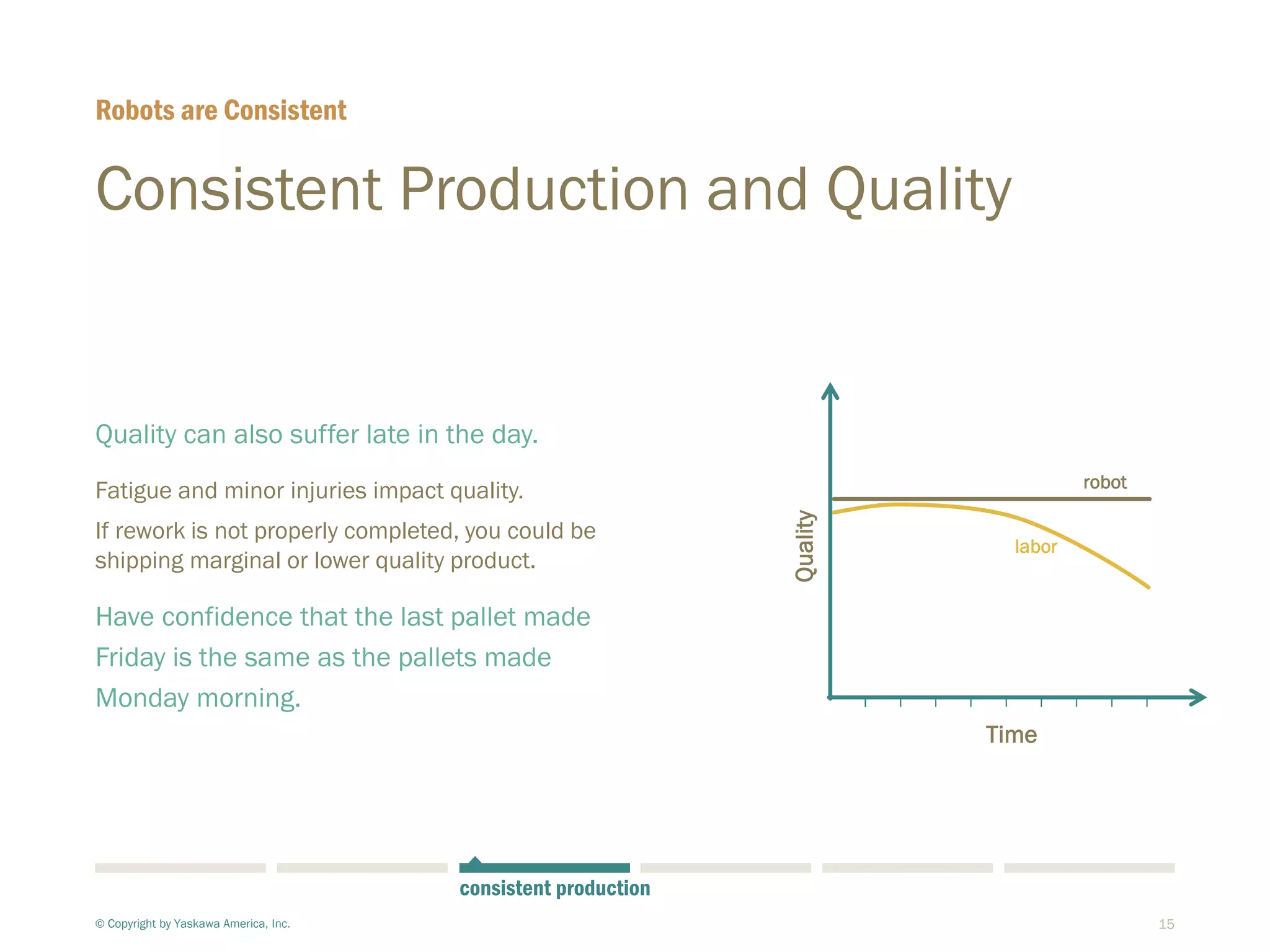

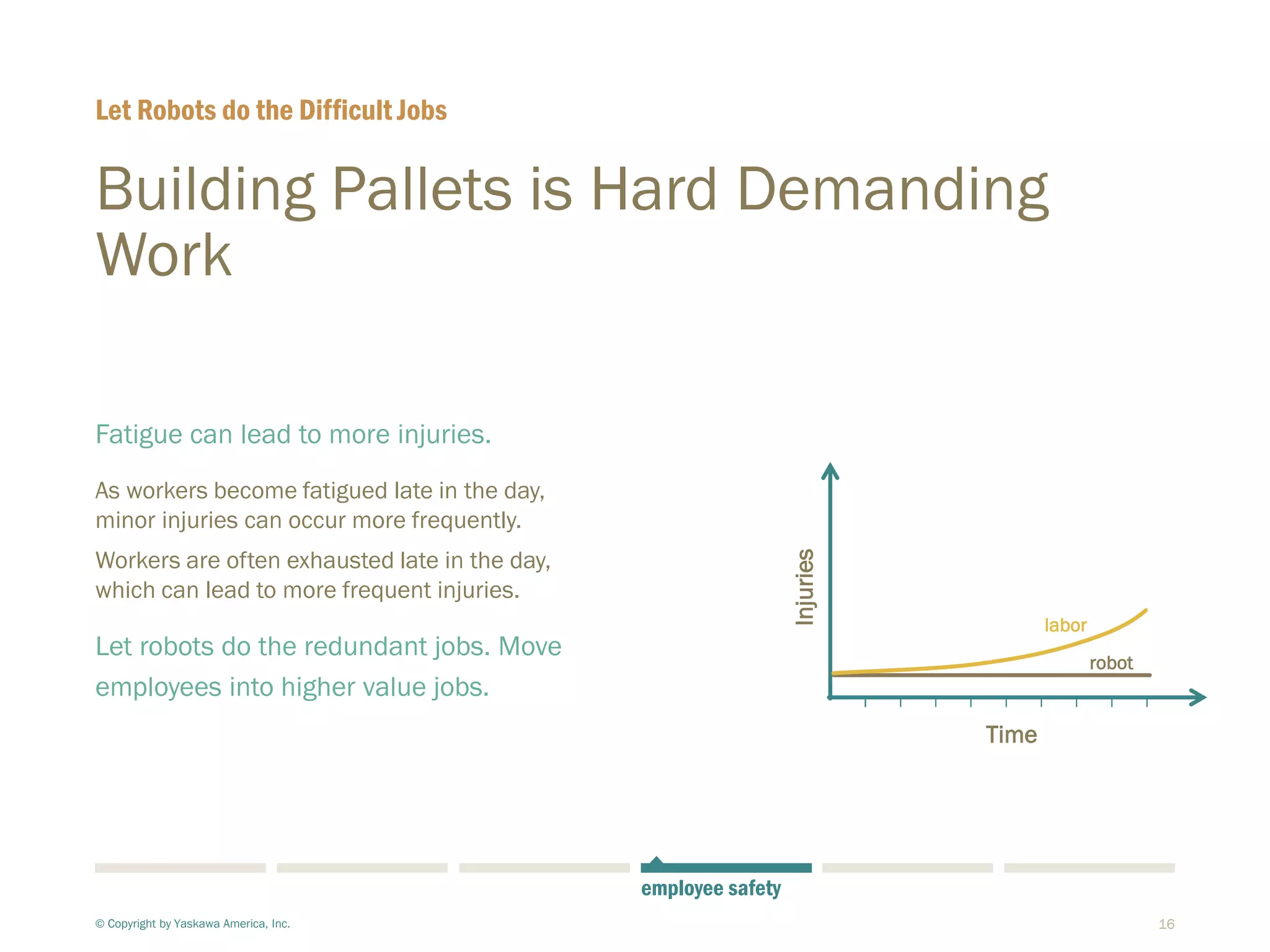

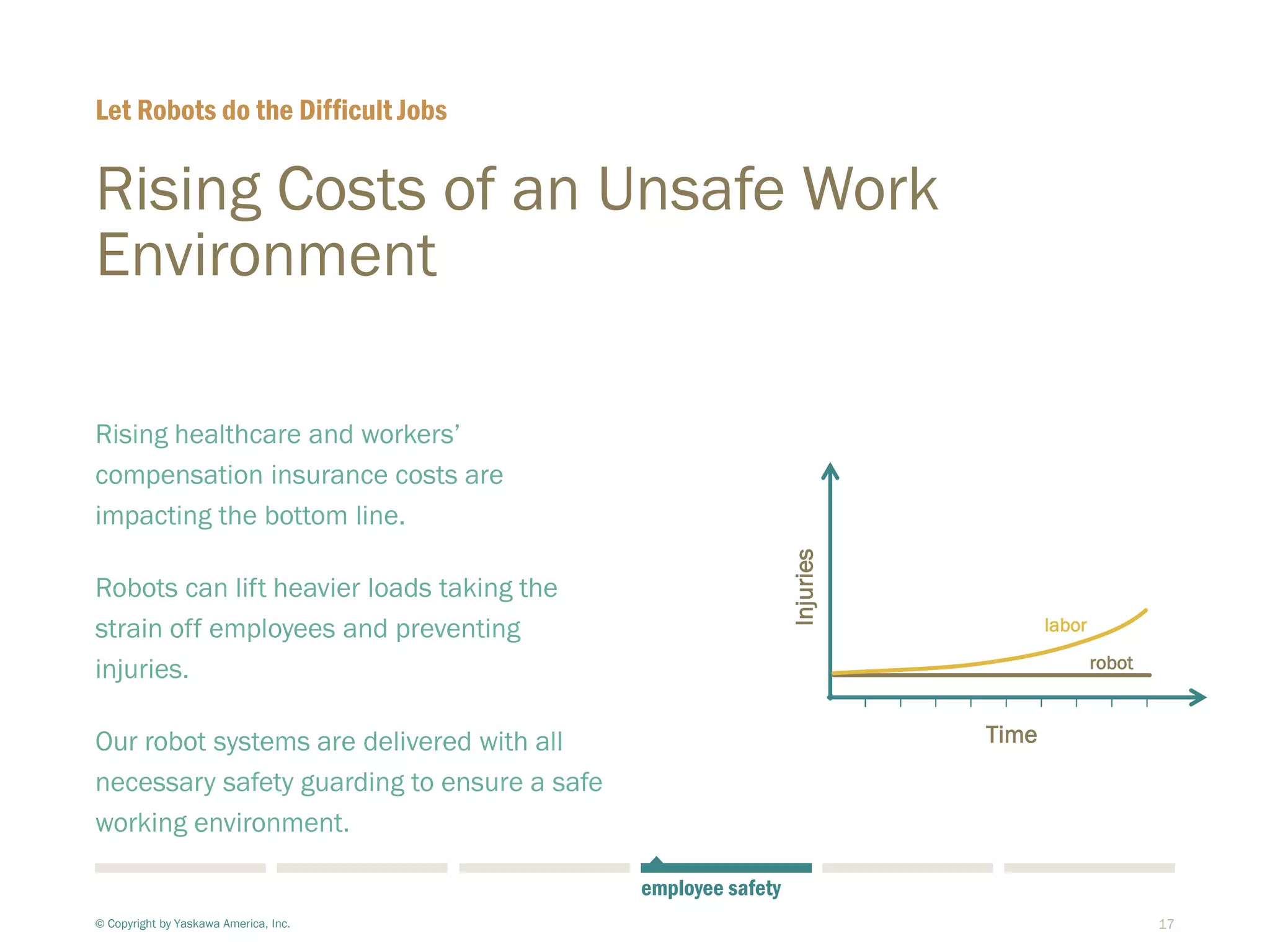

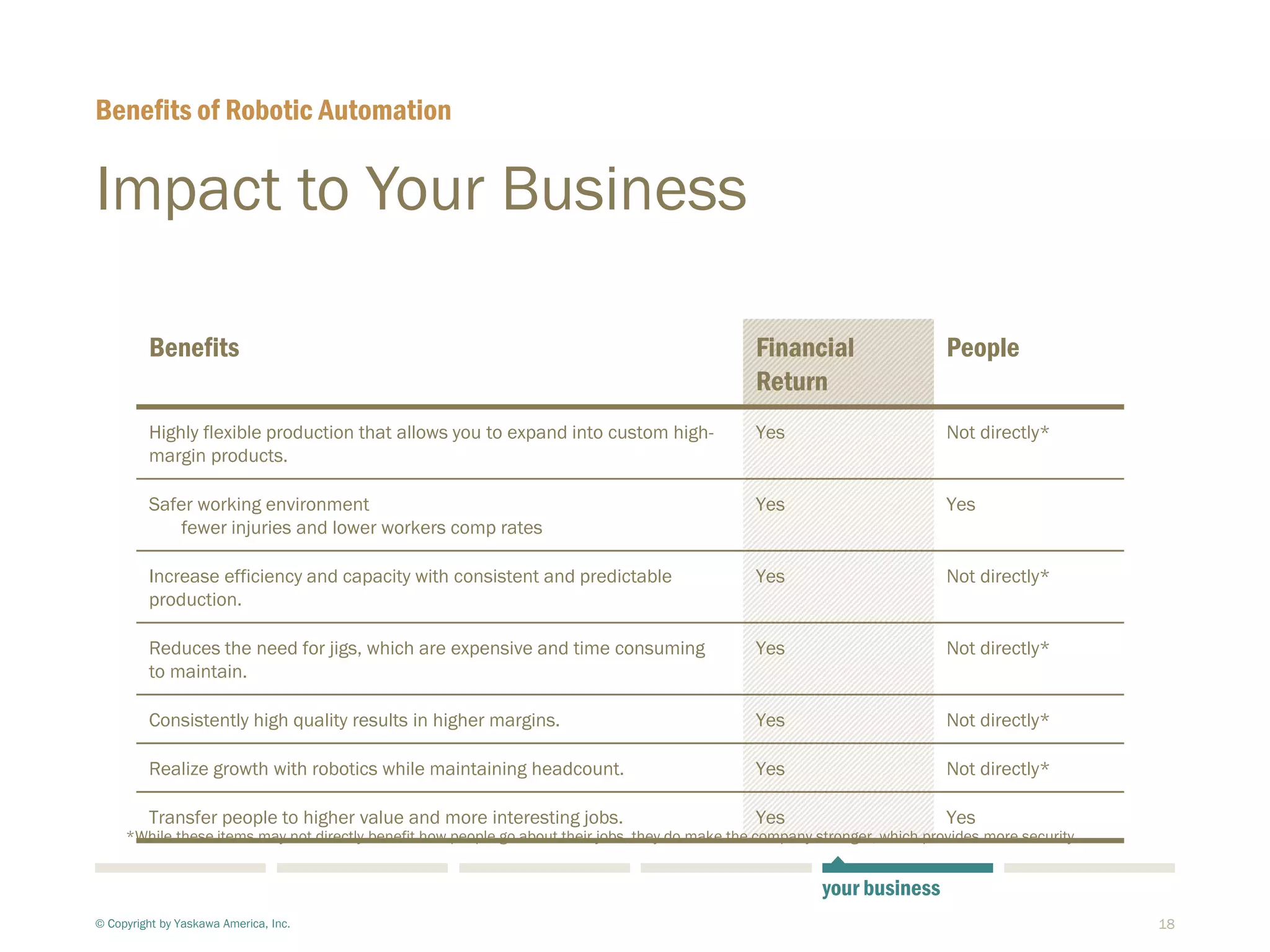

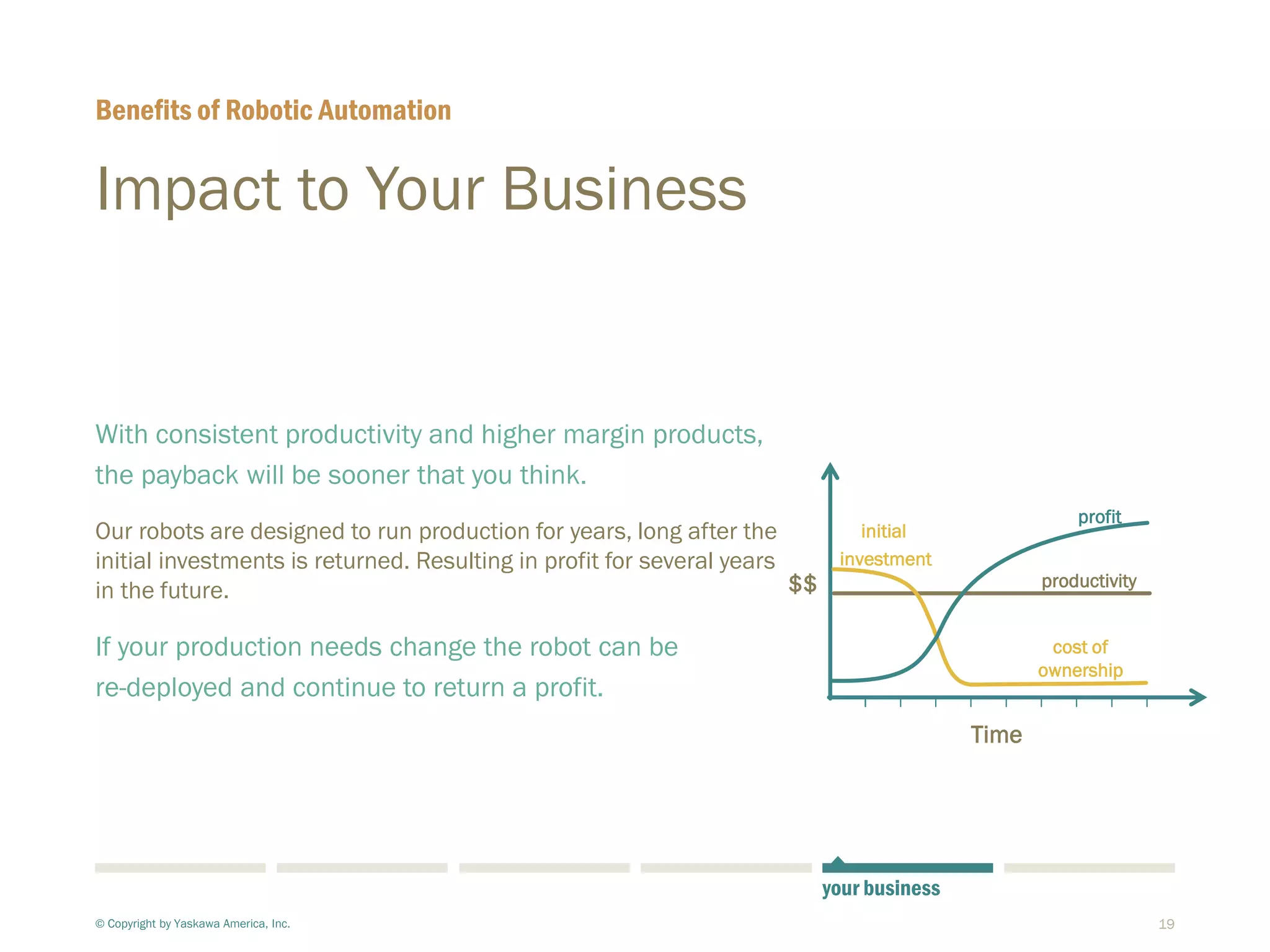

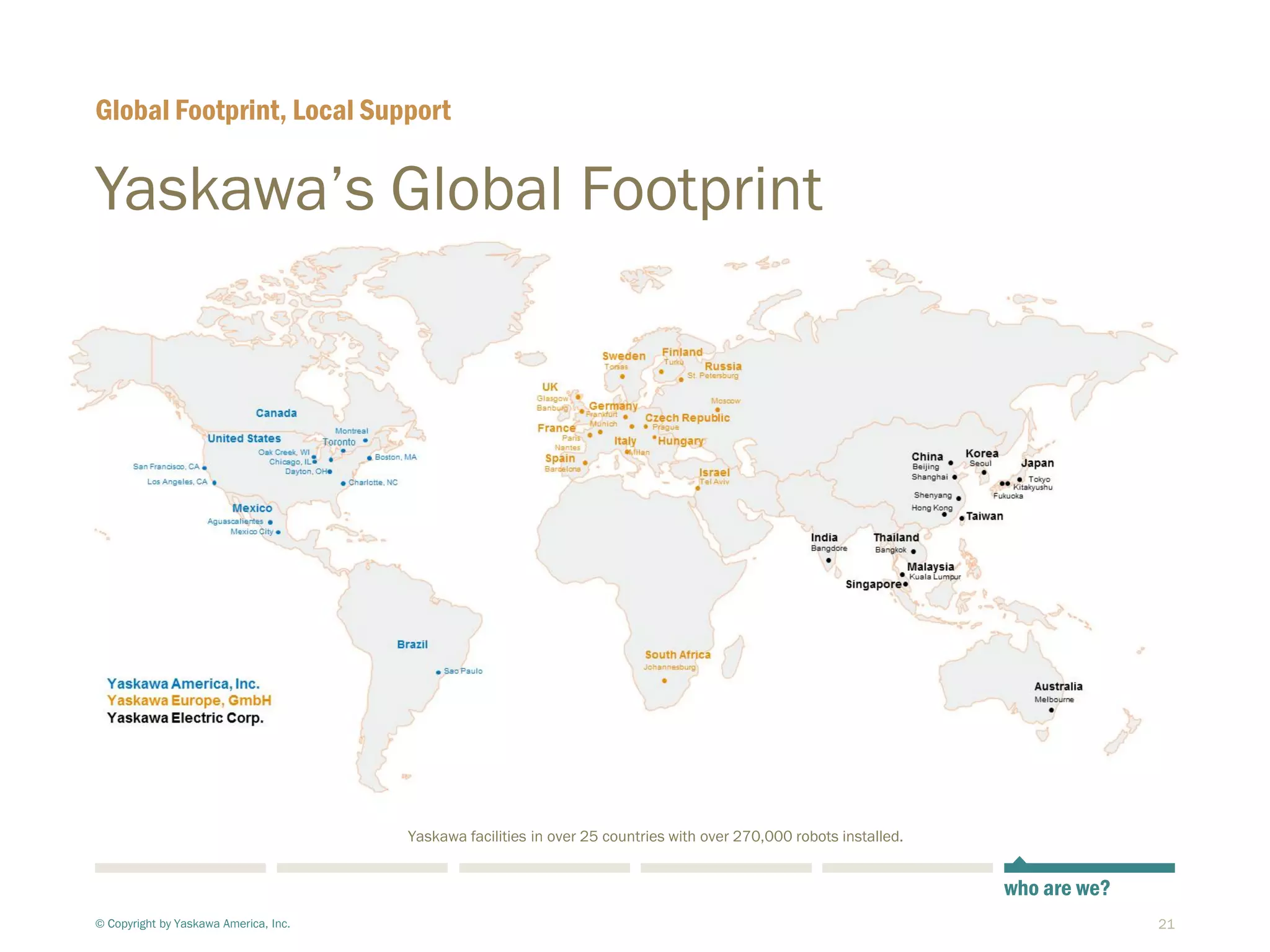

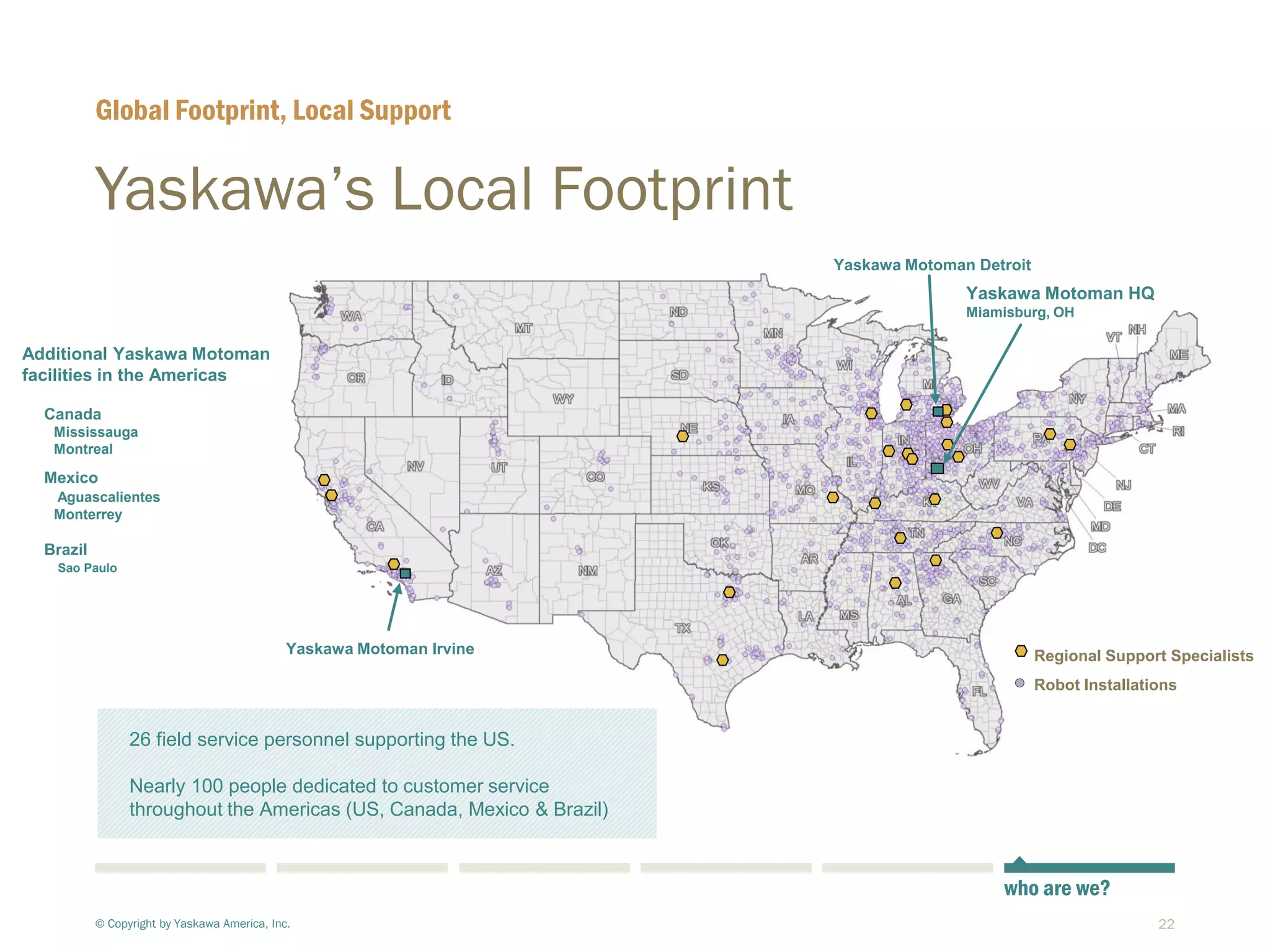

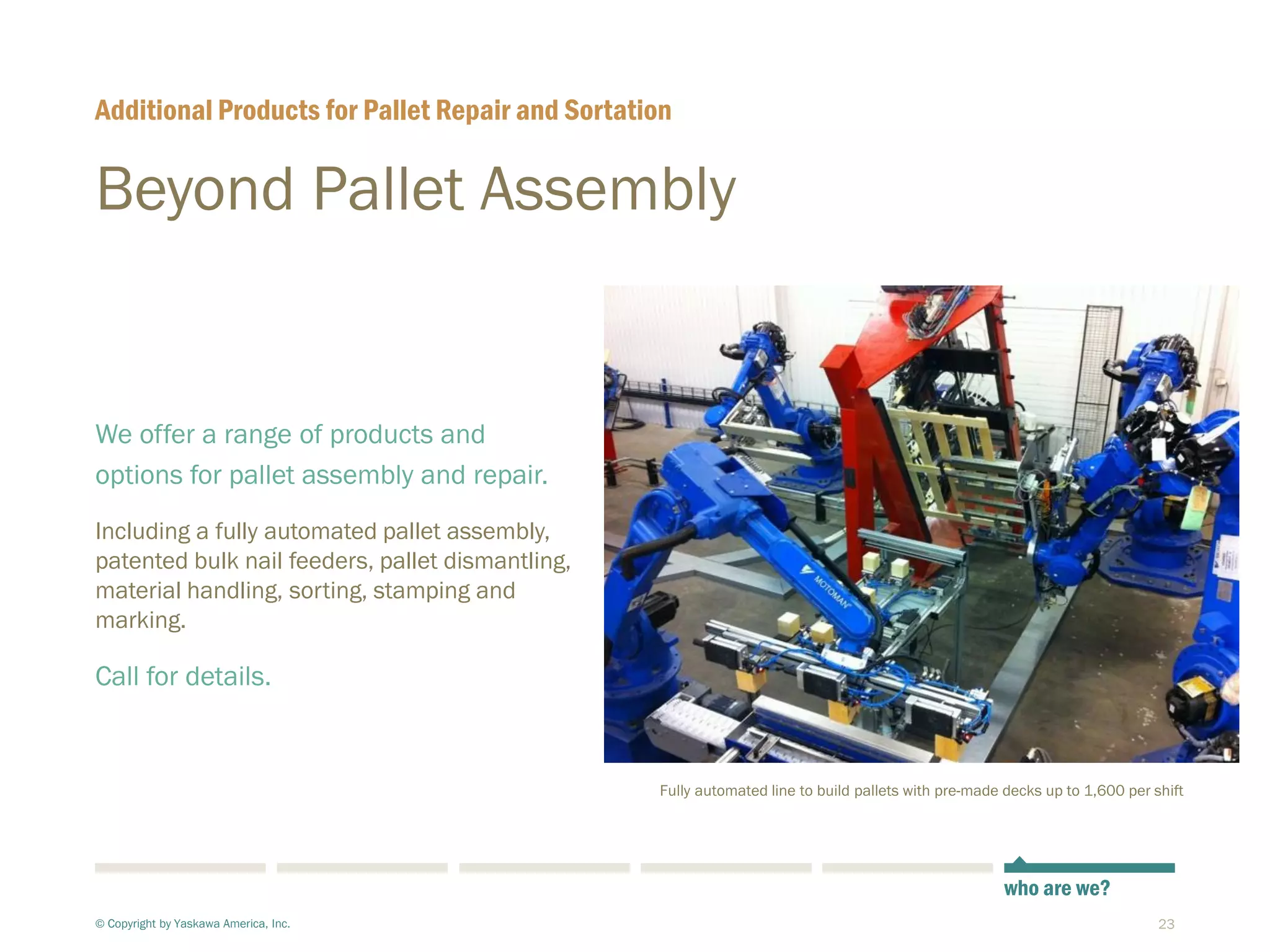

Robotic pallet assembly can help companies respond to increasing customer demands for custom pallets. Robots allow for high mix production with fast changeovers and consistent quality and throughput. This reduces injuries for employees from dangerous and repetitive tasks. Robotic automation can provide a safer working environment, increased efficiency, and higher profit margins to benefit both the company's financial returns and its employees. Yaskawa Motoman offers robotic pallet assembly solutions and has over 300,000 robots installed globally to support customers locally.