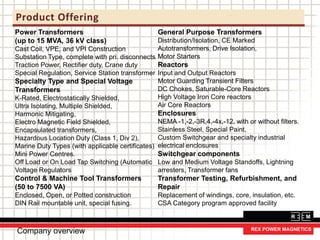

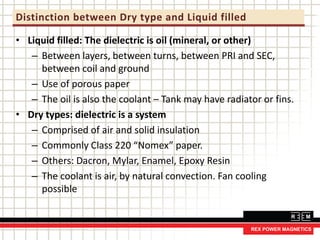

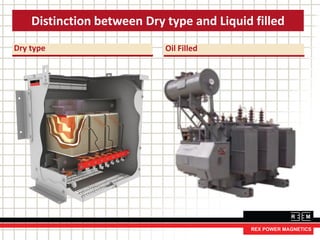

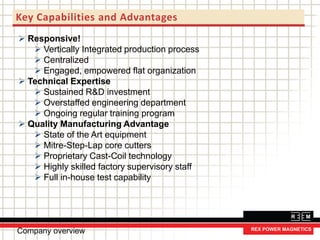

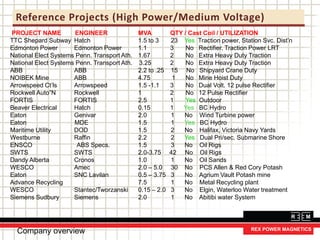

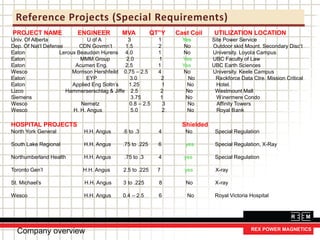

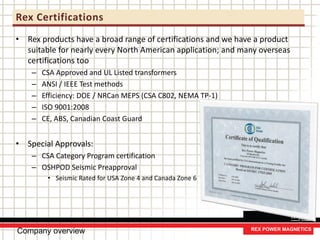

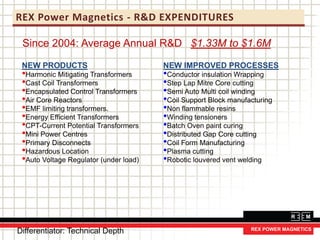

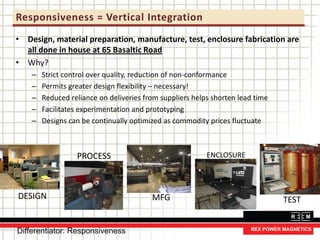

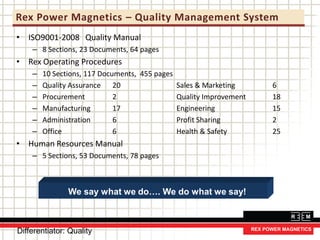

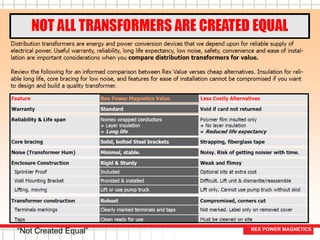

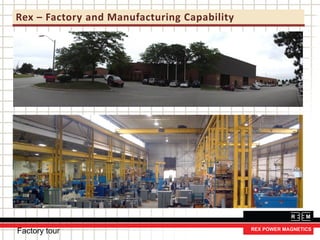

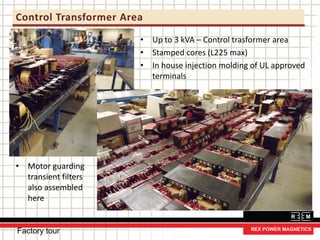

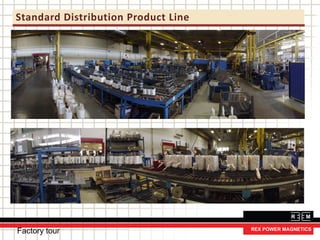

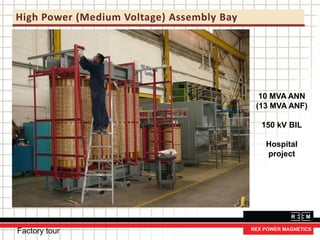

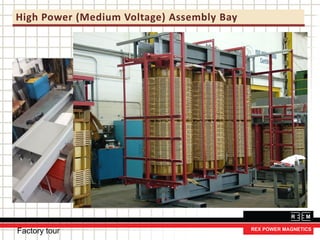

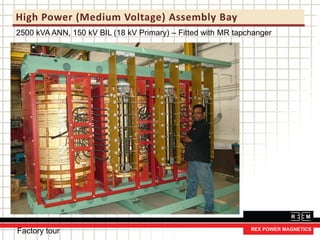

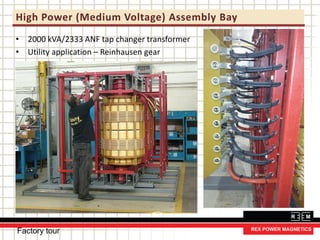

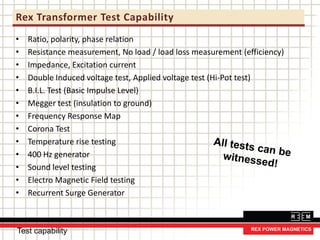

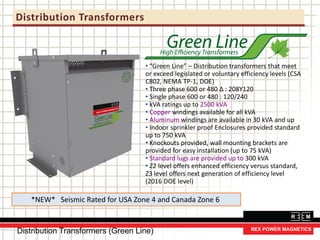

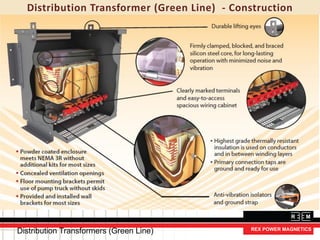

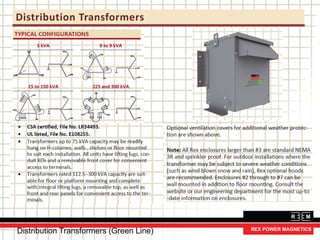

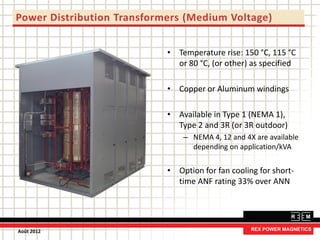

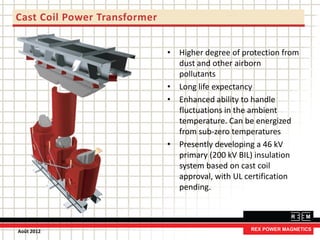

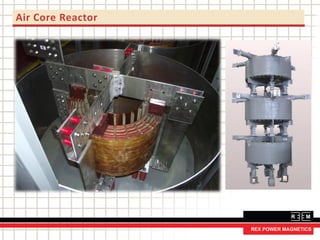

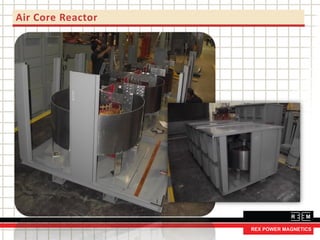

This document provides an overview of a Canadian manufacturer of power magnetic products. It discusses the company's capabilities including its product offering ranging from power transformers to reactors and enclosures. It highlights the company's key advantages such as its responsive nature, technical expertise, and quality manufacturing processes. The document also provides examples of reference projects demonstrating the company's ability to provide specialized transformer solutions for various industries.