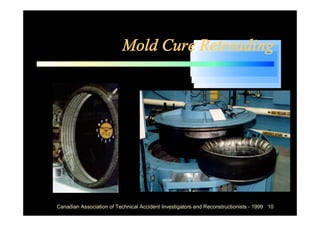

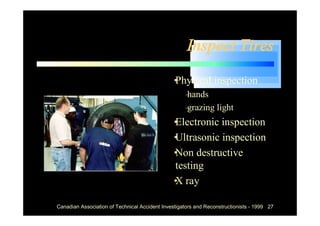

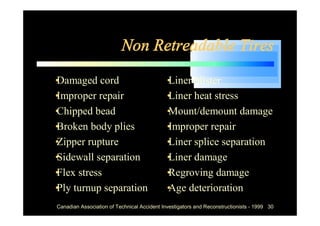

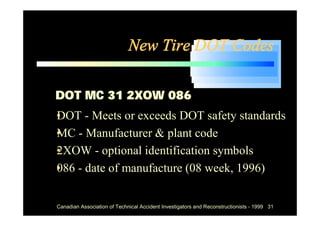

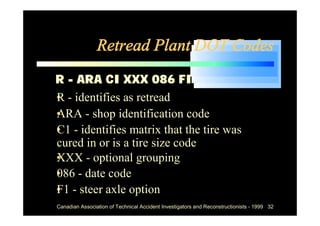

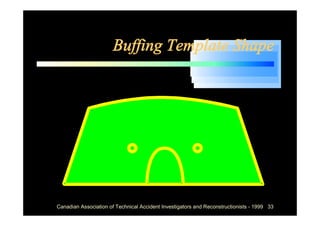

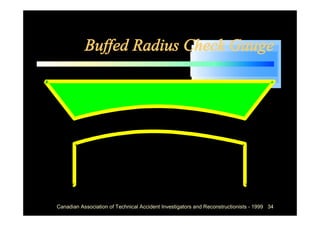

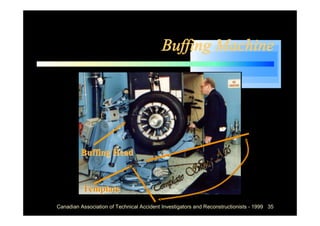

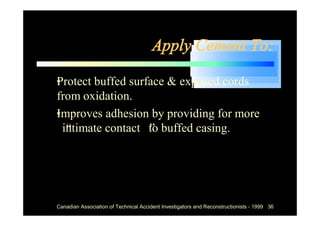

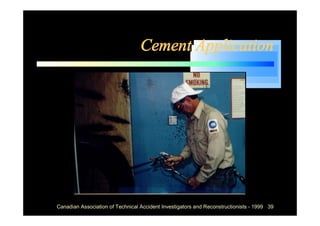

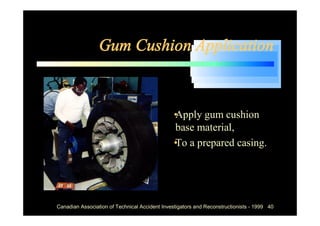

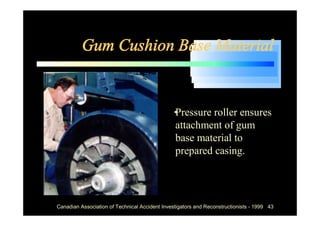

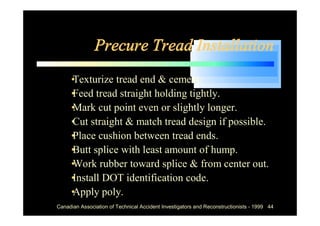

This document provides an overview of commercial tire retreading, including definitions, processes, and training related to tire manufacturing and maintenance. It details the steps in the retreading process such as inspection, buffing, cementing, tread application, and vulcanization, along with the importance of tire maintenance and factors affecting performance. Key points on tire classification, retreadability, and inspection methods are also included.