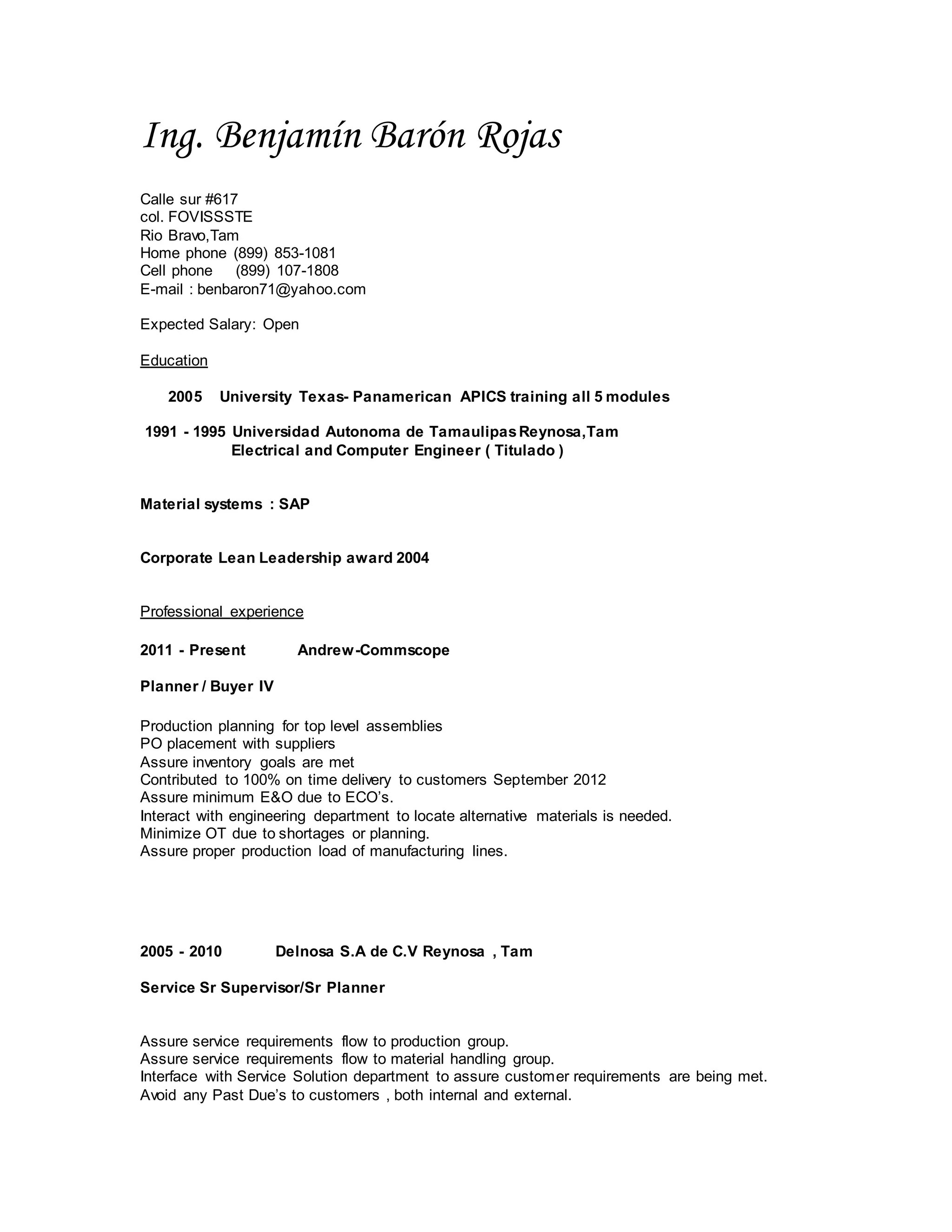

Benjamín Barón Rojas is seeking a new position and has over 20 years of experience in production planning, material planning, and operations management. He has a degree in electrical and computer engineering and is proficient in SAP and APICS training. His career includes roles as a planner, buyer, production control supervisor, and production readiness supervisor where he helped launch new products, improve operations performance, and ensure customer requirements and deadlines were met.