Resume

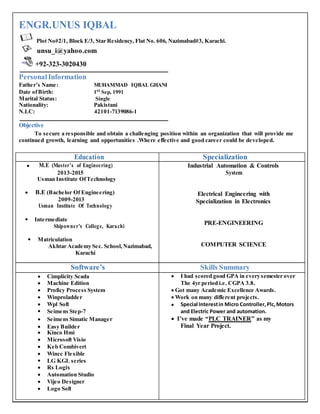

- 1. ENGR.UNUS IQBAL Plot No#2/1, Block E/3, Star Residency, Flat No. 606, Nazimabad#3, Karachi. unsu_i@yahoo.com +92-323-3020430 PersonalInformation Father’s Name: MUHAMMAD IQBAL GHANI Date ofBirth: 1st Sep, 1991 Marital Status: Single Nationality: Pakistani N.I.C: 42101-7139086-1 Objective To secure a responsible and obtain a challenging position within an organization that will provide me continued growth, learning and opportunities .Where effective and good career could be developed. Education Specialization M.E (Master’s of Engineering) Industrial Automation & Controls 2013-2015 System Usman Institute OfTechnology B.E (Bachelor Of Engineering) Electrical Engineering with 2009-2013 Specialization in Electronics Usman Institute Of Technology Intermediate PRE-ENGINEERING Shipowner’s College, Karachi Matriculation COMPUTER SCIENCEAkhtar Academy Sec. School,Nazimabad, Karachi Software’s Skills Summary Cimplicity Scada I had scored good GPA in every semester over Machine Edition The 4yr period i.e. CGPA 3.8. Proficy Process System Got many Academic Excellence Awards. Winproladder Work on many different projects. Wpl Soft Special Interestin Micro Controller,Plc,Motors Seimens Step-7 and Electric Power and automation. Seimens Simatic Manager I’ve made “PLC TRAINER” as my Easy Builder Final Year Project. Kinco Hmi Microsoft Visio Keb Combivert Wincc Flexible LG KGL series Rs Logix Automation Studio Vijeo Designer Logo Soft

- 2. Work Experience: I had good hands on experience in the field of Automation & Controls. Current Job: BAIG ENGINEERING (18 months) Designation:AUTOMATION ENGINEER Previous Job: SPEEDYAUTOMATION (6 Months) Designation: PROJECTENGINEER (At SpeedyAutomation my job was to attend the customer i.e. technical discussion, developed quotations, programming of PLC’s, HMI Designing and Instruments handling). Previous Job: ACT AUTOMATION (6 Months) Designation: TRAINEE ENGINEER 1. Current Projects Programmed and Automate Thin Film Extruder Machine at ‘LUCKY INDUSTRIES’, Site Area Karachi. (In this Project a PLC Based PID developed for the controlling of heater. System of 3CPU based on a network such that any system can be controlled from any panel using modbus technique). Designed, programmed and developed a PLC Based monitoring control of more than 400I/O’s for Pakistan Submarine at Pakistan Navy Dockyard Karachi. Designed HMI of AUTOMATICWINDER MACHINE at Osaka Tape Industries. 2. Speedy Automation Projects K-Electric Alarm Annunciation. (In this project we’re developing a DCS System at Bin Qasim Power Plant. A Redundant System of 2500 I/O’s PLC system would be installed). Wireless Tank Gauging And Alarm System. (In this project we’re developing a monitoring system at Shell Storage tanks. its level, Pressure, Temperature & Viscosity would be wirelessly monitored to a remote station on Modbus Protocol by using wireless radio devices). 3. Projects that I’ve done, Programmed Boiler Panelfor SOLARKAZINTERNATIONAL, KorangiIndustrial Area Automate the Dispensing Booth for LINZ PHARMACEUTICAL , KorangiIndustrial Area Automate Single Axis Pipe Bending Machine at ICON ENGINEERING ,Hyderi Automate Cotton Suction Machine at EASTERN TEXTILE, KorangiIndustrial Area Programmed Dancing Fountain located at GOLF CLUB ,DHA Production Counter Sample Using PLC and Microcontroller for ATLAS HONDA,Site Area Automate Shell CNG Pump , PatelPara Karachi Programmed and automate Electric Heater at ZAIB APPAREL,Korangi Automate, Programmed and Modify different types of TRANSFORMER (AC & DC, Air Cooled and Oil cooled , 1200 to 5000 Amp) at LUCKYALMUNIUM,Site Area,Karachi Designed an automatic PLC based control system of ABSORPTIONCHILLER PLANT at GELCAPS PHARMA Programmed and Automate Sterilizer’s of BOSCH’s PHARMA Programmed and Automate many different types of machines i.e. Filling And Packaging Machines At M.A Engineering Works ,Nazimabad#4 , Karachi. Designed a PID control System for CRISPO SULEMANJI , Site Area Karachi

- 3. Developed a Distributed Control System at GOLF CLUB on their irrigation system. (Note: All the projects completed in all respect ofMachine/Plant needs and ran satisfactory ) 3. Communication of PLC’s,VFD, Digital PanelMeter etc using different protocols. SERIAL MODBUS TECHNIQUE PROFIBUS CAN BUS 4. Controlling and Monitoring of PLC through Wireless Medium. 5. I can work on many different PLC’s like Schneider, GeFanuc, Siemens, LS, Mitsubishi, Delta, Fatek, Omron, Keyence,Koyo, Allen Bradley , SAIA Burgess and OPC.

- 4. 6. I had also done work on many different HMI’s and Operator Panel of Schneider ,Kinco, Touch win, Weintek, Hitech, Delta and Siemens. 7. Troubleshoot and modify many PLC programs at, Molding Machines at Hygiene Container , New Karachi 2 Axis, 3 Axis & 4 Axis Feather Boring Machine at NewKarachi 20 Head Printing Machine at IDRESS PRINTS , New Karachi UV Coating Machine at REHMAN PACKAGES ,Korangi Industrial Area Zip Manufacturing Machine at SWISS ZIPPER , New Karachi Bollard at CENTRE POINT BUILDING ,Defence Anodizing Plant at SINOPAK ,Korangi Thinner Recycler Machine at INDUS TOYOTA COMPANY. 8. I can also work for Building Management System,SCADA and DCS. 9. Expertise in PLC Programming, HMI designing, Electrical Panel wiring,Variable Frequency Drive (VFD/Inverter) ,Servo Drive Wiring Diagrams and Project Report Writing . 10. I had also made CET-11 Trainer for Pakistan Navy.