This document summarizes the wing design project for a Cessna 177 Cardinal aircraft. It describes using Xfoil software to analyze the NACA 2415 airfoil and generate aerodynamic data. Key points analyzed include wing loading during different flight conditions, maneuver loading during banked turns, and interpreting Xfoil output to create V-n diagrams showing stall curves. The document contains the project description, assumptions made, parameters chosen, and a Gantt chart showing the project timeline. Tables and figures are included to illustrate concepts and results.

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

8. Centroid & Area Moments of Inertia

8.1 Cantilever Beam Model

The calculations for centroids and moments of inertia in relation to our wing design are all based

on the underlying assumption for the shape of the wing. We began our analysis by taking a simplified

cross section of the wing (Figure 18). The design assumes a uniform cross section from root to tip. All

parts of the wing are also assumed to be composed of straight segments. The cross section is

approximated using three spars, eight brackets and four skin panels.

Table 3 Dimensions used in centroid & moment calculations

VARIABLE DIMENSIONS

Chord Length 1.5 m

Height 0.2235 m

SparThickness 0.0025 m

SkinThickness 0.001016 m

Spar Height 0.999797 m

Bracket Height 0.012 m

BracketThickness 0.0025 m

Theta 30 deg

Alpha 10 deg

Half Chord Length [m] 0.75

Half Height [m] 0.11175

Half SparThickness [m] 0.00125

Half Spar Height [m] 0.4998985

Half BracketThickness [m] 0.00125

Theta [rad] 0.523598333](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-27-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

8.2 Centroid Calculations

Part of our project involved carrying out hand calculations to corroborate the results of our

MATLAB code. For the centroid calculation, many of the specifications were assumed to be the same as

NACA 2412. Among them were: spar thickness (.0025 meters), skin thickness (.001016 meters) and the

area of the bracket (.0003 square meters). Other data was updated where applicable, such as chord

length (1.5 meters). We were given freedom over the location of the spars, and chose initial locations of

0 [m], 0.75 [m] and 1.5 [m]. Another assumption that we made was to assume that the brackets are

point masses located at the joint of the spar and the skin. In other words, the bracket height is

neglected. The bracket height is only used to calculate the area of the bracket in the cross section.

Figure 18: Simplified Wing Cross Section

In general, the centroid is calculated from an area-weighted average of the centroid of each of the

individual components. In our case this consists of 15 individual components. The MATLAB code

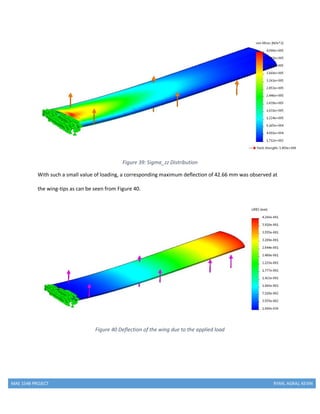

provided additional formulas to work with, some of which provided helpful assumptions in the

calculations. The x-coordinate of the centroid for the spars is set at their position coordinate on the

wing. The y-coordinate of the centroid for the spars is set to zero for root spar and middle spar, while

the spar out at the wing tip is calculated using trigonometry. This equation is given by:](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-28-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

I 𝑥𝑦 = ∑ 𝐴𝑖 ∗ (

𝑛

𝑖=1

𝑥𝑖 − 𝑥̅) ∗ (𝑦𝑖 − 𝑦̅)

(21)

We used the formulas provided to calculate the area moment of inertia for the leading edge of the wing.

The values of Ixx, Iyy and Ixy for the entire wing are found by summing the values for the individual

components. The data used in the calculations for the three spars is shown in Table 5, the data for the

brackets in

Table 6 and the data for the wing’s skin in

. The net values for the leading edge of the wing are displayed in

Table 8.

Table 5: Spar Data

SPARS (3)

_

x

[m]

_

y

[m]

Area [m

2

]

Ixx

[m

4

]

Iyy

[m

4

]

Ixy

[m

4

]

1 0 0 0.00055875 0.00001103 0.00032871 -0.00005348

2 0.75 0 0.00055875 0.00001103 0.00000016 -0.00000119

3 1.5 -0.433 0.00055875 0.00005540 0.00030021 -0.00012623

Table 6: Bracket Data

BRACKETS (8)

_

x

[m]

_

y

[m]

Area [m

2

]

Ixx

[m

4

]

Iyy

[m

4

]

Ixy

[m

4

]

SKIN (4)

_

x

[m]

_

y

[m]

Area [m

2

]

Ixx

[m

4

]

Iyy

[m

4

]

Ixy

[m

4

]

1 top 0.375 0.1118 0.000762 4.26E-05 0.00015 -7.066E-05

1 bottom 0.375 -0.1118 0.000762 1.3E-07 0.00015 -3.896E-06

2 top 1.125 -0.1048 0.00087988 1.41E-05 0.000154 -1.75E-05

2 bottom 1.125 -0.3283 0.00087988 5.02E-05 0.000154 -8.79E-05](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-30-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

1 top 0.0013 0.1118 0.00003 1.679E-06 1.76E-05 -5.4E-06

1 bottom 0.0013 -0.1118 0.00003 5.103E-09 1.76E-05 -3E-07

2 top 0.74875 0.1118 0.00003 1.679E-06 9.99E-09 -1.3E-07

2 bottom 0.74875 -0.1118 0.00003 5.103E-09 9.99E-09 -7.1E-09

3 top 0.75125 0.1118 0.00003 1.679E-06 7.44E-09 -1.1E-07

3 bottom 0.75125 -0.1118 0.00003 5.103E-09 7.44E-09 -6.2E-09

4 top 1.49875 -0.3213 0.00003 1.158E-06 1.61E-05 -4.3E-06

4 bottom 1.49875 -0.5448 0.00003 5.291E-06 1.61E-05 -9.2E-06

Table 7: Wing Skin Data

Table 8: Area Moment of Inertia Results

Net Area Moment of Inertia [m

4

]

Ixx 0.00019600

Iyy 0.00131007

Ixy -0.00038037

9. Shear Force, Bending, Deflection

This section of the report will go through the steps from load to deflection. Using the load intensity

equations calculated for wx and wy. The equation for shear force in the y-direction is found through a

SKIN (4)

_

x

[m]

_

y

[m]

Area [m

2

]

Ixx

[m

4

]

Iyy

[m

4

]

Ixy

[m

4

]

1 top 0.375 0.1118 0.000762 4.26E-05 0.00015 -7.066E-05

1 bottom 0.375 -0.1118 0.000762 1.3E-07 0.00015 -3.896E-06

2 top 1.125 -0.1048 0.00087988 1.41E-05 0.000154 -1.75E-05

2 bottom 1.125 -0.3283 0.00087988 5.02E-05 0.000154 -8.79E-05](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-31-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

Figure 22: My vs Wing Span

The equations for u’’ and v’’ are given by equations 26 and 27:

𝑑2 𝑢

𝑑𝑧2 = −𝐾 ∗ [−𝑀𝑥 ∗ 𝐼𝑥𝑦 + 𝑀 𝑦 ∗ 𝐼𝑥𝑥] (26)

𝑑2 𝑣

𝑑𝑧2 = −𝐾 ∗ [𝑀𝑥 ∗ 𝐼 𝑦𝑦 − 𝑀 𝑦 ∗ 𝐼𝑥𝑦] (27)

𝐾 =

1

𝐸∗(𝐼 𝑥𝑥∗𝐼 𝑦𝑦−𝐼 𝑥𝑦

2 )

(28)

The deflections due to bending are found by integrating u’’ and v’’ twice. The constants of integration go

to zero because we integrate from the LHS. Ultimately, we compare the deflections at the tip by

executing numerical integration in MATLAB with equations 29 and 30:

𝑢( 𝑧) = ∑

𝑑𝑢

𝑑𝑧

∗ (𝑧𝑖+1 − 𝑧𝑖) (29)

𝑣( 𝑧) = ∑

𝑑𝑣

𝑑𝑧

∗ (𝑧𝑖+1 − 𝑧𝑖) (30)](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-35-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

𝐼 𝑥′,𝑖 is the Area MOI of the ith

component about its own centroid about the x-axis (Negligible)

𝐼 𝑦′,𝑖 is the Area MOI of the ith

component about its own centroid about the y-axis (Negligible)

11. Shear Flow – Calculations

Using the calculated x-y coordinates to define the profile of the wing and the associated areas at each

point for spar caps and stringers, shear flow throughout the structure can be determined. Ideally, the

coordinate system would be centered at the centroid of the cross section, but this can be corrected for

through a simple coordinate transfer. Each point will be treated as a boom where the area of the boom

corresponds to the effective area of the skin, stringers, or spar caps adjacent to that point. This is

calculated such that axial stress is conserved between the actual cross section and the simplified boom

cross section. The final equation is shown in Equation (39).

𝐴 𝐵𝑜𝑜𝑚 = 𝐴 𝑠𝑝𝑎𝑟 𝑐𝑎𝑝 𝑜𝑟 𝑠𝑡𝑟𝑖𝑛𝑔𝑒𝑟 + ∑ [

𝑡𝑏

6

(2 +

𝜎 𝑧𝑧(𝑛+1)

𝜎 𝑧𝑧(𝑛)

)]𝑛

𝑖=1 (39)

Where the area of the spar cap or stringer are only for that specific point, n is the number of adjacent

panels, t is the thickness of that adjacent panel, b is the length of the adjacent panel, σzz(n+1) is the stress

at the point on the other end of the adjacent panel, and σzz is the stress at the current point. Typically n

is equal to 2, one for each of the adjacent skin panels. However at the locations where the spar meets

the skin, n is equivalent to 3 to include the contributions due to the spar. σzz in this equation is calculated

using the moment in the X and Y directions and implemented into Equation (40).

𝜎𝑧𝑧,𝑖 =

𝑀 𝑥(𝐼 𝑦𝑦(𝑦 𝑖−𝑦 𝑐)−𝐼 𝑥𝑦(𝑥 𝑖−𝑥 𝑐))

𝐼 𝑥𝑥 𝐼 𝑦𝑦−𝐼 𝑥𝑦

2 +

𝑀 𝑦(𝐼 𝑥𝑥(𝑥 𝑖−𝑥 𝑐)−𝐼 𝑥𝑦(𝑦 𝑖−𝑦 𝑐))

𝐼 𝑥𝑥 𝐼 𝑦𝑦−𝐼 𝑥𝑦

2 (40)

Where the moments of inertia are the previously calculated inertia terms for the wing cross section, x

and y are the coordinates of the point, and xc and yc are the x-y coordinates of the centroid if the points

are not already normalized.](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-42-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

Figure 29 Shear Flow Idealization

Starting with point 1, the Δqb, or change in sheer flow from one side of the boom to the other is

calculated at each point around the profile using Equation (41).

Δ𝑞 𝑏,𝑖 =

𝑆 𝑦 𝐼 𝑥𝑦−𝑆 𝑥 𝐼 𝑥𝑥

𝐼 𝑥𝑥 𝐼 𝑦𝑦−𝐼 𝑥𝑦

2 𝐴 𝐵𝑜𝑜𝑚,𝑖( 𝑥𝑖 − 𝑥 𝑐) +

𝑆 𝑥 𝐼 𝑥𝑦−𝑆 𝑦 𝐼 𝑦𝑦

𝐼 𝑥𝑥 𝐼 𝑦𝑦−𝐼 𝑥𝑦

2 𝐴 𝐵𝑜𝑜𝑚,𝑖( 𝑦𝑖 − 𝑦𝑐) (41)

Where Sx and Sy are the shear forces, ABoom,I is the effective boom area at that point, xi and yi are the x-y

components of the point, and xc and yc are the centroid coordinates if not normalized. From this the

total qb at a given point is the sum of the Δqb’s for all previous points as shown in equation X. The values

of qb are shown in the Appendix.

𝑞 𝑏,𝑘 = ∑ Δ𝑞 𝑏,𝑖

𝑘

𝑖=1 (42)

To calculate the total q, the relationship between cell 1 and cell 2 must be accounted for. This is

considered by examining the total moment on the system in Equation (43) and the twist rate of each cell

using Equations (44) and (45).

𝑀0 + 𝑆 𝑦 𝜉0 − 𝑆 𝑥 𝜂0 = 2𝐴1 𝑞0,1 + 2𝐴2 𝑞0,2 + ∑ 2𝑞 𝑏,𝑖Δ𝐴𝑖

𝑛

𝑖=1 (43)

𝑑𝜃

𝑑𝑧

=

1

2𝐴1 𝐺

[𝑞0,1 (∑

((𝑥 𝑖+1−𝑥 𝑖)2+(𝑦 𝑖+1−𝑦 𝑖)2)

1

2

𝑡 𝑠𝑘𝑖𝑛

𝑛

𝑖=1 ) + (𝑞0,1 − 𝑞0,2)

(𝑦 𝑏𝑜𝑡−𝑦𝑡𝑜𝑝)

𝑡 𝑠𝑝𝑎𝑟

+

(𝑆 𝑦 𝐼 𝑥𝑦−𝑆 𝑥 𝐼 𝑥𝑥)

𝐼 𝑥𝑥 𝐼 𝑦𝑦−𝐼 𝑥𝑦

2 ∑ 𝐴 𝑏𝑜𝑜𝑚,𝑖 𝑥𝑖

((𝑥 𝑖+1−𝑥 𝑖)2+(𝑦 𝑖+1−𝑦 𝑖)2)

1

2

𝑡 𝑠𝑘𝑖𝑛

𝑛

𝑖=1 +

(𝑆 𝑥 𝐼 𝑥𝑦−𝑆 𝑦 𝐼 𝑦𝑦)

𝐼 𝑥𝑥 𝐼 𝑦𝑦−𝐼 𝑥𝑦

2 ∑ 𝐴 𝑏𝑜𝑜𝑚,𝑖 𝑦𝑖

((𝑥 𝑖+1−𝑥 𝑖)2+(𝑦 𝑖+1−𝑦 𝑖)2)

1

2

𝑡 𝑠𝑘𝑖𝑛

𝑛

𝑖=1 ]

(44)](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-44-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

𝑑𝜃

𝑑𝑧

=

1

2𝐴2 𝐺

[𝑞0,2 (∑

((𝑥 𝑖+1−𝑥 𝑖)2+(𝑦 𝑖+1−𝑦 𝑖)2)

1

2

𝑡 𝑠𝑘𝑖𝑛

𝑛

𝑖=1 ) + (𝑞0,2 − 𝑞0,1)

(𝑦𝑡𝑜𝑝−𝑦 𝑏𝑜𝑡)

𝑡 𝑠𝑝𝑎𝑟

+ 𝑞0,2

(𝑦𝑡𝑜𝑝−𝑦 𝑏𝑜𝑡)

𝑡 𝑠𝑝𝑎𝑟

+

(𝑆 𝑦 𝐼 𝑥𝑦−𝑆 𝑥 𝐼 𝑥𝑥)

𝐼 𝑥𝑥 𝐼 𝑦𝑦−𝐼 𝑥𝑦

2 ∑ 𝐴 𝑏𝑜𝑜𝑚,𝑖 𝑥𝑖

((𝑥 𝑖+1−𝑥 𝑖)2+(𝑦 𝑖+1−𝑦 𝑖)2)

1

2

𝑡 𝑠𝑘𝑖𝑛

𝑛

𝑖=1 +

(𝑆 𝑥 𝐼 𝑥𝑦−𝑆 𝑦 𝐼 𝑦𝑦)

𝐼 𝑥𝑥 𝐼 𝑦𝑦−𝐼 𝑥𝑦

2 ∑ 𝐴 𝑏𝑜𝑜𝑚,𝑖 𝑦𝑖

((𝑥 𝑖+1−𝑥 𝑖)2+(𝑦 𝑖+1−𝑦 𝑖)2)

1

2

𝑡 𝑠𝑘𝑖𝑛

𝑛

𝑖=1 ]

(45)

It can be assumed that the wing cross section behaves as a rigid body and thus the twist rates are

equivalent. This leaves three equations with three unknowns; dθ/dz, q0,1, and q0,2. Solving the system of

equations gives the q0,1 and q0,2 to complete Equation (46).

𝑞𝑡𝑜𝑡𝑎𝑙,𝑖 = 𝑞 𝑏,𝑖 + 𝑞0,1 𝑜𝑟 2 (46)

Where the q0 is the appropriate term for the cell containing the point in question. This resulting shear

flow (qtotal) is in terms of the shear force per unit length. To get this into shear stress, the shear flow

must be divided by the thickness, resulting in units of shear force per unit area (Equation (47)).

𝜎𝑧𝑠,𝑖 =

𝑞 𝑡𝑜𝑡𝑎𝑙,𝑖

𝑡 𝑠𝑘𝑖𝑛

(47)

Combining the shear stress and the axial stress from Equation (47) at each point, the equivalent

principle stress can be calculated. Equation (48) defines this relationship.

𝜎𝑒𝑞,𝑖 = √2𝜎𝑧𝑧,𝑖

2 + 6𝜎𝑧𝑠,𝑖

2 (48)

11.1 Shear Flow – Results

The results of these calculations for the first of the 10 critical points being analyzed (PHAA at Sea Level)

can be seen in Figure 30, shear stress, and Figure 31, equivalent stress. As the legend on the right

indicates, the colors correspond to the magnitude of the stress at that location.](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-45-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

Figure 33 Product of Shear Flow and Boom Area

13.Buckling, Fatigue & Von Mises Stress

13.1 Von Mises Stresses

An important test in the design of our wing was to check the yield stress against the Von Mises

yield criterion. The tensile yield strength of AL 2024 T3 is 345 MPa and the ultimate tensile

strength is 483 MPa. The Von Mises equation is given in terms of principal stresses by equation

49 below.

𝜎𝑒𝑞 = √

[( 𝜎11 − 𝜎22)2 + ( 𝜎22 − 𝜎33)2 + ( 𝜎33 − 𝜎11)2 + 6( 𝜎12

2

+ 𝜎23

2

+ 𝜎31

2 )]

2

(49)](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-48-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

In our analysis, equation 49 reduces to equation 50 because we only have one longitudinal

component and one shear component.

𝜎𝑒𝑞 = √

[2( 𝜎𝑧𝑧)2 + 6( 𝜎𝑧𝑠)2]

2

(50)

Table 9: Von Mises Stress Calculation

The calculation verifies that our wing design meets the Von Mises Yield Criterion with a factor of

safety of 1.4 for yield and 2.0 for fracture.

13.2 Column Buckling

We considered column buckling in our wing design to avoid stringer buckling, which is achieved

by adjusting the spacing of the ribs. The theory for the buckling analysis was worked out by Euler in

the eighteenth century. Euler’s equations for a load P applied to the ends of a beam can be seen in

the equations and Figure 34 below:

Figure 34: Column Buckling](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-49-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

We use two equations to solve for the rib spacing:

𝑃𝐶𝑅 =

(𝜋2

𝐸𝐼)

𝑙 𝑒

2

(51)

The variables, their values, and the units for each term are outlined in tables 10 & 11 below.

𝑃𝐶𝑅 = 1.5𝜎𝑧𝑧 𝐴 𝑠𝑡𝑟𝑖𝑛𝑔𝑒𝑟

(52)

There is an n-squared factor in equation 51 that disappears when we set n equal to one (setting n equal

to one gives the smallest value for P where the column remains in equilibrium [Megson 271]). Next, by

setting equations (51) & (52) equal to each other and solving for effective length, we obtain the results

in Table 10.

Table 10: Rib Spacing

Table 11: Stringer Area

We use the following equation (53) from Megson [Table 8.1, pg. 272] to solve for the rib spacing given

the effective length:

𝑙 𝑒

𝑙

= 2 (53)

Setting Equation 53 equal to 2 gives us the most conservative value for rib spacing, as a larger effective

length decreases the value for P critical that yields failure in the column. Given a half-span of 5.41

meters, this would suggest 10 ribs evenly spaced along the wing.](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-50-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

13.3 Skin (Thin Plate) Buckling

We consider thin plate buckling theory to determine the design for the skin plates that are

strengthened by the ribs and stringers. This analysis will compare the critical buckling load of the

individual plates with the total compressive plate buckling stress. The critical buckling load is given by

equation 54:

𝑁𝑋,𝐶𝑅 =

𝑘𝜋2

𝐸𝑡3

12𝑏2(1 − 𝑣2)

(54)

We set the buckling coefficient k equal to 8.5, set the Elastic Modulus for AL 2024 T3 to 73.1

[GPa], set Poisson’s ratio, v, equal to 0.33, while t and b are the skin thickness and plate length,

respectively. Next, we summed the critical buckling load for each section and divided by the skin

thickness to find the total compressive plate buckling stress.

𝜎 𝐶𝑅 =

𝑛 ∗ 𝑁𝑋,𝐶𝑅

𝑡

(55)

Here n is the number of plates, and t is the skin thickness. The calculations are shown in Table 12 below.

Table 12

13.4 Shear Buckling of Skin

In addition to column buckling and skin (thin plate) buckling, plate buckling from shear loading

of the wing’s skin was considered. The coefficient, k, used for plate buckling from shear loading is

given by Figure 35. Using the appropriate value for k, the buckling stress is calculated using

equation 54. With the calculated values for shear stress in the skin below the critical buckling

stress, the geometry of the wing design passed this test.](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-51-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

Figure 35: Shear Buckling Coefficients for Flat Plates (Megson 315)

13.5 Fracture & Fatigue

Fatigue is defined as the progressive deterioration of the strength of a material or structural

component during service such that failure can occur at much lower stress levels than the

ultimate stress level [Megson 455]. Fracture can also occur at stresses below the yield stress if an

initial crack is present. A small crack, if undetected, can manifest into catastrophic failure. Figure

36 below from Megson (pg. 423) illustrates the reduction in failure stress as the number of

repetitions of this stress increases.

Figure 36 Failure Stress vs Number of Loading repetitions

Here we analyze the number of flight cycles our wing can endure before a crack grows by 1.8

centimeters, given an initial crack size of 0.2 centimeters.](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-52-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

The equation for the number of loading/flight cycles (N) until failure is given by Equation 56:

𝑁 =

𝑎 𝐶𝑅

1−

𝑚

2

− 𝑎𝑖

1−

𝑚

2

𝐶(1 −

𝑚

2 )𝜋2 𝜎∞

2

(56)

To solve for aCR, we plug in a value for KIC (26 [MPa*m^.5]) into Equation (57)

𝑎 𝐶𝑅 =

1

𝜋

(

𝐾𝐼𝐶

𝜎∞

)2

(57)

The results are given in Error! Reference source not found.. The critical crack length is calculated as

approximately 5.4mm.

Table 13: Flight Cycles to Failure

14. Aeroelasticity

14.1 Divergence

Wing divergence is the process of an applied load increasing due to aerodynamic loads (i.e. a

positive torsional pitch moment) that eventually build and cause the wing to reach a divergence

point. The deflection due to the increasing load causes the angle of attack to increase, and the

increasing wing deflection and twist this creates can lead to failure. The torsional divergence

speed is calculated from equation 58, where U is the torsional divergence speed:

𝑀 = 𝐶𝑈2

(𝜃 + 𝛼0)

(58)](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-53-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

W=1100*9.8; % Newtons

rho0=1.225; % Kg/m^3

rhoC=.7809; % Kg/m^3

VC=230*1000/3600; % m/s

VD=VC*1.5; % m/s

V=[0:0.5:VD]; % m/s

mu=1.983e-5; % pa*sec

g=32.17; % ft/s^2

A_cap=.0003; % m^2

A_str=.0001; % m^2

t_spar=.0025; % m

t_skin= .001; % m

x_spar=c/3; % m

x_strU=[0:5:95]*1.2/100; % m

x_strL=x_strU; % m

G=27579029160; % pa for 2024 all tempers

% Calculate a Reynolds Number

Re0=rho0*VC*c/mu;

ReC=rhoC*VC*c/mu;

[alpha1,CL1,CD1,CDp1,CM1,Top_Xtr1,Bot_Xtr1]=textread('naca24150.

pol','%f %f %f %f %f %f %f','headerlines', 12);

[alpha2,CL2,CD2,CDp2,CM2,Top_Xtr2,Bot_Xtr2]=textread('naca2415C.

pol','%f %f %f %f %f %f %f','headerlines', 12);

alpha={alpha1,alpha2};

CL={CL1,CL2};

CD={CD1,CD2};

CDp={CDp1,CDp2};

CM={CM1,CM2};

Top_Xtr={Top_Xtr1,Top_Xtr2};

Bot_Xtr={Bot_Xtr1,Bot_Xtr2};

alphar{1}=deg2rad(alpha{1});

alphar{2}=deg2rad(alpha{2});

ind=find(CL{1}>0,1);

CD0(1)=CD{1}(ind);

clear ind

ind=find(CL{2}>0,1);

CD0(2)=CD{2}(ind);

clear ind](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-71-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

[CLmax(1),mind(1)]=max(CL{1});

[CLmin(1),mind(2)]=min(CL{1});

[CLmax(2),mind(3)]=max(CL{2});

[CLmin(2),mind(4)]=min(CL{2});

Vspos(1)=sqrt(2*W/(CLmax(1)*rho0*S));

Vsneg(1)=sqrt(2*W/(abs((1))*rho0*S));

Vspos(2)=sqrt(2*W/(CLmax(2)*rhoC*S));

Vsneg(2)=sqrt(2*W/(abs(CLmin(2))*rhoC*S));

ind1(1)=find(alpha{1}==-7);

ind2(1)=find(alpha{1}==10);

ind1(2)=find(alpha{2}==-7);

ind2(2)=find(alpha{2}==10);

linefit(1,:)=polyfit(alphar{1}(ind1(1):ind2(1)),CL{1}(ind1(1):in

d2(1)),1);

linefit(2,:)=polyfit(alphar{2}(ind1(2):ind2(2)),CL{2}(ind1(2):in

d2(2)),1);

x=linspace(-.3,.3)';

y(:,1)=linefit(1,1).*x+linefit(1,2);

xinter(:,1)=-linefit(1,2)/linefit(1,1);

y(:,2)=linefit(2,1).*x+linefit(2,2);

xinter(:,2)=-linefit(2,2)/linefit(2,1);

CL3Dslope(1,1)=linefit(1,1)/(1+linefit(1,1)/(pi*A*e));

CL3Dline(1,1)=CL3Dslope(1,1);

CL3Dline(1,2)=-CL3Dslope(1,1)*xinter(:,1);

CL3Dslope(2,1)=linefit(2,1)/(1+linefit(2,1)/(pi*A*e));

CL3Dline(2,1)=CL3Dslope(2,1);

CL3Dline(2,2)=-CL3Dslope(2,1)*xinter(:,2);

CLmax(1)=CLmax(1)*CL3Dline(1,1)/linefit(1,1);

CLmin(1)=CLmin(1)*CL3Dline(1,1)/linefit(1,1);

CLmax(2)=CLmax(2)*CL3Dline(2,1)/linefit(2,1);

CLmin(2)=CLmin(2)*CL3Dline(2,1)/linefit(2,1);

% CLmax(1)=CL3Dline(1,1)*alphar{1}(mind(1))+CL3Dline(1,2);

% CLmin(1)=CL3Dline(1,1)*alphar{1}(mind(2))+CL3Dline(1,2);

% CLmax(2)=CL3Dline(2,1)*alphar{2}(mind(3))+CL3Dline(2,2);

% CLmin(2)=CL3Dline(2,1)*alphar{2}(mind(4))+CL3Dline(2,2);

% y3D(:,1)=CL3Dline(1,1).*x+CL3Dline(1,2);

% y3D(:,2)=CL3Dline(2,1).*x+CL3Dline(2,2);

y3Dline1{1}=(CL3Dline(1,1)/linefit(1,1)).*CL{1};](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-72-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

for j=1:2

maxpos(j)=max(nposi{j});

maxneg(j)=max(nnegi{j});

npos(maxpos(j)+1:end,j)=4.4;

nneg(maxneg(j)+1:nnegi{3},j)=-1.76;

for n=nnegi{3}:length(V)

nneg(n,j)=manslope*V(n)+manint;

end

end

npos(end+1,:)=zeros(1,2);

nneg(end+1,:)=zeros(1,2);

V(end+1)=V(end);

%% Calculate the Gust Load Factor

UeC=50; % ft/s

UeD=25; % ft/s

VCk=VC*1.944; % knots

VDk=VD*1.944; % knots

cft=c*3.28084; % ft

Wlbf=W*0.224809; % lbf

Sft2=S*10.7639; % ft^2

rho0s=rho0*0.00194032; % slug/ft^3

rhoCs=rhoC*0.00194032; % slug/ft^3

u0=2*Wlbf/Sft2/(rho0s*cft*CL3Dslope(1)*g);

uC=2*Wlbf/Sft2/(rhoCs*cft*CL3Dslope(2)*g);

Kg0=.88*u0/(5.3+u0);

KgC=.88*uC/(5.3+uC);

nC(1)=1+Kg0*CL3Dslope(1)*UeC*VCk/(498*(Wlbf/Sft2));

nC(2)=1+KgC*CL3Dslope(2)*UeC*VCk/(498*(Wlbf/Sft2));

nD(1)=1+Kg0*CL3Dslope(1)*UeD*VDk/(498*(Wlbf/Sft2));

nD(2)=1+KgC*CL3Dslope(2)*UeD*VDk/(498*(Wlbf/Sft2));

ngustposS(:,1)=[1,nC(1),nD(1),1];

ngustnegS(:,1)=[1,-(nC(1)-2),-(nD(1)-2),1];

ngustposS(:,2)=[1,nC(2),nD(2),1];

ngustnegS(:,2)=[1,-(nC(2)-2),-(nD(2)-2),1];

vgust=[0,VC,VD,0];

ngustpos(:,1)=interp1(vgust(1:3),ngustposS(1:3,1),V);

ngustneg(:,1)=interp1(vgust(1:3),ngustnegS(1:3,1),V);](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-74-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

ngustpos(:,2)=interp1(vgust(1:3),ngustposS(1:3,2),V);

ngustneg(:,2)=interp1(vgust(1:3),ngustnegS(1:3,2),V);

count=0;

countn=0;

for j=1:2

for n=1:length(V)

if V(n)<Vspos(j)

else

count=count+1;

Vcomp{j}(count)=V(n);

end

if V(n)>Vspos(j)&& n<=maxpos(j)

nComp{j}(count)=npos(n,j);

elseif n>maxpos(j)

nComp{j}(count)=max(npos(n,j),ngustpos(n,j));

end

if V(n)<Vsneg(j)

else

countn=countn+1;

Vcomn{j}(countn)=V(n);

end

if V(n)>Vsneg(j)&&n<=maxneg(j)

nComn{j}(countn)=nneg(n,j);

elseif n>maxneg(j)

nComn{j}(countn)=min(nneg(n,j),ngustneg(n,j));

end

end

count=0;

countn=0;

end

nComp{1}=[0,nComp{1},0];

Vcomp{1}=[Vspos(1),Vcomp{1},VD];

nComp{2}=[0,nComp{2},0];

Vcomp{2}=[Vspos(2),Vcomp{2},VD];

nComn{1}=[0,0,nComn{1},0];

Vcomn{1}=[Vspos(1),Vsneg(1),Vcomn{1},VD];

nComn{2}=[0,0,nComn{2},0];

Vcomn{2}=[Vspos(2),Vsneg(2),Vcomn{2},VD];

figure('Position',[50,50,1200,500])

subplot(1,2,1)

plot(V,npos(:,1),'b')

hold on

plot(vgust,ngustposS(:,1),'r')](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-75-320.jpg)

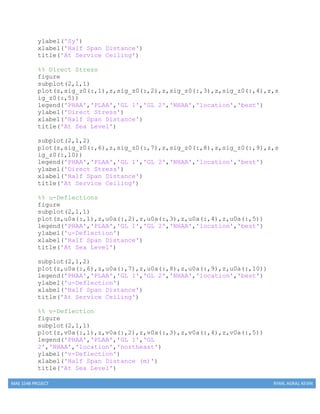

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

plot(Vcomp{1},nComp{1},'g--','linewidth',2)

plot(V,nneg(:,1),'b')

plot(vgust,ngustnegS(:,1),'r')

plot(Vcomn{1},nComn{1},'g--','linewidth',2)

legend('Maneuver Limit','Gust Loading','Combined

Loading','Location','northwest')

title('V-n Diagram at Sea Level')

xlabel('Velocity (m/s)')

ylabel('Load Factor (n)')

subplot(1,2,2)

plot(V,npos(:,2),'b')

hold on

plot(vgust,ngustposS(:,2),'r')

plot(Vcomp{2},nComp{2},'g--','linewidth',2)

plot(V,nneg(:,2),'b')

plot(vgust,ngustnegS(:,2),'r')

plot(Vcomn{2},nComn{2},'g--','linewidth',2)

legend('Maneuver Limit','Gust Loading','Combined

Loading','Location','northwest')

title('V-n Diagram at 4450 m')

xlabel('Velocity (m/s)')

ylabel('Load Factor (n)')

%% Calculating Wx and Wy

LCs=[59.5 4.4

95.5 4.4

95.5 -1.1

64 -1.78

39.5 -1.76

75.5 4.4

95.5 4.4

95.5 -1.298

64 -2.051

50.5 -1.76];

nz=100;

for n=1:length(LCs)

if n>length(LCs)/2

rho=rhoC;

CD0T=CD0(2);

m=2;

else

rho=rho0;

CD0T=CD0(1);](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-76-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

m=1;

end

L(n) = LCs(n,2)*W; % N

lift

CLCP(n) = 2*L(n)/rho/LCs(n,1)^2/S; %

lift coefficient

% Alpha(n)=(CLCP(n)-CL3Dline(2))/CL3Dline(1);

Alpha(n)=interp1(y3Dline1{m},alphar{m},CLCP(n));

D(n) = 0.5*rho*LCs(n,1)^2*S*(CD0(m) + CLCP(n)^2/pi/A/e); %

N drag

z = 0:b/2/nz:b/2; % root to tip (half

span)

% lift distribution

l_rect(:,n) = L(n)/b.*ones(1,nz+1);

l_ellip (:,n)= (4*L(n)/pi/b).*sqrt(1-(2.*z./b).^2);

l (:,n)= (l_rect(:,n) + l_ellip(:,n))./2; %

N/m

d (:,n)=D(n)/b.*ones(1,nz+1);

for m=1:length(d)

if m>.8*length(d)

d(m,n)=d(m,n)*1.1;

end

end

figure('Position',[50,50,1200,500])

subplot(1,2,1)

p=plotyy([z',z',z'],[l_ellip(:,n),l_rect(:,n),l(:,n)],z,d(:,n));

ylabel(p(1),'Lift Force (N/m)')

xlabel('z (m)')

ylabel(p(2),'Drag Force (N/m)')

legend('lift elliptic distribution','lift rectangular

distribution','combined lift distribution','Drag

Distribution','location','best')

% rotate into x-y coordinate

wy(:,n) = cos(Alpha(n)).*l(:,n) + sin(Alpha(n)).*d(:,n);

wx(:,n) = -sin(Alpha(n)).*l(:,n) + cos(Alpha(n)).*d(:,n);

% Note: wx and wy are defined from root to tip

subplot(1,2,2)

plot(z,wy,z,wx,'linewidth',2)](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-77-320.jpg)

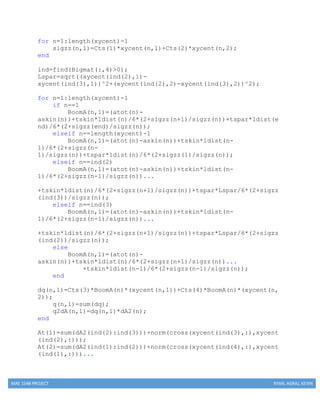

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

xlabel('z (m)')

ylabel('Distributed Load (N/m)')

legend('w_y','w_x','location','best')

end

figure('Position',[50,50,800,500])

plot(z,l(:,1),'-',z,l(:,2),'-',z,l(:,3),'-',z,l(:,4),'-

',z,l(:,5),'-',...

z,l(:,6),'--',z,l(:,7),'--',z,l(:,8),'--',z,l(:,9),'--

',z,l(:,10),'--','linewidth',2)

ylabel('Lift Force (N/m)')

xlabel('z (m)')

legend('PHAA SL','PLAA SL','Gust 1 SL','Gust 2 SL','NHAA

SL','PHAA CA','PLAA CA','Gust 1 CA','Gust 2 CA','NHAA

CA','location','west')

Rho(1:5)=rho0;

Rho(6:10)=rhoC;

Cd(1:5)=CD(1);

Cd(6:10)=CD(2);

for n=1:length(LCs)

[z1t,Mx0t,My0t,Sx0t,Sy0t,sig_z0t,u0t,v0t] =

DeflectionLoadscode(wx(:,n),wy(:,n),LCs(n,2),Rho(n),LCs(n,1),Alp

ha(n),Cd(n),nz);

z1(:,n)=z1t;

Mx0(:,n)=Mx0t;

My0(:,n)=My0t;

Sx0(:,n)=Sx0t;

Sy0(:,n)=Sy0t;

sig_z0(:,n)=sig_z0t;

u0a(:,n)=u0t;

v0a(:,n)=v0t;

clear z1t Mx0t My0t Sx0t Sy0t sig_z0t u0t v0t

end

%% X Moments

figure

subplot(2,1,1)

plot(z,Mx0(:,1),z,Mx0(:,2),z,Mx0(:,3),z,Mx0(:,4),z,Mx0(:,5))

legend('PHAA','PLAA','GL 1','GL 2','NHAA','location','best')

ylabel('Mx')

xlabel('Half Span Distance')

title('At Sea Level')

subplot(2,1,2)

plot(z,Mx0(:,6),z,Mx0(:,7),z,Mx0(:,8),z,Mx0(:,9),z,Mx0(:,10))

legend('PHAA','PLAA','GL 1','GL 2','NHAA','location','best')](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-78-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

subplot(2,1,2)

plot(z,v0a(:,6),z,v0a(:,7),z,v0a(:,8),z,v0a(:,9),z,v0a(:,10))

legend('PHAA','PLAA','GL 1','GL

2','NHAA','location','northeast')

ylabel('v-Deflection')

xlabel('Half Span Distance (m)')

title('At Service Ceiling')

%% Recalculating the Airfoil Section

[cq,Ixx,Iyy,Ixy,x,yU,yL,Bigmat,i_strU,dx,i_spar,i_strL] =

airfoil_section(c,A_cap,A_str,t_spar,t_skin,x_spar,x_strU,x_strL

);

Ivals=[Ixx,Iyy,Ixy];

for n=1:length(LCs)

SMvals=[Mx0(1,n),My0(1,n),Sx0(1,n),Sy0(1,n)]; % at the root

[sigeq(:,n),sigzs(:,n),sigzz(:,n),qtot(:,n),xyc,xycent,qb(:,n),s

igcheck(:,n)]=shearflow(Bigmat,cq,SMvals,Ivals,t_skin,t_spar,G);

figure

scatter(xycent(:,1),xycent(:,2),10,sigzs(:,n),'filled')

c=colorbar;

c.Label.String='sigma_z_s (pa)';

ylim ([-.3 .3])

xlabel('X Coordinate (m)')

ylabel('Y Coordinate (m)')

figure

scatter(xycent(:,1),xycent(:,2),10,sigeq(:,n),'filled')

c=colorbar;

c.Label.String='sigma_e_q (pa)';

ylim ([-.3 .3])

xlabel('X Coordinate (m)')

ylabel('Y Coordinate (m)')

end

figure

scatter(xycent(:,1),xycent(:,2),10,sigeq(:,1),'filled')

c=colorbar;

c.Label.String='sigma_e_q';

ylim ([-.3 .3])](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-81-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

xlabel('X Coordinate (m)')

ylabel('Y Coordinate (m)')

figure

plot(x,yU,'k','Linewidth',2);

ylim([-0.3 0.3])

hold on

plot(i_strU*dx,yU(i_strU),'or','markersize',5);

plot([x_spar(1),x_spar(1)],[yU(i_spar(1)),yL(i_spar(1))],'b','Li

newidth',3);

scatter(xyc(1,1),xyc(1,2),'m*')

plot(x,yL,'k','Linewidth',2);

plot(i_strL*dx,yL(i_strL),'or','markersize',5);

plot([x(end),x(end)],[yU(end),yL(end)],'b','Linewidth',3);

ylabel('y (m)')

xlabel('x (m)')

grid on

legend('Airfoil','Stringers','Spars','Centriod')

figure

plot(qb)

ylabel('q_b (N/m)')

xlabel('Point Number')

legend('PHAA SL','PLAA SL','Gust 1 SL','Gust 2 SL','NHAA

SL','PHAA CA','PLAA CA','Gust 1 CA','Gust 2 CA','NHAA

CA','location','best')

figure

plot(sigcheck)

ylabel('Sigma_z_s*Boom Area (lbf)')

xlabel('Point Number')

legend('PHAA SL','PLAA SL','Gust 1 SL','Gust 2 SL','NHAA

SL','PHAA CA','PLAA CA','Gust 1 CA','Gust 2 CA','NHAA

CA','location','best')

function[sigeq,sigzs,sigzz,qtot,xyc,xycent,q,sigcheck]=shearflow

(Bigmat,xs,SMvals,Ivals,tskin,tspar,G)

xy=Bigmat(:,1:2);

if xy(1,2)~=xy(end,2)

xy(end+1,:)=xy(1,:);

end

b=ones(length(xy),1);](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-82-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

xy=[xy,b*0];

% calculate area of wing cross section

for n=1:length(xy)-1

dA2(n)=norm(cross(xy(n,:),xy(n+1,:)));

A2(n)=sum(dA2);

ldist(n,1)=sqrt((xy(n,1)-xy(n+1,1))^2+(xy(n,2)-

xy(n+1,2))^2);

askin(n,1)=Bigmat(n,6);

xyA(n,:)=[xy(n,1)*askin(n),xy(n,2)*askin(n)];

atot(n,1)=sum(Bigmat(n,3:6));

end

xyc(1,:)=[sum(xyA(:,1))/sum(askin),sum(xyA(:,2))/sum(askin)];

%normalize x and y vectors to centriod

xycent=xy-[b*xyc(1),b*xyc(2),b*0];

% calculate area of wing cross section

for n=1:length(xy)-1

dA2(n)=norm(cross(xycent(n,:),xycent(n+1,:)));

A2(n)=sum(dA2);

ldist(n,1)=sqrt((xycent(n,1)-xycent(n+1,1))^2+(xycent(n,2)-

xycent(n+1,2))^2);

askin(n,1)=Bigmat(n,6);

xyA(n,:)=[xycent(n,1)*askin(n),xycent(n,2)*askin(n)];

atot(n,1)=sum([Bigmat(n,3),Bigmat(n,5:6)]);

end

xyc(2,:)=[sum(xyA(:,1))/sum(askin),sum(xyA(:,2))/sum(askin)];

for n=1:length(xycent)-1

Ivec(n,:)=[askin(n)*(xycent(n,2)-

xyc(2))^2,askin(n)*(xycent(n,1)-xyc(1))^2,askin(n)*(xycent(n,1)-

xyc(1))*(xycent(n,2)-xyc(2))];

end

IvecT=[sum(Ivec(:,1)),sum(Ivec(:,2)),sum(Ivec(:,3))];

den1=IvecT(1)*IvecT(2)-IvecT(3)^2;

Cts=[(SMvals(2)*IvecT(1)-

SMvals(1)*IvecT(3))/den1,(SMvals(1)*IvecT(2)-

SMvals(2)*IvecT(3))/den1,...

(SMvals(4)*IvecT(3)-

SMvals(3)*IvecT(1))/den1,(SMvals(3)*IvecT(3)-

SMvals(4)*IvecT(2))/den1];](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-83-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

+norm(cross(xycent(ind(2),:),xycent(ind(3),:)))+sum(dA2(ind(3):i

nd(4)));

Bx(1)=sum(BoomA(ind(2):ind(3)).*xycent(ind(2):ind(3),1).*ldist(i

nd(2):ind(3))/tskin);

Bx(2)=sum(BoomA(ind(1):ind(2)).*xycent(ind(1):ind(2),1).*ldist(i

nd(1):ind(2))/tskin)+...

sum(BoomA(ind(3):ind(4)).*xycent(ind(3):ind(4),1).*ldist(ind(3):

ind(4))/tskin);

By(1)=sum(BoomA(ind(2):ind(3)).*xycent(ind(2):ind(3),2).*ldist(i

nd(2):ind(3))/tskin);

By(2)=sum(BoomA(ind(1):ind(2)).*xycent(ind(1):ind(2),2).*ldist(i

nd(1):ind(2))/tskin)+...

sum(BoomA(ind(3):ind(4)).*xycent(ind(3):ind(4),2).*ldist(ind(3):

ind(4))/tskin);

dytspar=(xycent(ind(2),2)-xycent(ind(3),2))/tspar;

dytback=(xycent(ind(1),2)-xycent(ind(4),2))/tspar;

ldtsk(1)=sum(ldist(ind(2):ind(3))/tskin);

ldtsk(2)=(sum(ldist(ind(1):ind(2)))+sum(ldist(ind(3):ind(4))))/t

skin;

b=[-Cts(3)*Bx(1)-Cts(4)*By(1);-Cts(3)*Bx(2)-

Cts(4)*By(2);SMvals(3)+SMvals(2)*xs-sum(q2dA)];

A=[ldtsk(1)+(-dytspar),-(-dytspar),-At(1)*G;-

dytspar,ldtsk(2)+dytspar+dytback,-At(2)*G;...

sum(q2dA(ind(2):ind(3))),sum(q2dA(ind(1):ind(2)))+sum(q2dA(ind(3

):ind(4))),0];

x=A^-1*b;

q01=x(1);

q02=x(2);

dthdz=x(3);

qtot=[q(ind(1):ind(2))+q02;q(ind(2)+1:ind(3))+q01;q(ind(3)+1:ind

(4))+q02];

sigzs=qtot/tskin;

for n=1:length(sigzs)

sigeq(n,1)=sqrt(2*sigzz(n)^2+6*sigzs(n)^2);](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-85-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

end

sigcheck=BoomA.*sigzs;

xycent=xycent(1:end-1,:);

function [cq,Ixx,Iyy,Ixy,x,yU,yL,Bigmat,i_strU,dx,i_spar,i_strL]

=

airfoil_section(c,A_cap,A_str,t_spar,t_skin,x_spar,x_strU,x_strL

)

%% airfoil section profile

% NACA 2415

m = 0.02; % 1st digit maximum camber (m) in percentage of the

chord

p = 0.4; % 2nd digit position of the maximum camber (p) in

tenths of chord

t = 0.15; % last 2 digits(Maximum thickness (t) of the airfoil

in percentage of chord)

cq = c/4;

nx = 500; % number of increments

dx = c/nx;

x = 0:dx:c; % even spacing

yc = zeros(1,nx+1);

yt = zeros(1,nx+1);

yU0 = zeros(1,nx+1);

yL0 = zeros(1,nx+1);

theta = zeros(1,nx+1);

xb = p*c;

i_xb = xb/dx + 1;

for i = 1:nx+1

yt(i) = 5*t*c*(0.2969*sqrt(x(i)/c) - 0.1260*(x(i)/c) -

0.3516*(x(i)/c)^2 + 0.2843*(x(i)/c)^3 - 0.1015*(x(i)/c)^4);

if i <= i_xb

yc(i) = m*x(i)/p^2*(2*p - x(i)/c);

theta(i) = atan(2*m/p^2*(p - x(i)/c));

else

yc(i) = m*(c - x(i))/(1-p)^2*(1 + x(i)/c - 2*p);

theta(i) = atan(2*m/(1-p)^2*(p-x(i)/c));

end

yU0(i) = yc(i) + yt(i)*cos(theta(i));

yL0(i) = yc(i) - yt(i)*cos(theta(i));

end](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-86-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

% The last 20% of the chord length of the airfoil was neglected

under the assumption that

% this section contained flaps and ailerons, and would therefore

not support aerodynamic loads.

i_xend = round(0.8*c/dx)+1;

x = x(1:i_xend);

yU = yU0(1:i_xend);

yL = yL0(1:i_xend);

% Here the airfoil profile is approximated by assuming xU0=x &

xL0=x.

%% adding stringers, spar caps and spars

% spars only

x_spar = [x_spar,x(end)]; % x_spar: location of

spars and spar caps

n_spar = length(x_spar); % Number of spars

i_spar = round(x_spar./dx)+1; % number of divisions to

get to x_spar

h_spar = yU(i_spar) - yL(i_spar); % height of spar

Cy_spar = (yU(i_spar) + yL(i_spar))/2; % y coord of centroid of

spar

A_spar = t_spar.*h_spar; % Area of spar = t*h

array_spar = zeros(1,length(x));

j=1;

for i = 1:length(x)

if i == i_spar(j)

array_spar(i)=A_spar(j);

j=j+1;

else

array_spar(i)=0;

end

end

array_cap = zeros(1,length(x));

array_cap(i_spar) = A_cap;

%% stringers

i_strU = round(x_strU./dx)+1; % index in x array

corresponding to the Upper stringer locations

i_strL = round(x_strL./dx)+1; % index in x array

corresponding to the Lower stringer locations

% Remove Stringer where there are spars for Upper Part

commonind = [];

for i=1:length(i_spar)](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-87-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

for j=1:length(i_strU)

if i_spar(i) == i_strU(j)

commonind = [commonind , j];

end

end

end

i_strU (commonind) = [];

% Remove Stringer where there are spars for Lower Part

commonind = [];

for i=1:length(i_spar)

for j=1:length(i_strL)

if i_spar(i) == i_strL(j);

commonind = [commonind , j];

end

end

end

i_strL(commonind) = [];

n_strU = length(i_strU); % Number of stringers in upper

half

n_strL = length(i_strL); % Number of stringers in lower

half

% Creating aray of Stringer areas for putting in Bigmatrix

array_strU = zeros(1,length(x));

array_strU(i_strU) = A_str;

array_strL = zeros(1,length(x));

array_strL(i_strL) = A_str;

%% skins

% nodes include spar caps and stringers

x_nodeU = [x_spar,x_strU]; % x-coord of (stringers,spar

caps) combined

x_nodeU = sort(x_nodeU); % x-coord of nodes (Sorted)

n_nodeU = length(x_nodeU);

i_nodeU = round(x_nodeU./dx)+1; % index of nodes

% MODIFIED SKIN CODE

n_skinU = length(x)-1;

for i = 1:n_skinU

L_skinU(i) = sqrt((x(i)-x(i+1))^2 + (yU(i)-yU(i+1))^2);

A_skinU(i) = t_skin*L_skinU(i);

Cx_skinU(i) = (x(i)+x(i+1))/2;

Cy_skinU(i) = (yU(i)+yU(i+1))/2;

end

n_skinL = length(x)-1;

for i = 1:n_skinL](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-88-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

L_skinL(i) = sqrt((x(i)-x(i+1))^2 + (yL(i)-yL(i+1))^2);

A_skinL(i) = t_skin*L_skinL(i);

Cx_skinL(i) = (x(i)+x(i+1))/2;

Cy_skinL(i) = (yU(i)+yU(i+1))/2;

end

A_skinU = [0 A_skinU]; % adding zero to the front of the array

A_skinL = [A_skinL 0]; % same as above (Now 401 elements)

% skin should be broken into smaller elements for higher

accuracy of calculation

% break one skin element into two by adding one more node in

between

%%

% x_skinU = zeros(1,2*length(x_nodeU)-1);

% for i = 1:length(x_nodeU)-1

% x_skinU(2*i-1) = x_nodeU(i);

% x_skinU(2*i) = (x_nodeU(i) + x_nodeU(i+1))/2;

% end

% x_skinU(end) = x_nodeU(end);

%

% i_skinU = round(x_skinU/dx)+1;

% n_skinU = length(x_skinU)-1;

% L_skinU = zeros(1,n_skinU);

% A_skinU = zeros(1,n_skinU);

% Cx_skinU = zeros(1,n_skinU);

% Cy_skinU = zeros(1,n_skinU);

% for i = 1:n_skinU

% L_skinU(i) = sqrt((yU(i_skinU(i+1)) - yU(i_skinU(i)))^2 +

(x_skinU(i+1) - x_skinU(i))^2);

% A_skinU(i) = t_skin*L_skinU(i);

% Cx_skinU(i) = (x_skinU(i+1) + x_skinU(i))/2;

% Cy_skinU(i) = (yU(i_skinU(i+1)) + yU(i_skinU(i)))/2;

% end

%

% % lower part

% x_nodeL = [x_spar,x_strL]; % x-coord of (stringers,spar

caps) combined

% n_nodeL = length(x_nodeL);

% x_nodeL = sort(x_nodeL); % x-coord of nodes (Sorted)

% i_nodeL = round(x_nodeL./dx)+1; % index of nodes

%

% x_skinL = zeros(1,2*length(x_nodeL)-1);

% for i = 1:length(x_nodeL)-1

% x_skinL(2*i-1) = x_nodeL(i);

% x_skinL(2*i) = (x_nodeL(i) + x_nodeL(i+1))/2;

% end](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-89-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

%Lower Stringers

for i = 1:n_strL

Cx_sum = Cx_sum + x_strL(i)*A_str;

Cy_sum = Cy_sum + yL(i_strL(i))*A_str;

A_sum = A_sum + A_str;

end

%All spar caps

for i = 1:n_spar

Cx_sum = Cx_sum + 2*A_cap*x_spar(i);

Cy_sum = Cy_sum + A_cap*Cy_spar(i);

A_sum = A_sum + A_cap;

end

Cx = Cx_sum/A_sum;

Cy = Cy_sum/A_sum;

% figure

% plot(x,yU,'k',x,yL,'k','Linewidth',2);

% ylim([-0.3 0.3])

% hold on

%

plot(i_strU*dx,yU(i_strU),'or',i_strL*dx,yL(i_strL),'or','marker

size',5);

%

plot([x_spar(1),x_spar(1)],[yU(i_spar(1)),yL(i_spar(1))],'b',[x(

end),x(end)],[yU(end),yL(end)],'b','Linewidth',3);

%

plot(x_spar,yU(i_spar),'sg',x_spar,yL(i_spar),'sg','markersize',

7);

% scatter(Cx,Cy,'m*')

% ylabel('y (m)')

% xlabel('x (m)')

% grid on

%% Area moments of inertia

% initial value

Ixx = 0;

Iyy = 0;

Ixy = 0;

% Spars MOI

for i = 1:n_spar

Ixx = Ixx + t_spar*h_spar(i)^3/12 + A_spar(i)*(Cy_spar(i)-

Cy)^2;

Iyy = Iyy + t_spar^3*h_spar(i)/12 + A_spar(i)*(x_spar(i)-

Cx)^2;](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-91-320.jpg)

![MAE 154B PROJECT RYAN, AGRAJ, KEVIN

% x_strL = x_strL-Cx;

%% Big Matrix containing all the values

for i = 1:length(x) %inverting the coordinates

x2(i) = x(end-(i-1));

yUtemp(i) = yU(end-(i-1));

array_captemp(i) = array_cap(end-(i-1));

array_spartemp(i) = array_spar(end-(i-1));

array_strUtemp(i) = array_strU(end-(i-1));

A_skinUtemp(i) = A_skinU(end-(i-1));

end

% yU = yUtemp;

% array_cap = array_captemp;

% array_spar = array_spartemp;

% array_strU = array_strUtemp;

% A_skinU = A_skinUtemp;

Bigmat = [x2(1:end-1)' yUtemp(1:end-1)' array_captemp(1:end-1)'

array_spartemp(1:end-1)' array_strUtemp(1:end-1)'

A_skinUtemp(1:end-1)' ; ...

x',yL',array_cap',array_spar',array_strL',A_skinL'] ;

%Bigmat = [x2' yU' array_cap' array_spar' array_strU' A_skinU' ;

...

%x',yL',array_cap',array_spar',array_strL',A_skinL'] ;

end](https://image.slidesharecdn.com/6e03d563-46c5-4e39-b180-83d24f29102e-170124015624/85/Report-Wing-Structure-Design-Spring-16-93-320.jpg)