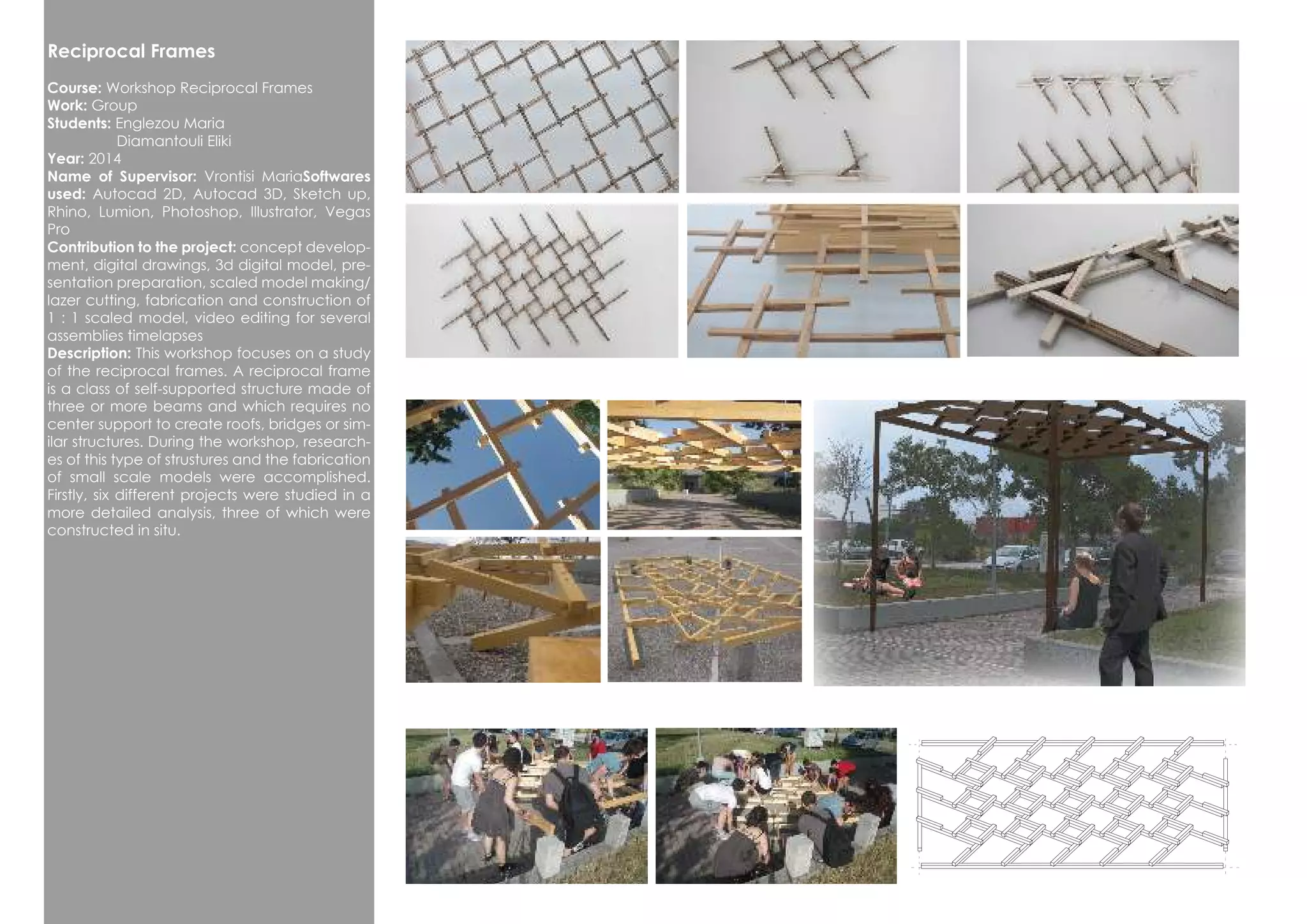

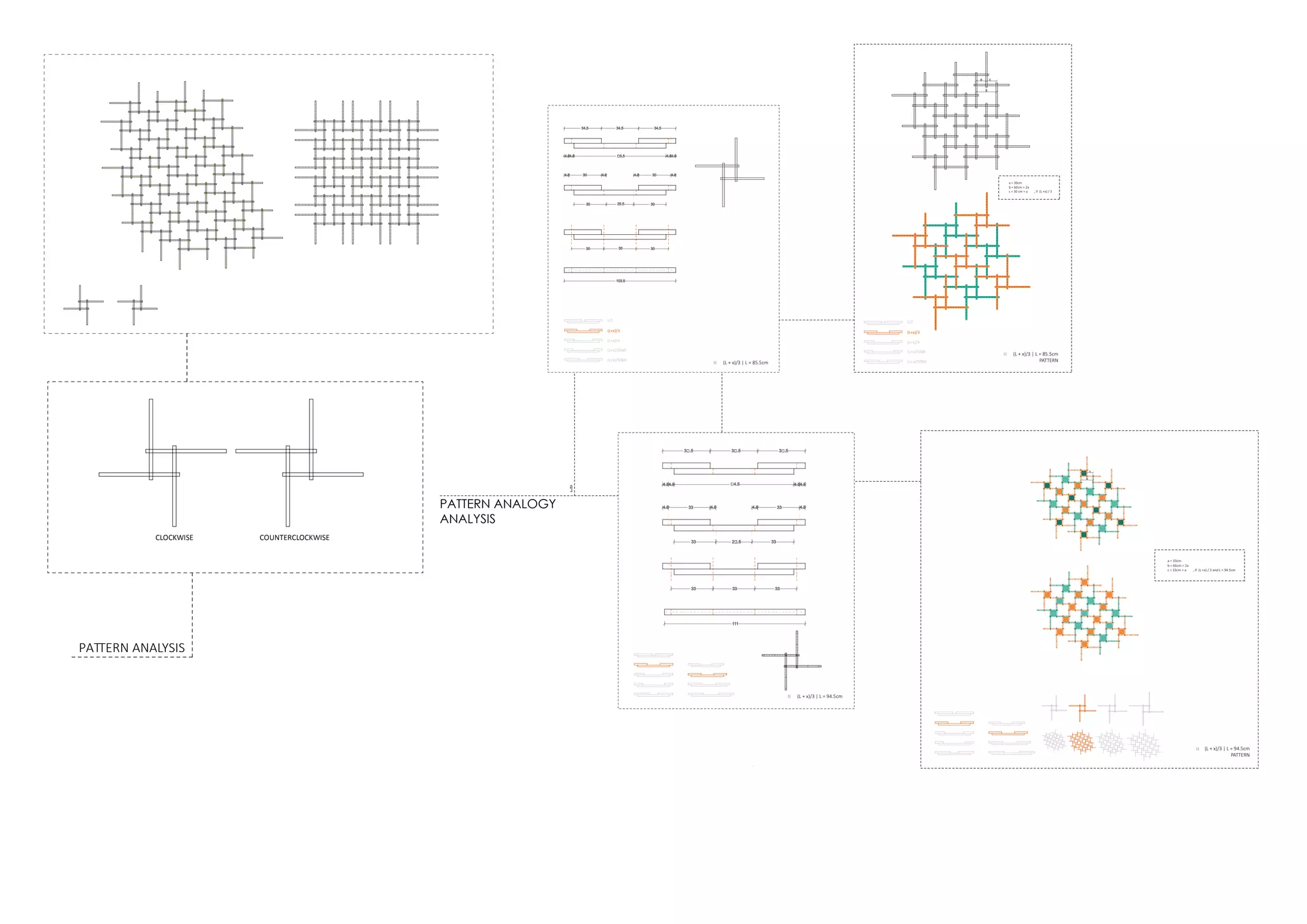

This workshop focused on studying reciprocal frames, a type of self-supported structure that requires no center support. Students developed concepts, created digital drawings and 3D models, and fabricated a 1:1 scale model. Six projects were analyzed in detail and three were constructed. The model explored different patterns and support methods for the frame units.

![WITHOUT BEAMS | 12 SUPPORTS||

WITHOUT BEAMS | 12 SUPPORTS||

LONGITUDINAL & TRANSVERSAL BEAMS | 12 SUPPORTS

- 4 SUPPORTS IN THE CORNERS

-2 LEVELS-LAYERS

LONGITUDINAL & TRANSVERSAL BEAMS | 12 SUPPORTS

- 4 SUPPORTS IN THE CORNERS

- 2 LEVELS-LAYERS

||

SUPPORT ANALYSIS

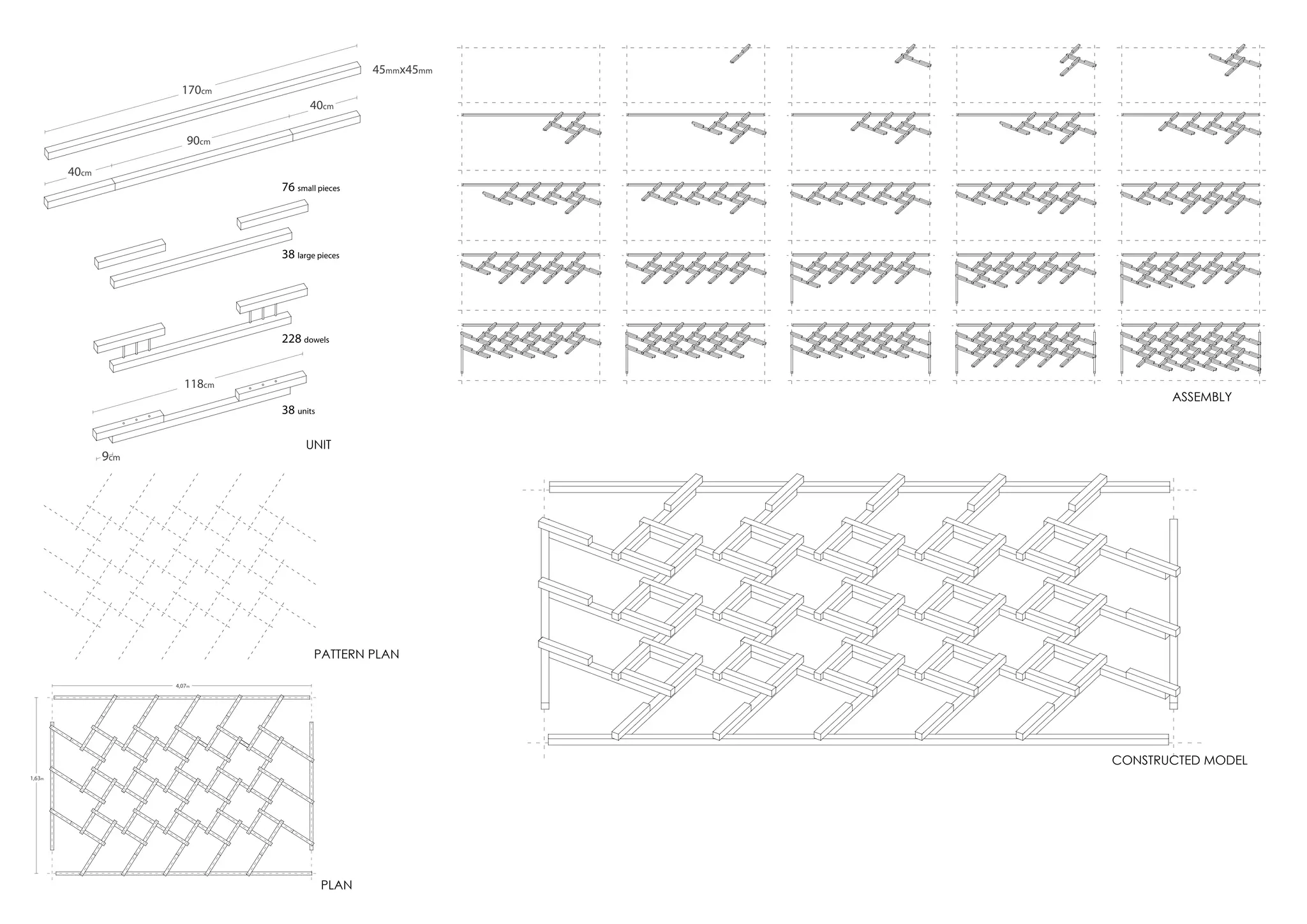

40 RF UNITS

31 RF UNITS

417.42

275.12

LAYER #1 | RF STRUCTURE

LAYER #2 | RF STRUCTURE

348.83

281.74

LAYER #1 | RF STRUCTURE

LAYER #2 | RF STRUCTURE

B1A1 B1A1 A1

A2

B2

SIDEb

SIDE c

A2

B2

SIDEd

SIDE a

B1 A1 A1 B1B1

SIDE aSIDE b

SIDE d SIDE c

LAYER #1 | TRANSVERSAL/LONGITUDINAL SUPPORT BEAM &

RF STRUCTURE

LAYER #2 | RF STRUCTURE

SIDE b

SIDE a

SIDE c

A

B

24 RF UNITS

2 TRANSVERSE BEAMS (SANDWICH METHOD)

2 LONGITUDINAL BEAMS (SANDWICH METHOD)

5 RF UNITS TYPE A1

2 RF UNITS TYPE A2

[A1, A2 : DIFFERENT DIMENSIONS]

5 RF UNITS TYPE B1

2 RF UNITS TYPE B2

[B1, B2 : DIFFERENT DIMENSIONS]

B1 A1 B1 A1 B1

SIDE a

SIDEb

A2

B2

A2

A2

B2

A2

SIDEd

B1A1 B1A1 A1

SIDE c

SIDE a

SIDE b

A

B

38 RF UNITS

2 TRANSVERSE BEAMS (SANDWICH METHOD)

2 LONGITUDINAL BEAMS (SANDWICH METHOD)

5 RF UNITS TYPE A1

4 RF UNITS TYPE A2

[A1, A2 : DIFFERENT DIMENSIONS]

5 RF UNITS TYPE B1

4 RF UNITS TYPE B2

[B1, B2 : DIFFERENT DIMENSIONS]

SIDE b SIDE a

SIDE cSIDE d

LAYER #1 | TRANSVERSAL/LONGITUDINAL SUPPORT BEAM &

RF STRUCTURE

LAYER #2 | RF STRUCTURE

SUPPORT ANALYSIS

FABRICATION DETAIL

PRODUCEDBYANAUTODESKEDUCATIONALPRODUCT

PRODUCEDBYANAUTODESKEDUCATIONALPRODUCT

PRODUCEDBYANAUTODESKEDUCATIONALPRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PRODUCEDBYANAUTODESKEDUCATIONALPRODUCT

PRODUCEDBYANAUTODESKEDUCATIONALPRODUCT

PRODUCEDBYANAUTODESKEDUCATIONALPRODUCT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

Because of the existing weather

conditions and the multiple

asseblies the structure collapsed

and the units fell apart. There-

fore, we added 2 screws per

unit to make them more stable](https://image.slidesharecdn.com/fe9bd048-f6f1-4123-a88d-b2788640c525-161027201454/75/Reciprocal-Frames_2-4-2048.jpg)