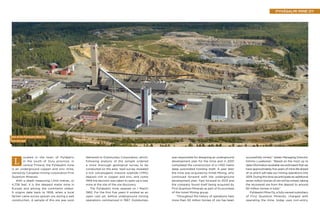

The Pyhäsalmi mine in Finland is one of the deepest mines in Europe at 1,444 meters deep, and has been operating for over 50 years. It is nearing the end of its life but expects to mine an additional 7 million tons of ore over the next 5 years. The mine produces significant amounts of copper and zinc and is a major contributor to the local economy but plans are being made for after mining operations cease.

![[ Issue 85 ] BE Weekly2

to the surface

The Pyhäsalmi mine is one of the deepest and

oldest mines in Europe and has been producing vast

amounts of copper and zinc for over 50 years.

As Managing Director, Kimmo Luukkonen

explains, even as it approaches the end of its

life the mine has much still to give

Pyhäsalmi Mine Oy

Bringing ore

words by Will Daynes research by Abi Abagun](https://image.slidesharecdn.com/pyhsalmi-europe-mining-may14-bro-s-140428100950-phpapp01/85/Pyhasalmi-europe-mining-may14-bro-s-2-320.jpg)