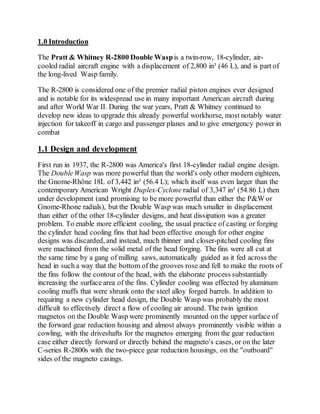

This document provides an overview of the Pratt & Whitney R-2800 Double Wasp radial aircraft engine. Some key points:

- The R-2800 was introduced in 1937 and was considered one of the most powerful and widely used radial piston engines of WWII. It powered many important American aircraft including the F4U Corsair and P-47 Thunderbolt.

- The engine underwent numerous design improvements over its lifetime to increase power output. By 1944, experimental models produced 2,800 hp using water injection.

- Over 125,000 R-2800 engines were produced between 1939-1960. After WWII, the engine continued to be used in aircraft like the Canadair CL-215 well