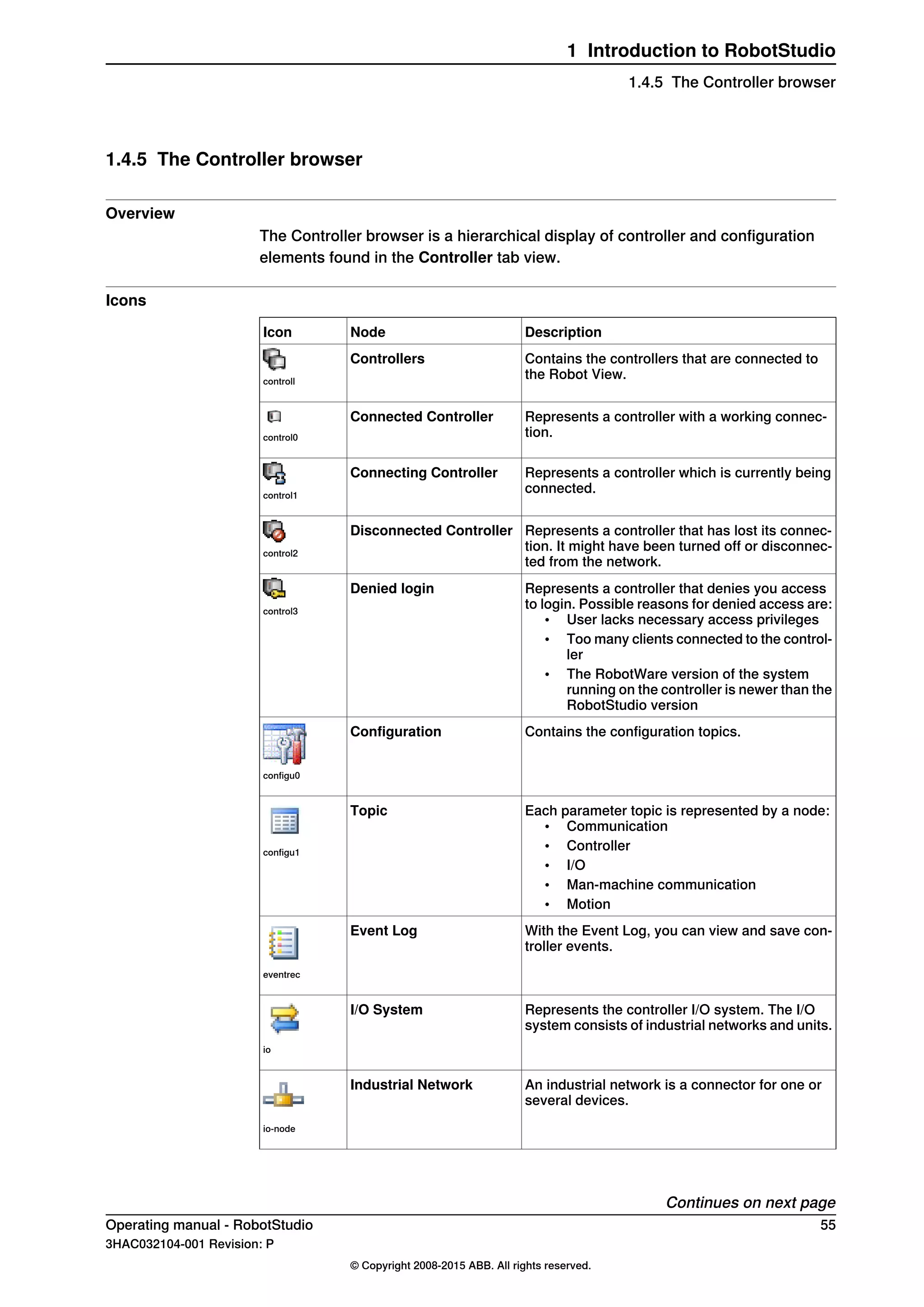

This document provides an overview of the RobotStudio operating manual. It includes sections on installing and licensing RobotStudio, the user interface, building robot stations, programming robots, deploying and distributing programs, simulating programs, working online with controllers, and using the different tabs in RobotStudio. The table of contents lists over 20 main sections and numerous subsections that comprise the full manual.

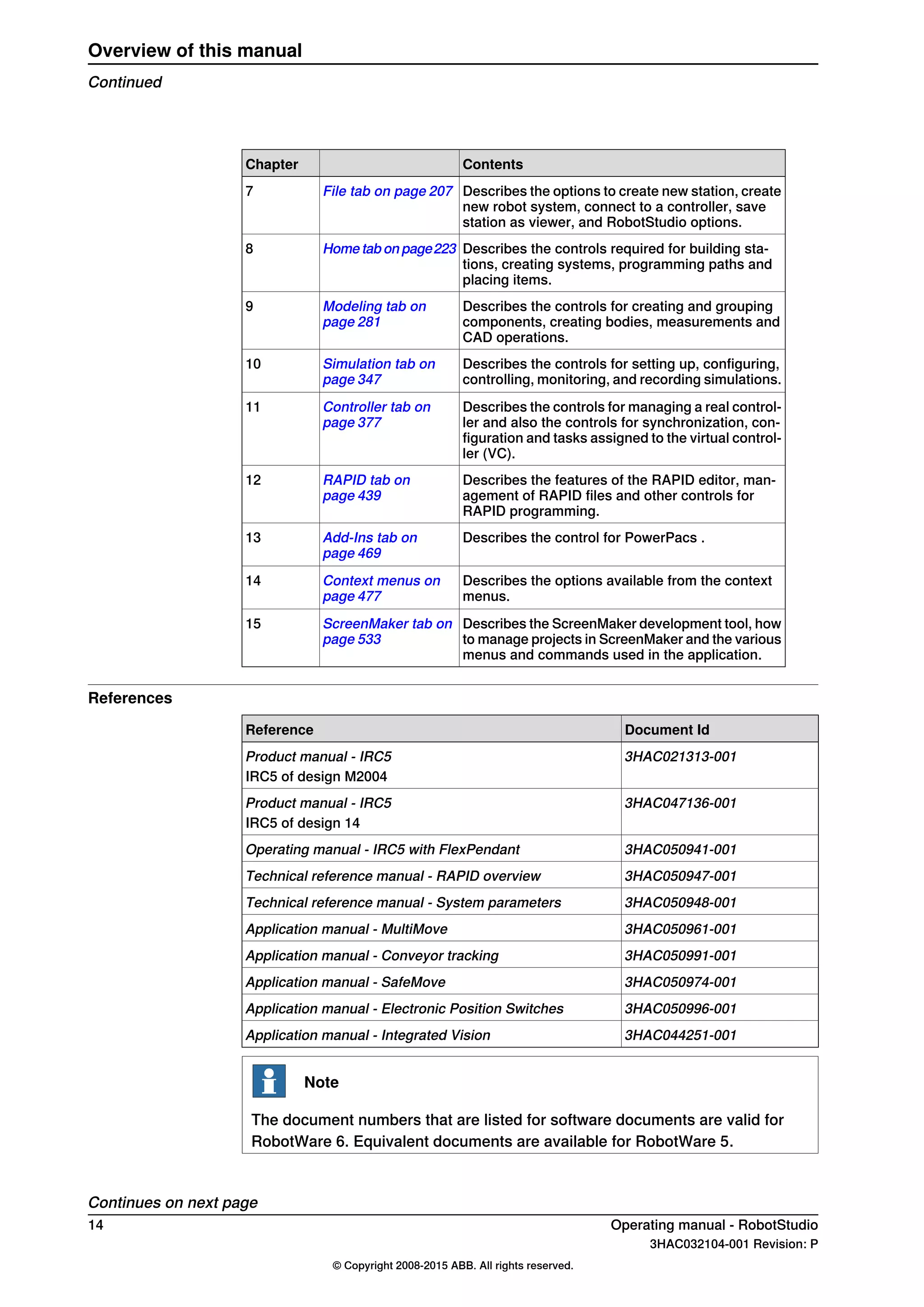

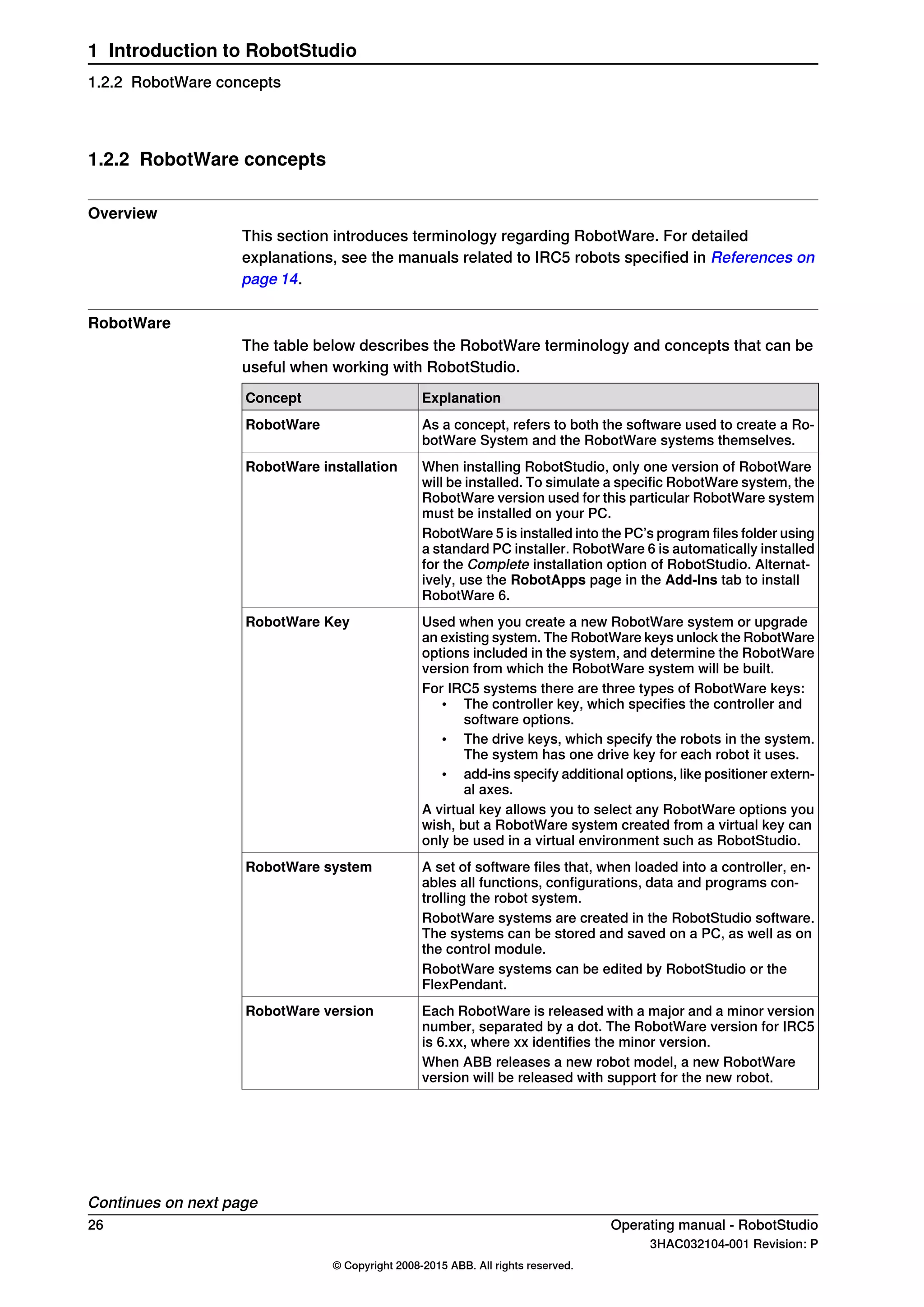

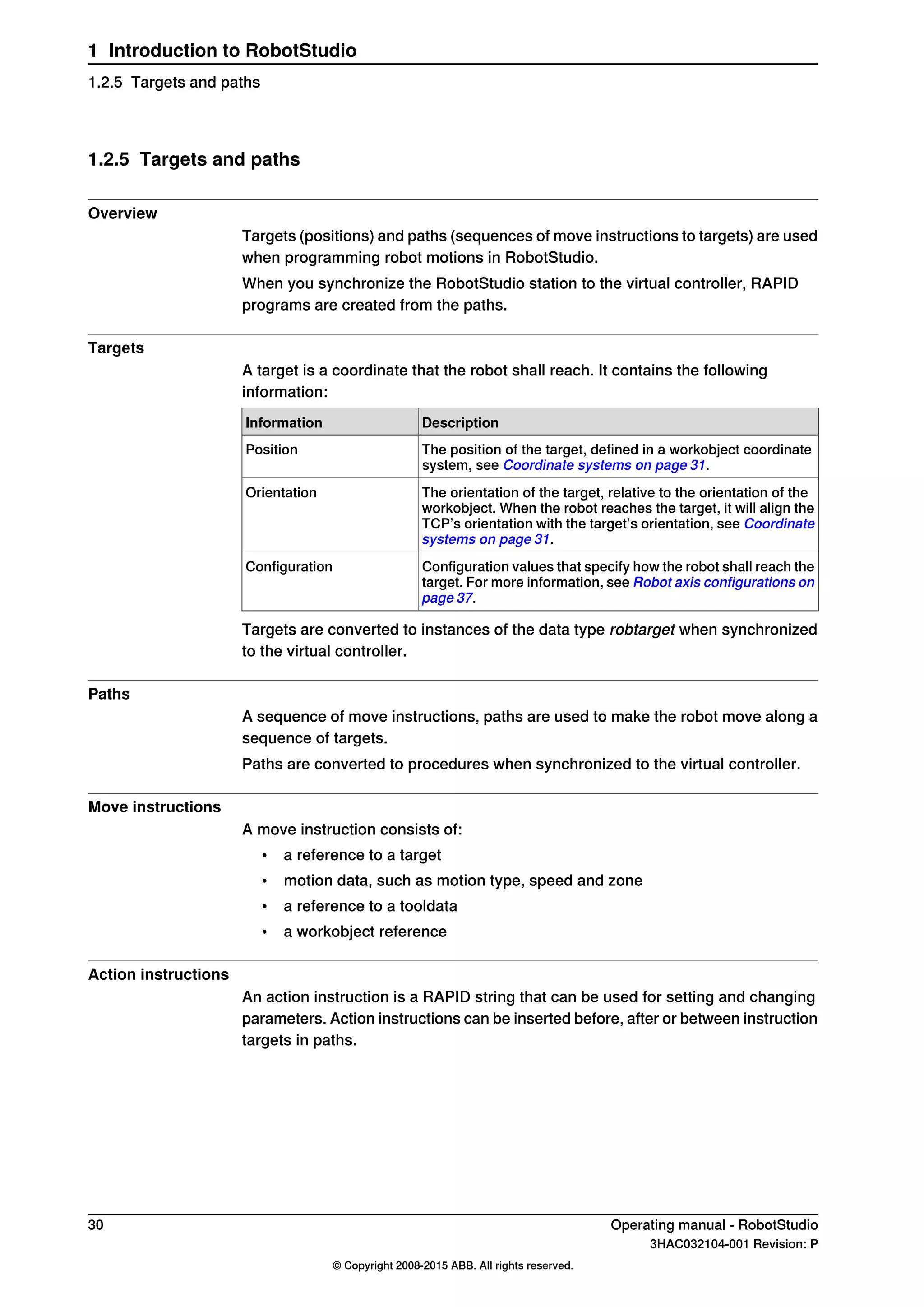

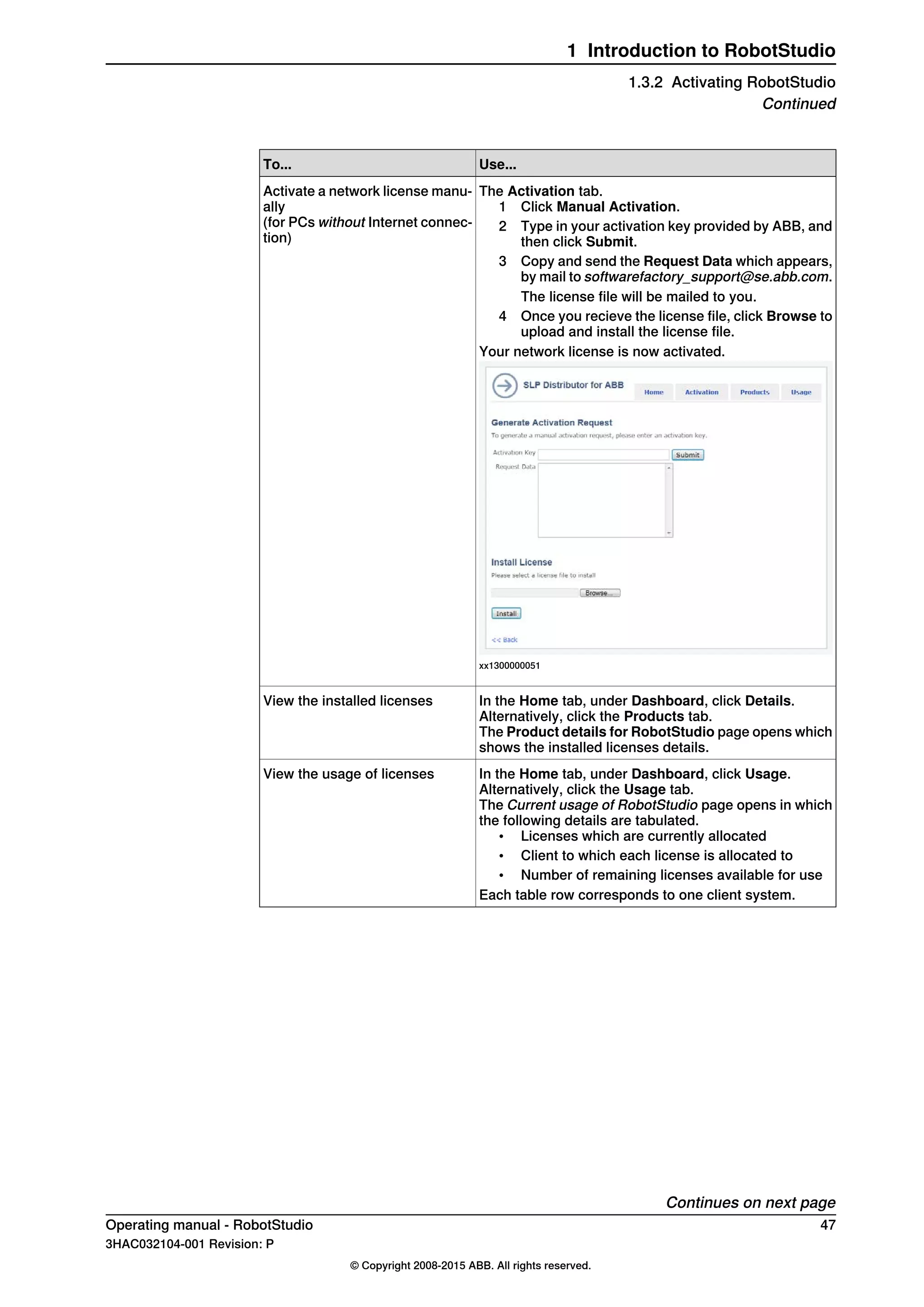

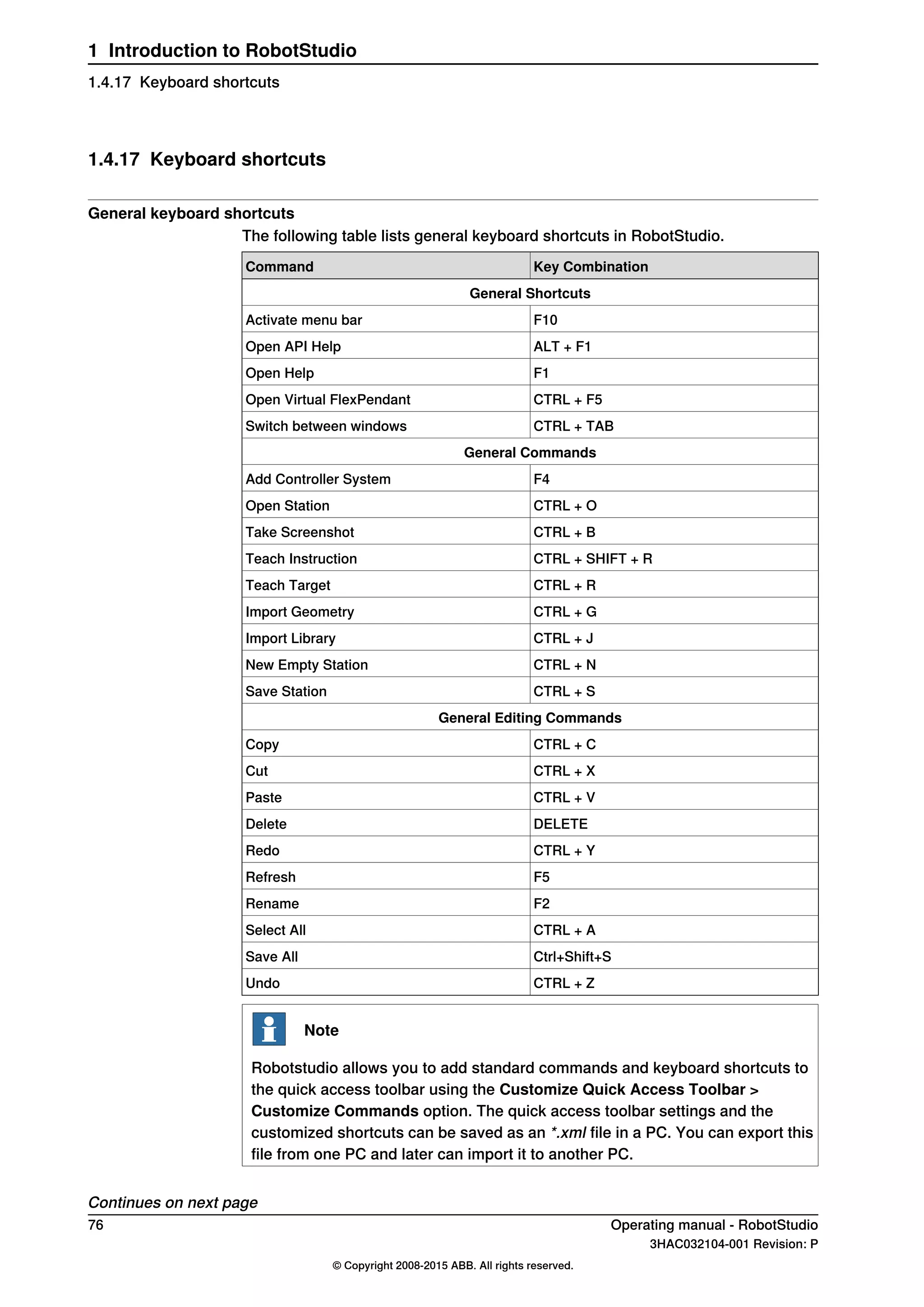

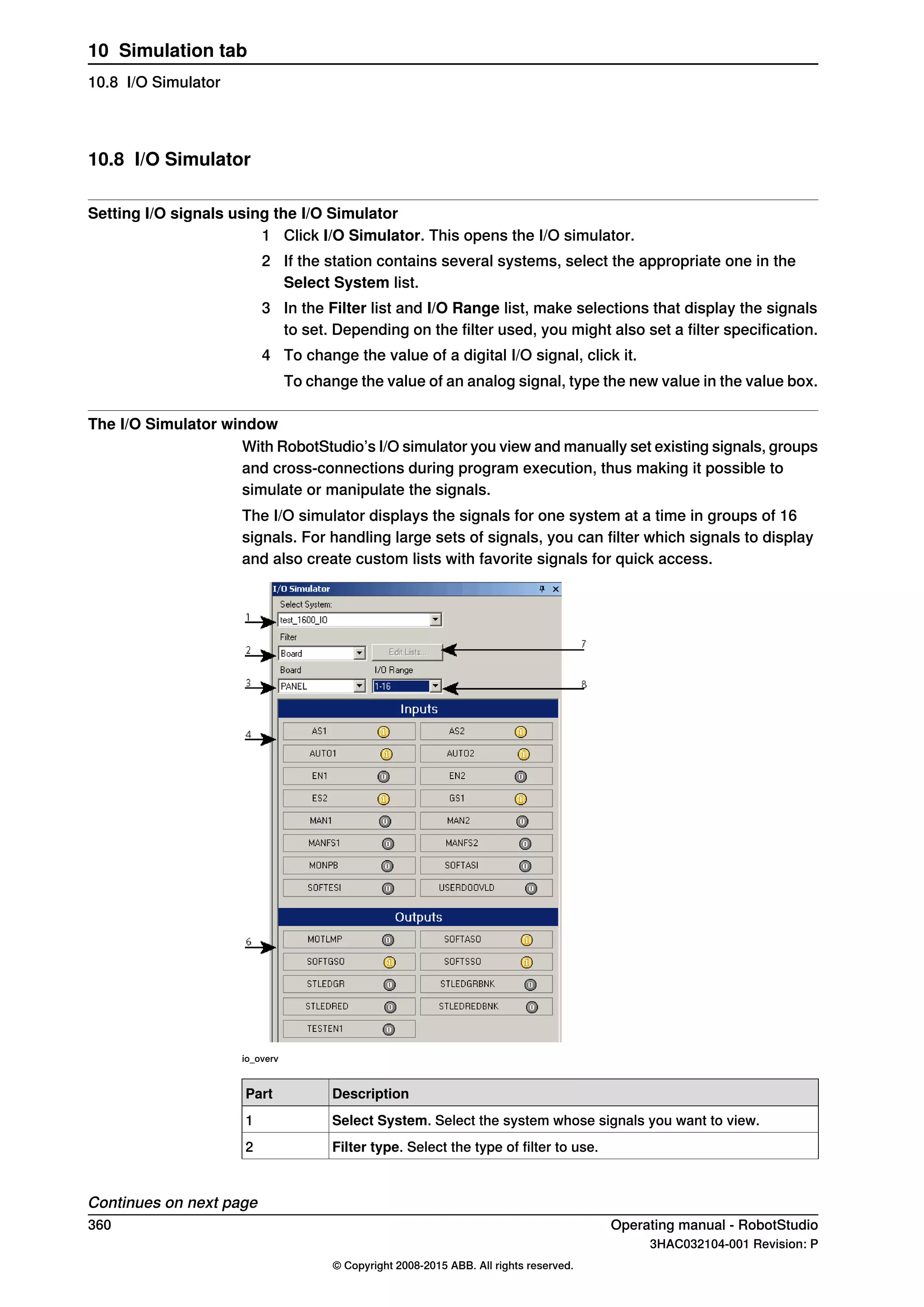

![How configurations are denoted

The robot’s axis configurations are denoted by a series of four integers, specifying

in which quadrant of a full revolution significant axes are located. The quadrants

are numbered from zero for positive (counterclockwise) rotation and from -1 for

negative (clockwise) rotation.

For a linear axis, the integer specifies the range (in meters) from the neutral position

in which the axis is located.

A configuration for a six-axis industrial robot (like IRB 140) may look like:

[0-121]

The first integer (0) specifies the position of axis 1: somewhere in the first positive

quadrant (between 0 and 90 degrees rotation).

The second integer (-1) specifies the position of axis 4: somewhere in the first

negative quadrant (between 0 and -90 degrees rotation).

The third integer (2) specifies the position of axis 6: somewhere in the third positive

quadrant (between 180 and 270 degrees rotation).

The fourth integer (1) specifies the position of axis x, a virtual axis used for

specifying the wrist center in relation to other axes.

Configuration monitoring

When executing a robot program, you can choose whether to monitor configuration

values. If configuration monitoring is turned off, configuration values stored with

the targets are ignored, and the robot will use the configuration closest its current

configuration for reaching the target. If turned on, it will only use the specified

configuration for reaching the targets.

Configuration monitoring can be turned off and on for joint and linear movements

independently and is controlled by the ConfJ and ConfL action instructions.

Turning configuration monitoring off

Running a program without configuration monitoring may result in different

configurations each time a cycle is executed: When the robot returns to the start

position after completing a cycle, it may choose a different configuration then the

original.

For programs with linear move instructions this might cause a situation where the

robot gets closer and closer its joint limits and eventually will not be able to reach

the target.

For programs with joint move instructions this might cause sweeping, unpredictable

movements.

Turning configuration monitoring on

Running a program with configuration monitoring forces the robot to use the

configurations stored with the targets. This results in predictable cycles and

predictable motions. In some situations, however, like when the robot moves to a

target from an unknown position, using configuration monitoring may limit the

robot’s reachability.

When programming offline, you must assign a configuration to each target if the

program shall be executed with configuration monitoring.

38 Operating manual - RobotStudio

3HAC032104-001 Revision: P

© Copyright 2008-2015 ABB. All rights reserved.

1 Introduction to RobotStudio

1.2.7 Robot axis configurations

Continued](https://image.slidesharecdn.com/prog-150726124729-lva1-app6892/75/Prog-38-2048.jpg)

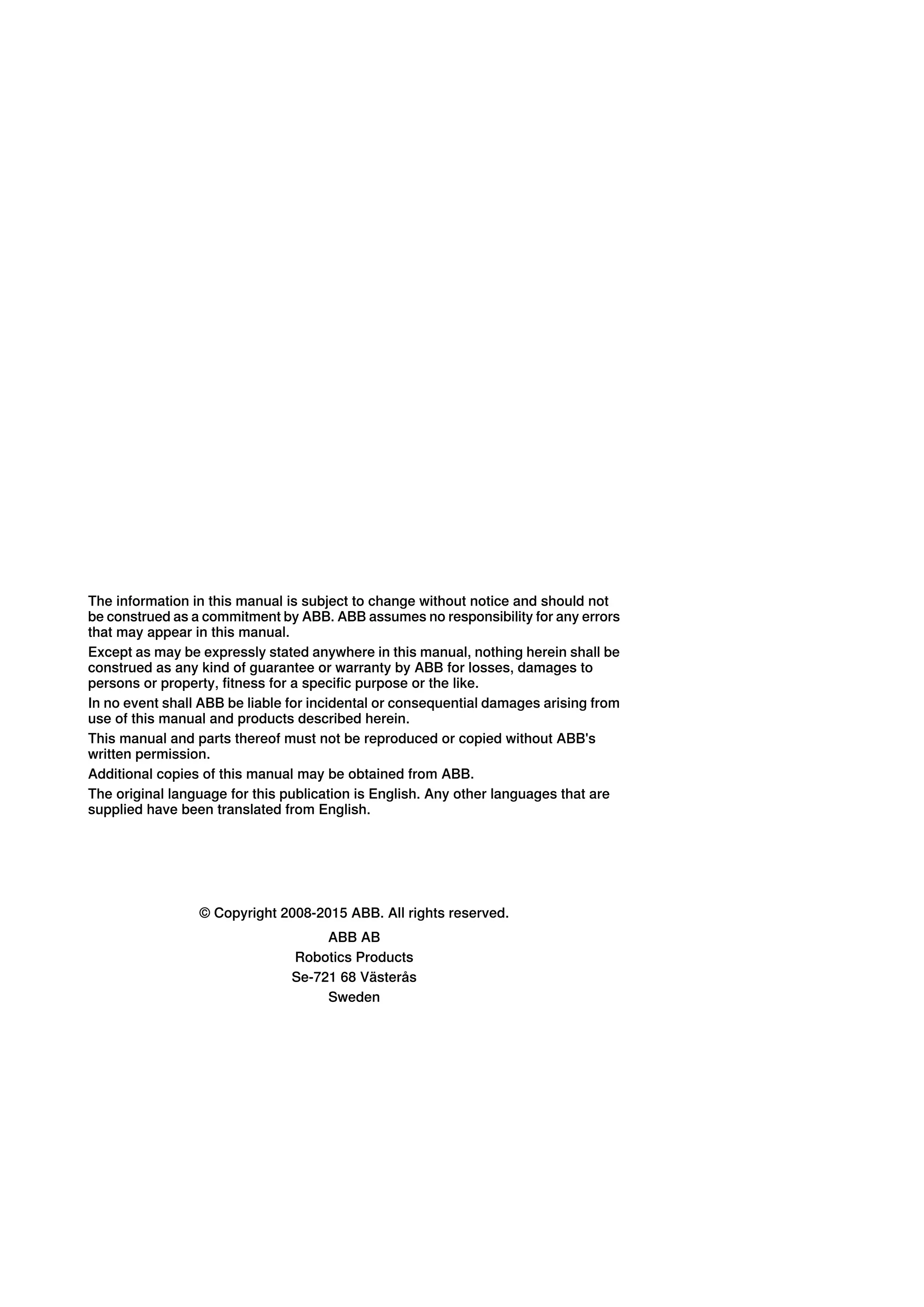

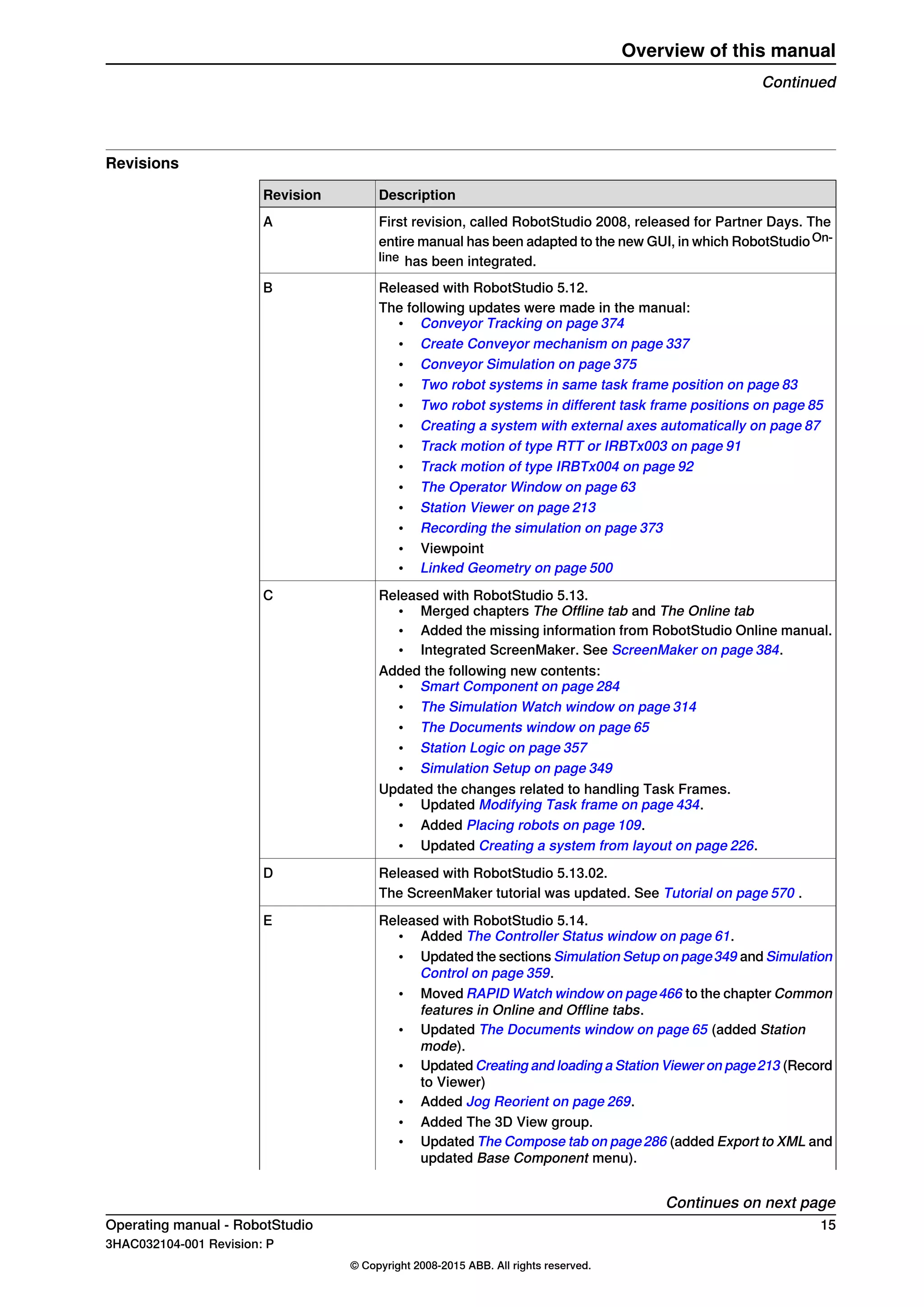

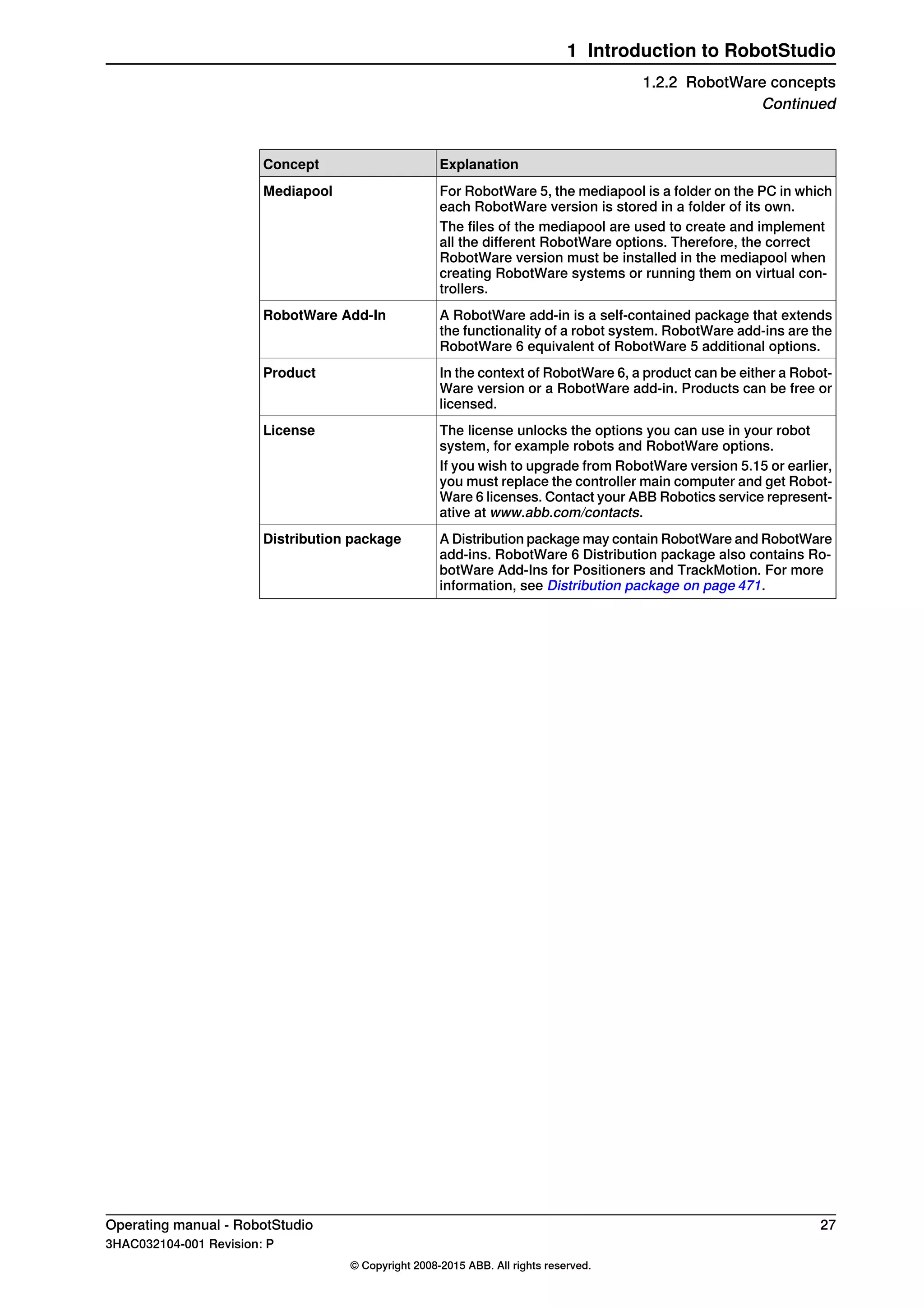

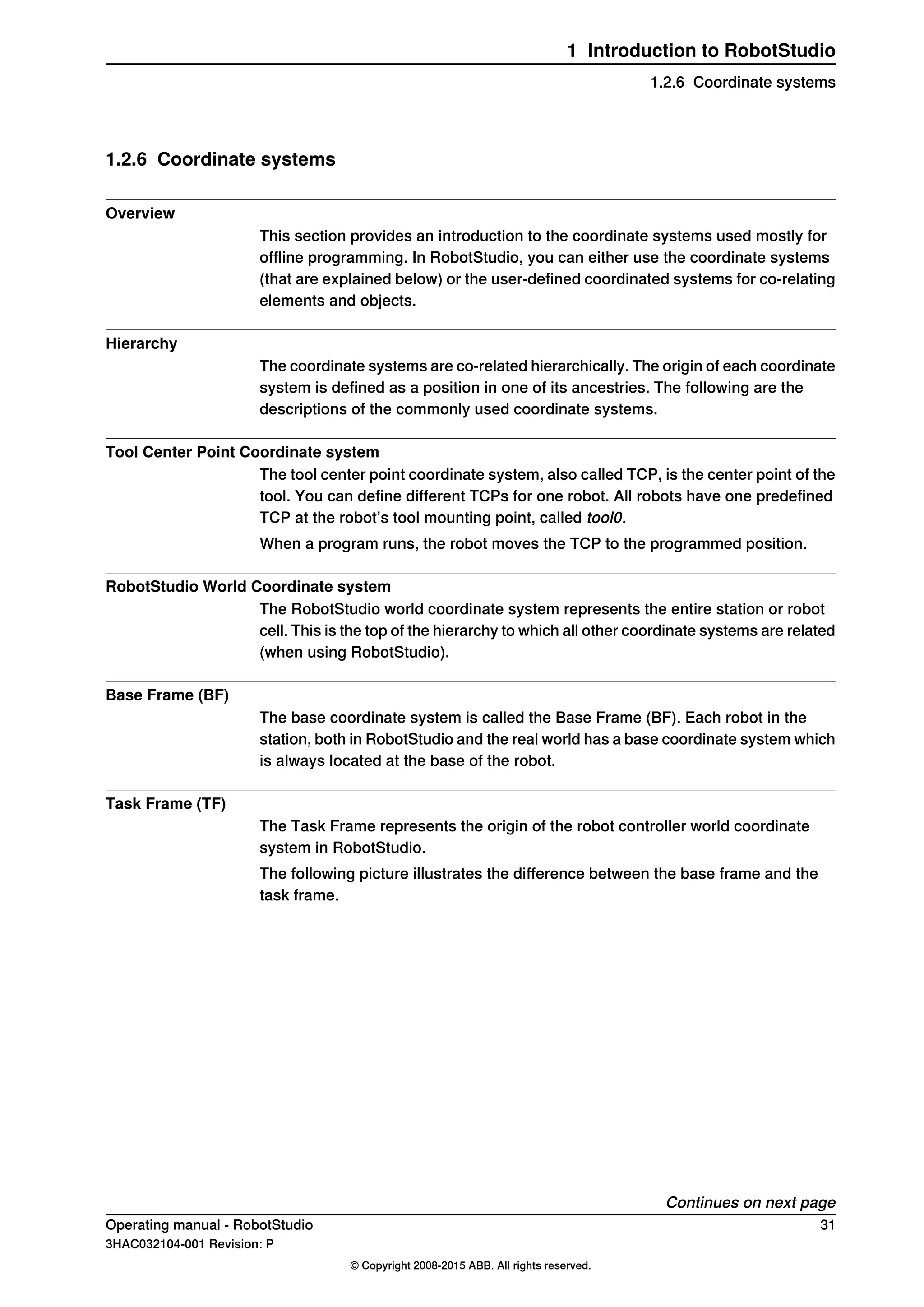

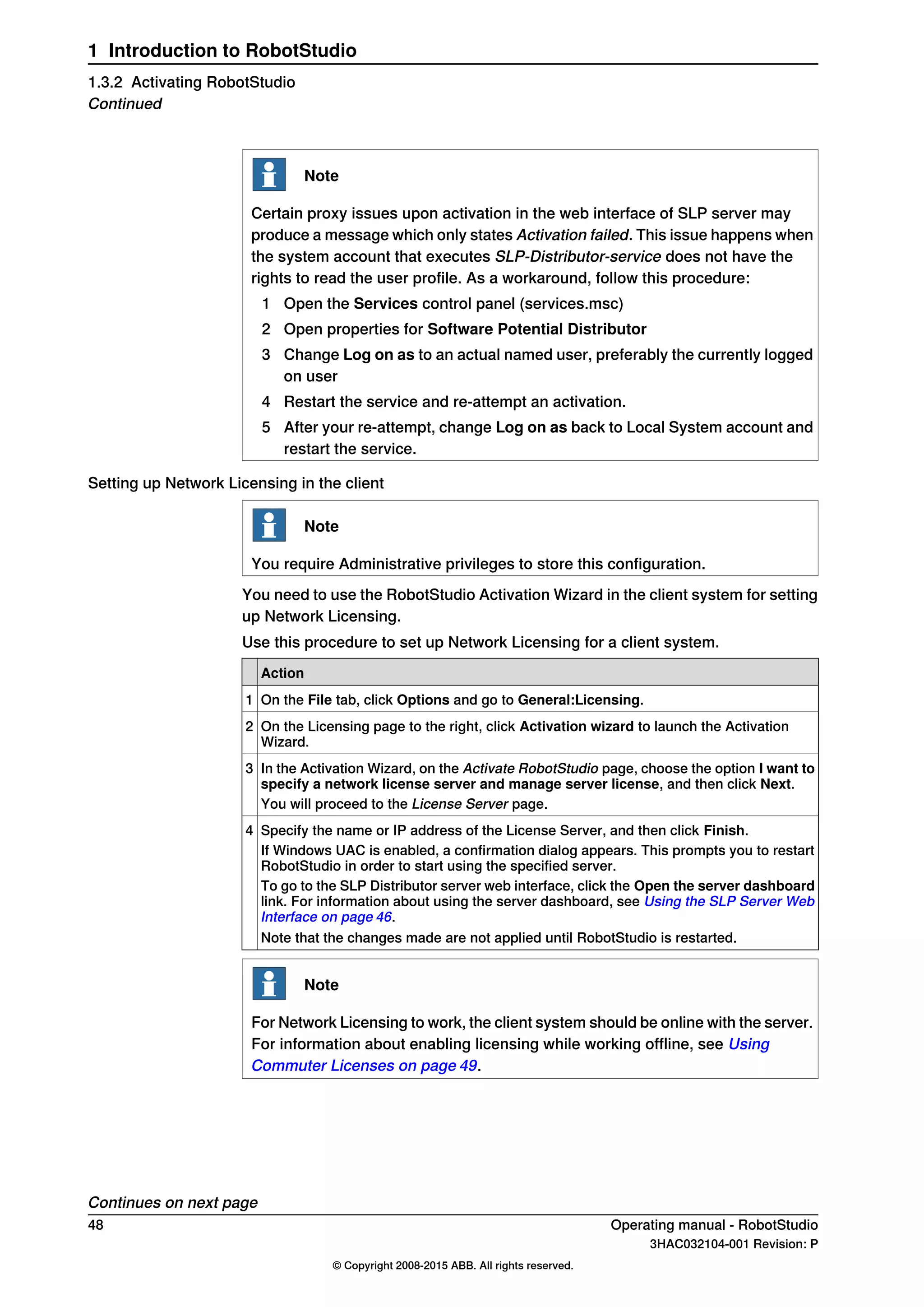

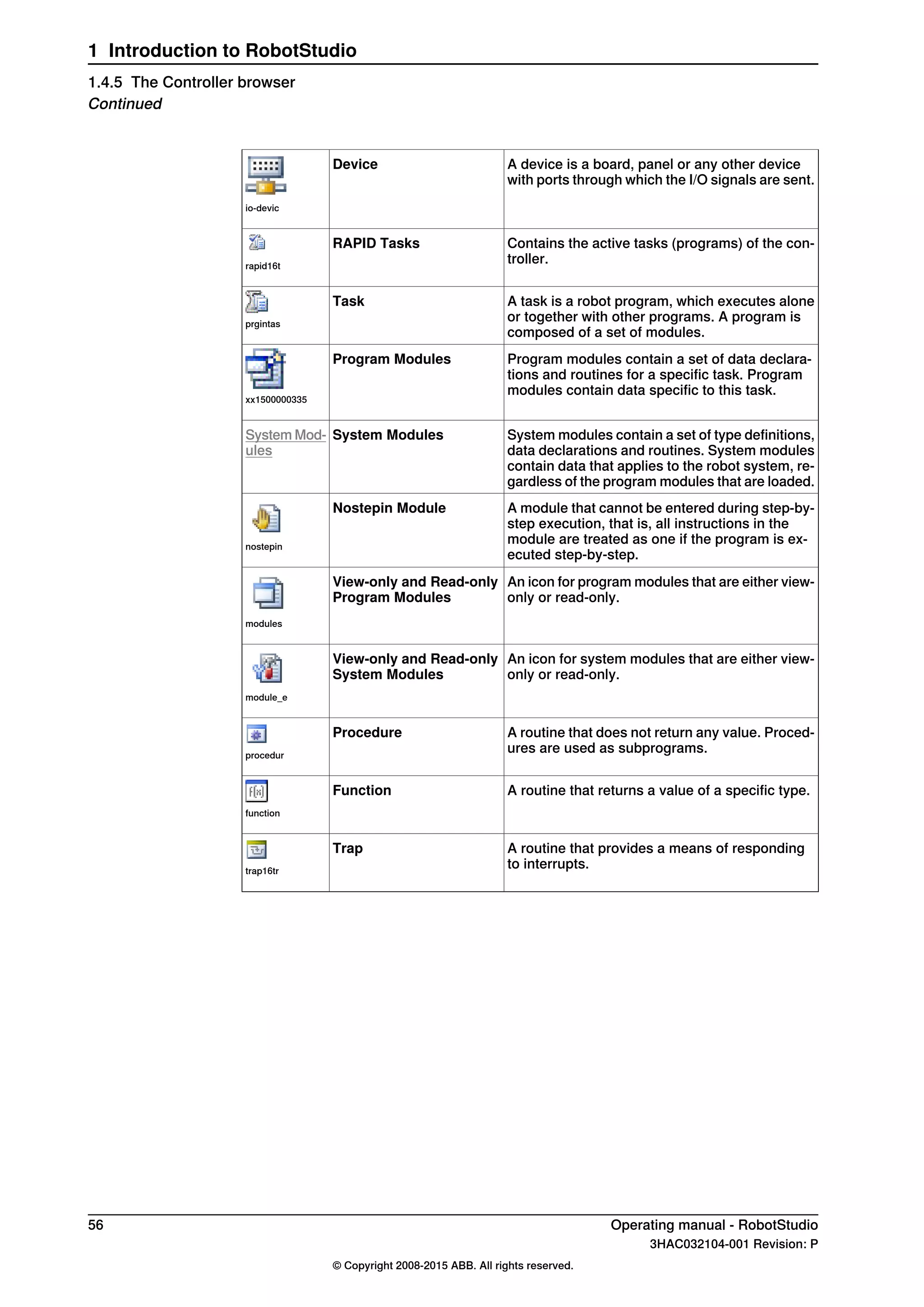

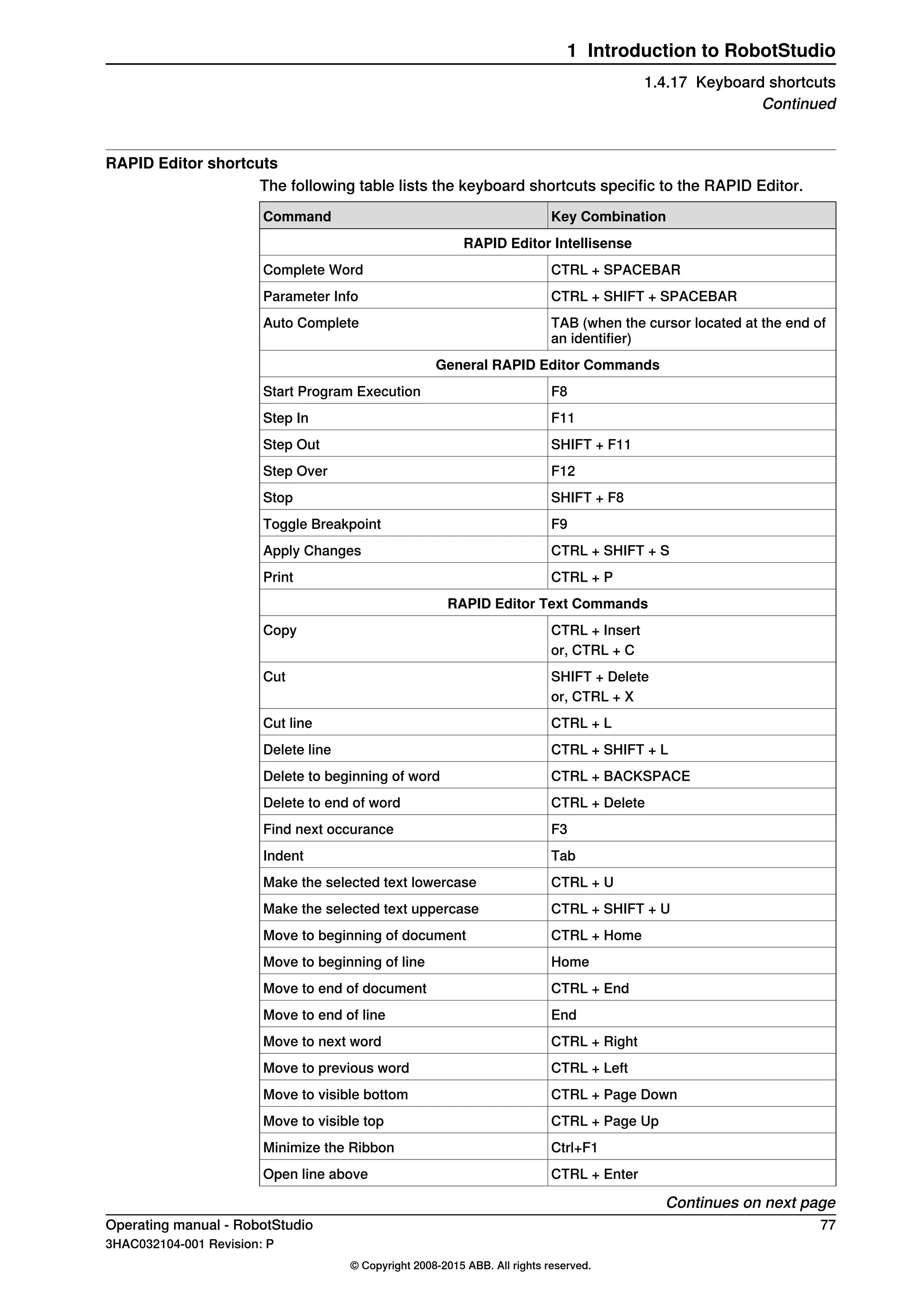

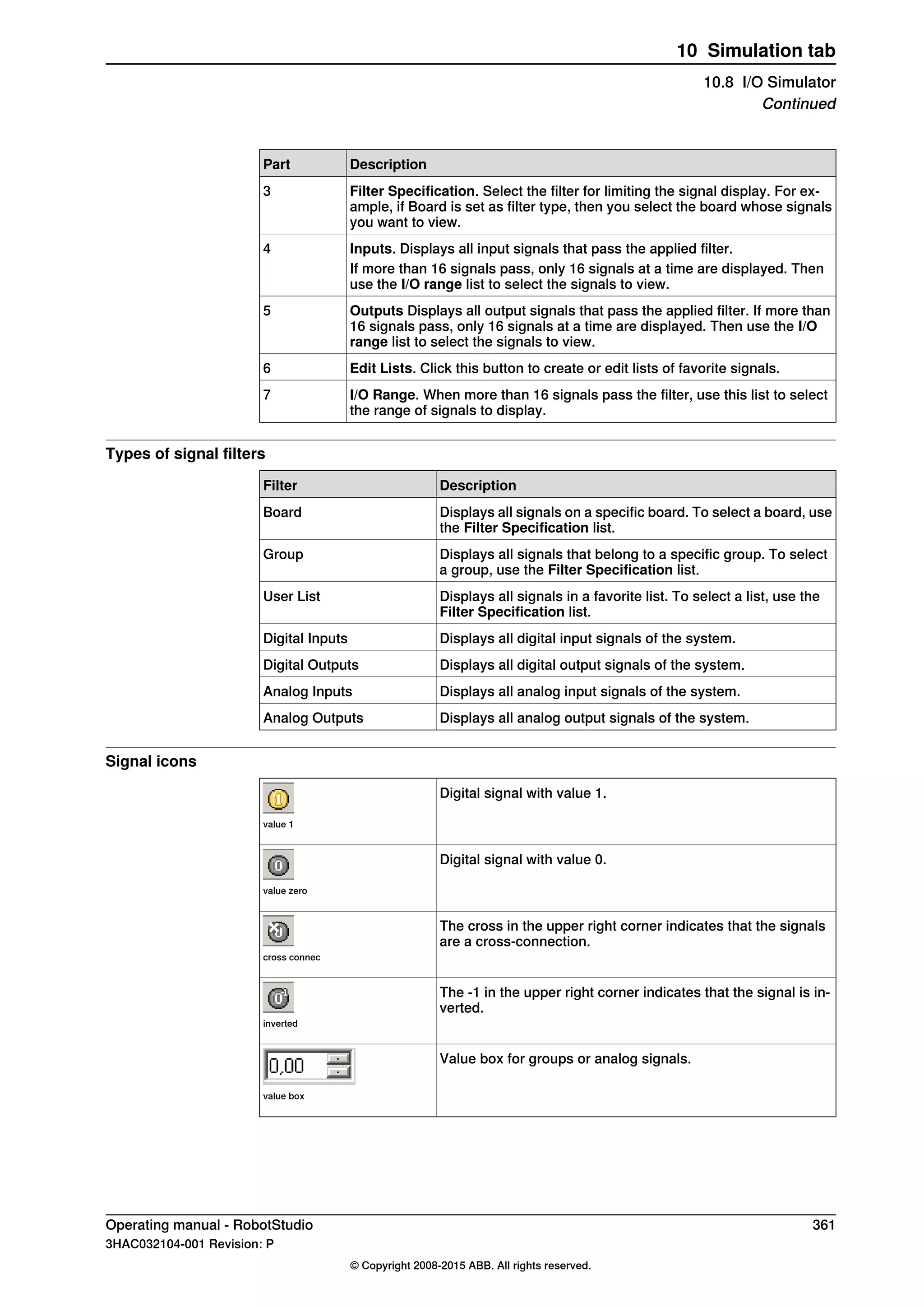

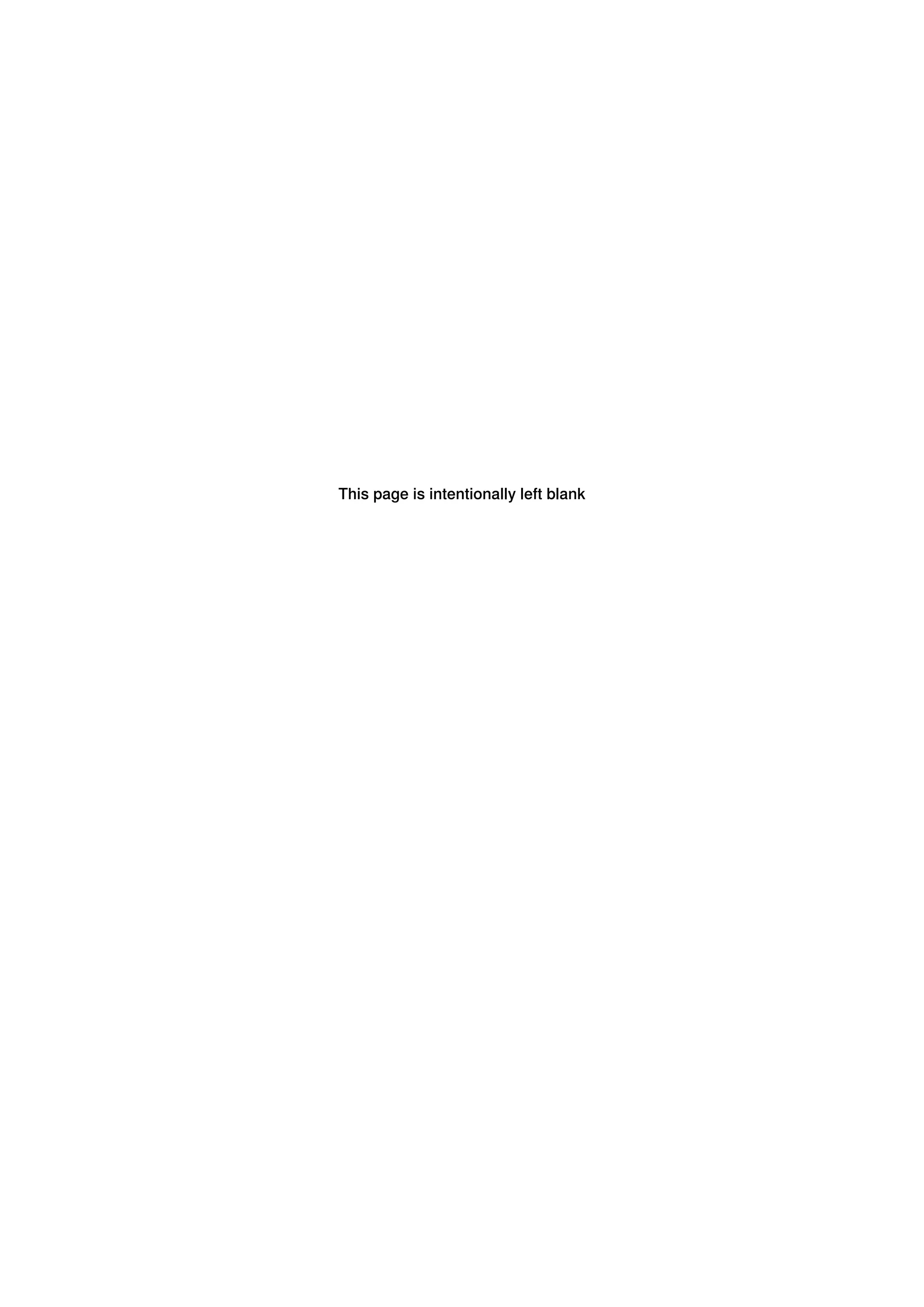

![9.4 Smart Component

9.4.1 Smart Component

Overview

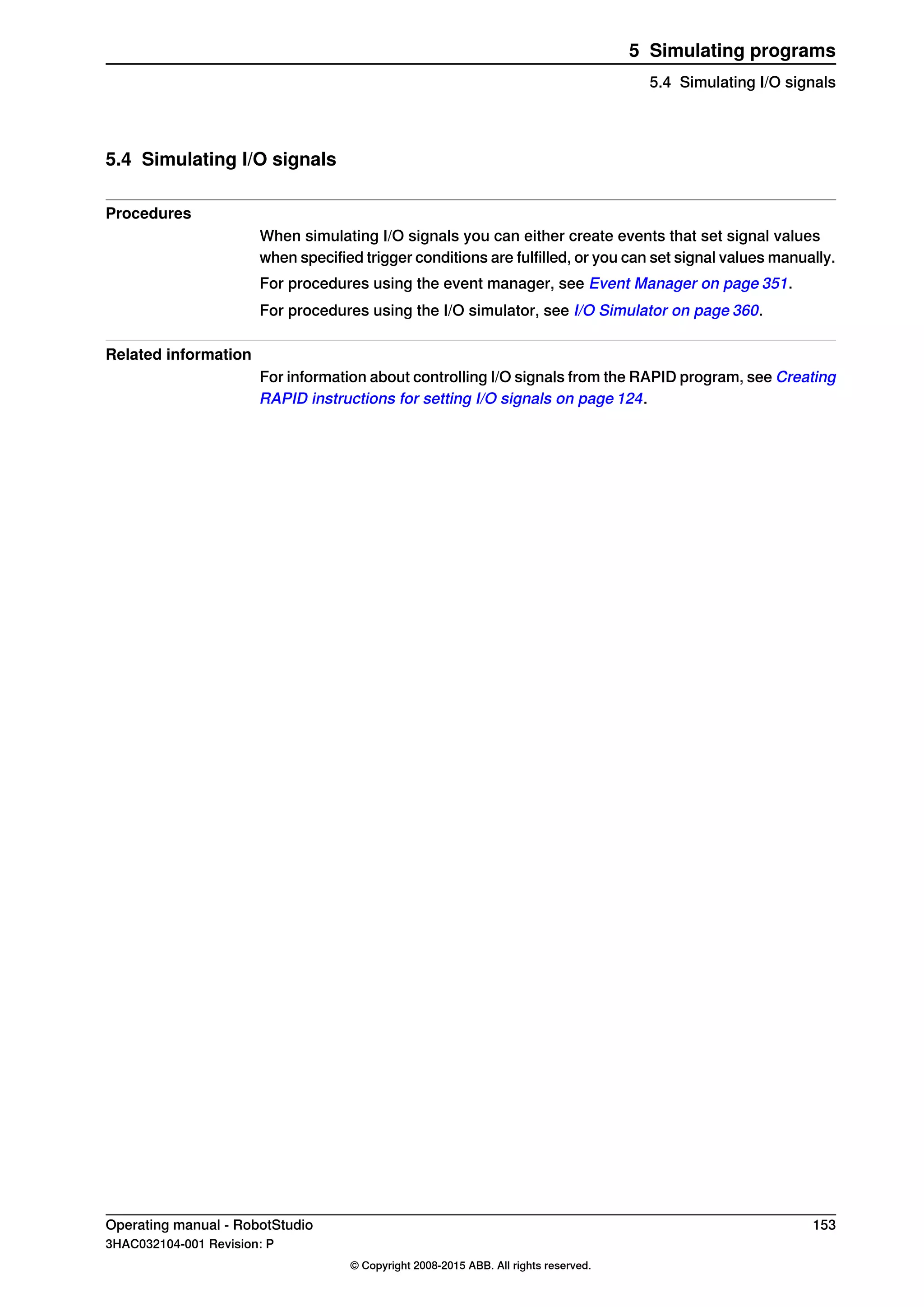

Smart Component is a RobotStudio object (with or without a 3D graphical

representation) that has the behavior which can be implemented by code-behind

and/or aggregation of other Smart Components.

Terminology

The following table describes the different terminologies that you come across

when working with Smart Component.

DefinitionTerm

A .NET class associated with a Smart Component that can

implement custom behavior by reacting to certain events, for

example simulation time steps and changes in property values.

Code behind

An object attached to a Smart Component that has value, type

and certain other characteristics. The property value is used

by code behind to control the behavior of the Smart Component.

[Dynamic] property

Connects the value of one property to the value of another

property.

[Property] binding

Key-value pairs that contain additional information about a

dynamic property, for example value constraints.

[Property] attributes

An object attached to a Smart Component that has a value and

a direction (input/output), analogous to I/O signals on a robot

controller. The signal value is used by code behind to control

the behavior of the Smart Component.

[I/O] signal

Connects the value of one signal to the value of a different

signal.

[I/O] connection

The process of connecting several Smart Components using

bindings and/or connections in order to implement a more

complex behavior.

Aggregation

Data object contained in a Smart Component. Uses include

code behind assembly and localized resources.

Asset

284 Operating manual - RobotStudio

3HAC032104-001 Revision: P

© Copyright 2008-2015 ABB. All rights reserved.

9 Modeling tab

9.4.1 Smart Component](https://image.slidesharecdn.com/prog-150726124729-lva1-app6892/75/Prog-284-2048.jpg)

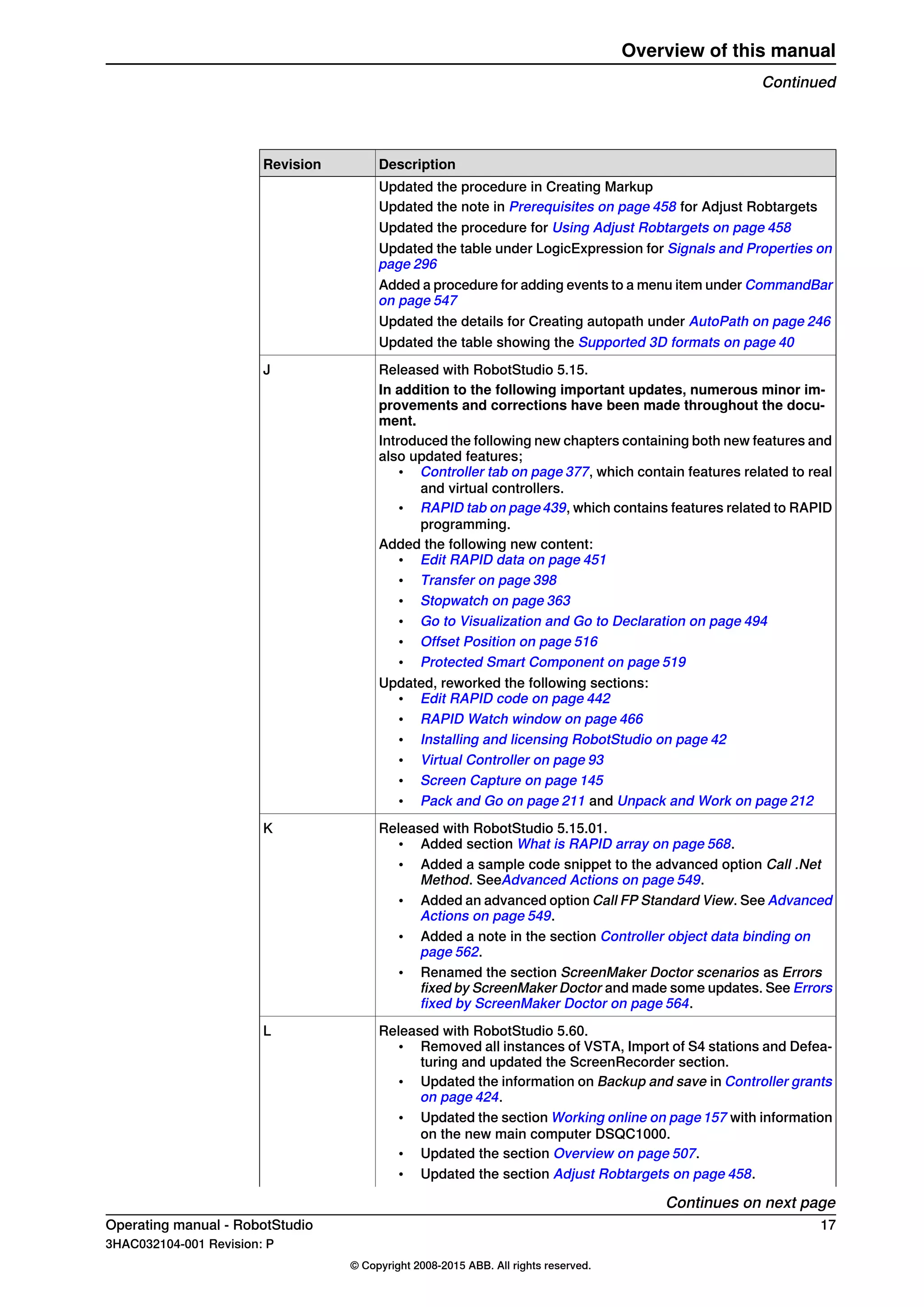

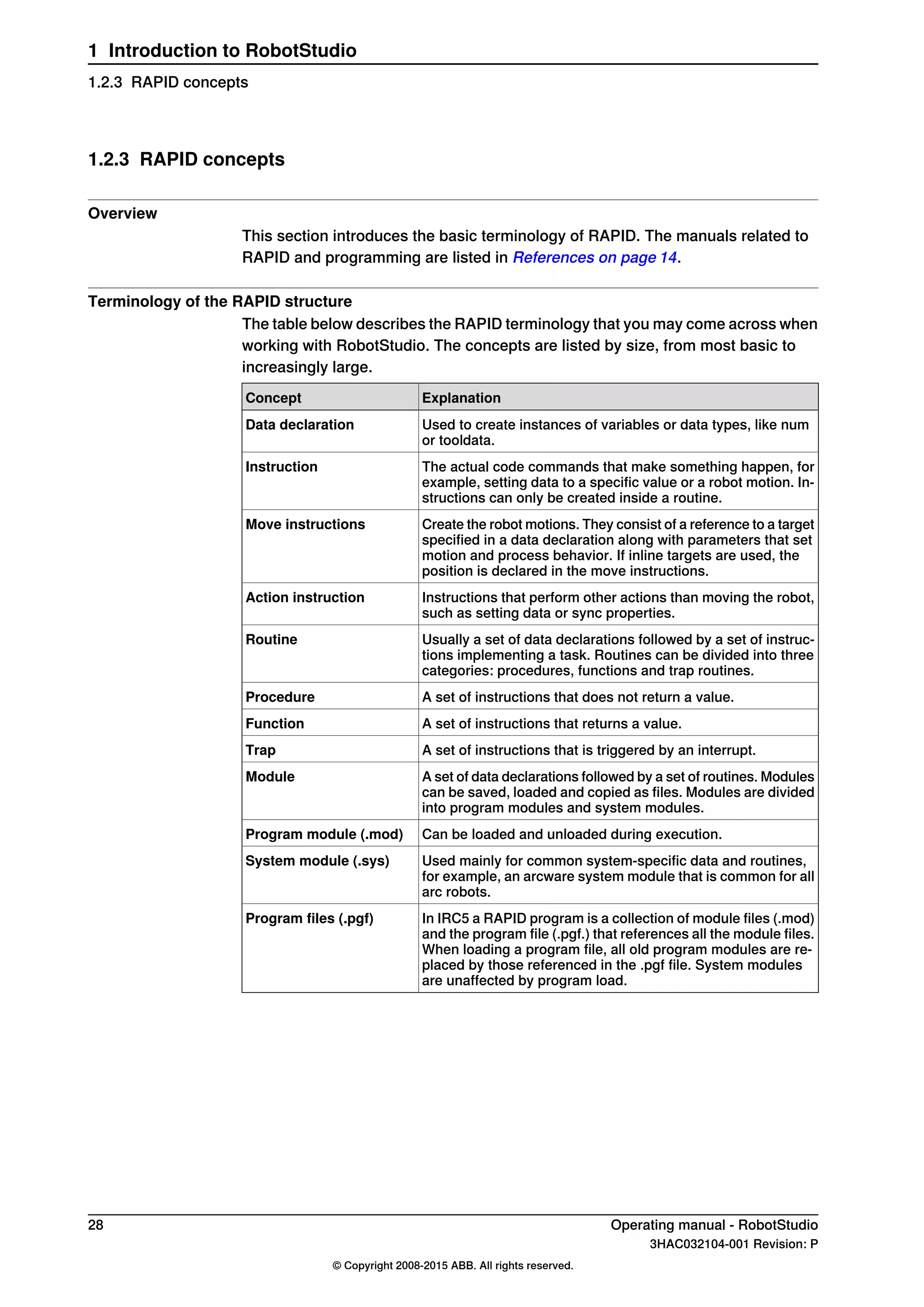

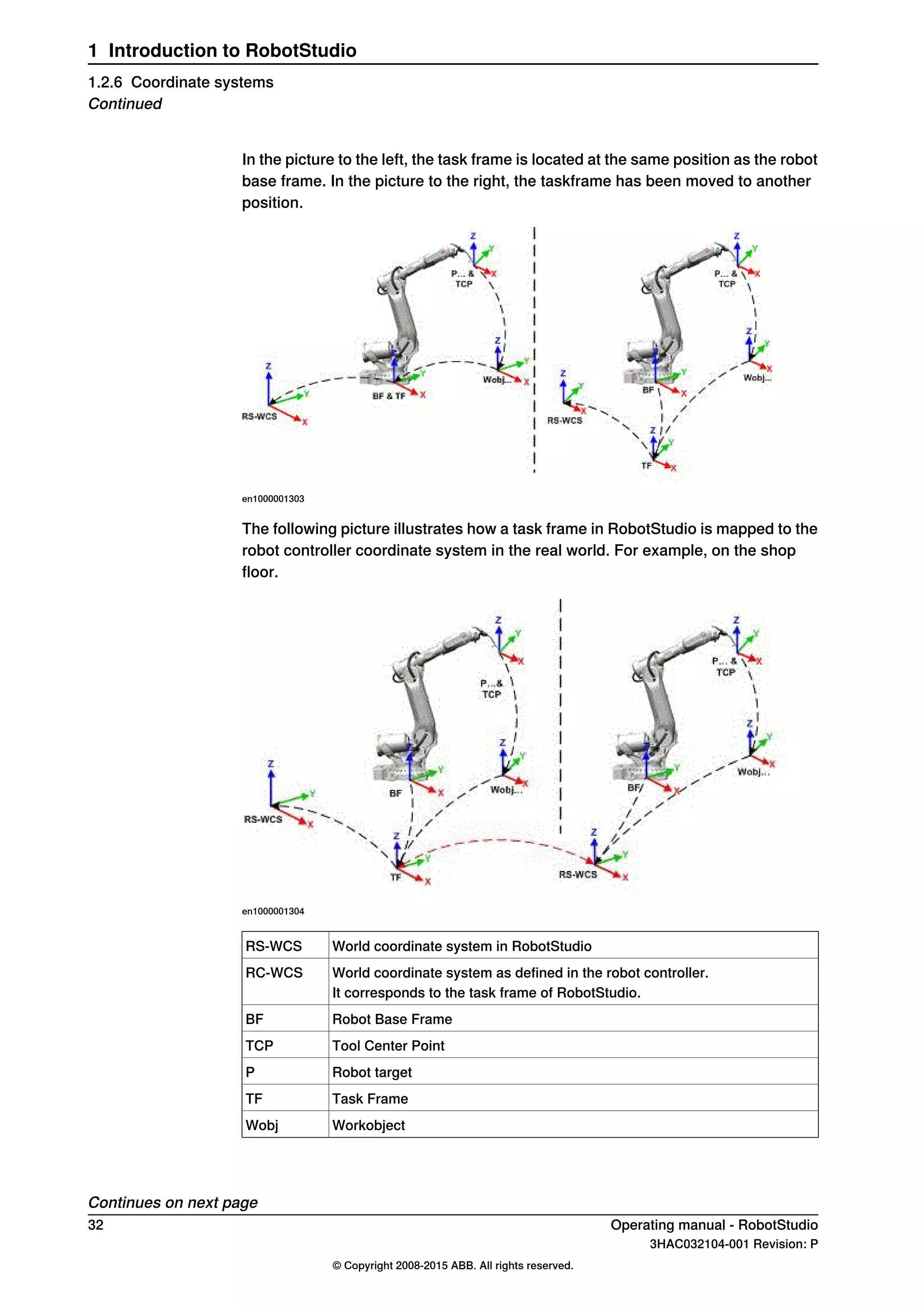

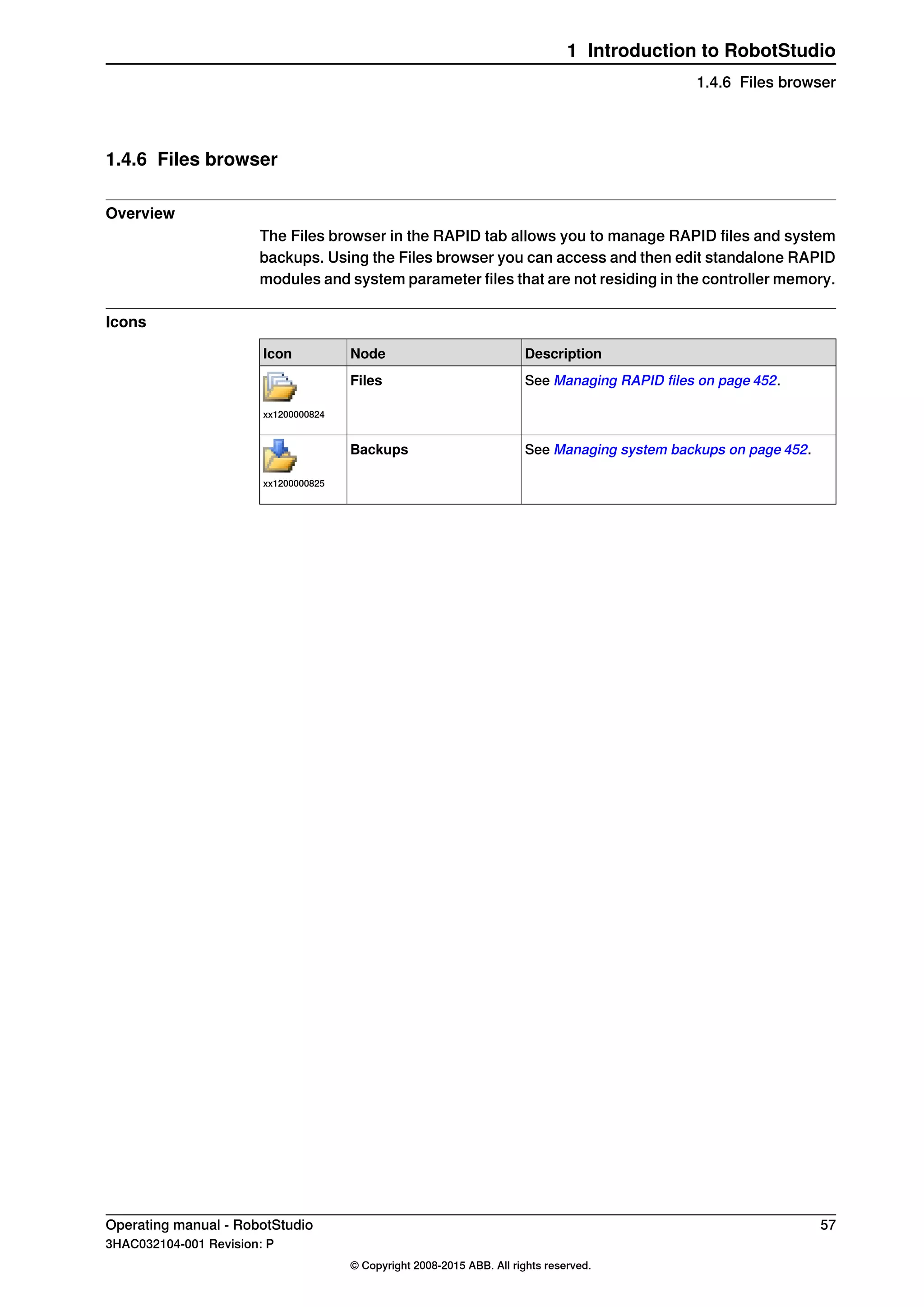

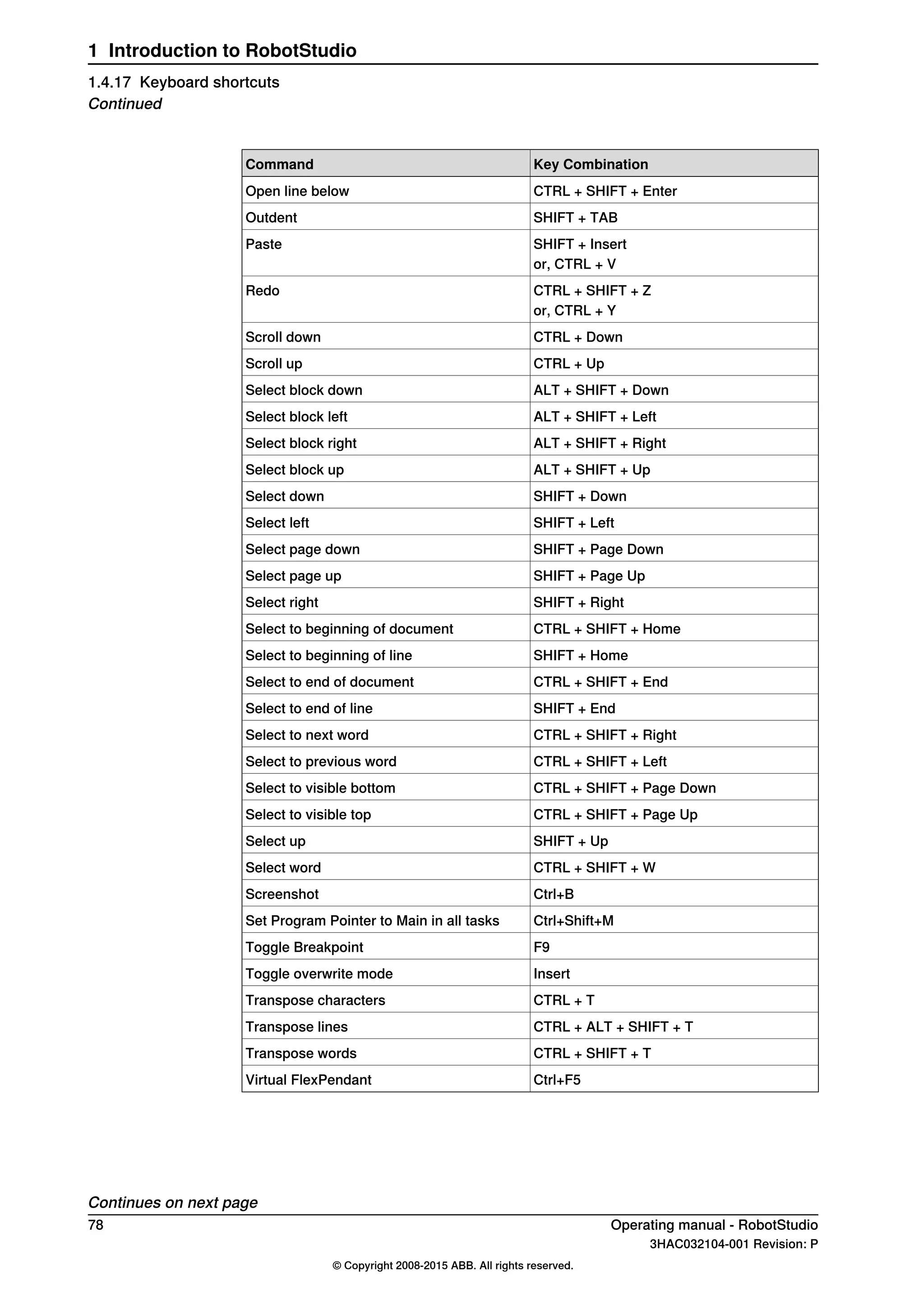

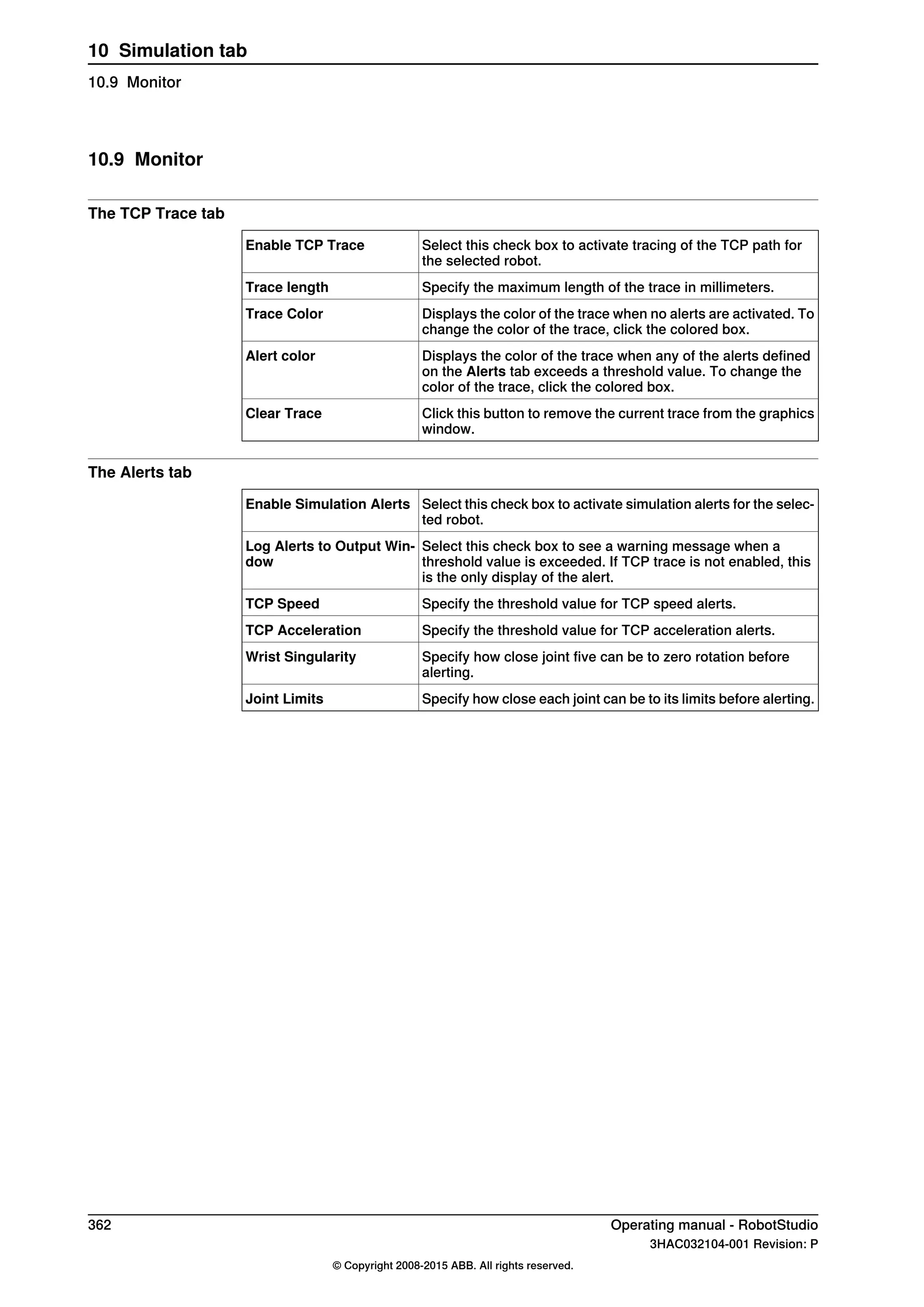

![bound variable. 0 and 1 for digital input. It is also possible to bind to RAPID variables

and have multiple states and values for the values in the RAPID variable.

Set the SelectedStateValue property to bind to a controller object:

How to get radio buttons to show state when entering

The objective is to have two radio buttons that controls one digital output. When

the screen is loaded, the buttons should show the current state of the output.

Actions

Create a group or a panel and place the two radio buttons on the group or panel.

For button1, set the property default value to True and bind the property to the

value of the controller digital output signal.

For button2, do not do any changes.

When the screen is loaded, the state of the two radio buttons is established

correctly.

What is RAPID array

A RAPID array is a variable that contains more than one value. An index is used

to indicate one of the values.

Sample RAPID array

Consider the following RAPID code.

VAR string part{3} := ["Shaft", "Pipe", "Cylinder"];

Here, ‘part’ is a RAPID array which consists of three values. The index of the array

in part ranges from 1 to 3.

The index of a RAPID array should not be negative and should start with 1.

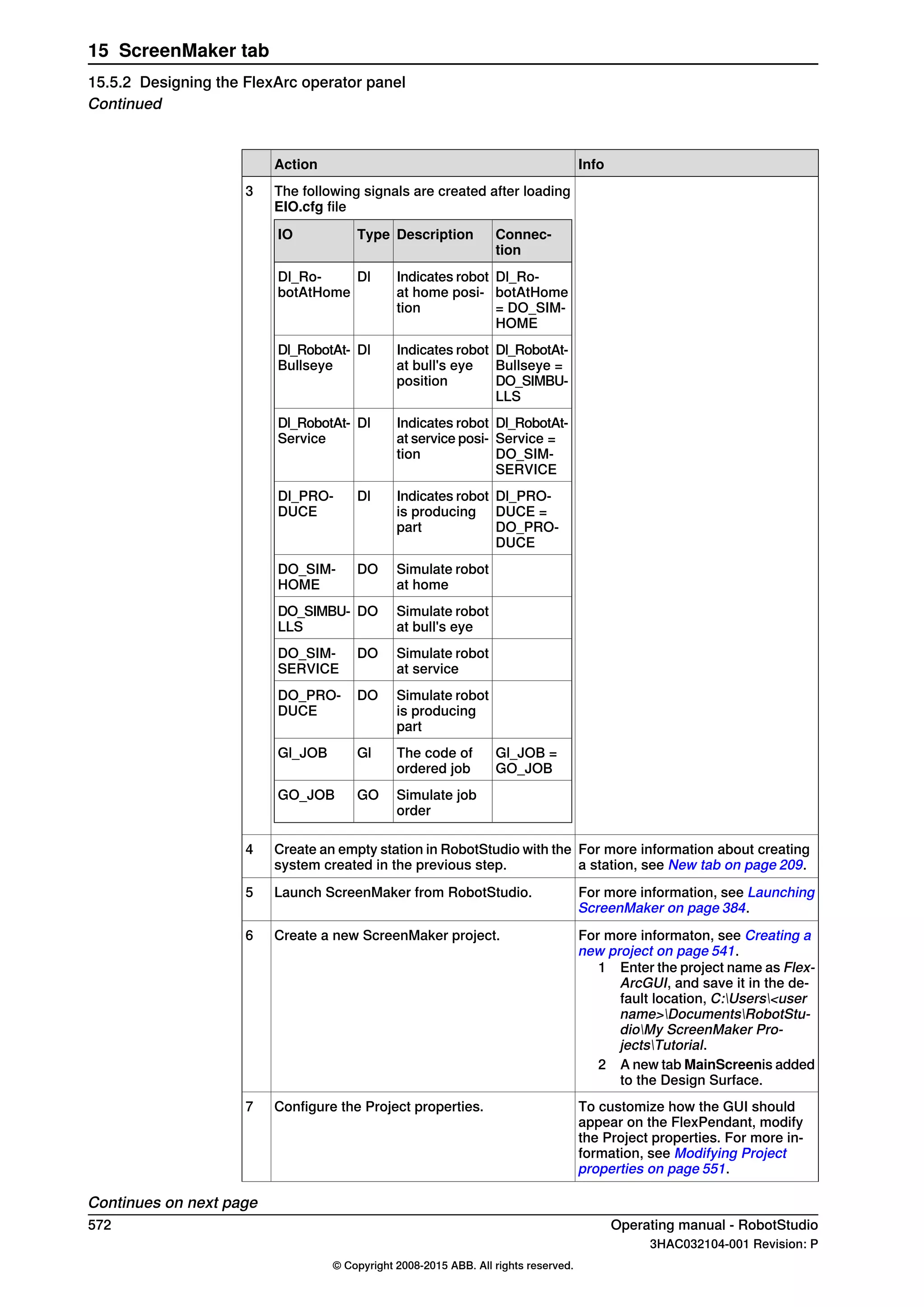

Screen navigation

Screen navigation in ScreenMaker follows a tree structure.

Consider the following example,

• To open screen A1, you first have to open Screen A

• To navigate from screen A1 to screen B1, you first have to close screen A1

and then Screen A and navigate from Main Screen through Screen B to

screen B1.

• Similarly, to navigate from screen B1 to screen C1, you first have to close

screen B1 and Screen B and then navigate from Main Screen through Screen

C to screen C1.

Continues on next page

568 Operating manual - RobotStudio

3HAC032104-001 Revision: P

© Copyright 2008-2015 ABB. All rights reserved.

15 ScreenMaker tab

15.4 Frequently asked questions

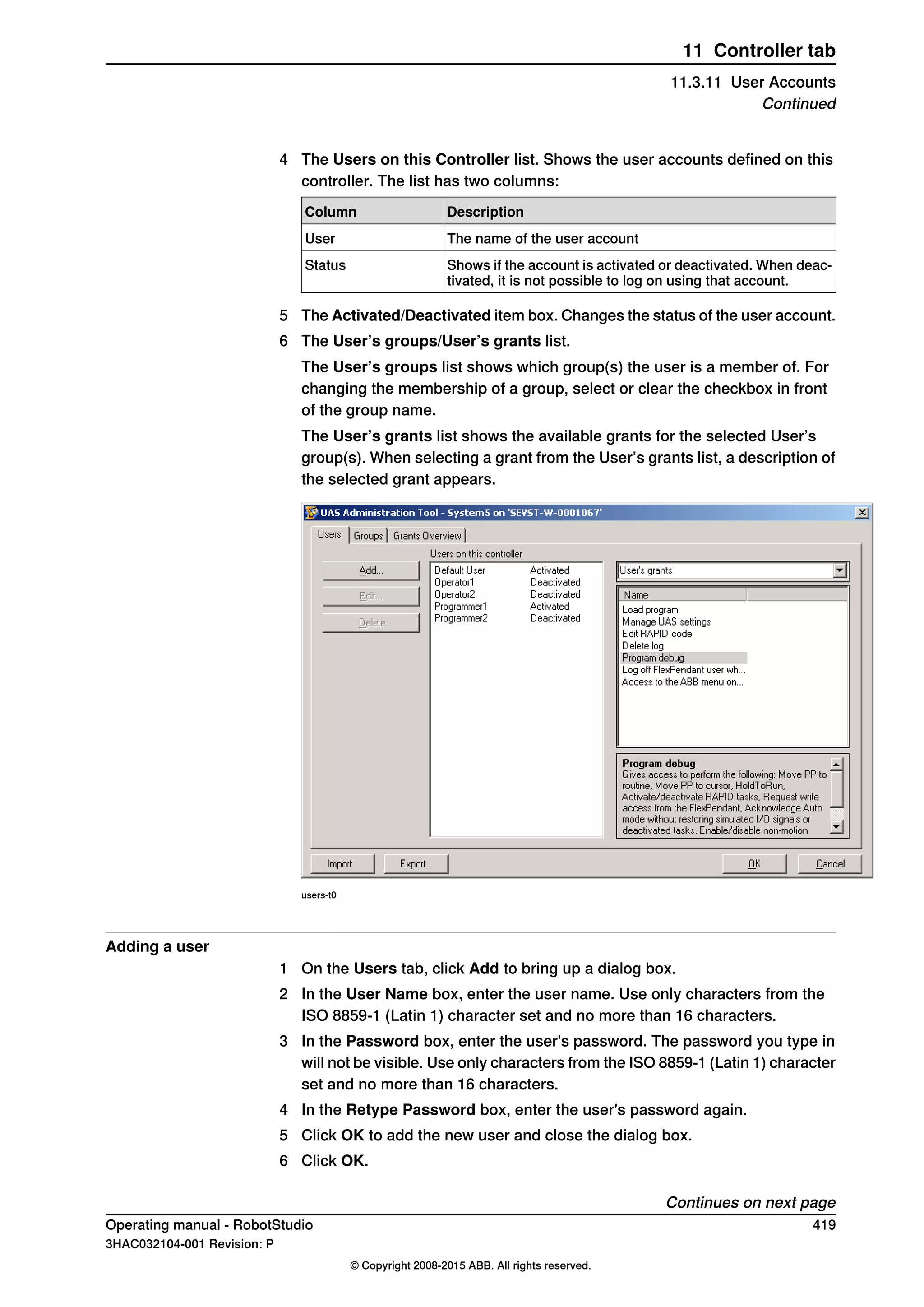

Continued](https://image.slidesharecdn.com/prog-150726124729-lva1-app6892/75/Prog-568-2048.jpg)