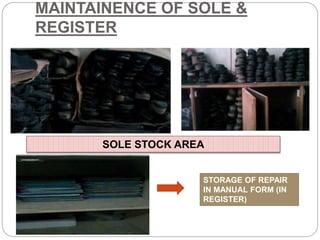

This document provides an overview of product training from Warehouse Panki. It discusses the different types of soles and socks used in shoe making, including PU, TPR, rubber, EVA and crepe soles. The document describes the machines used in shoe making as well as the repairing, pasting and quality check processes. It also covers the areas of stock maintenance for soles and shoes/garments in the warehouse. The training was provided by Mr. Pawan Prajapati and made by Miss. Arti Poddar, with Mr. Vipul Pandey as the HOD.