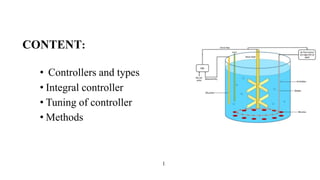

The document discusses integral controllers used in fermenters, outlining their role in regulating fermentation parameters such as temperature and pH. It details the advantages and disadvantages of integral controllers, their ability to reduce steady-state errors, and the importance of tuning these controllers for optimal performance. Various tuning methods, including manual and automatic tuning, are also described to ensure effective regulation of fermentation processes.