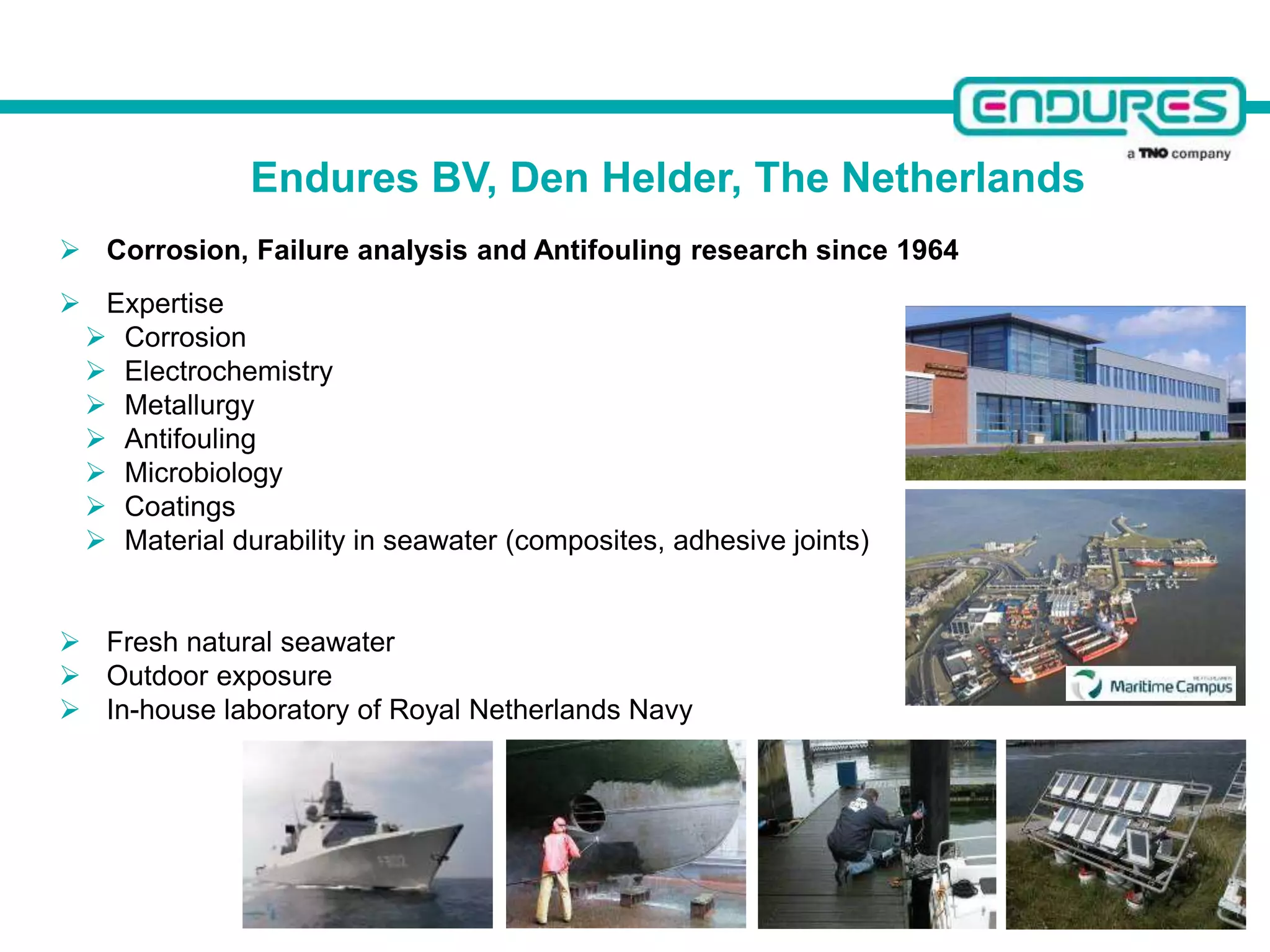

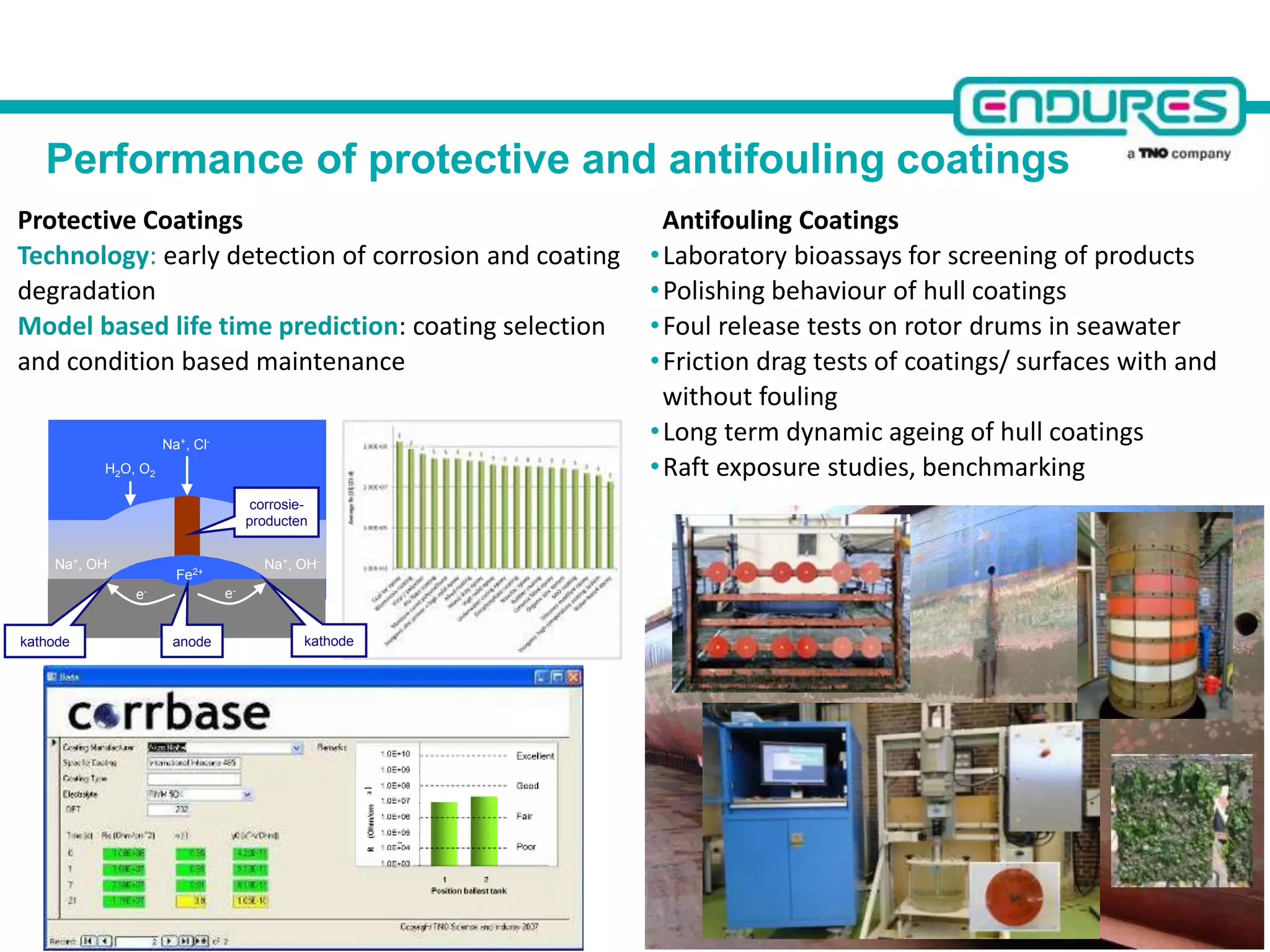

Endures B.V., based in Den Helder, Netherlands, aims to be a European center of excellence in corrosion, failure analysis, and fouling control by evolving from single customer projects to multi-client business programs. The company specializes in various fields, including electrochemistry, microbiology, and material durability, and utilizes advanced laboratory facilities for testing and research. Endures serves diverse market segments, comprising maritime and offshore industries, and has notable clients such as Shell and Damen.