Course Title: Automotive Tribology

Course Code: AUT 518b

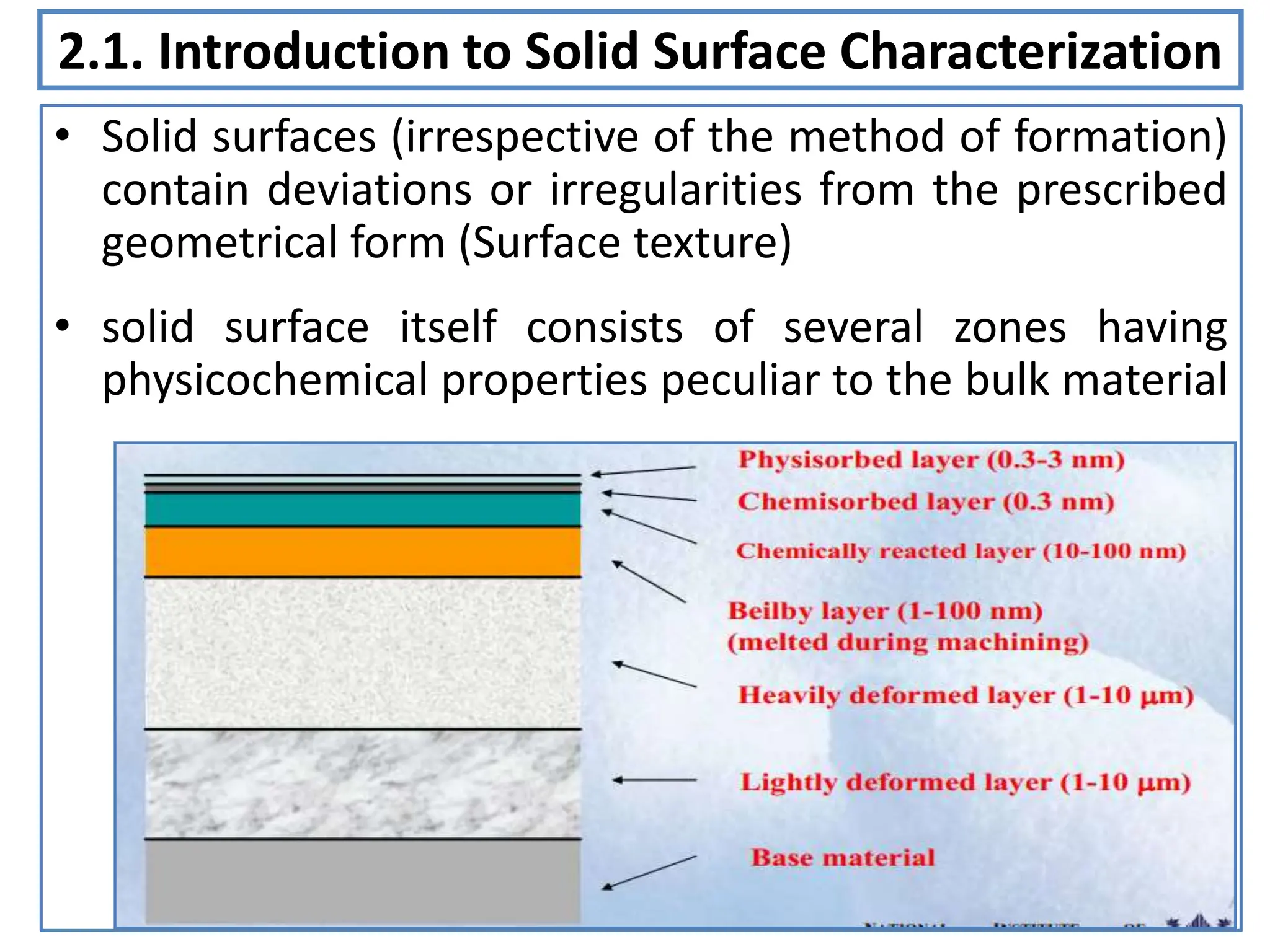

Cr. Hours 3

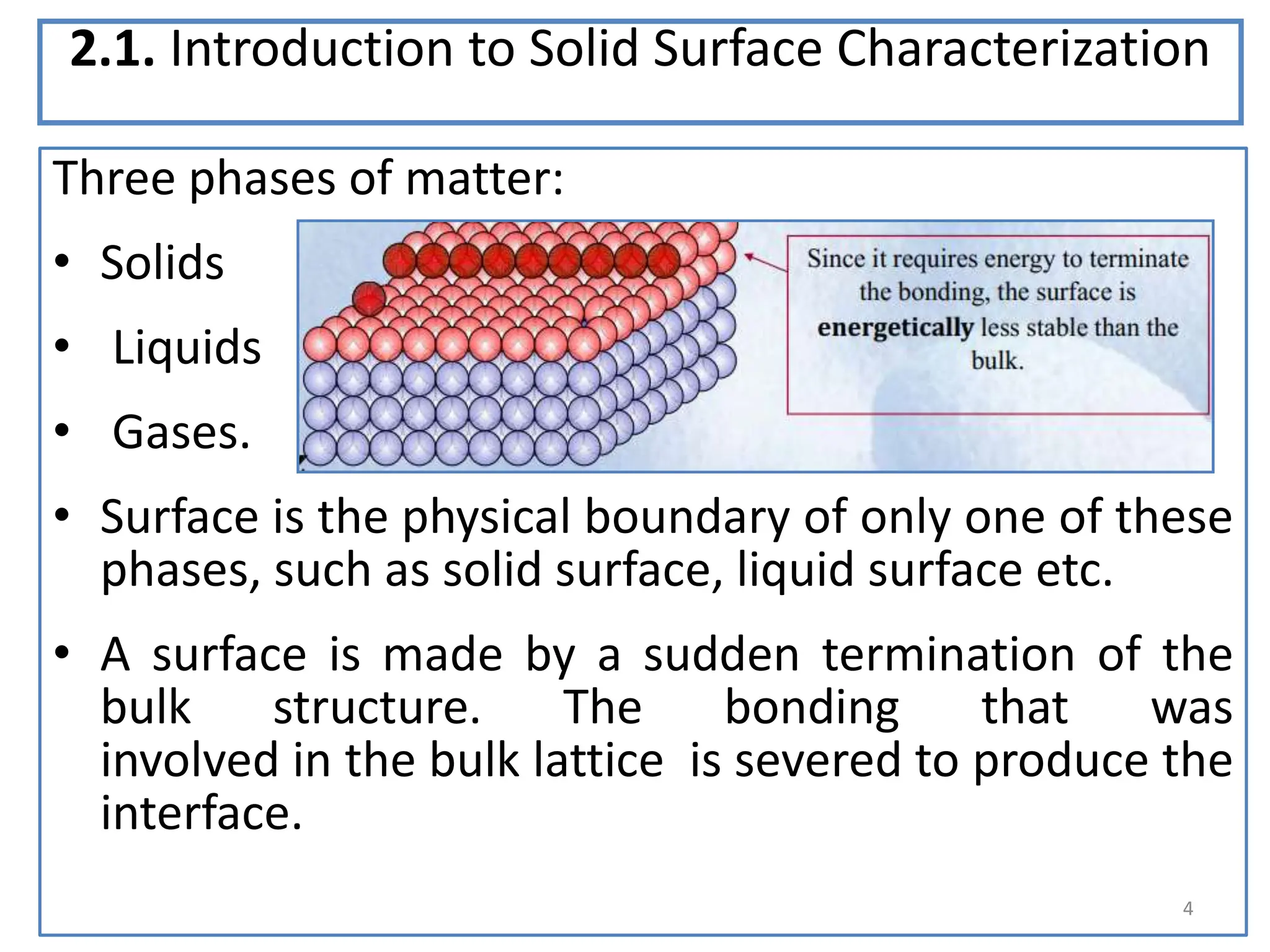

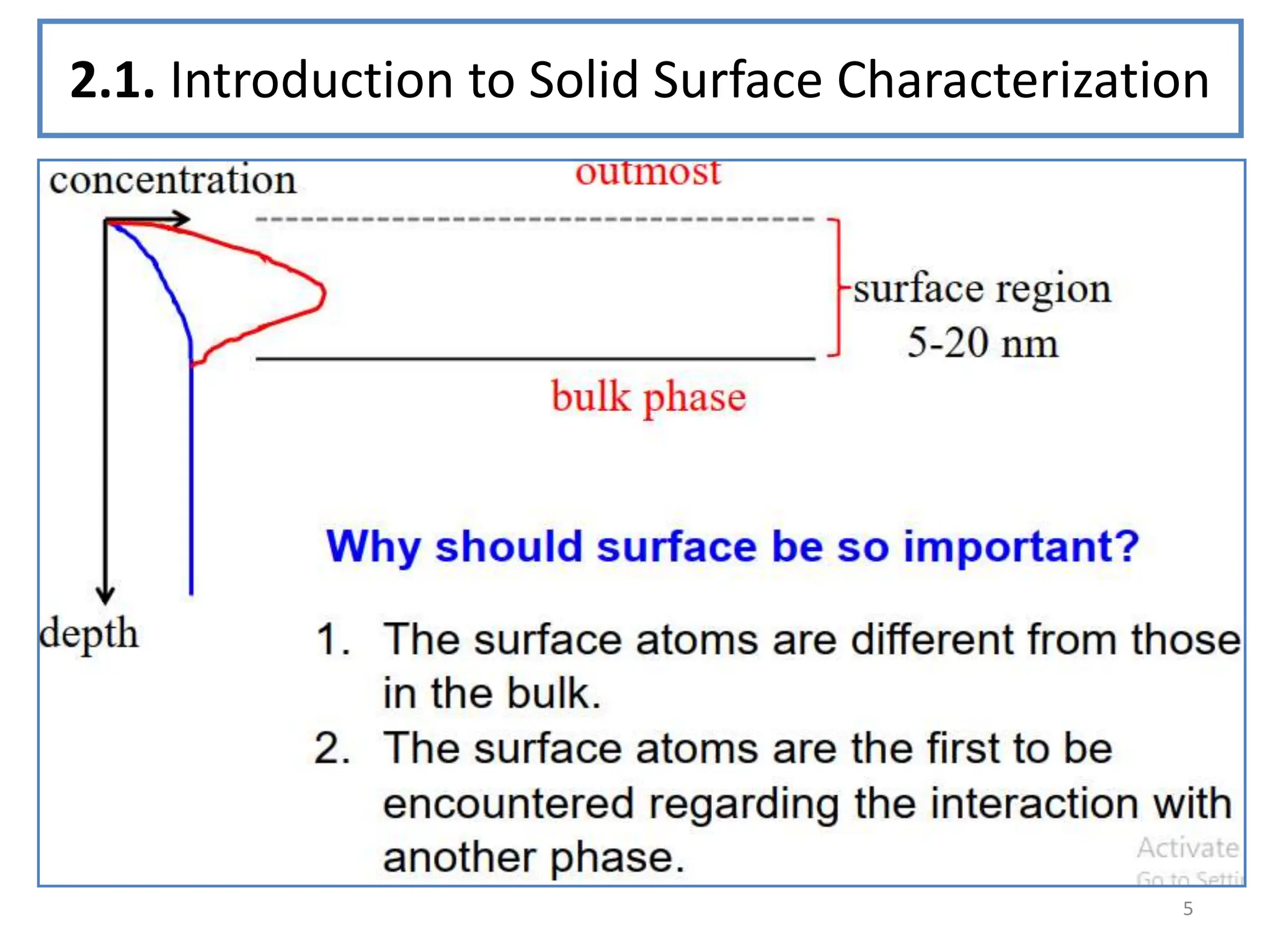

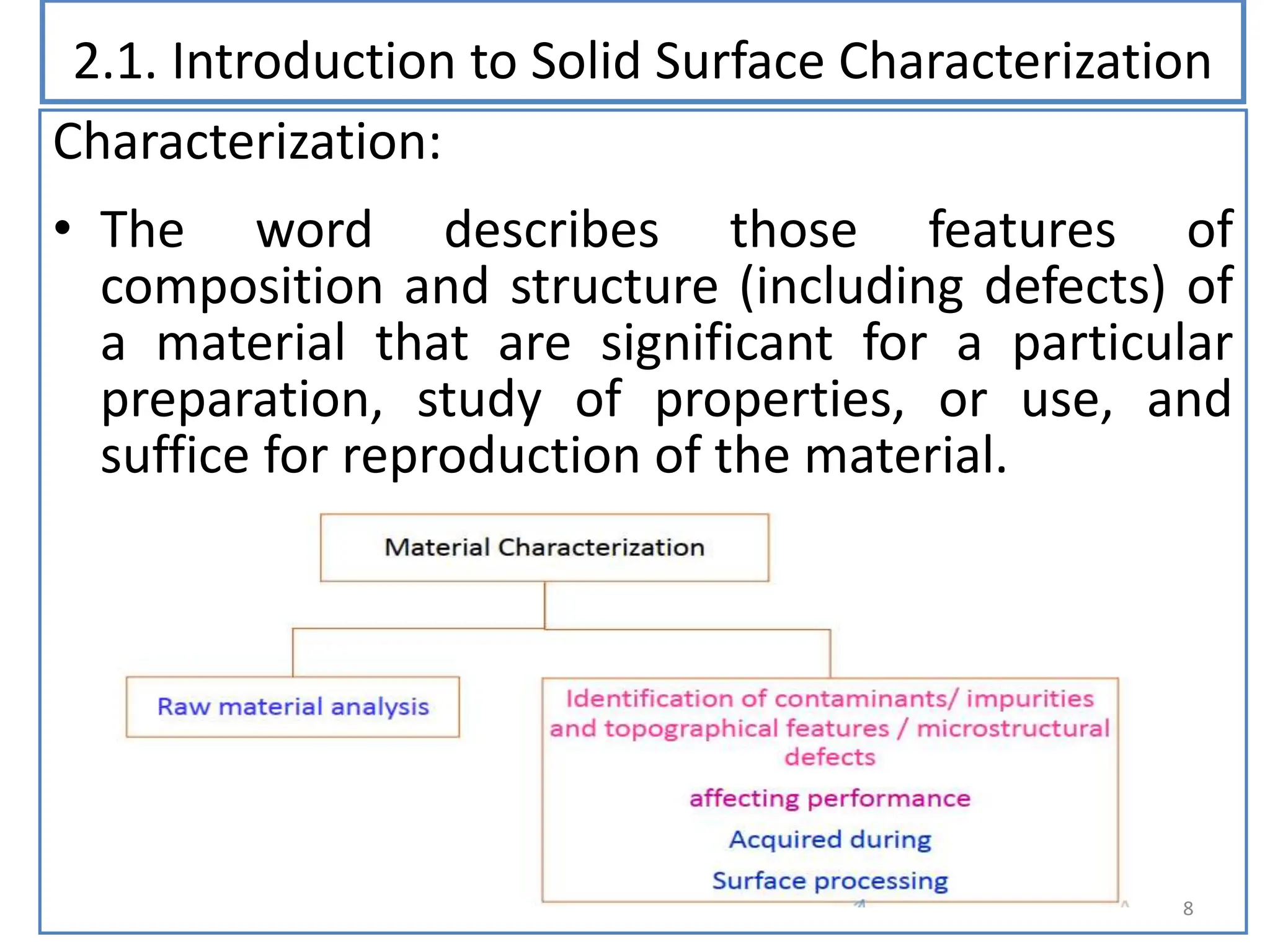

This is a 3 credit hour course on Automotive Tribology for 2nd year MSc Automotive Technology students. It will be held on Mondays from 8:00-12:00 in Room 6. The course outline includes chapters on friction and wear of metal surfaces, introduction to solid surface characterization, and friction and wear mechanisms. Assessment will include deliverables related to chapter two on friction and wear of metal surfaces. The course instructor is Hailemariam N.