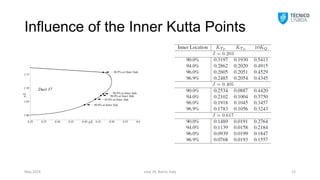

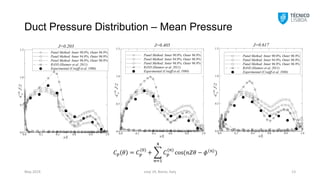

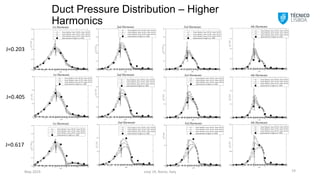

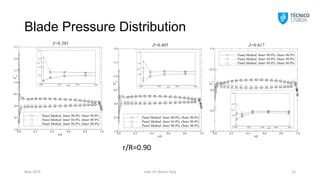

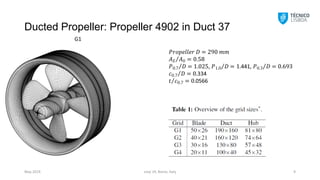

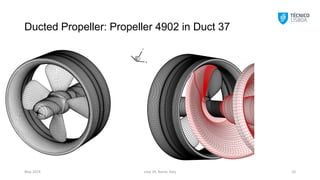

The document discusses potential flow modeling of ducted propellers with blunt trailing edges, utilizing a panel method to evaluate pressure distributions and forces. The study investigates the applicability of the Kutta condition in modeling flows and assesses grid convergence and pressure distributions based on various configurations and trailing edge shapes. Results include numerical analyses and comparisons with experimental data, indicating the effectiveness of the proposed modeling approach for different duct and propeller systems.

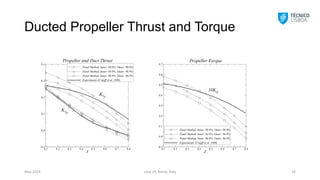

![Results: Grid Convergence Study

smp´19, Rome, Italy 11

May 2019

Kutta points at 96.9%

r/R

(

R

2

)

0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

-0.03

0.00

0.03

0.06

0.09

G4

G3

G2

G1

Blade Circulation

J=0.203

J=0.405

J=0.617

Position between blades [deg.]

(

R

2

)

0 10 20 30 40 50 60 70 80 90

0.15

0.20

0.25

0.30

0.35

0.40 G4

G3

G2

G1

Duct Circulation

J=0.617

J=0.203

J=0.405

x/L

y/L

0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.55 0.60

1.00

1.05

1.10

1.15

Duct 37

94.0%

99.5%

99.0%

96.9%

96.0%

98.0%](https://image.slidesharecdn.com/smp19romemay2019jbfc-210212170337/85/Potential-Flow-Modelling-of-Ducted-Propellers-with-Blunt-Trailing-Edge-Duct-Using-a-Panel-Method-11-320.jpg)