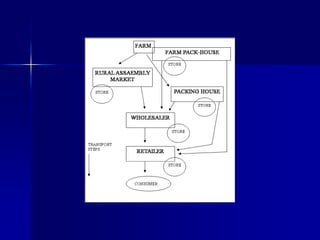

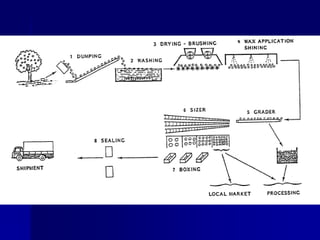

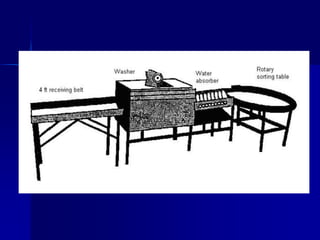

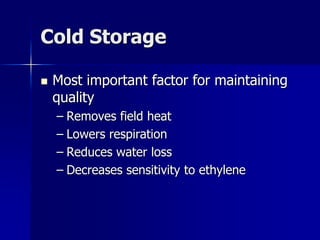

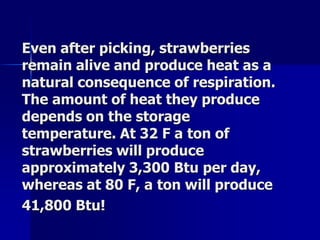

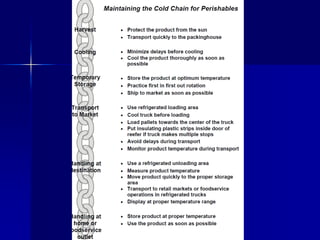

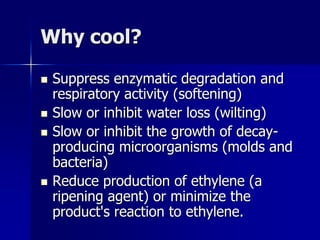

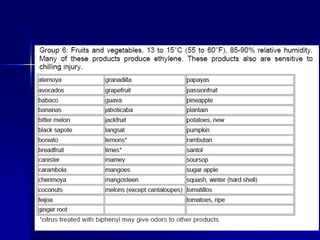

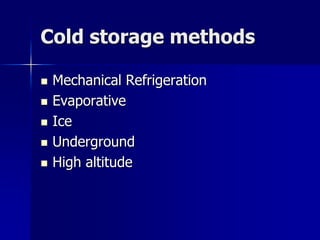

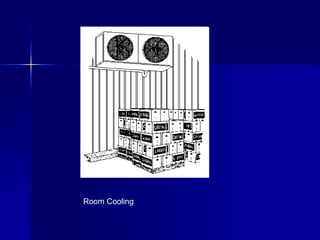

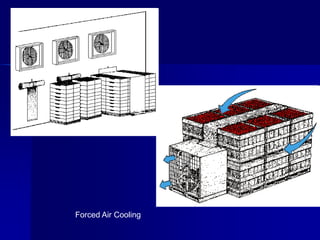

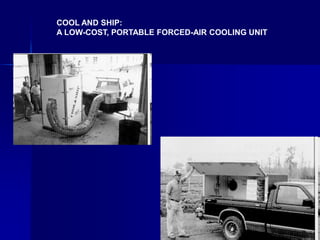

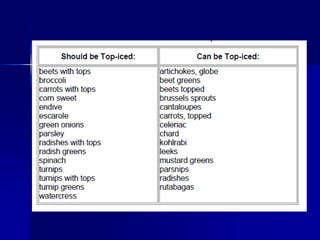

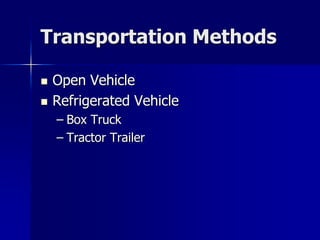

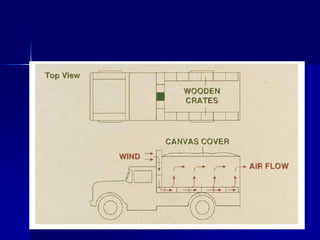

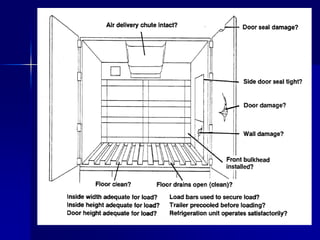

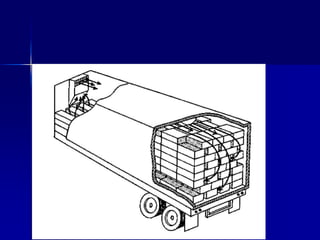

The document discusses the importance of proper post-harvest handling and transportation methods for small-scale produce growers to maintain high quality. It outlines several key steps: [1] Proper harvesting techniques and rapid cooling of produce after picking; [2] Use of packing sheds with features like washers, sizers and cold storage; [3] Transportation of produce in refrigerated vehicles. Maintaining proper cooling throughout the post-harvest process is essential for preserving quality, safety and reducing losses from field to consumer.