This user guide provides information about the PowerLogic Series 800 Power Meter. It describes the hardware, features, setup, metering capabilities, inputs/outputs, alarms, logging, waveform capture, and disturbance monitoring functions of the PowerLogic power meters. The guide contains safety and operational instructions as well as technical specifications for using the meters.

![© 2011 Schneider Electric. All Rights Reserved.

PowerLogicTM

Series 800 Power Meter 63230-500-225A2

Contents 3/2011

vi

Chapter 8—Waveform Capture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -63

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -63

Waveform Capture - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -63

Waveform Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -64

How the Power Meter Captures an Event - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -64

Channel Selection in PowerLogic Software - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -64

Chapter 9—Disturbance Monitoring (PM870) - - - - - - - - - - - - - - - - - - - - - - - - - - - - -65

About Disturbance Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -65

Capabilities of the PM870 During an Event - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -67

Chapter 10—Maintenance and Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - -69

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -69

Power Meter Memory - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -69

Identifying the Firmware Version, Model, and Serial Number - - - - - - - - - - - - - - - - -70

Viewing the Display in Different Languages - - - - - - - - - - - - - - - - - - - - - - - - - - - - -70

Technical Support - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -70

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -71

Appendix A—Instrument Transformer Wiring: Troubleshooting Tables - - - - - - - - 73

Using This Appendix - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -73

Section I: Common Problems for 3-Wire and 4-Wire Systems - - - - - - - - - - - - - - - -74

Section II: 3-Wire System Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -75

Section III: 4-Wire System Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - -76

Field Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -78

Appendix B—Register List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 79

Register List Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -79

About Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -79

How Date and Time are Stored in Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - -80

How Signed Power Factor is Stored in the Register - - - - - - - - - - - - - - - - - - - - - - - -80

Supported Modbus Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -81

Resetting Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -81

Appendix C—Using the Command Interface- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

Overview of the Command Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -83

Operating Outputs from the Command Interface - - - - - - - - - - - - - - - - - - - - - - - - - -86

Using the Command Interface to Change Configuration Registers - - - - - - - - - - - - -86

Conditional Energy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -87

Incremental Energy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -88

Setting Up Individual Harmonic Calculations - - - - - - - - - - - - - - - - - - - - - - - - - - - - -89

Changing Scale Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -90

Enabling Floating-point Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -91

Appendix D—Advanced Power Quality Evaluations - - - - - - - - - - - - - - - - - - - - - - - 93

Power Quality Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -93

SEMI-F47/ITI (CBEMA) Specification - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -93

EN50160:2000 Specification - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -95

How Evaluation Results Are Reported - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -95

Possible Configurations Through Register Writes - - - - - - - - - - - - - - - - - - - - - - - - -96

Evaluation During Normal Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -96

Evaluations During Abnormal Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -97

Operation with PQ Advanced Enabled - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -99

Advanced Power Quality Evaluation System Configuration

and Status Registers [EN50160 and SEMI-F47/ITI (CBEMA)] - - - - - - - - - - - - - - - -99

EN50160 Evaluation Data Available Over a Communications Link - - - - - - - - - - - - 101

Setting Up PQ Advanced Evaluation from the Display - - - - - - - - - - - - - - - - - - - - - 104

Glossary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 105

Terms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 105

Abbreviations and Symbols - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 107

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 109](https://image.slidesharecdn.com/pm800userguide-150708030314-lva1-app6891/85/Pm800-userguide-6-320.jpg)

![© 2011 Schneider Electric. All Rights Reserved.

PowerLogicTM

Series 800 Power Meter 63230-500-225A2

Chapter 3—Operation 3/2011

12

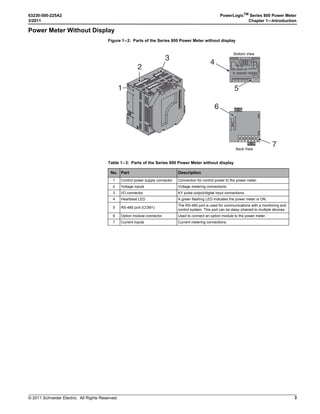

Figure 3–2: Abbreviated List of PM800 Menu Items in IEEE (IEC) Mode

➀ Available on the PM810 only when an optional Power Meter Logging Module (PM810LOG) is installed. Available on all other PM800 Series models.

➁ Available with some models.

➂ Both IEC and IEEE modes are available. Depending on the mode selected, menu labels will be different. See “Display Mode Change” on page 24 to select the

desired mode.

➃ The PM810 has a volatile clock. The PM810 with an optional Power Meter Logging Module (PM810LOG), and all other PM800 Series models, have a non-volatile

clock.

PHASE I - DMD UNBAL

PWR (PQS) PHASE P - DMD

TRUE DISPL

V L-L (U) V L-N (V) I

MINMX AMPS (I) VOLTS (U-V) UNBAL PWR (PQS) PF HZ (F) THD V THD I

ACTIV HIST

DATE TIME LANG COMMS (COM) METER ALARM I/O PASSW TIMER ADVAN

AMPS (I)

VOLTS (U-V)

PWR (PQS)

ENERG (E)

PF

HZ (F)

THD

MINMX

ALARM

I/O

RESET

SETUP

DIAG

HARM

METER ENERG (E) DMD MINMX MODE TIMER

CONTR

MAINT

TIMER

PM8M2222

COMM1

COMM2

PM8RD

D OUT D IN A OUT A IN

METER REG CLOCK

1

3

2

D OUT [Digital KY Out]

D IN [Digital In]

A OUT [Analog Out]

A IN [Analog In]

PM8M2222

PM8M2222, PM8M26, and PM8M22

4 4

4

1

V L-L (U) V L-N (V) I

V L-L (U) V L-N (V)

Wh VAh VARh INC

LEVEL 1 LEVEL 2](https://image.slidesharecdn.com/pm800userguide-150708030314-lva1-app6891/85/Pm800-userguide-19-320.jpg)