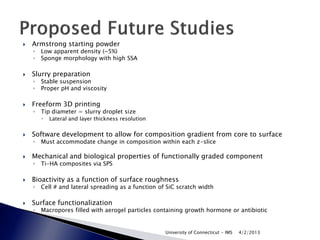

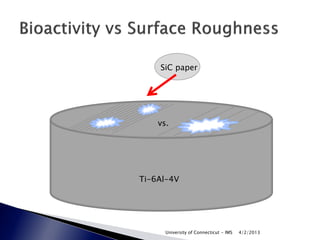

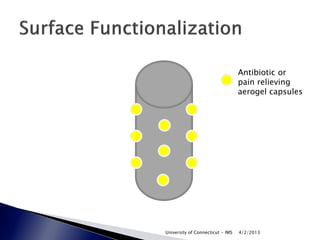

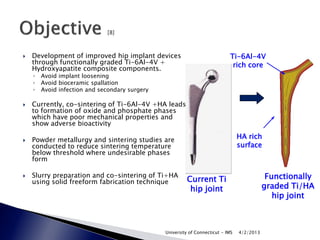

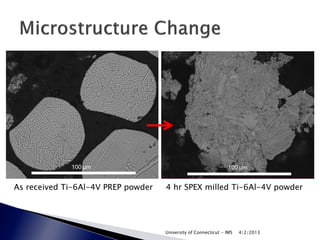

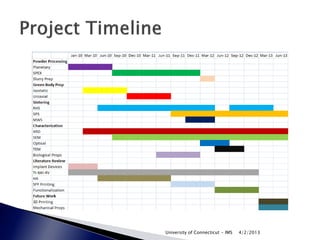

This dissertation proposal focuses on the development of functionally graded orthopedic implants using Ti-6Al-4V, addressing challenges in current biomedical implants related to stress and mechanical bonding. It describes proposed methodologies such as powder processing and sintering techniques, along with necessary experiments and validation of mechanical and biological properties. The goal is to enhance the performance and longevity of hip implant devices while minimizing the risk of complications such as loosening or infection.

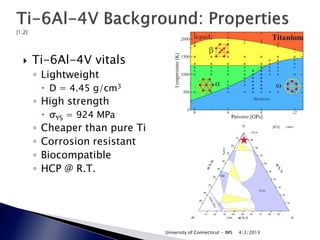

![ [1] Hennig, R., Lenosky, T., Trinkle, D., Rudin, S., Wilkins, J. "Classical potential describes martensitic

phase transformations between the alpha, beta, and omega titanium phases," Physical Review B,

78,054121, 2008.

[2] Kubaschewski O., Wainwright C., and Kirby F.J., “The Heats of Formation in the Vanadium-Titanium-

Aluminium System,” J. Inst. Met., 89, 1960, 139-144.

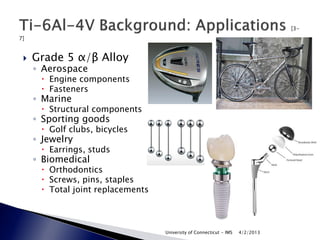

[3] Honma BERES 7 Series Driver, honmagolf.com, 2010.

[4] Solid Grade 5 Titanium, TNG Body Jewlery, 2012.

[5] Deutsch, A., “Bike review: Merlin works CR 6/4,” Brooklyn Arches Cycling, 2012.

[6] Titanium dental implants, Naomi Dental, 2011

[7] Total hip replacement, defectivejoints.com, 2011

[8] Shaw, L., “Rapid prototyping of functionally graded orthopedic implants via the slurry mixing and

dispensing process,” NSF proposal submitted 2009.

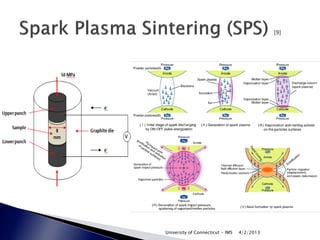

[9] What’s SPS, “Principles and mechanism of the SPS process,” Fuji Electronic Industrial Co.

University of Connecticut - IMS 4/2/2013](https://image.slidesharecdn.com/phdproposalformattedslideshow-130402153045-phpapp02/85/PhD-Dissertation-Proposal-Presentation-38-320.jpg)