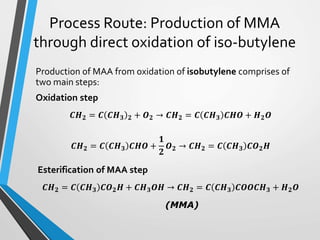

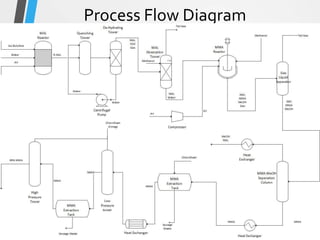

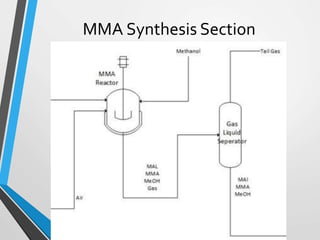

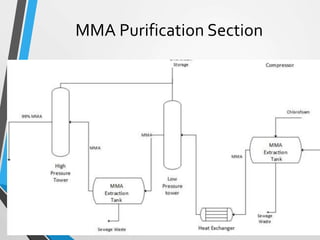

The document summarizes the two-step process for producing poly(methyl methacrylate) (PMMA) from isobutylene. The first step involves oxidizing isobutylene to methacrylic acid (MAA) through two reactions. The second step is the esterification of MAA with methanol to produce methyl methacrylate (MMA). The process involves four main sections - MAL synthesis, MMA synthesis, separation of MAL and methanol, and purification of MMA. Key reaction conditions and equipment used at each stage are also outlined.