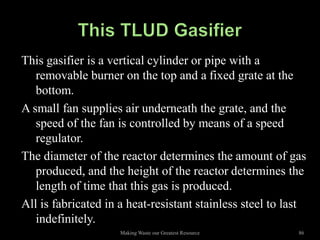

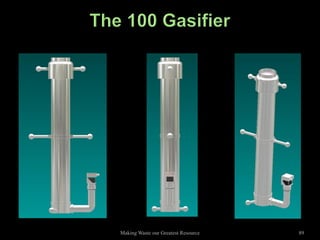

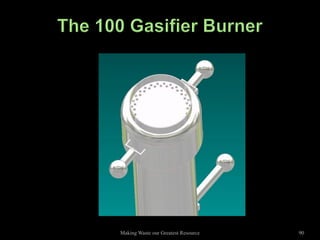

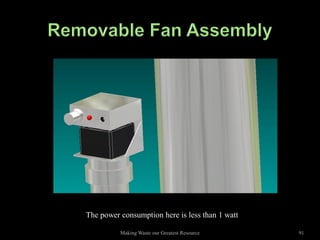

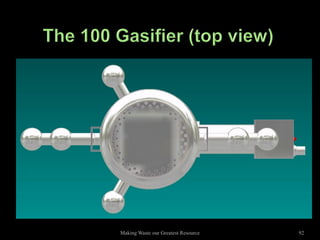

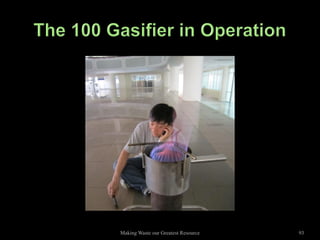

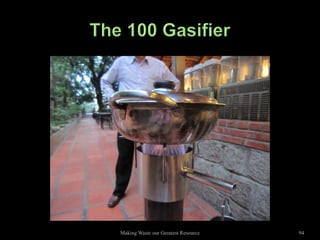

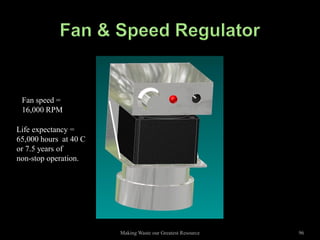

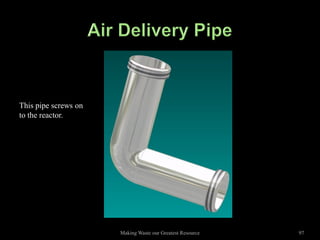

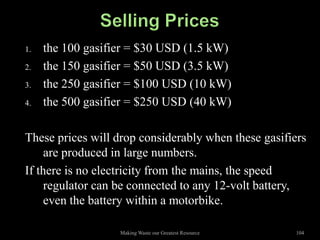

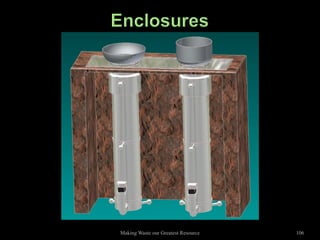

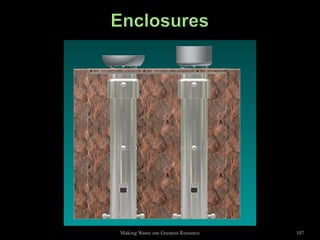

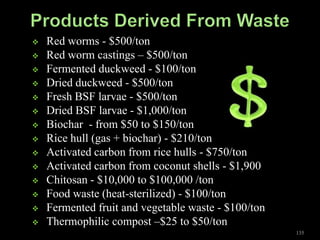

The document discusses the use of gasifiers to convert biomass waste, such as rice hulls, into biochar and gas, highlighting the economic potential of transforming waste into valuable resources. It outlines the specifications, models, and costs of various gasifiers, alongside potential applications in agriculture and energy generation. The concept of waste resource centers is proposed for managing scavengers and maximizing economic returns from waste-derived products, promoting sustainability and environmental responsibility.