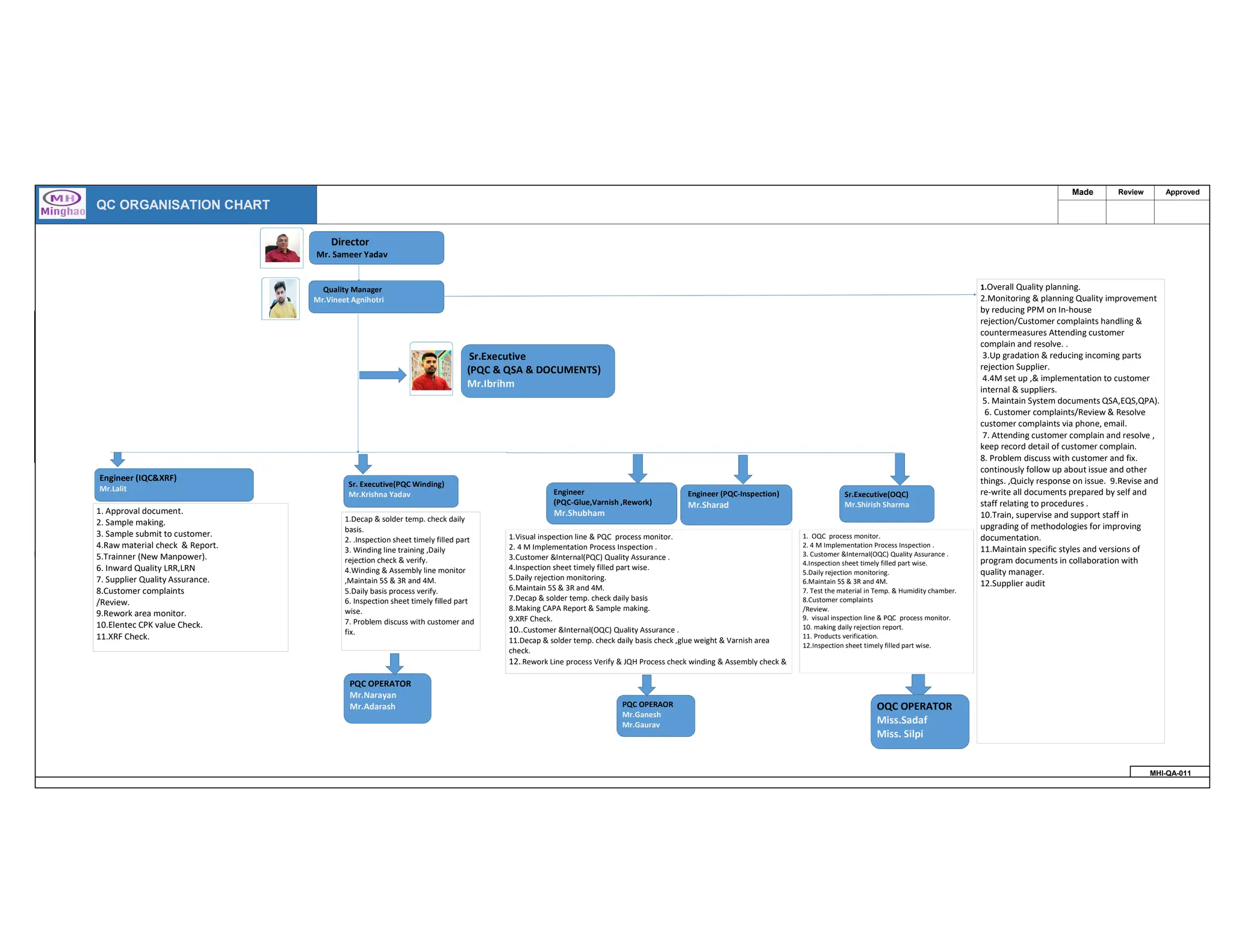

The document outlines the organizational structure and responsibilities of the quality management team, including key personnel and their roles in quality assurance, inspection, and complaint resolution. It details processes for monitoring quality, including daily checks and training, as well as the management of customer complaints and supplier audits. Overall, it emphasizes the importance of maintaining quality standards and continuous improvement within the organization.