OffshoreErectionWorkPack

- 1. 7.f to TOTE TANK valve - OD10x1.5mm L= ca. 4m 27 28 22 21

- 2. 1. Bolting the skid in place (12 pcs., M24x130), 2. Mounting of ladder (bolts: 12 pcs. bolts M12x45mm+12 nuts M12+24 washers - cl.8.8/cl.8/HV140 hot dip galv.), 3. Mounting of handrails (bolts: 21 pcs. M16x60+nuts M16+2washers mm cl. 8.8/cl.8/HV140 hot dip galv.), 4. Mounting of pad eyes covers (2 pcs, bolts: 5 pcs/each Hex socket countersunk head scrw. M6x10 mm SS), 5. Mounting of bumpers (bolts: 24 pcs. M16x90+2nutsM16+2washers hot dip galv.; rubber pads: 8pcs; springs supports for TODO couplings: 2pcs.), 6. Mounting of safety gate (bolts: 4pcs. M8x16+washer hot dip galv.), 7. Mounting of dispenser unit: a. Hold down Bolts: 8pcs.M20x30+washer hot dip galv., b. Earth bounding M10, c. Open hazardous drain connection (bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv. +1gsk.2"spiral wound I/O 316L), d. Pipes spool mounting i. 2” fuel line spool no. 11, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, ii. 2” fuel line spool no. 18, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, iii. 2” fuel line spool no. 8, bolts: 24pcs. 5/8"x90mm+24nuts+24washers hot dip galv.+6gsk.2"spiral wound I/O 316L, iv. 2” deluge spool no. 13, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, v. 2” deluge spool no. 5, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, vi. ¾” sample line spool no. 38, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, vii. ¾” sample recycle line spool no. 39, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, e. dispenser cables routing and connection to RIO in pump compartment, JB’s including yellow light and light fixtures power supply, f. dispenser air supply OD20 mm connection 8. Mounting of eyewash container and terminate cable to heater, brackets+thd bar M6/M8+nuts/washers, 9. Mounting of loose gratings on top level of skid (2 or 3 pcs over the lifting pad eyes), bolts 8pcs. compl. of 2 brackets+1nut hot dip galv., 10. Mounting of transfer (2” compl. of bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L) and sample (3/4” compl. of bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L) flexible hoses for transportable tank, 11. Mounting of loose flame detectors on brackets + cable routing and connection to JB, bolts: 4pcs./each M8x30+1nut+2washers, 12. Mounting of Local Control System in Safe area, 13. Mounting of SCADA system in Telecom room, 14. Connecting of skid to open hazardous drain system, bolts: 8pcs. 3/4"x115mm+2nuts+2washers hot dip galv.+1gsk.8"spiral wound I/O 316L, 15. Positioning and anchoring of fire extinguishers, 16. Mounting of cable trays from LCS location to AFS Skid location, 17. Routing of cables from LCS to AFS and connect to JB and cabinet terminals, 18. Routing of cable from LCS to DCS and connection to cabinets terminals, 19. Routing of cables from LCS to SCADA system and connection to cabinets terminals, 20. Routing and connection to TP-105 3" #150 RF ASME B 16.5 of deluge supply line - bolts 5/8"x95 4 pcs + gasket SPW I/O 316L 21. Routing and connection to TPP-11 3/4" #150 RF ASME B 16.5 of Instrumentation air supply line - bolts 1/2"x60 4 pcs + gasket SPW I/O 316L 22. Routing and connection to TPP-12 3/4" #150 RF ASME B 16.5 of Plant air supply line bolts - 1/2"x60 4 pcs + gasket SPW I/O 316L 23. Install and connect two light fixtures in tote tank area. 24. Pull and connect profibus interface cable to RIO in pump unit. 25. Pull and connect clean earth cables to RIO’s and LCP’s. 26. Pull and connect power supply to light fixture in maintenance platform from nearby light circuit. 27. compressed air tubing for TOTE TANK foot valve (OD10x1.5mm L=4m + 2 OD10 x 1/4" NPT male terminals + 1 ball valve 1/4" + flex hose 1/4" NPT L=1m + 1/8"BSPx1/4" quick conn. Male & 1/4"Female + 1bushing 3/4Mx1/4F NPT+ 4 thd 1/4" NPT 90 elbow + 6 clamp supports + 8 hex nipple 1/4" NPT). NOTE: All strike out activi- ties are Customer scope and super- vised by Supplier. 31 33 28. mounting of pressure safety device PY7771. a. bracket adapting and mounting b. tubing connection OD10x1,5mm mounting. 29. mounting on missing tags. 30. replacement of wrong lenght bolts on piping. 31. installing of drain plugs on K32YC04. 32. installing of drain plugs on K32YC06. 33. replacement of relief valves RV7734A/B. 34. Missing Antislip rung mounting. 35. Interlock system for the valves K32HOV542 and 543 36. Green dot to be added for the open position of the valve K32HOV526. 37. Anchoring system for the earthing bars inside the Electrical and Instrumentation Cabinets

- 3. DRA.K32Z10 - OFFSHORE ERECTION MECHANICAL WORK PACK DESCRIPTION - 2 1. Bolting the skid in place (12 pcs., M24x130), 2. Mounting of ladder (bolts: 12 pcs. bolts M12x45mm+12 nuts M12+24 washers - cl.8.8/cl.8/HV140 hot dip galv.), 3. Mounting of handrails (bolts: 21 pcs. M16x60+nuts M16+2washers mm cl. 8.8/cl.8/HV140 hot dip galv.), 4. Mounting of pad eyes covers (2 pcs, bolts: 5 pcs/each Hex socket countersunk head scrw. M6x10 mm SS), 5. Mounting of bumpers (bolts: 24 pcs. M16x90+2nutsM16+2washers hot dip galv.; rubber pads: 8pcs; springs supports for TODO couplings: 2pcs.), 6. Mounting of safety gate (bolts: 4pcs. M8x16+washer hot dip galv.), 7. Mounting of dispenser unit: a. Hold down Bolts: 8pcs.M20x30+washer hot dip galv., b. Earth bounding M10, c. Open hazardous drain connection (bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv. +1gsk.2"spiral wound I/O 316L), d. Pipes spool mounting i. 2” fuel line spool no. 11, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, ii. 2” fuel line spool no. 18, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, iii. 2” fuel line spool no. 17, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, iv. 2” deluge spool no. 13, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, v. 2” deluge spool no. 5, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, vi. ¾” sample line spool no. 38, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, vii. ¾” sample recycle line spool no. 39, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, e. Cables routing and connection to RIO and JB’s terminals, 8. Mounting of eyewash container, heater cable connection to JB, brackets+thd bar M6/M8+nuts/washers, 9. Mounting of loose gratings on top level of skid (2 or 3 pcs over the lifting pad eyes), bolts 8pcs. compl. of 2 brackets+1nut hot dip galv., 10. Mounting of transfer (2” compl. of bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L) and sample (3/4” compl. of bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L) flexible hoses for transportable tank, 11. Mounting of loose flame detectors on brackets + cable routing and connection to JB, bolts: 4pcs./each M8x30+1nut+2washers, 12. Mounting of Local Control System in Safe area, 13. Mounting of SCADA system in Telecom room, 14. Connecting of skid to open hazardous drain system, bolts: 8pcs. 3/4"x115mm+2nuts+2washers hot dip galv.+1gsk.8"spiral wound I/O 316L, 15. Positioning and anchoring of fire extinguishers, 16. Mounting of cable trays from LCS location to AFS Skid location, 17. Routing of cables from LCS to AFS and connect to JB and cabinet terminals, 18. Routing of cable from LCS to DCS and connection to cabinets terminals, 19. Routing of cables from LCS to SCADA system and connection to cabinets terminals, 20 21 22 1. Bolting the skid in place (12 pcs., M24x130), 2. Mounting of ladder (bolts: 12 pcs. bolts M12x45mm+12 nuts M12+24 washers - cl.8.8/cl.8/HV140 hot dip galv.), 3. Mounting of handrails (bolts: 21 pcs. M16x60+nuts M16+2washers mm cl. 8.8/cl.8/HV140 hot dip galv.), 4. Mounting of pad eyes covers (2 pcs, bolts: 5 pcs/each Hex socket countersunk head scrw. M6x10 mm SS), 5. Mounting of bumpers (bolts: 24 pcs. M16x90+2nutsM16+2washers hot dip galv.; rubber pads: 8pcs; springs supports for TODO couplings: 2pcs.), 6. Mounting of safety gate (bolts: 4pcs. M8x16+washer hot dip galv.), 7. Mounting of dispenser unit: a. Hold down Bolts: 8pcs.M20x30+washer hot dip galv., b. Earth bounding M10, c. Open hazardous drain connection (bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv. +1gsk.2"spiral wound I/O 316L), d. Pipes spool mounting i. 2” fuel line spool no. 11, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, ii. 2” fuel line spool no. 18, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, iii. 2” fuel line spool no. 8, bolts: 24pcs. 5/8"x90mm+24nuts+24washers hot dip galv.+6gsk.2"spiral wound I/O 316L, iv. 2” deluge spool no. 13, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, v. 2” deluge spool no. 5, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, vi. ¾” sample line spool no. 38, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, vii. ¾” sample recycle line spool no. 39, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, e. dispenser cables routing and connection to RIO in pump compartment, JB’s including yellow light and light fixtures power supply, f. dispenser air supply OD20 mm connection 8. Mounting of eyewash container and terminate cable to heater, brackets+thd bar M6/M8+nuts/washers, 9. Mounting of loose gratings on top level of skid (2 or 3 pcs over the lifting pad eyes), bolts 8pcs. compl. of 2 brackets+1nut hot dip galv., 10. Mounting of transfer (2” compl. of bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L) and sample (3/4” compl. of bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L) flexible hoses for transportable tank, 11. Mounting of loose flame detectors on brackets + cable routing and connection to JB, bolts: 4pcs./each M8x30+1nut+2washers, 12. Mounting of Local Control System in Safe area, 13. Mounting of SCADA system in Telecom room, 14. Connecting of skid to open hazardous drain system, bolts: 8pcs. 3/4"x115mm+2nuts+2washers hot dip galv.+1gsk.8"spiral wound I/O 316L, 15. Positioning and anchoring of fire extinguishers, 16. Mounting of cable trays from LCS location to AFS Skid location, 17. Routing of cables from LCS to AFS and connect to JB and cabinet terminals, 18. Routing of cable from LCS to DCS and connection to cabinets terminals, 19. Routing of cables from LCS to SCADA system and connection to cabinets terminals, 20. Routing and connection to TP-105 3" #150 RF ASME B 16.5 of deluge supply line - bolts 5/8"x95 4 pcs + gasket SPW I/O 316L 21. Routing and connection to TPP-11 3/4" #150 RF ASME B 16.5 of Instrumentation air supply line - bolts 1/2"x60 4 pcs + gasket SPW I/O 316L 22. Routing and connection to TPP-12 3/4" #150 RF ASME B 16.5 of Plant air supply line bolts - 1/2"x60 4 pcs + gasket SPW I/O 316L 23. Install and connect two light fixtures in tote tank area. 24. Pull and connect profibus interface cable to RIO in pump unit. 25. Pull and connect clean earth cables to RIO’s and LCP’s. 26. Pull and connect power supply to light fixture in maintenance platform from nearby light circuit. 27. compressed air tubing for TOTE TANK foot valve (OD10x1.5mm L=4m + 2 OD10 x 1/4" NPT male terminals + 1 ball valve 1/4" + flex hose 1/4" NPT L=1m + 1/8"BSPx1/4" quick conn. Male & 1/4"Female + 1bushing 3/4Mx1/4F NPT+ 4 thd 1/4" NPT 90 elbow + 6 clamp supports + 8 hex nipple 1/4" NPT). 27 34 32 28 36 28. mounting of pressure safety device PY7771. a. bracket adapting and mounting b. tubing connection OD10x1,5mm mounting. 29. mounting on missing tags. 30. replacement of wrong lenght bolts on piping. 31. installing of drain plugs on K32YC04. 32. installing of drain plugs on K32YC06. 33. replacement of relief valves RV7734A/B. 34. Missing Antislip rung mounting. 35. Interlock system for the valves K32HOV542 and 543 36. Green dot to be added for the open position of the valve K32HOV526. 37. Anchoring system for the earthing bars inside the Electrical and Instrumentation Cabinets NOTE: All strike out activi- ties are Customer scope and super- vised by Supplier.

- 4. DRA.K32Z10 - OFFSHORE ERECTION MECHANICAL WORK PACK DESCRIPTION - 3 1. Bolting the skid in place (12 pcs., M24x130), 2. Mounting of ladder (bolts: 12 pcs. bolts M12x45mm+12 nuts M12+24 washers - cl.8.8/cl.8/HV140 hot dip galv.), 3. Mounting of handrails (bolts: 21 pcs. M16x60+nuts M16+2washers mm cl. 8.8/cl.8/HV140 hot dip galv.), 4. Mounting of pad eyes covers (2 pcs, bolts: 5 pcs/each Hex socket countersunk head scrw. M6x10 mm SS), 5. Mounting of bumpers (bolts: 24 pcs. M16x90+2nutsM16+2washers hot dip galv.; rubber pads: 8pcs; springs supports for TODO couplings: 2pcs.), 6. Mounting of safety gate (bolts: 4pcs. M8x16+washer hot dip galv.), 7. Mounting of dispenser unit: a. Hold down Bolts: 8pcs.M20x30+washer hot dip galv., b. Earth bounding M10, c. Open hazardous drain connection (bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv. +1gsk.2"spiral wound I/O 316L), d. Pipes spool mounting i. 2” fuel line spool no. 11, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, ii. 2” fuel line spool no. 18, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, iii. 2” fuel line spool no. 17, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, iv. 2” deluge spool no. 13, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, v. 2” deluge spool no. 5, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, vi. ¾” sample line spool no. 38, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, vii. ¾” sample recycle line spool no. 39, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, e. Cables routing and connection to RIO and JB’s terminals, 8. Mounting of eyewash container, heater cable connection to JB, brackets+thd bar M6/M8+nuts/washers, 9. Mounting of loose gratings on top level of skid (2 or 3 pcs over the lifting pad eyes), bolts 8pcs. compl. of 2 brackets+1nut hot dip galv., 10. Mounting of transfer (2” compl. of bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L) and sample (3/4” compl. of bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L) flexible hoses for transportable tank, 11. Mounting of loose flame detectors on brackets + cable routing and connection to JB, bolts: 4pcs./each M8x30+1nut+2washers, 12. Mounting of Local Control System in Safe area, 13. Mounting of SCADA system in Telecom room, 14. Connecting of skid to open hazardous drain system, bolts: 8pcs. 3/4"x115mm+2nuts+2washers hot dip galv.+1gsk.8"spiral wound I/O 316L, 15. Positioning and anchoring of fire extinguishers, 16. Mounting of cable trays from LCS location to AFS Skid location, 17. Routing of cables from LCS to AFS and connect to JB and cabinet terminals, 18. Routing of cable from LCS to DCS and connection to cabinets terminals, 19. Routing of cables from LCS to SCADA system and connection to cabinets terminals, 1. Bolting the skid in place (12 pcs., M24x130), 2. Mounting of ladder (bolts: 12 pcs. bolts M12x45mm+12 nuts M12+24 washers - cl.8.8/cl.8/HV140 hot dip galv.), 3. Mounting of handrails (bolts: 21 pcs. M16x60+nuts M16+2washers mm cl. 8.8/cl.8/HV140 hot dip galv.), 4. Mounting of pad eyes covers (2 pcs, bolts: 5 pcs/each Hex socket countersunk head scrw. M6x10 mm SS), 5. Mounting of bumpers (bolts: 24 pcs. M16x90+2nutsM16+2washers hot dip galv.; rubber pads: 8pcs; springs supports for TODO couplings: 2pcs.), 6. Mounting of safety gate (bolts: 4pcs. M8x16+washer hot dip galv.), 7. Mounting of dispenser unit: a. Hold down Bolts: 8pcs.M20x30+washer hot dip galv., b. Earth bounding M10, c. Open hazardous drain connection (bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv. +1gsk.2"spiral wound I/O 316L), d. Pipes spool mounting i. 2” fuel line spool no. 11, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, ii. 2” fuel line spool no. 18, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, iii. 2” fuel line spool no. 8, bolts: 24pcs. 5/8"x90mm+24nuts+24washers hot dip galv.+6gsk.2"spiral wound I/O 316L, iv. 2” deluge spool no. 13, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, v. 2” deluge spool no. 5, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, vi. ¾” sample line spool no. 38, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, vii. ¾” sample recycle line spool no. 39, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, e. dispenser cables routing and connection to RIO in pump compartment, JB’s including yellow light and light fixtures power supply, f. dispenser air supply OD20 mm connection 8. Mounting of eyewash container and terminate cable to heater, brackets+thd bar M6/M8+nuts/washers, 9. Mounting of loose gratings on top level of skid (2 or 3 pcs over the lifting pad eyes), bolts 8pcs. compl. of 2 brackets+1nut hot dip galv., 10. Mounting of transfer (2” compl. of bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L) and sample (3/4” compl. of bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L) flexible hoses for transportable tank, 11. Mounting of loose flame detectors on brackets + cable routing and connection to JB, bolts: 4pcs./each M8x30+1nut+2washers, 12. Mounting of Local Control System in Safe area, 13. Mounting of SCADA system in Telecom room, 14. Connecting of skid to open hazardous drain system, bolts: 8pcs. 3/4"x115mm+2nuts+2washers hot dip galv.+1gsk.8"spiral wound I/O 316L, 15. Positioning and anchoring of fire extinguishers, 16. Mounting of cable trays from LCS location to AFS Skid location, 17. Routing of cables from LCS to AFS and connect to JB and cabinet terminals, 18. Routing of cable from LCS to DCS and connection to cabinets terminals, 19. Routing of cables from LCS to SCADA system and connection to cabinets terminals, 20. Routing and connection to TP-105 3" #150 RF ASME B 16.5 of deluge supply line - bolts 5/8"x95 4 pcs + gasket SPW I/O 316L 21. Routing and connection to TPP-11 3/4" #150 RF ASME B 16.5 of Instrumentation air supply line - bolts 1/2"x60 4 pcs + gasket SPW I/O 316L 22. Routing and connection to TPP-12 3/4" #150 RF ASME B 16.5 of Plant air supply line bolts - 1/2"x60 4 pcs + gasket SPW I/O 316L 23. Install and connect two light fixtures in tote tank area. 24. Pull and connect profibus interface cable to RIO in pump unit. 25. Pull and connect clean earth cables to RIO’s and LCP’s. 26. Pull and connect power supply to light fixture in maintenance platform from nearby light circuit. 27. compressed air tubing for TOTE TANK foot valve (OD10x1.5mm L=4m + 2 OD10 x 1/4" NPT male terminals + 1 ball valve 1/4" + flex hose 1/4" NPT L=1m + 1/8"BSPx1/4" quick conn. Male & 1/4"Female + 1bushing 3/4Mx1/4F NPT+ 4 thd 1/4" NPT 90 elbow + 6 clamp supports + 8 hex nipple 1/4" NPT). 27 28. mounting of pressure safety device PY7771. a. bracket adapting and mounting b. tubing connection OD10x1,5mm mounting. 29. mounting on missing tags. 30. replacement of wrong lenght bolts on piping. 31. installing of drain plugs on K32YC04. 32. installing of drain plugs on K32YC06. 33. replacement of relief valves RV7734A/B. 34. Missing Antislip rung mounting. 35. Interlock system for the valves K32HOV542 and 543 36. Green dot to be added for the open position of the valve K32HOV526. 37. Anchoring system for the earthing bars inside the Electrical and Instrumentation Cabinets NOTE: All strike out activi- ties are Customer scope and super- vised by Supplier.

- 5. DRA.K32Z10 - OFFSHORE ERECTION MECHANICAL WORK PACK DESCRIPTION - 4 1. Bolting the skid in place (12 pcs., M24x130), 2. Mounting of ladder (bolts: 12 pcs. bolts M12x45mm+12 nuts M12+24 washers - cl.8.8/cl.8/HV140 hot dip galv.), 3. Mounting of handrails (bolts: 21 pcs. M16x60+nuts M16+2washers mm cl. 8.8/cl.8/HV140 hot dip galv.), 4. Mounting of pad eyes covers (2 pcs, bolts: 5 pcs/each Hex socket countersunk head scrw. M6x10 mm SS), 5. Mounting of bumpers (bolts: 24 pcs. M16x90+2nutsM16+2washers hot dip galv.; rubber pads: 8pcs; springs supports for TODO couplings: 2pcs.), 6. Mounting of safety gate (bolts: 4pcs. M8x16+washer hot dip galv.), 7. Mounting of dispenser unit: a. Hold down Bolts: 8pcs.M20x30+washer hot dip galv., b. Earth bounding M10, c. Open hazardous drain connection (bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv. +1gsk.2"spiral wound I/O 316L), d. Pipes spool mounting i. 2” fuel line spool no. 11, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, ii. 2” fuel line spool no. 18, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, iii. 2” fuel line spool no. 17, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, iv. 2” deluge spool no. 13, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, v. 2” deluge spool no. 5, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, vi. ¾” sample line spool no. 38, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, vii. ¾” sample recycle line spool no. 39, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, e. Cables routing and connection to RIO and JB’s terminals, 8. Mounting of eyewash container, heater cable connection to JB, brackets+thd bar M6/M8+nuts/washers, 9. Mounting of loose gratings on top level of skid (2 or 3 pcs over the lifting pad eyes), bolts 8pcs. compl. of 2 brackets+1nut hot dip galv., 10. Mounting of transfer (2” compl. of bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L) and sample (3/4” compl. of bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L) flexible hoses for transportable tank, 11. Mounting of loose flame detectors on brackets + cable routing and connection to JB, bolts: 4pcs./each M8x30+1nut+2washers, 12. Mounting of Local Control System in Safe area, 13. Mounting of SCADA system in Telecom room, 14. Connecting of skid to open hazardous drain system, bolts: 8pcs. 3/4"x115mm+2nuts+2washers hot dip galv.+1gsk.8"spiral wound I/O 316L, 15. Positioning and anchoring of fire extinguishers, 16. Mounting of cable trays from LCS location to AFS Skid location, 17. Routing of cables from LCS to AFS and connect to JB and cabinet terminals, 18. Routing of cable from LCS to DCS and connection to cabinets terminals, 19. Routing of cables from LCS to SCADA system and connection to cabinets terminals, 1. Bolting the skid in place (12 pcs., M24x130), 2. Mounting of ladder (bolts: 12 pcs. bolts M12x45mm+12 nuts M12+24 washers - cl.8.8/cl.8/HV140 hot dip galv.), 3. Mounting of handrails (bolts: 21 pcs. M16x60+nuts M16+2washers mm cl. 8.8/cl.8/HV140 hot dip galv.), 4. Mounting of pad eyes covers (2 pcs, bolts: 5 pcs/each Hex socket countersunk head scrw. M6x10 mm SS), 5. Mounting of bumpers (bolts: 24 pcs. M16x90+2nutsM16+2washers hot dip galv.; rubber pads: 8pcs; springs supports for TODO couplings: 2pcs.), 6. Mounting of safety gate (bolts: 4pcs. M8x16+washer hot dip galv.), 7. Mounting of dispenser unit: a. Hold down Bolts: 8pcs.M20x30+washer hot dip galv., b. Earth bounding M10, c. Open hazardous drain connection (bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv. +1gsk.2"spiral wound I/O 316L), d. Pipes spool mounting i. 2” fuel line spool no. 11, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, ii. 2” fuel line spool no. 18, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, iii. 2” fuel line spool no. 17, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, iv. 2” deluge spool no. 13, bolts: 8pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, v. 2” deluge spool no. 5, bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L, vi. ¾” sample line spool no. 38, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, vii. ¾” sample recycle line spool no. 39, bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L, e. dispenser cables routing and connection to RIO in pump compartment, JB’s including yellow light and light fixtures power supply, f. dispenser air supply OD20 mm connection 8. Mounting of eyewash container and terminate cable to heater, brackets+thd bar M6/M8+nuts/washers, 9. Mounting of loose gratings on top level of skid (2 or 3 pcs over the lifting pad eyes), bolts 8pcs. compl. of 2 brackets+1nut hot dip galv., 10. Mounting of transfer (2” compl. of bolts: 4pcs. 5/8"x90mm+2nuts+2washers hot dip galv.+1gsk.2"spiral wound I/O 316L) and sample (3/4” compl. of bolts: 8pcs. 1/2"x65mm+2nuts+2washers hot dip galv.+2gsk.2"spiral wound I/O 316L) flexible hoses for transportable tank, 11. Mounting of loose flame detectors on brackets + cable routing and connection to JB, bolts: 4pcs./each M8x30+1nut+2washers, 12. Mounting of Local Control System in Safe area, 13. Mounting of SCADA system in Telecom room, 14. Connecting of skid to open hazardous drain system, bolts: 8pcs. 3/4"x115mm+2nuts+2washers hot dip galv.+1gsk.8"spiral wound I/O 316L, 15. Positioning and anchoring of fire extinguishers, 16. Mounting of cable trays from LCS location to AFS Skid location, 17. Routing of cables from LCS to AFS and connect to JB and cabinet terminals, 18. Routing of cable from LCS to DCS and connection to cabinets terminals, 19. Routing of cables from LCS to SCADA system and connection to cabinets terminals, 20. Routing and connection to TP-105 3" #150 RF ASME B 16.5 of deluge supply line - bolts 5/8"x95 4 pcs + gasket SPW I/O 316L 21. Routing and connection to TPP-11 3/4" #150 RF ASME B 16.5 of Instrumentation air supply line - bolts 1/2"x60 4 pcs + gasket SPW I/O 316L 22. Routing and connection to TPP-12 3/4" #150 RF ASME B 16.5 of Plant air supply line bolts - 1/2"x60 4 pcs + gasket SPW I/O 316L 23. Install and connect two light fixtures in tote tank area. 24. Pull and connect profibus interface cable to RIO in pump unit. 25. Pull and connect clean earth cables to RIO’s and LCP’s. 26. Pull and connect power supply to light fixture in maintenance platform from nearby light circuit. 27. compressed air tubing for TOTE TANK foot valve (OD10x1.5mm L=4m + 2 OD10 x 1/4" NPT male terminals + 1 ball valve 1/4" + flex hose 1/4" NPT L=1m + 1/8"BSPx1/4" quick conn. Male & 1/4"Female + 1bushing 3/4Mx1/4F NPT+ 4 thd 1/4" NPT 90 elbow + 6 clamp supports + 8 hex nipple 1/4" NPT). 7.f 28. mounting of pressure safety device PY7771. a. bracket adapting and mounting b. tubing connection OD10x1,5mm mounting. 29. mounting on missing tags. 30. replacement of wrong lenght bolts on piping. 31. installing of drain plugs on K32YC04. 32. installing of drain plugs on K32YC06. 33. replacement of relief valves RV7734A/B. 34. Missing Antislip rung mounting. 35. Interlock system for the valves K32HOV542 and 543 36. Green dot to be added for the open position of the valve K32HOV526. 37. Anchoring system for the earthing bars inside the Electrical and Instrumentation Cabinets 36 C NOTE: All strike out activi- ties are Customer scope and super- vised by Supplier.

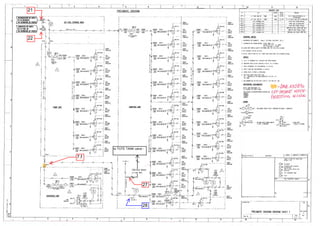

- 6. 7.d.i 7.d.ii7.d.iv DISPENSER INSTALLATION EXPLANATORY IMAGES

- 7. 7.d.iv 7.d.v 7.d.vi 7.d.i 7.d.vii 7.d.iii 7.d.ii9.2 DISPENSER INSTALLATION EXPLANATORY IMAGES

- 8. 7.e DISPENSER INSTALLATION EXPLANATORY IMAGES