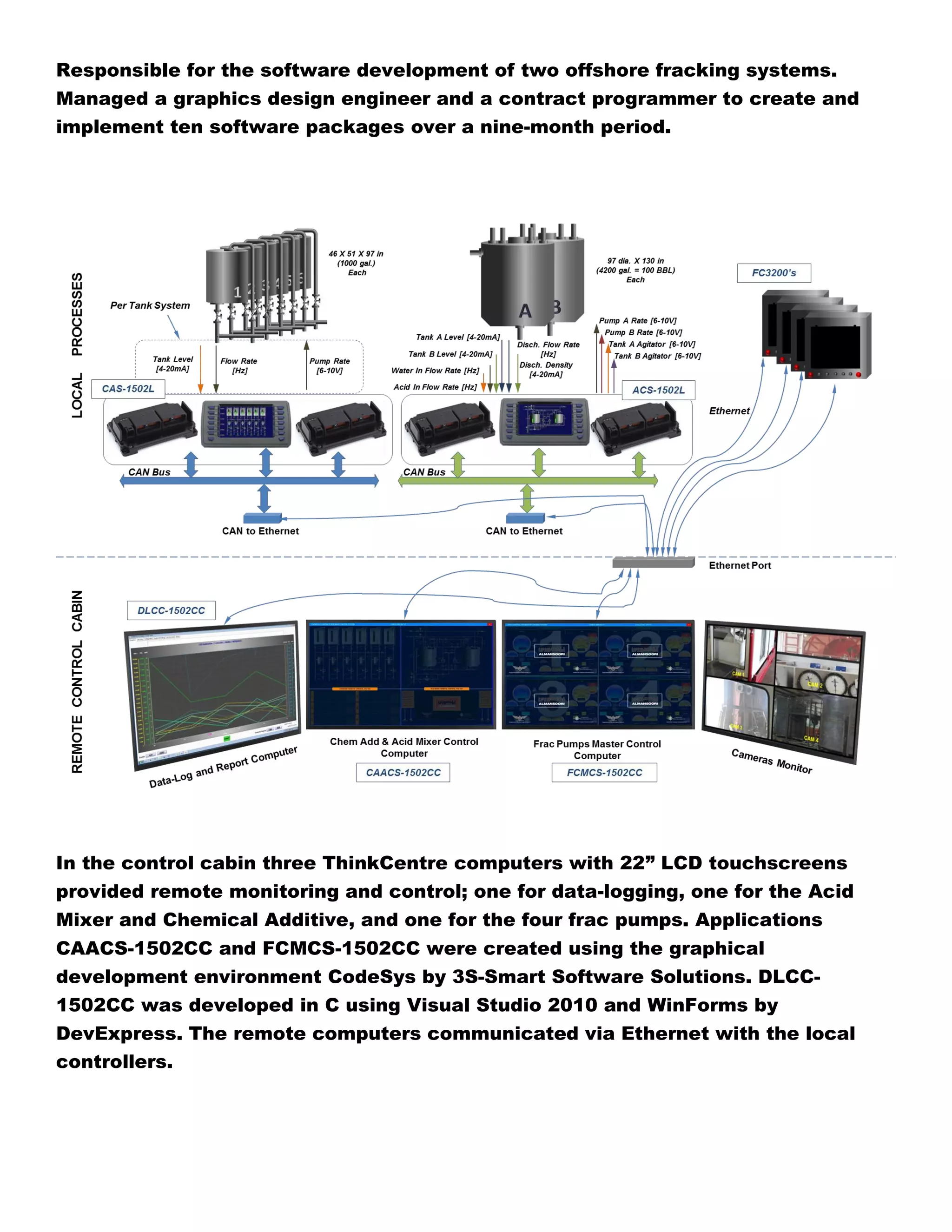

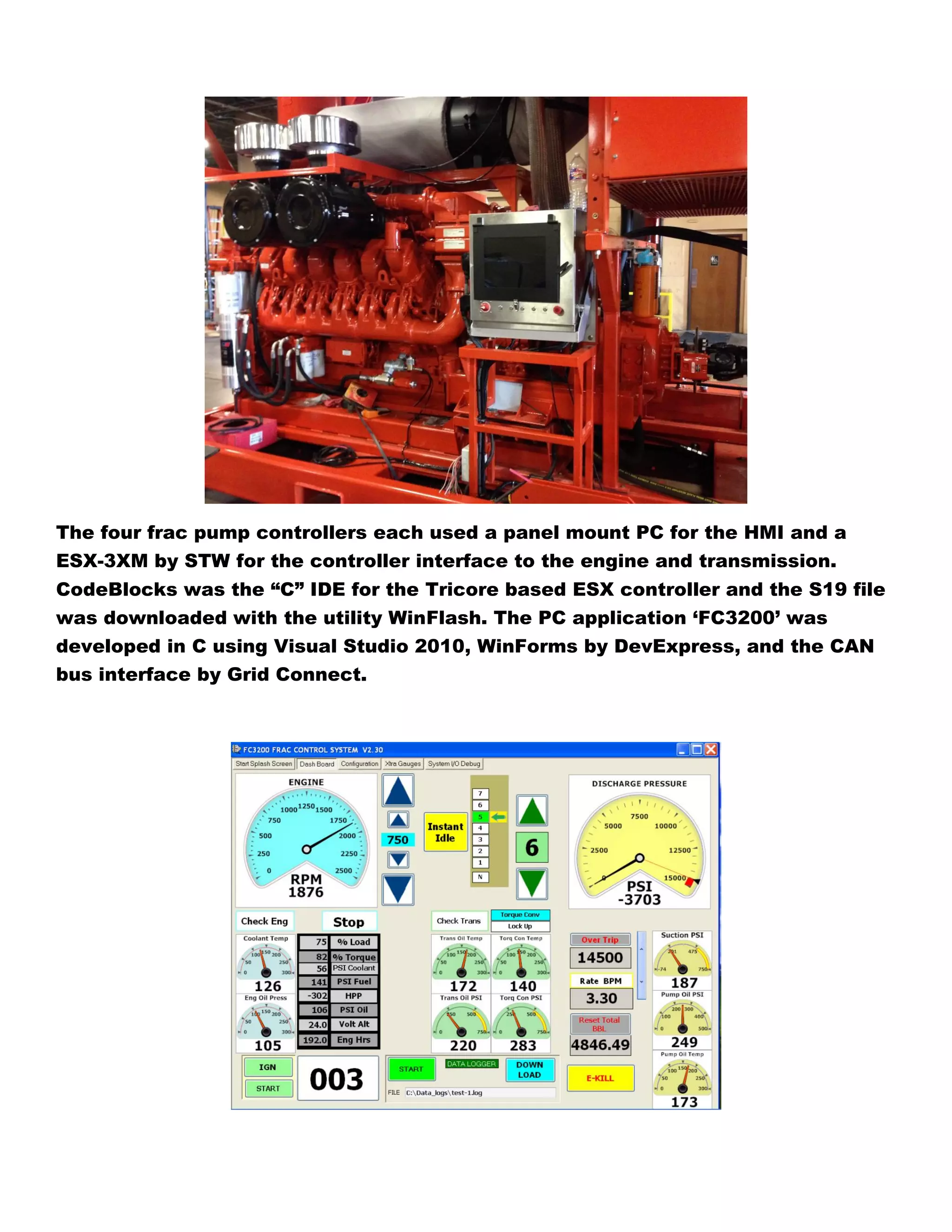

Responsible for developing ten software packages over nine months to control offshore fracking systems, including applications for remote monitoring and control of data logging, an acid mixer, chemical additive, and four frac pumps from three touchscreen computers. The acid mixer and chemical additive each used a VFX front panel with HFX modules communicating via PRO-FX software to the remote computer over CANNET and J1939 protocols. The four frac pump controllers used panel PCs and ESX-3XM interfaces with applications programmed in CodeBlocks and WinFlash to control engine and transmission components over a CAN bus interface.