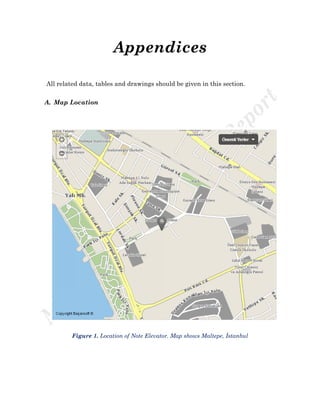

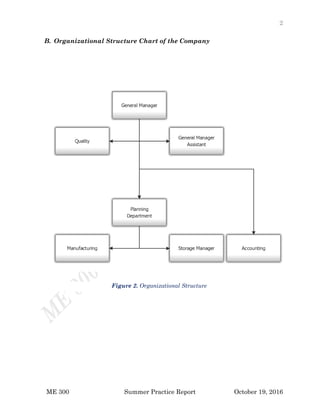

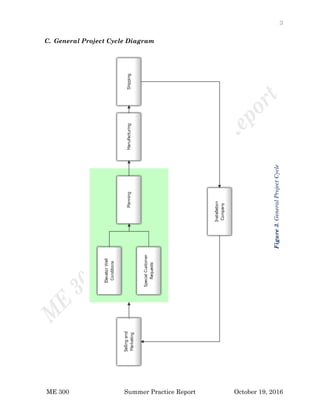

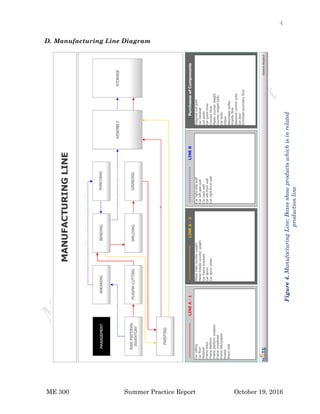

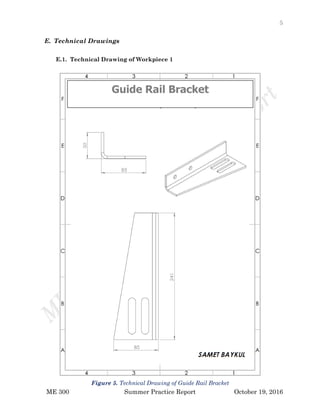

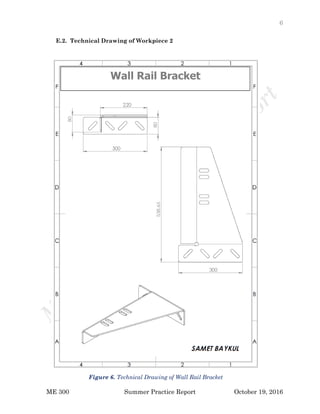

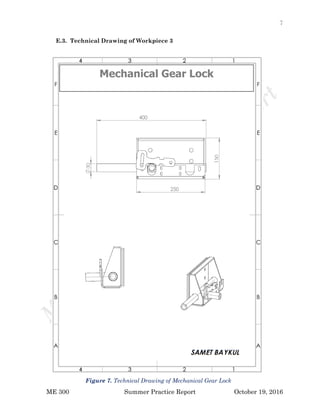

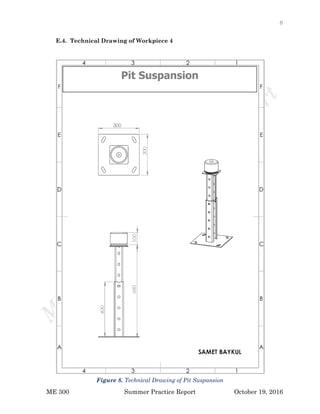

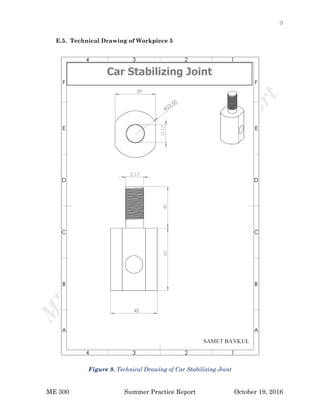

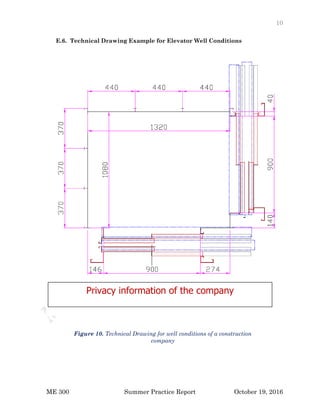

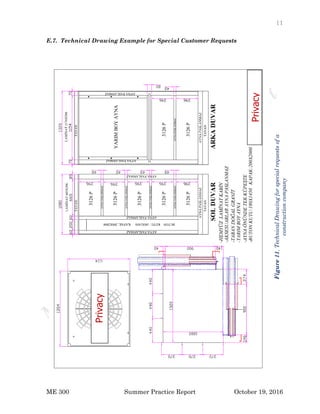

The ME300 Summer Practice Report by Samet Baykul provides an overview of the Note Elevator company, detailing its organizational structure, manufacturing processes, and specific projects undertaken during an internship. The report outlines the technical and operational aspects of the elevator manufacturing process, including various techniques such as shearing, drilling, and welding. It highlights the company's focus on delivering customized elevator solutions and the challenges faced in manufacturing efficiency and quality control.

![ii

ME 300 Summer Practice Report October 19, 2016

References

Asansör Sektörü Raporu (Sektörel Raporlar ve Analizler Serisi) [2]. (2015). Retrieved

from http://aysad.org.tr/Document/NoticeDocumentGalery/2015-2 Asansor-

sektoru-raporu-20-2112015133019.pdf

Black, J.T., & Kohser R.A. (2008). Materials & Processes in Manufacturing. U.S: Wiley.

Otis Elevator. Elevator 101 Introduction to Elevator Technology Technology. Retrieved

October 12, 2016, from Mass,

http://www.mass.gov/anf/docs/dcam/mafma/tutorials/elevator-101.pdf

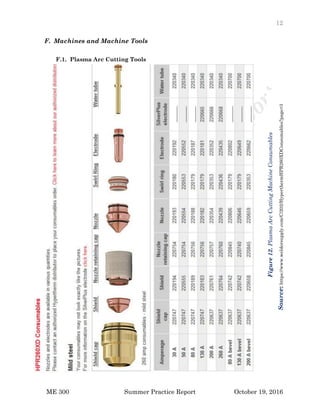

Hypertherm HPR260XD Consumable Parts

https://www.weldersupply.com/C/202/HyperthermHPR260XDConsumables?page=3

Shaun. (2013, January 29). Basic elevator components - part One. Retrieved October 12,

2016, from electrical-knowhow, http://www.electrical-

knowhow.com/2012/04/basic-elevator-components-part-one.html](https://image.slidesharecdn.com/2016-190801205111/85/Note-Elevator-Summer-Practice-Report-67-320.jpg)