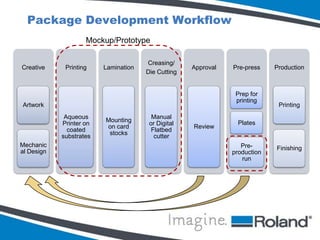

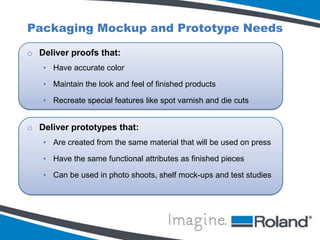

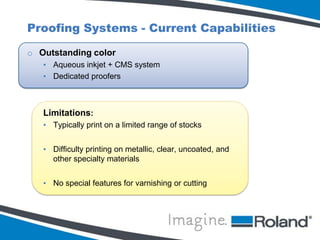

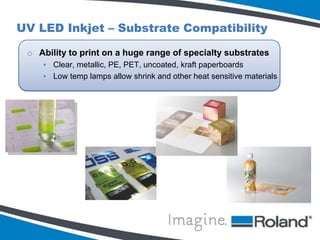

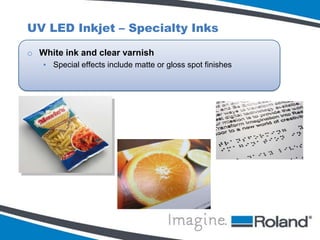

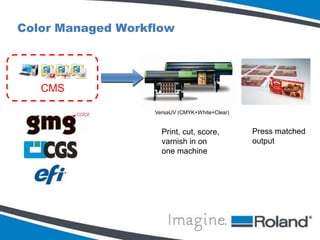

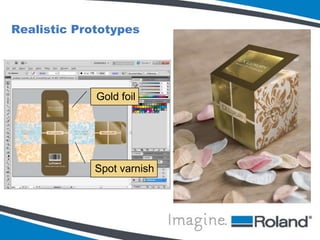

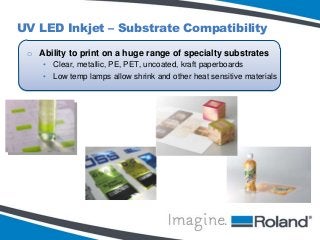

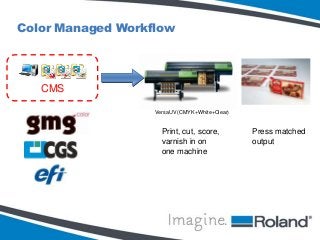

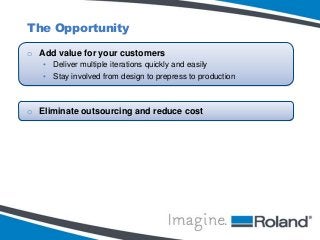

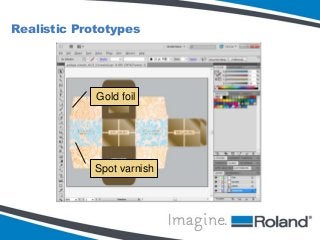

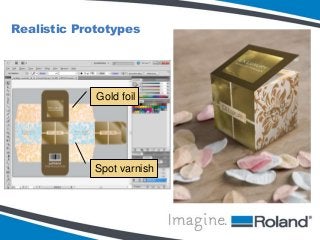

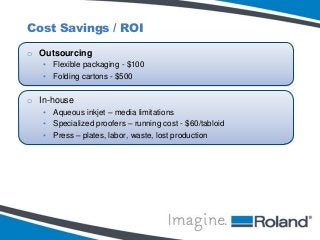

The document discusses advancements in packaging technologies at Roland DGA, focusing on workflows that encompass high-resolution printing, cutting, and prototype development. It highlights the benefits of UV LED inkjet, including substrate compatibility and integrated cutting capabilities, as well as cost savings by eliminating outsourcing. The document emphasizes the value added to customers through efficient proofing systems, realistic prototypes, and reduced waste.