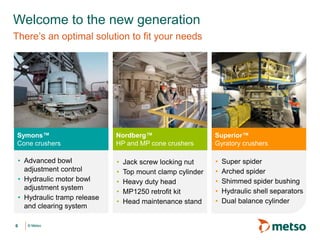

Metso offers new generation crusher upgrades that can improve productivity by up to 30% while lowering operational costs. The upgrades are available in easy-to-install kits and can be handled by a customer's maintenance crew or installed by Metso experts. As the original equipment manufacturer, Metso understands customers' crushing operations and needs, and offers a range of upgrade packages for cone crushers, gyratory crushers, and other crushing equipment to optimize performance, safety, and maintenance.