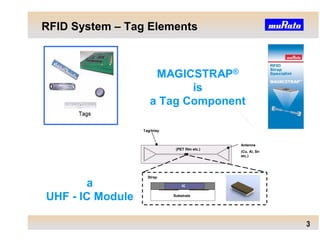

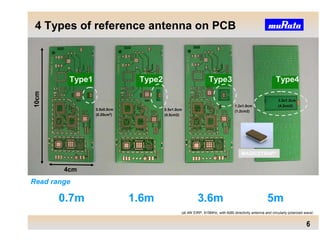

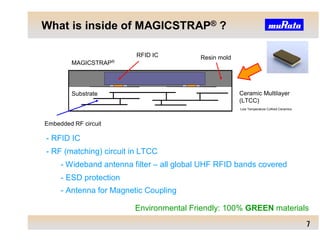

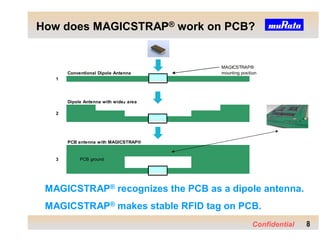

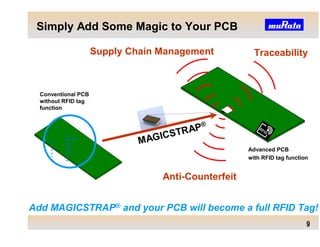

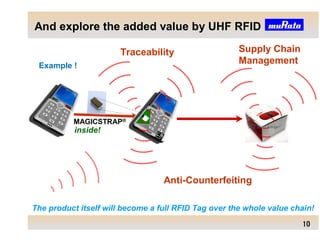

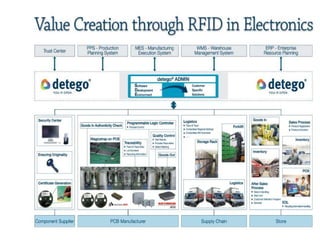

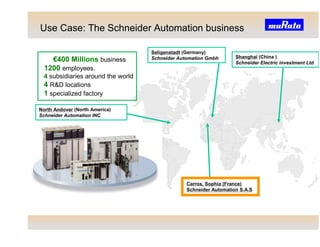

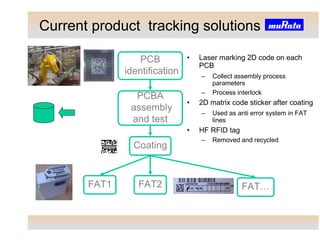

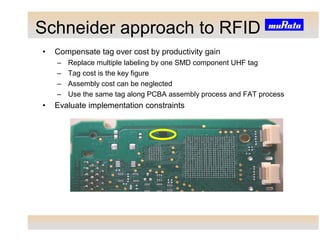

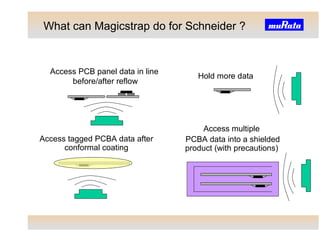

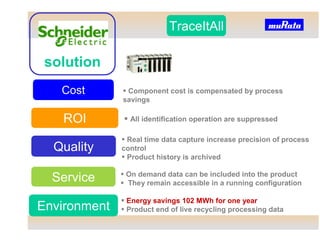

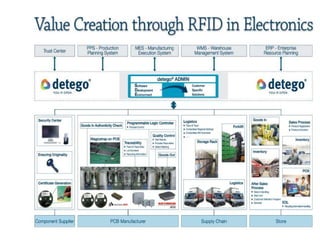

The document discusses how Murata's MAGICSTRAP product can be used to add RFID tagging capabilities to printed circuit boards (PCBs). MAGICSTRAP is an RFID tag component that can be placed directly on existing metal layers in a PCB or other substrate to act as the antenna, without needing additional antenna circuitry. This allows PCBs and other electronics to be easily tagged for applications like supply chain management, traceability, and anti-counterfeiting. A case study is presented of how Schneider Electric uses MAGICSTRAP to tag their PCBs for improved production tracking and quality control.