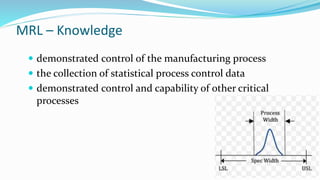

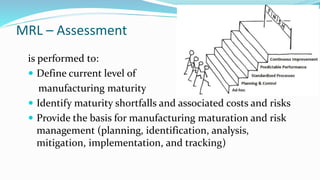

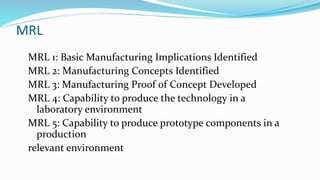

The document discusses Manufacturing Readiness Level (MRL) assessments, which evaluate the maturity of manufacturing processes, technologies, and systems. MRL assessments are performed to define the current level of manufacturing maturity, identify risks and costs, and provide a basis for further maturation. They target acquisition program managers, technology developers, and those intending to transition technologies to acquisition programs. The assessments evaluate manufacturing status, production readiness, management, and capability. MRL levels range from basic manufacturing implications being identified to full rate production being demonstrated.