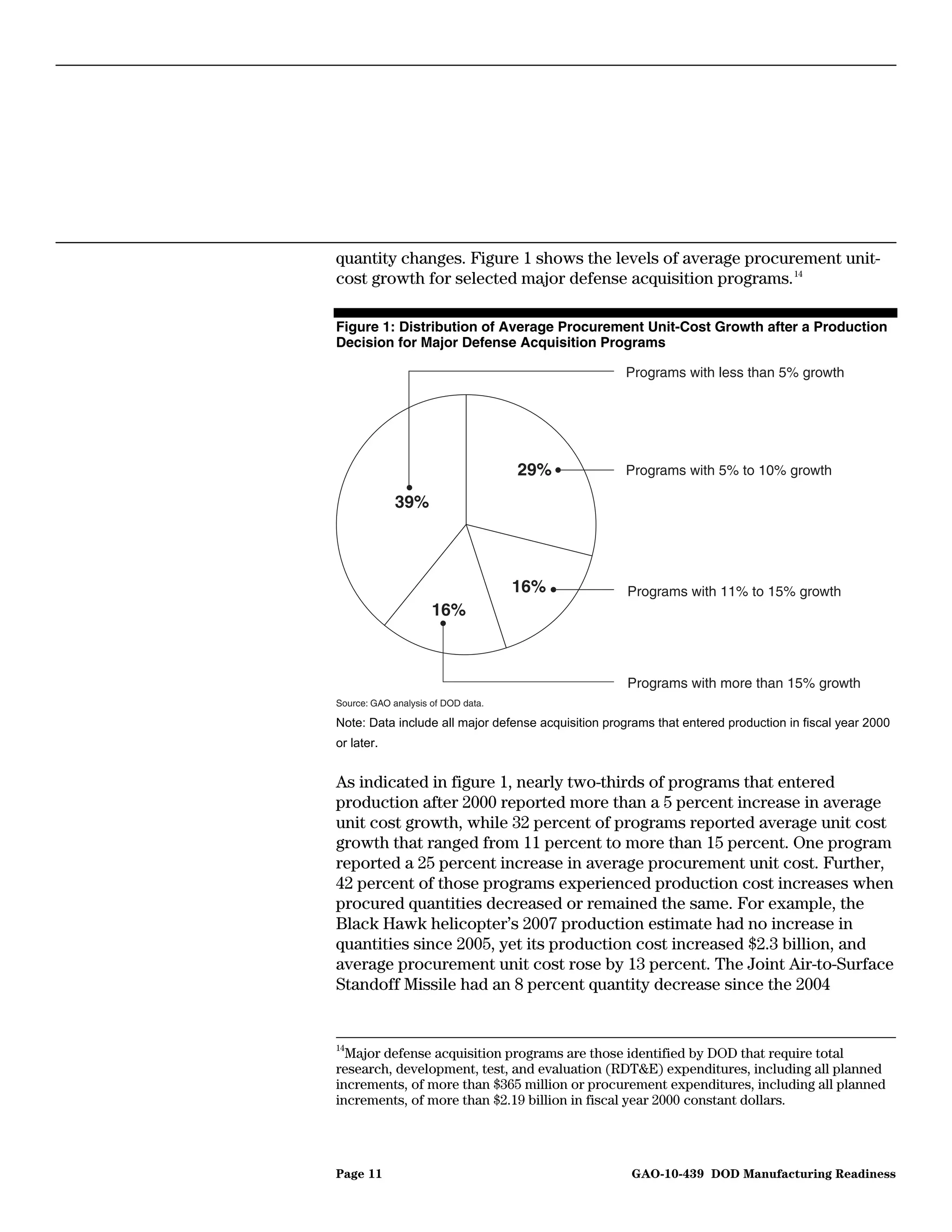

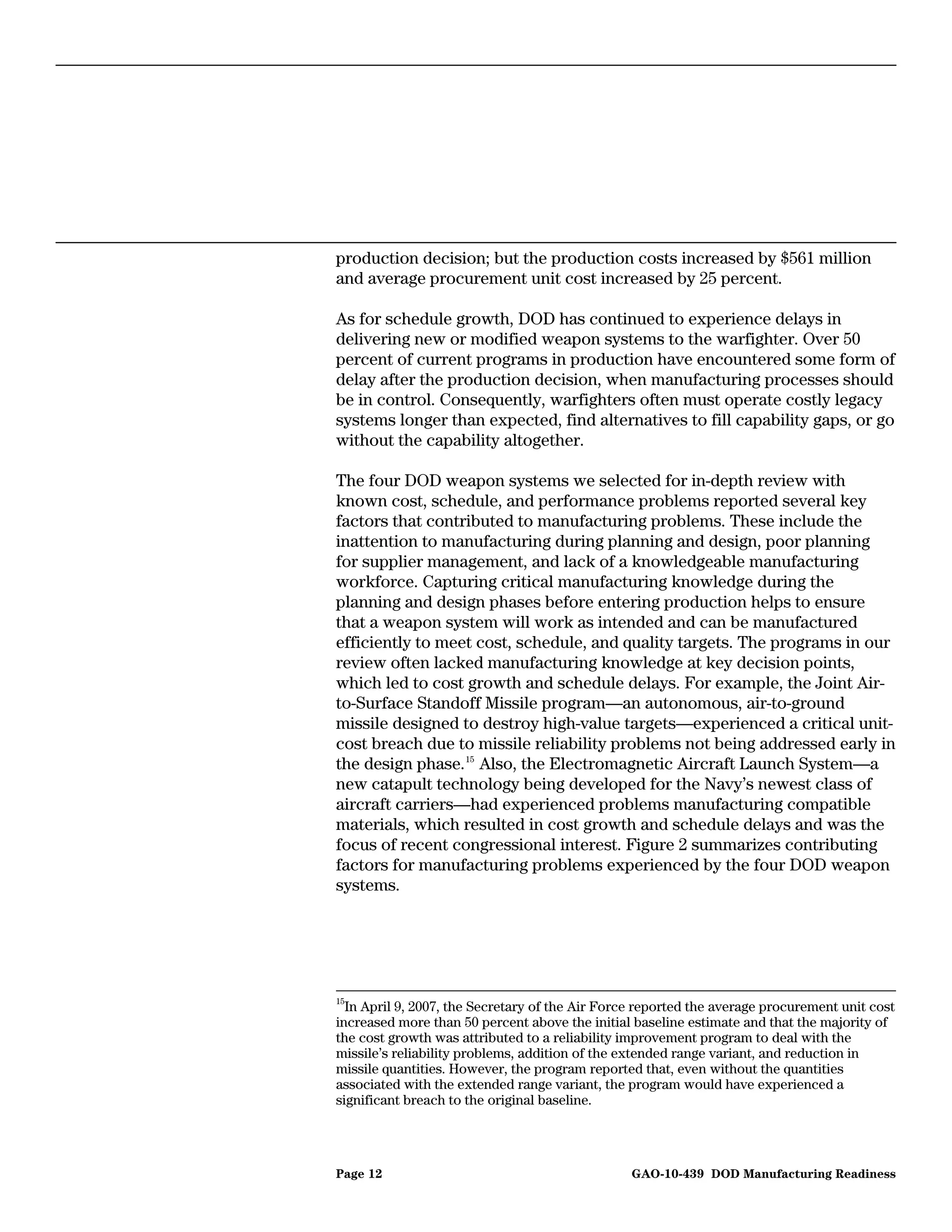

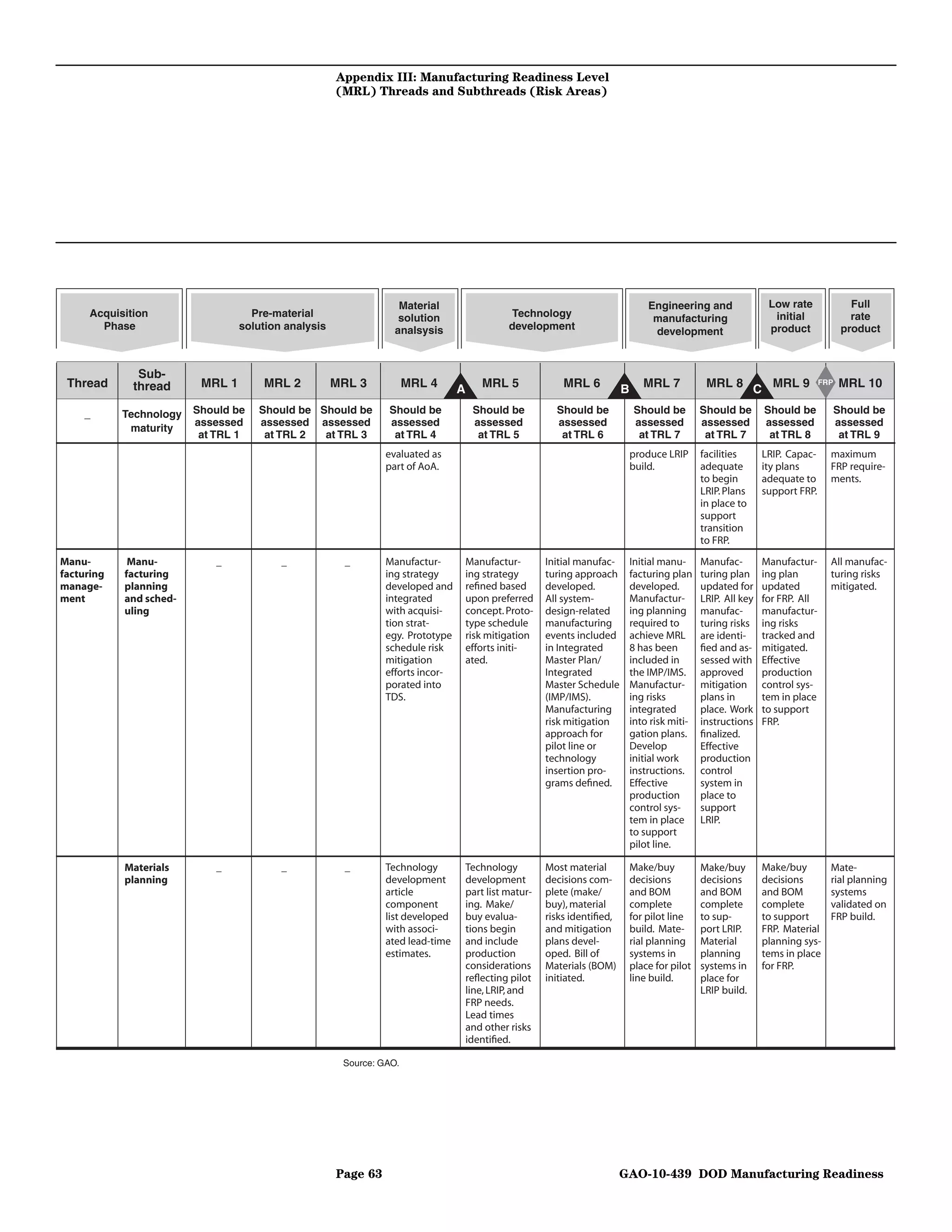

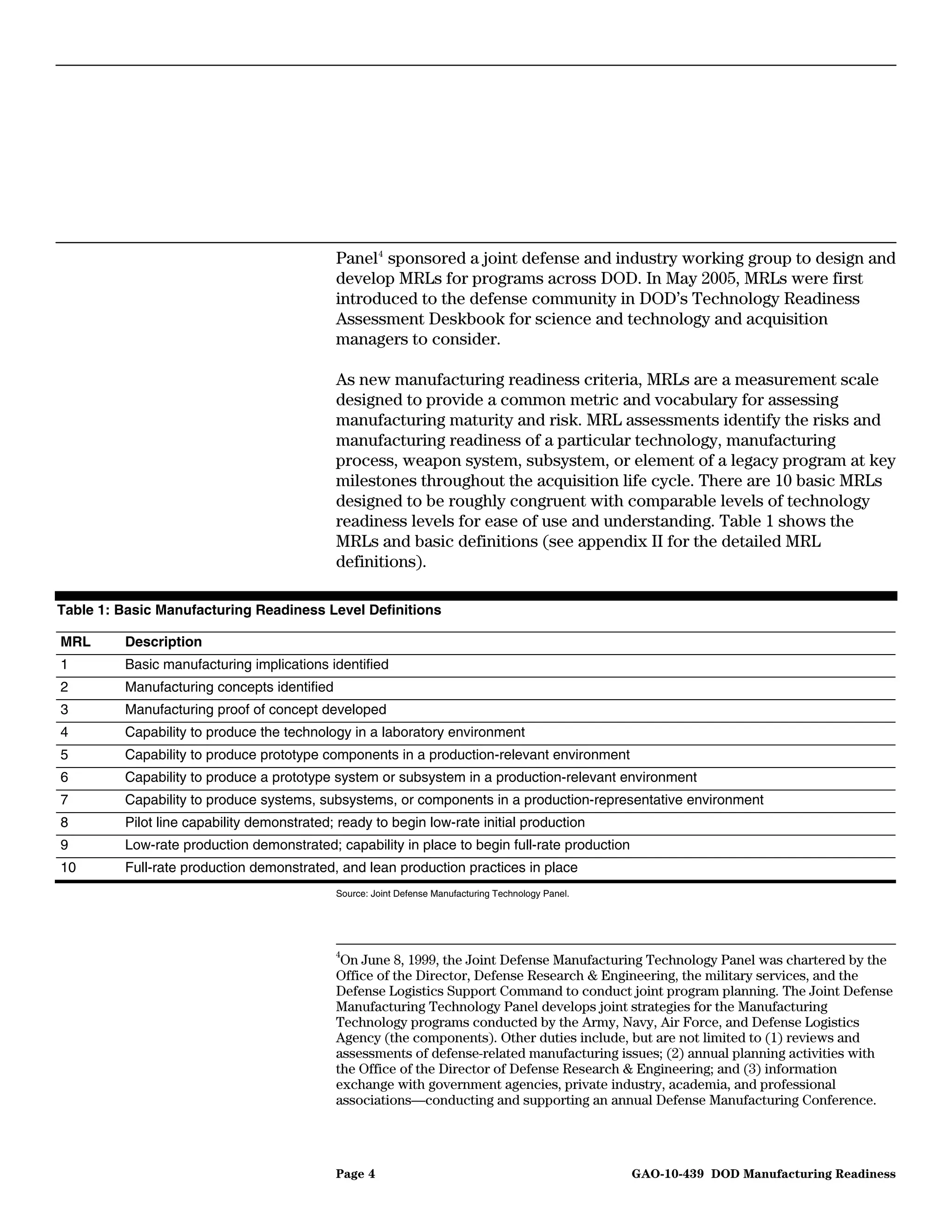

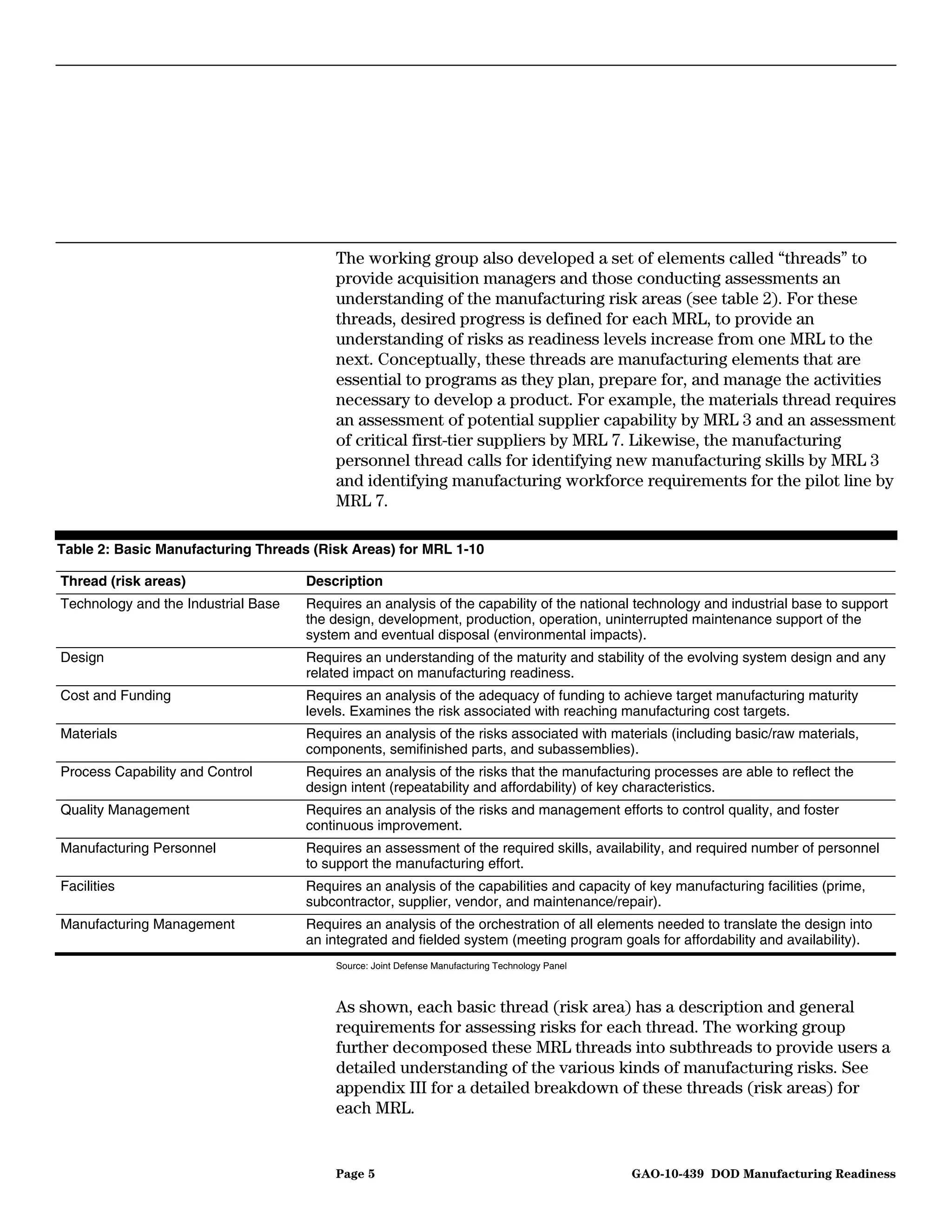

The United States Government Accountability Office (GAO) found that cost growth and schedule delays are prevalent problems in the Department of Defense's (DOD) acquisition of weapon systems. Manufacturing these complex systems has proven difficult, particularly during the transition from development to production. GAO identified several factors that contribute to these problems, including a lack of attention to manufacturing risks early in the design process. GAO recommends that DOD adopt a standardized approach called Manufacturing Readiness Levels (MRLs) to systematically identify and address manufacturing risks throughout the acquisition process. MRLs embody best practices from leading commercial firms for assessing producibility and process control. However, DOD has been slow to adopt a policy requiring MRL

![• A successful preliminary design review will “identify remaining design,

integration, and manufacturing risks.”

• A program may exit the technology development phase when “the

technology and manufacturing processes for that program or

increment have been assessed and demonstrated in a relevant

environment” and “manufacturing risks have been identified.”

After milestone B, one of the purposes of the engineering and

manufacturing development phase is to “develop an affordable and

executable manufacturing process.” The instruction says that: “the

maturity of critical manufacturing processes” is to be described in a post-

critical design review assessment; system capability and manufacturing

process demonstration shall show “that system production can be

supported by demonstrated manufacturing processes;” and the system

capability and manufacturing process demonstration effort shall end,

among other things, when “manufacturing processes have been effectively

demonstrated in a pilot line environment, prior to milestone C.”

Finally, at milestone C, the instruction establishes two entrance criteria for

the production and deployment phase, which include “no significant

manufacturing risks” and “manufacturing processes [are] under control (if

Milestone C is full-rate production).” Low-rate initial production follows in

order to ensure an “adequate and efficient manufacturing capability.” In

order to receive full-rate production approval, the following must be

shown:

1. “demonstrated control of the manufacturing process,”

2. “the collection of statistical process control data,” and

3. “demonstrated control and capability of other critical processes.”

Even with the updated policy instruction in place that includes guidance

for most knowledge-based practices, inconsistent implementation has

hindered DOD’s past efforts to reform its acquisition practices. For

example, we reported in 2006 that DOD was not effectively implementing

the knowledge-based approach process and evolutionary approach

emphasized in its policy. 13 While the policy outlined specific knowledge-

13

GAO, Defense Acquisitions: Major Weapon Systems Continue to Experience Cost and

Schedule Problems under DOD’s Revised Policy, GAO-06-368 (Washington, D.C.: Apr. 13,

2006).

Page 9 GAO-10-439 DOD Manufacturing Readiness](https://image.slidesharecdn.com/gao10439bestpracticesdodcanachievebetteroutcomesbystandardizingthewaymanufacturingrisksaremanaged-13178432279266-phpapp01-111005143457-phpapp01/75/Gao-10-439-Best-Practices-Dod-Can-Achieve-Better-Outcomes-By-Standardizing-The-Way-Manufacturing-Risks-Are-Managed-13-2048.jpg)