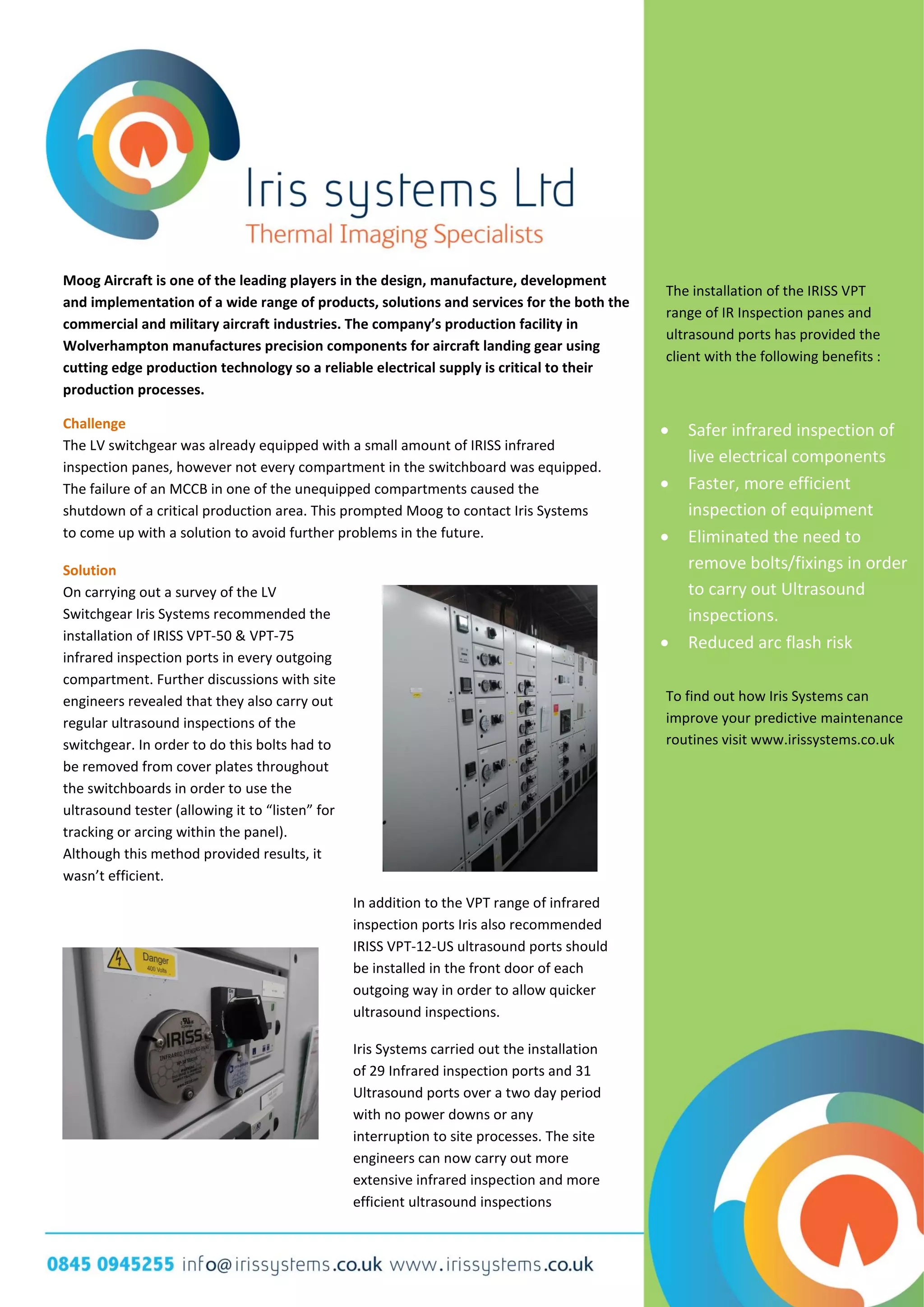

Moog Aircraft manufactures precision aircraft components and relies on reliable electricity. A switchgear failure caused an outage, prompting Moog to address issues. Iris Systems surveyed the switchgear and recommended installing infrared and ultrasound ports in compartments to allow safer, faster inspections without power downs. Iris installed 29 infrared and 31 ultrasound ports over two days, allowing more effective inspections without interruptions.