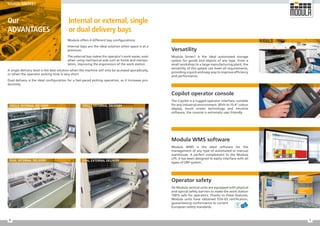

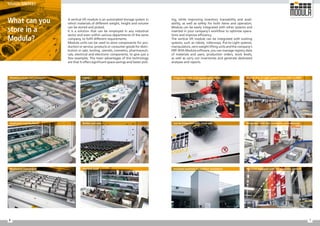

The Modula Sintes1 is an automated vertical lift module designed to optimize storage space, offering up to 90% floor space recovery and enhancing productivity with a throughput of up to 140 trays per hour. It features a modern design, various bay configurations, and complies with safety standards, making it suitable for diverse industrial applications. The system can integrate with existing workflows and ERP systems, supporting efficient inventory management and improving operational performance.