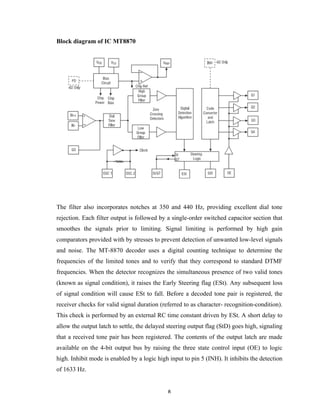

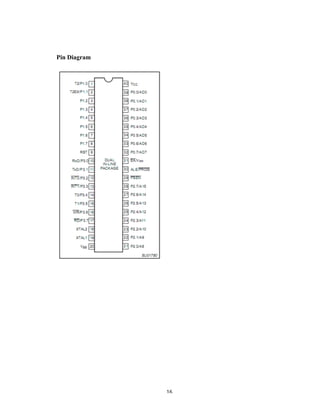

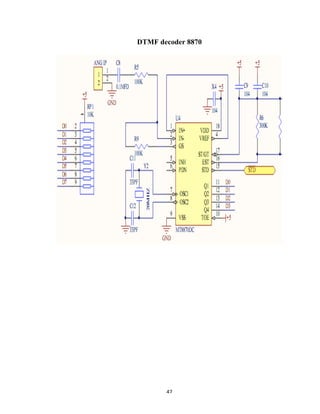

This document discusses the use of remotely controlled robots for dangerous tasks like mine detection and clearance. It describes how DTMF signaling is used to control robots over telephone lines by sending tone codes. The document provides details on the hardware and software used in a robot controlled by a mobile phone, including an 89C51 microcontroller, MT8870 DTMF decoder, motors, and a metal detector. It summarizes the advantages and disadvantages of this robot design.