Embed presentation

Downloaded 30 times

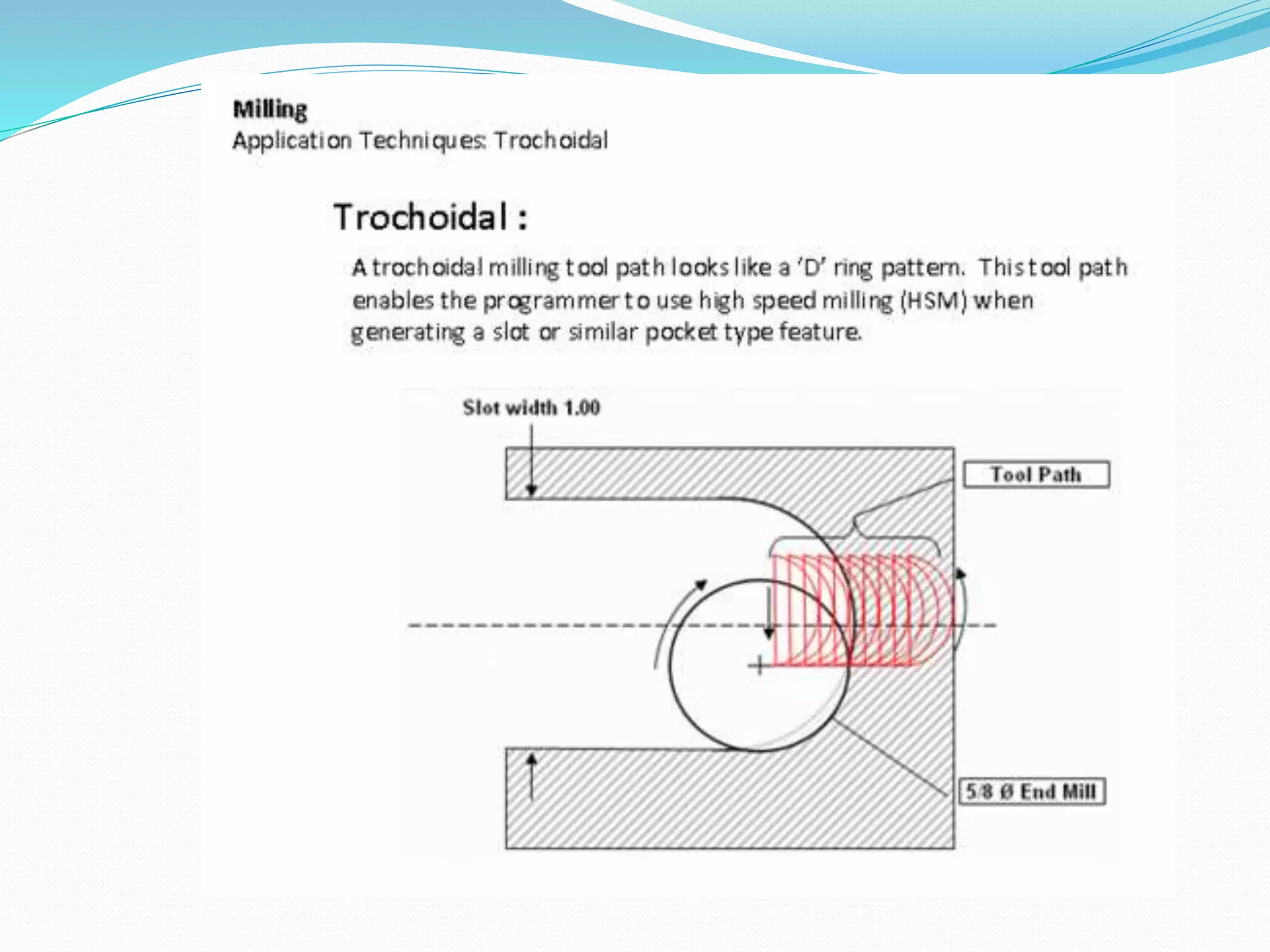

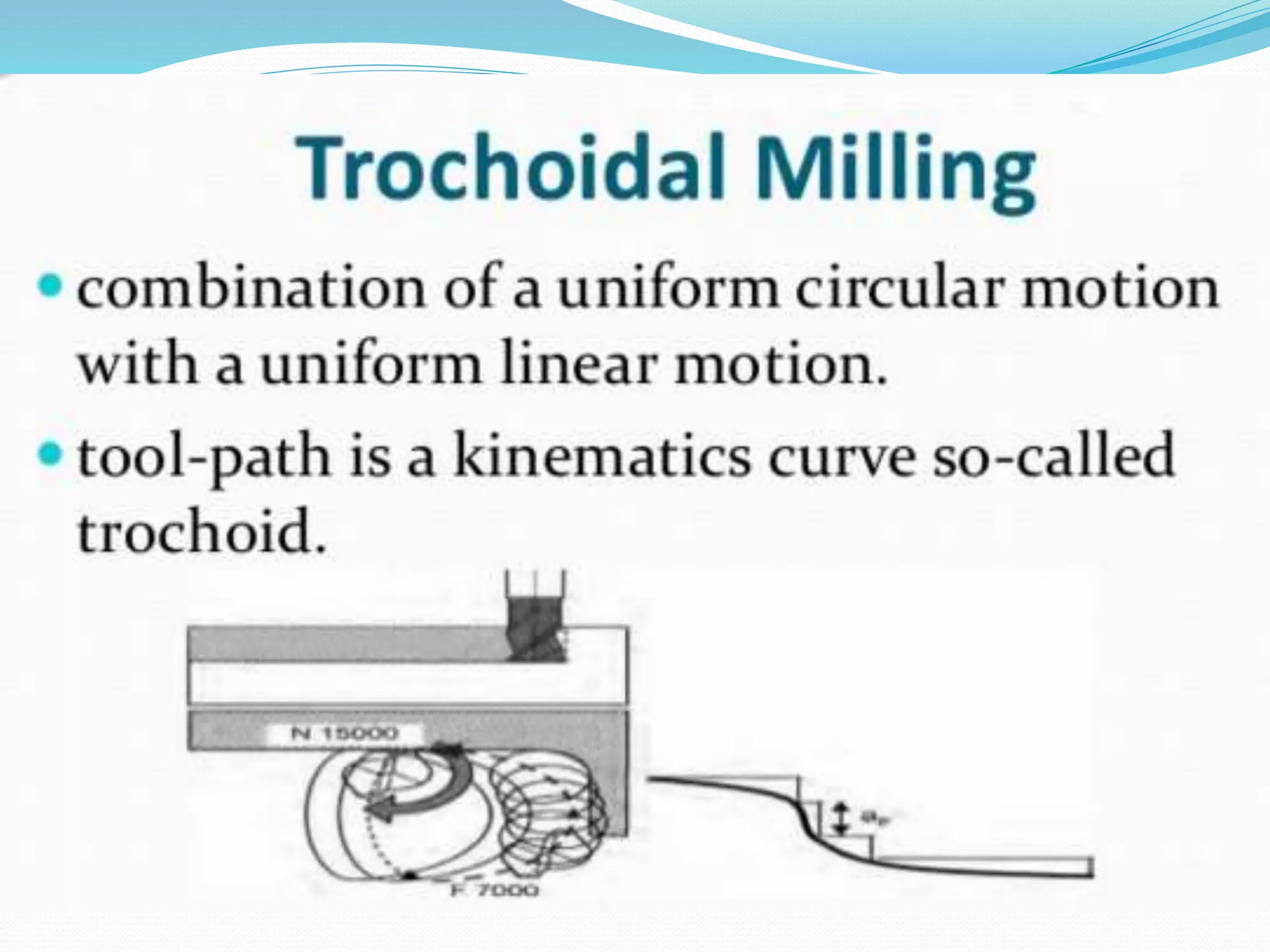

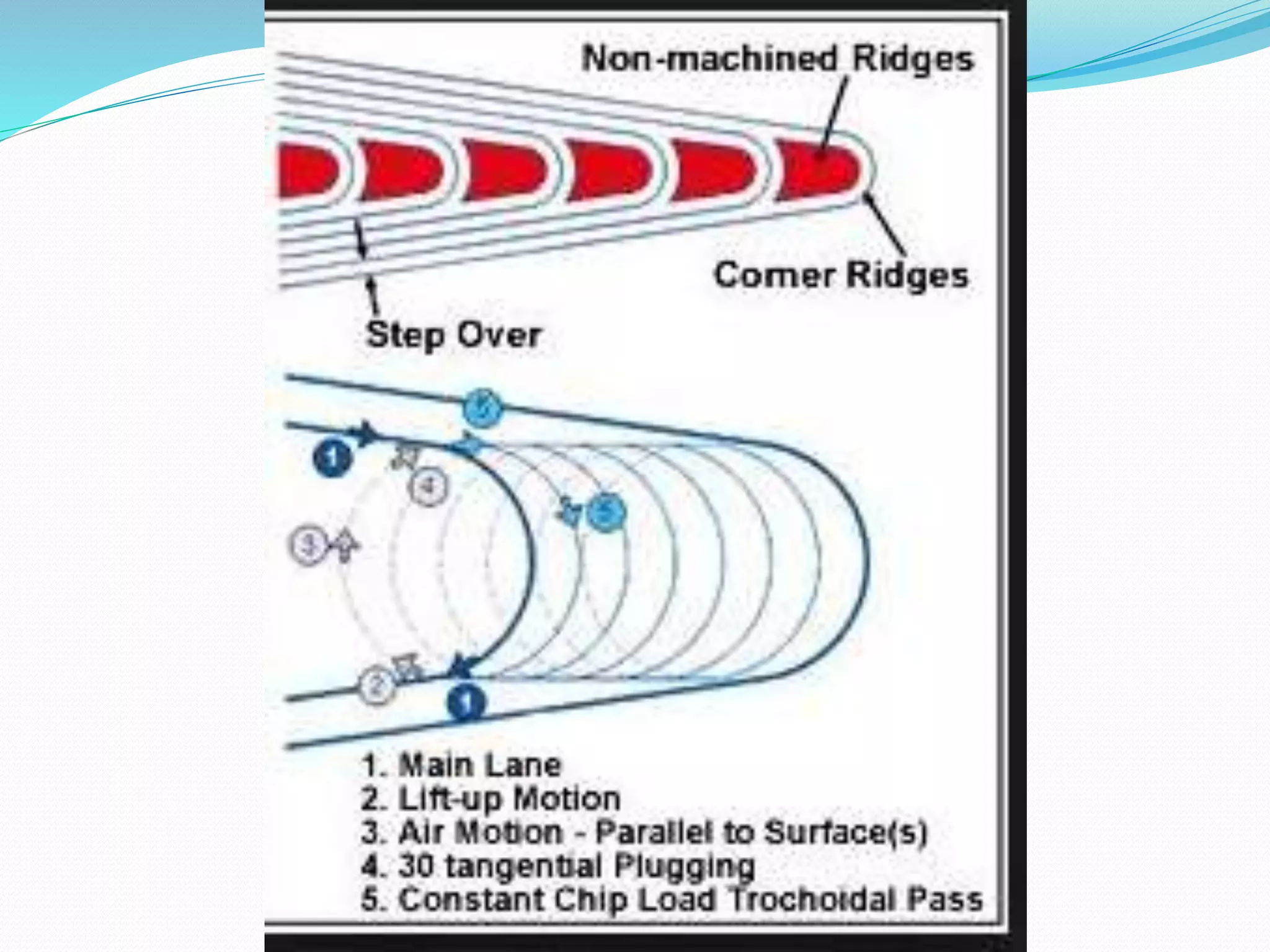

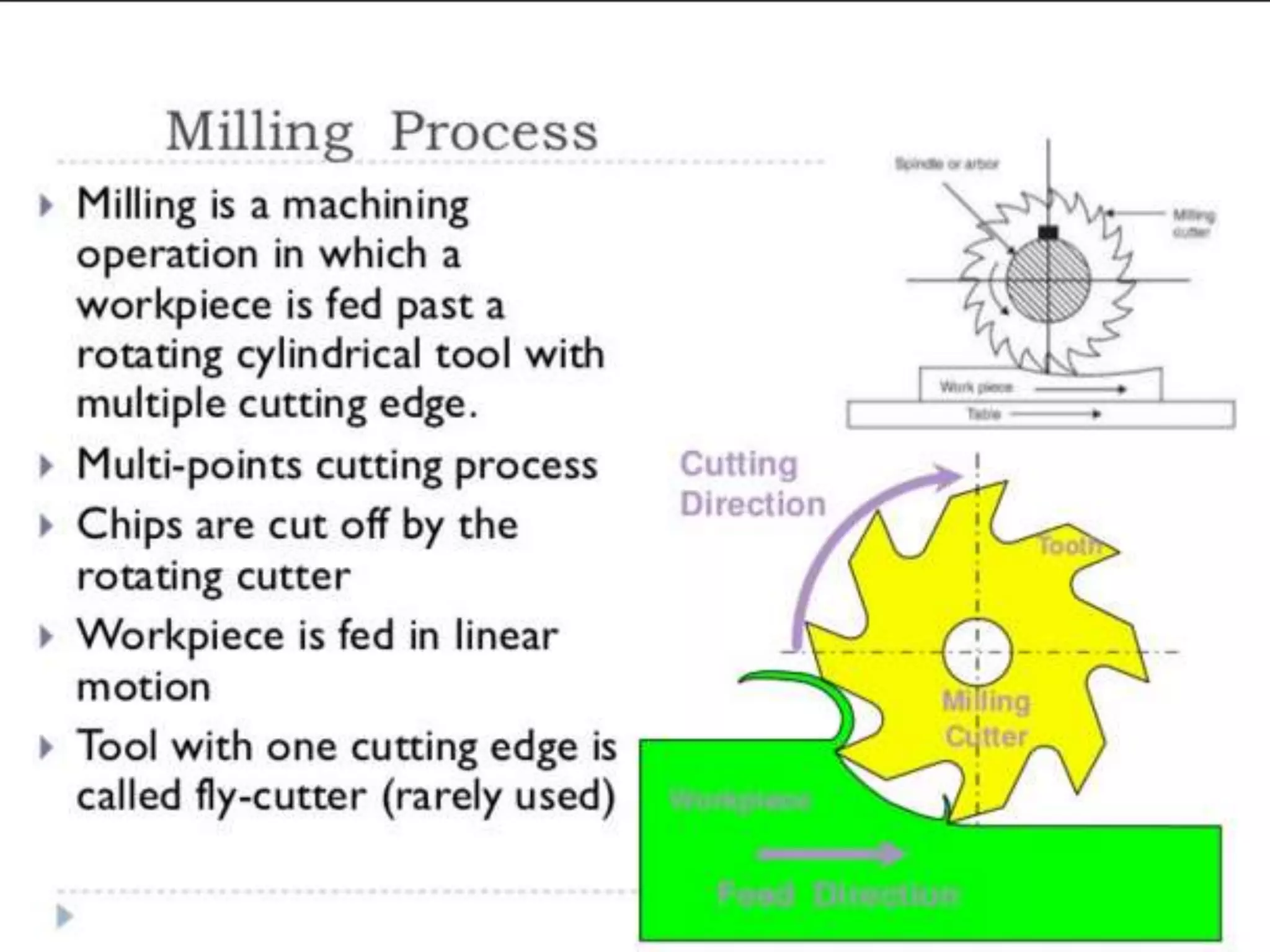

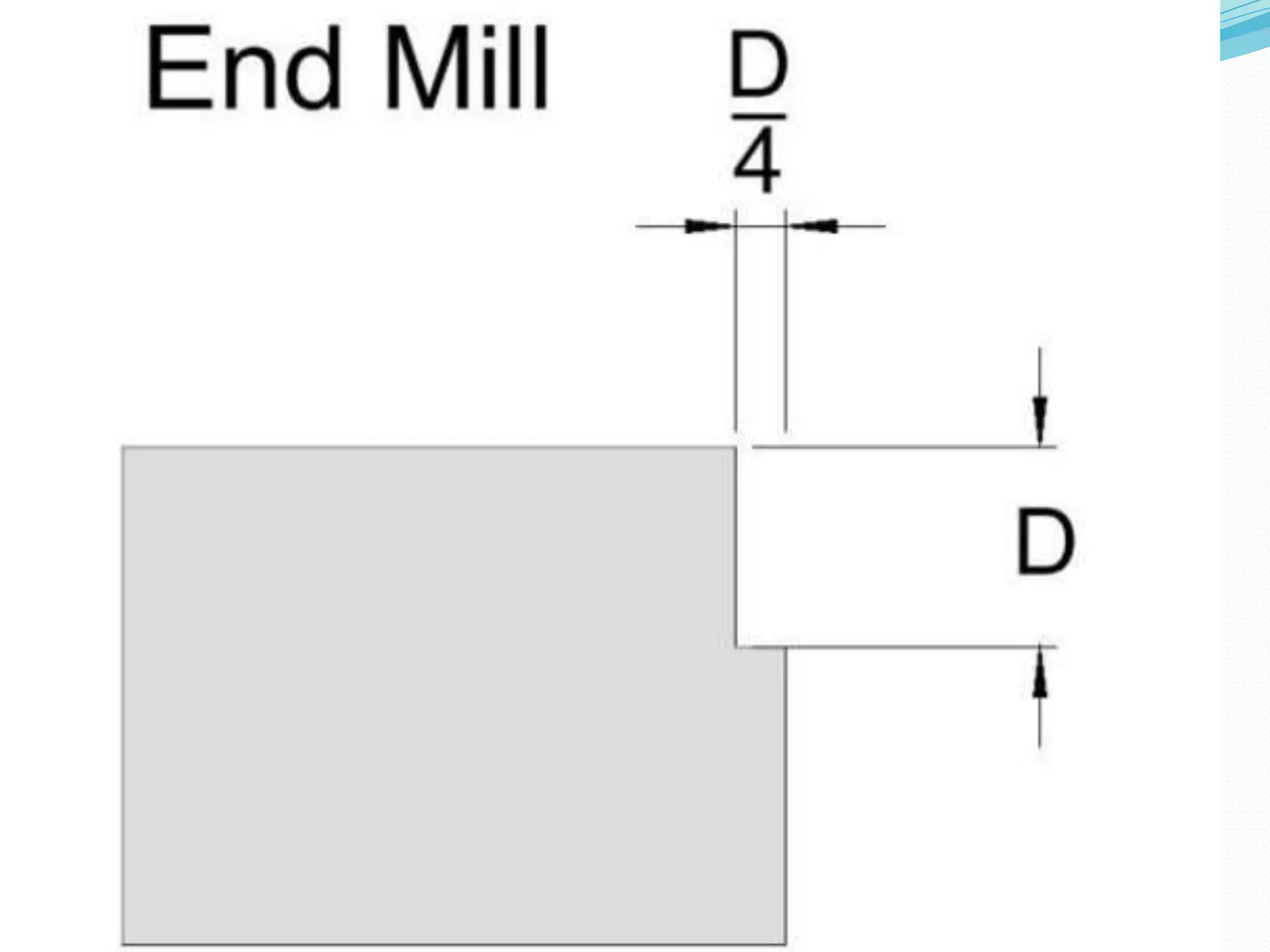

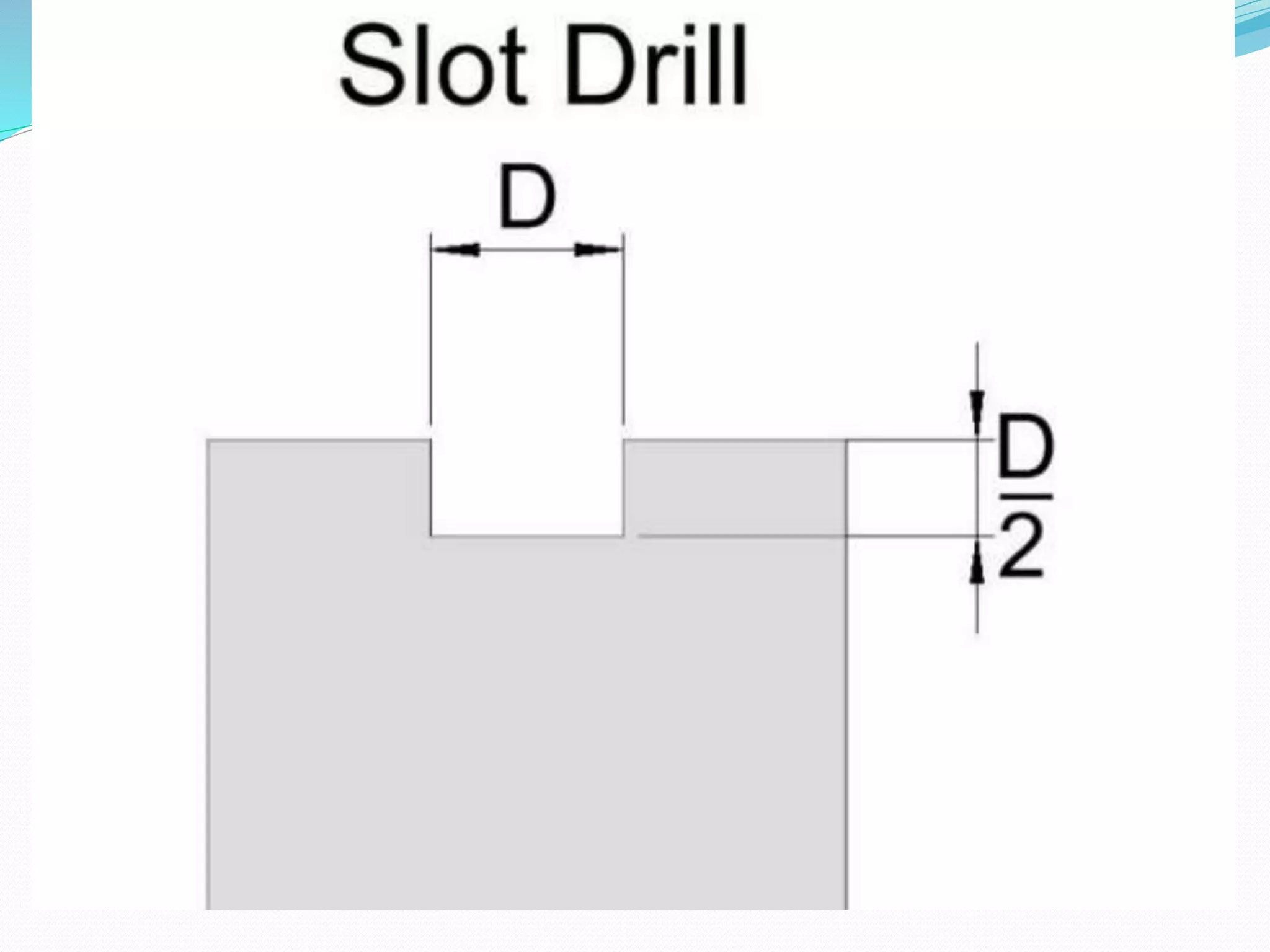

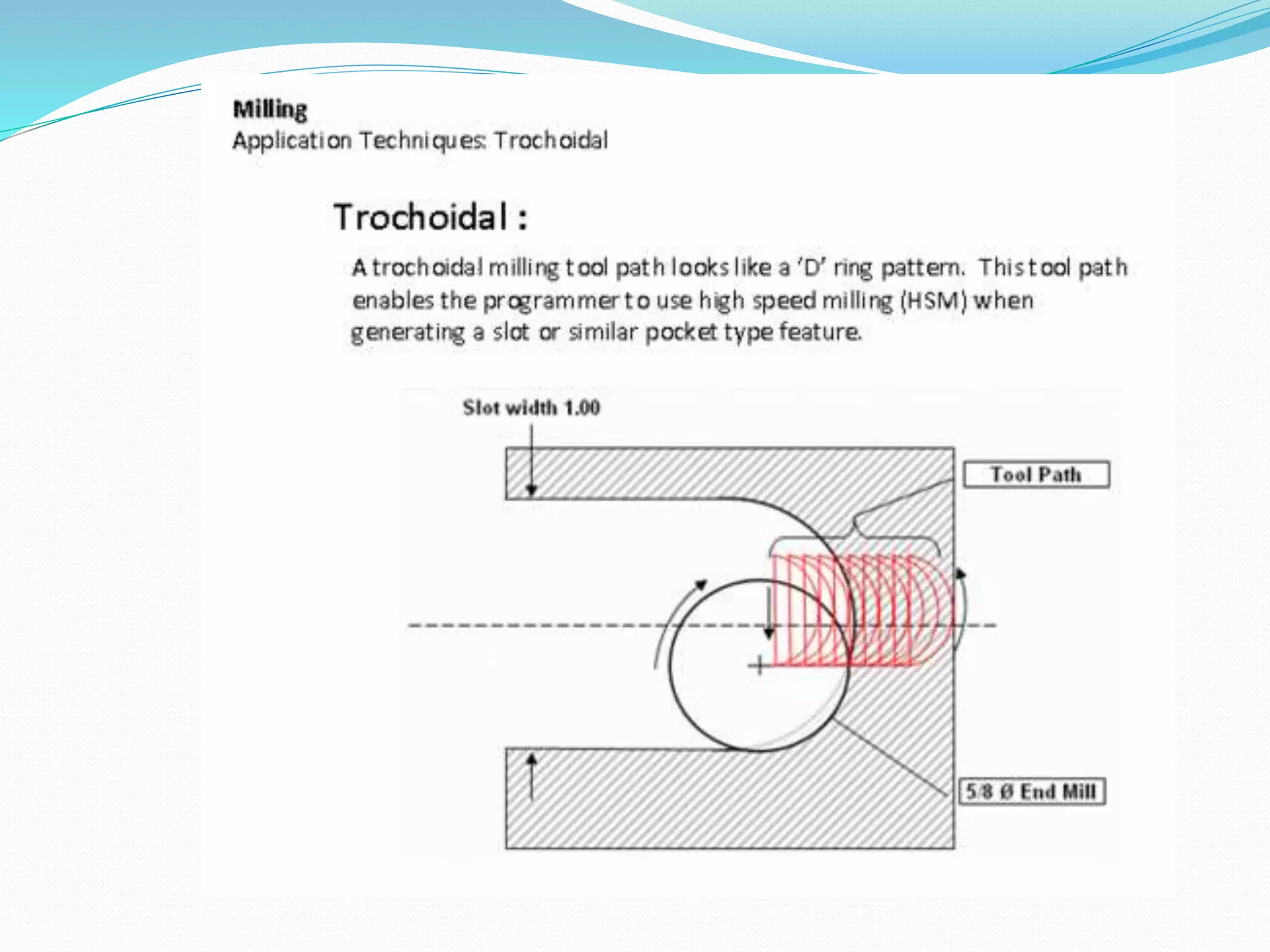

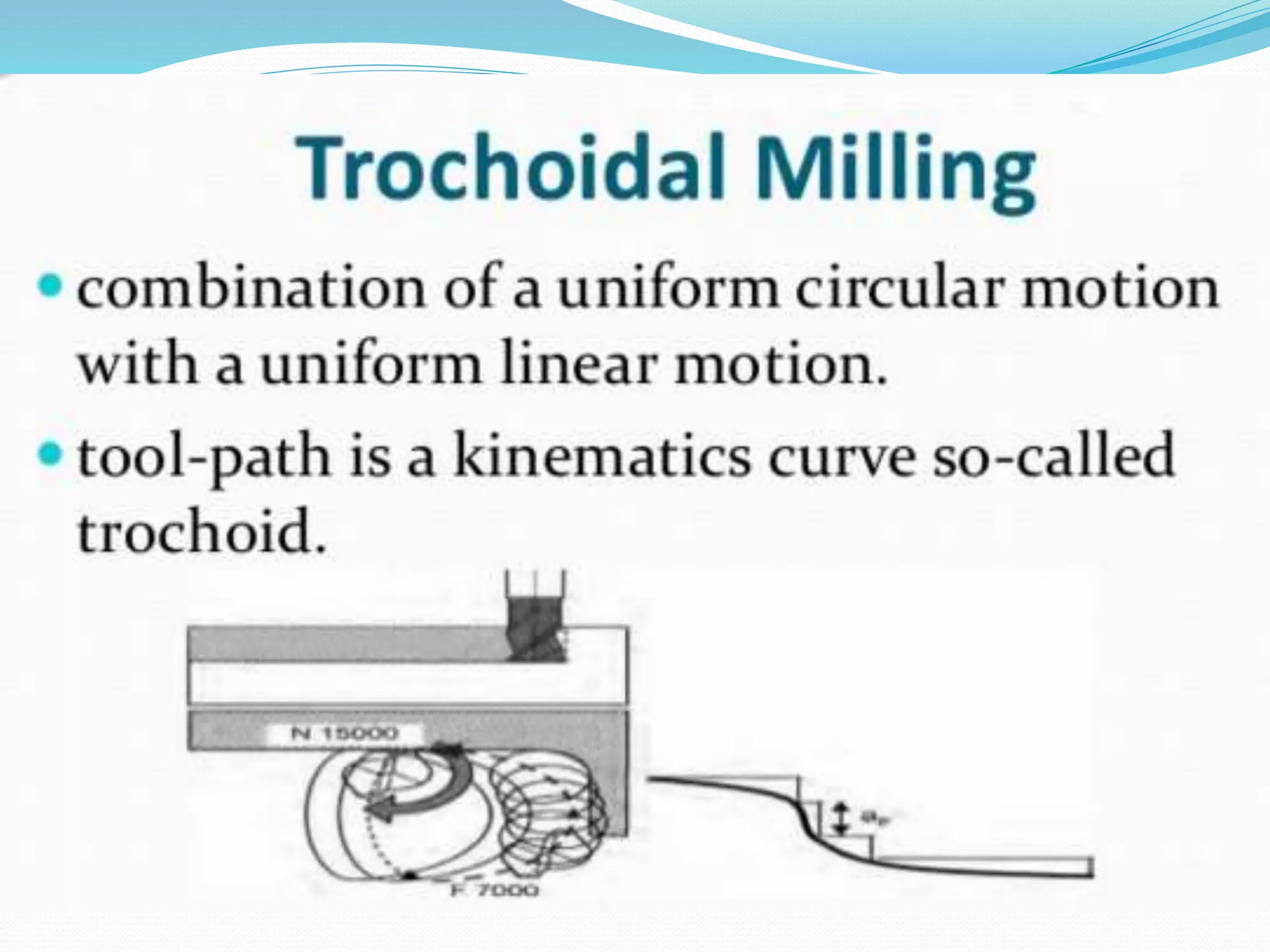

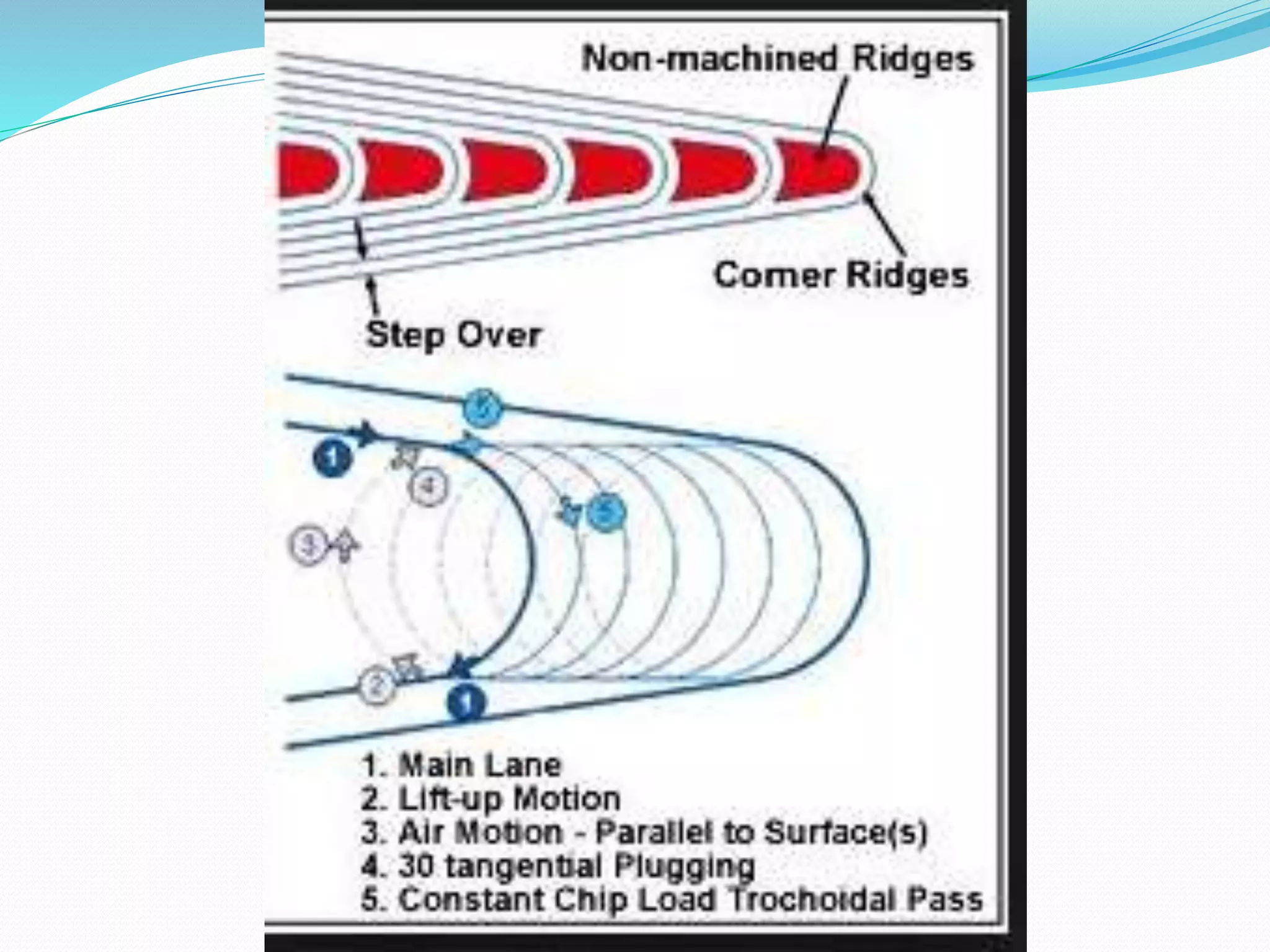

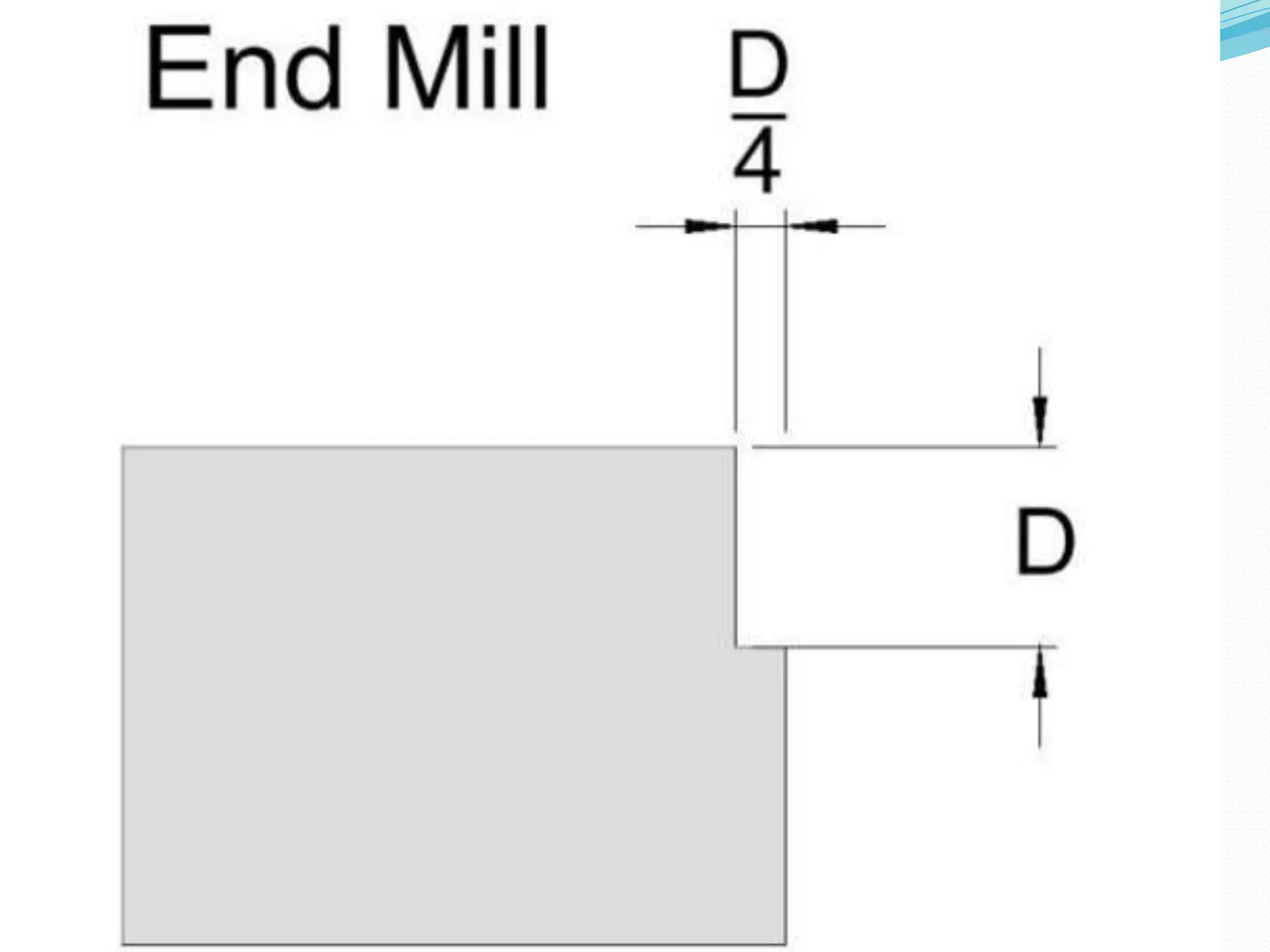

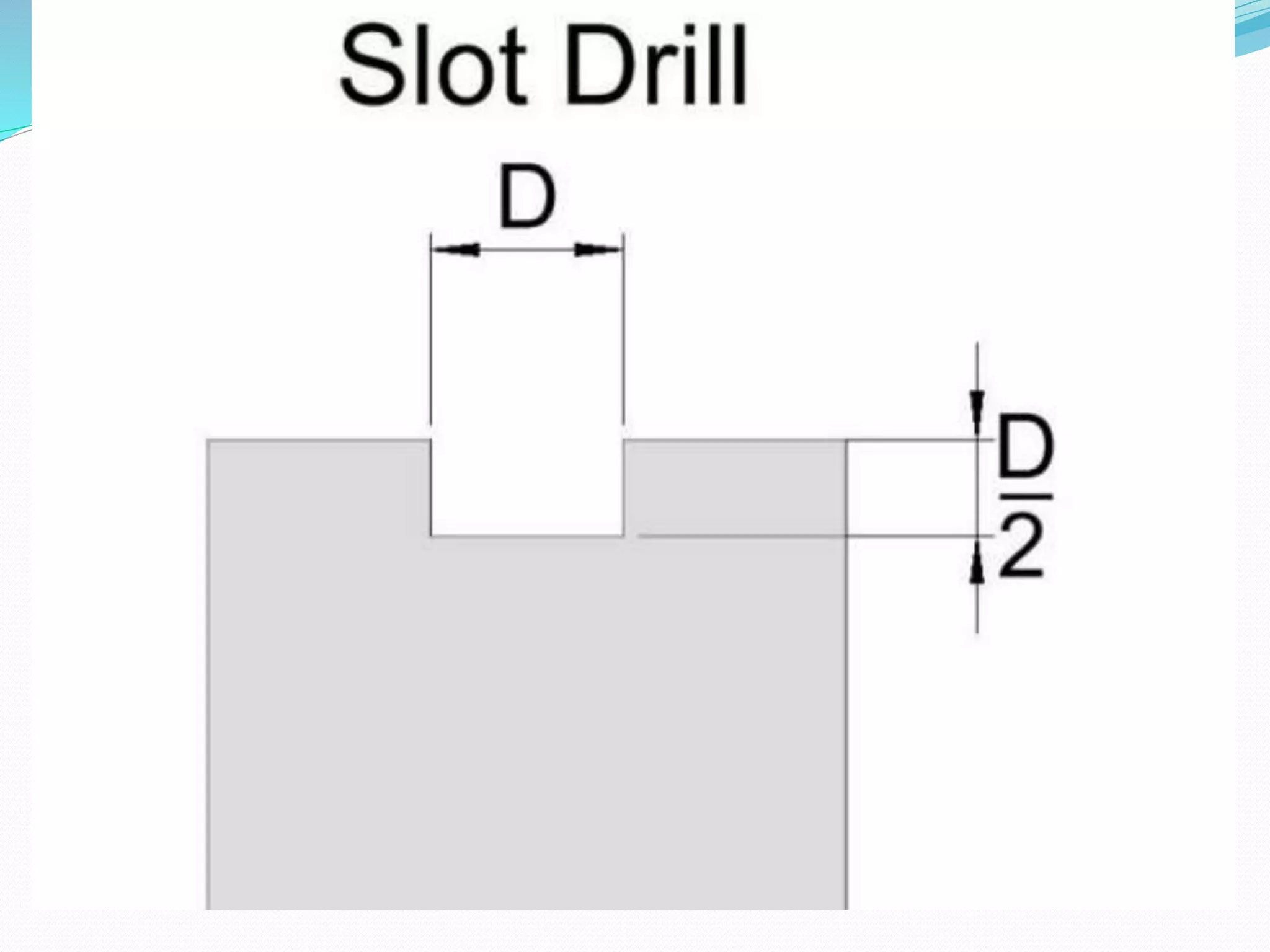

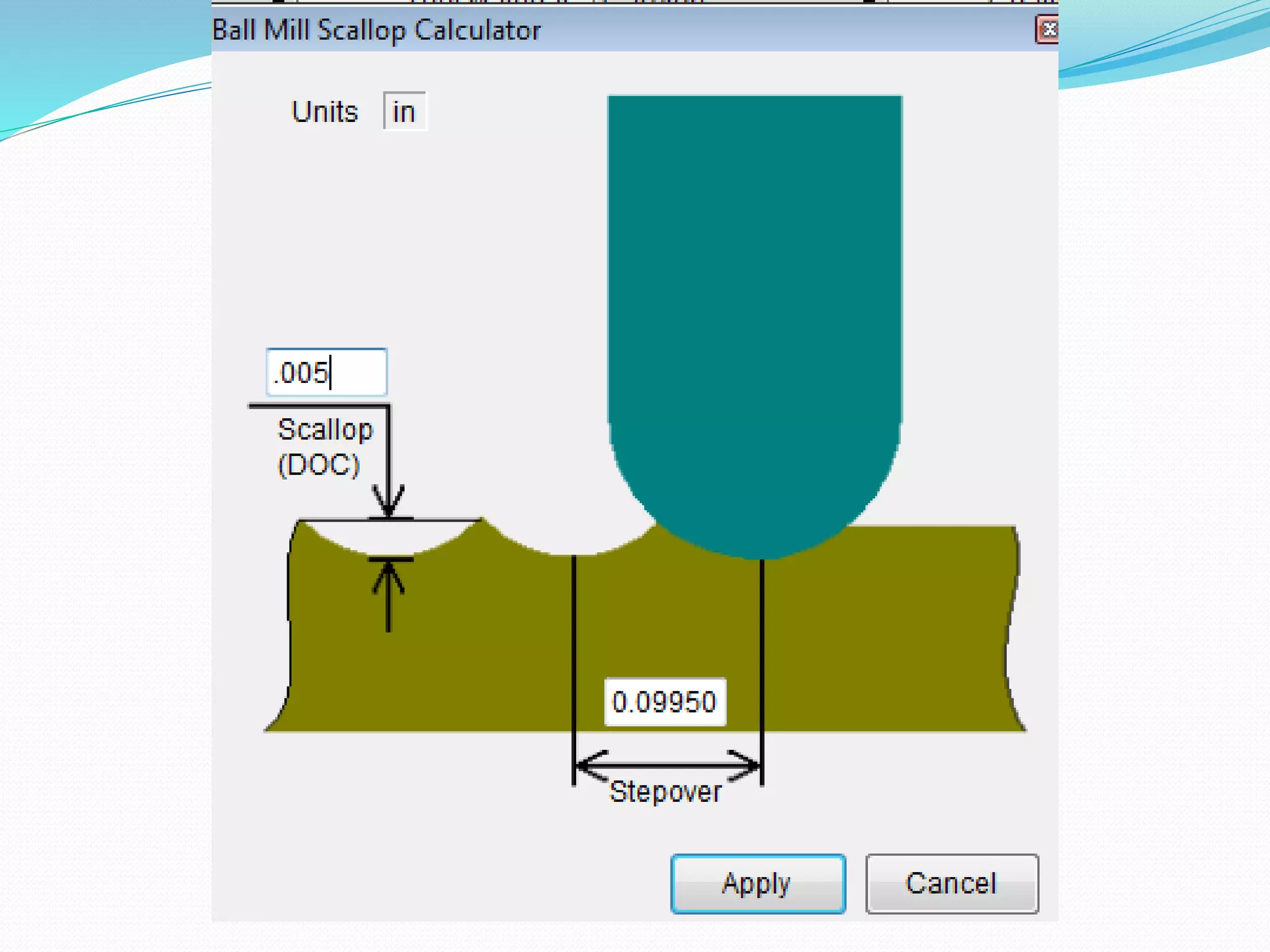

Trochoidal milling is an efficient alternative to standard slot milling that uses a circular motion of an end mill to cut a slot width through a trochoid method. This high-speed machining technique produces slots in an efficient manner using an end mill moving in a circular pattern to machine the slot width.