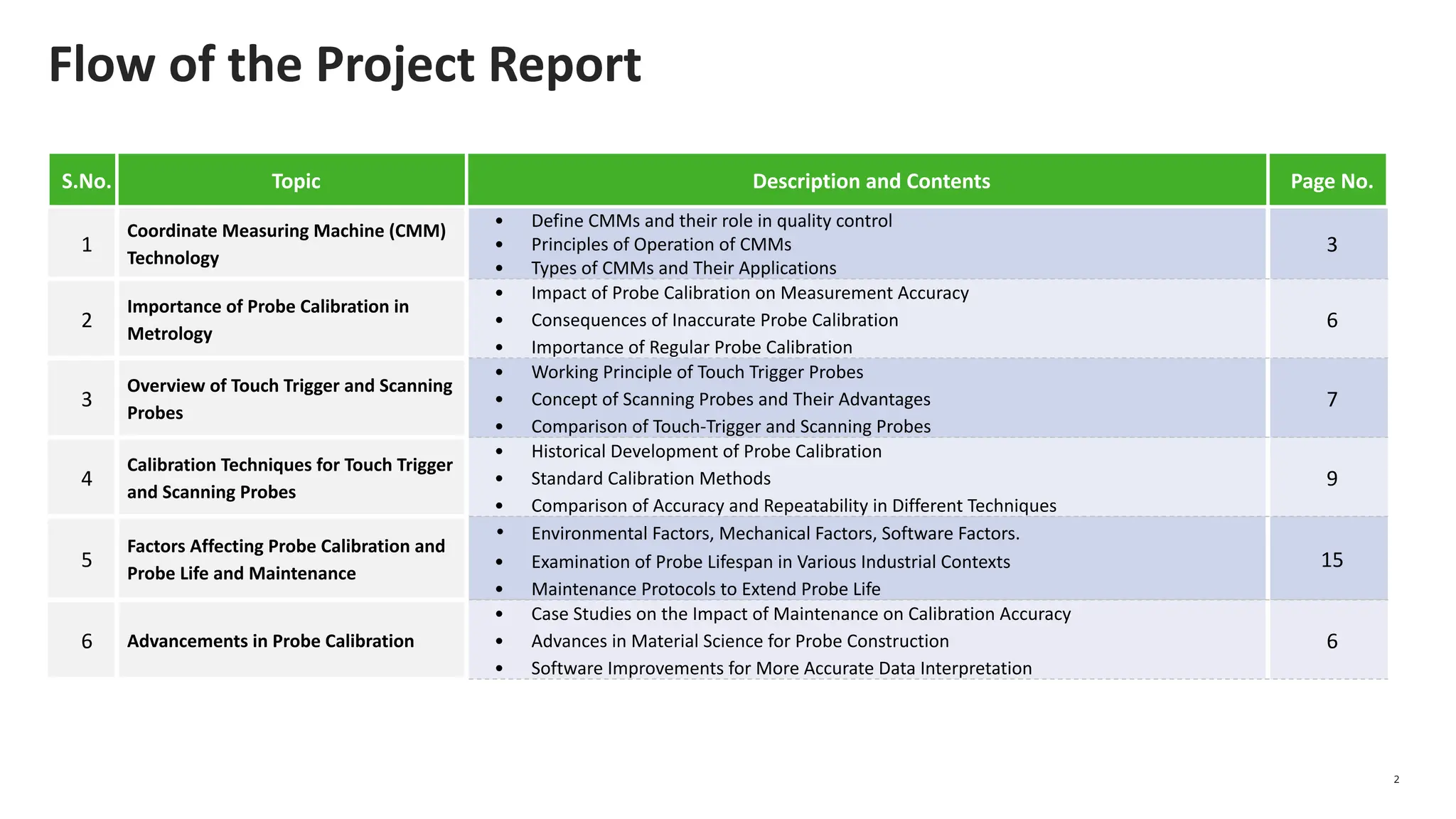

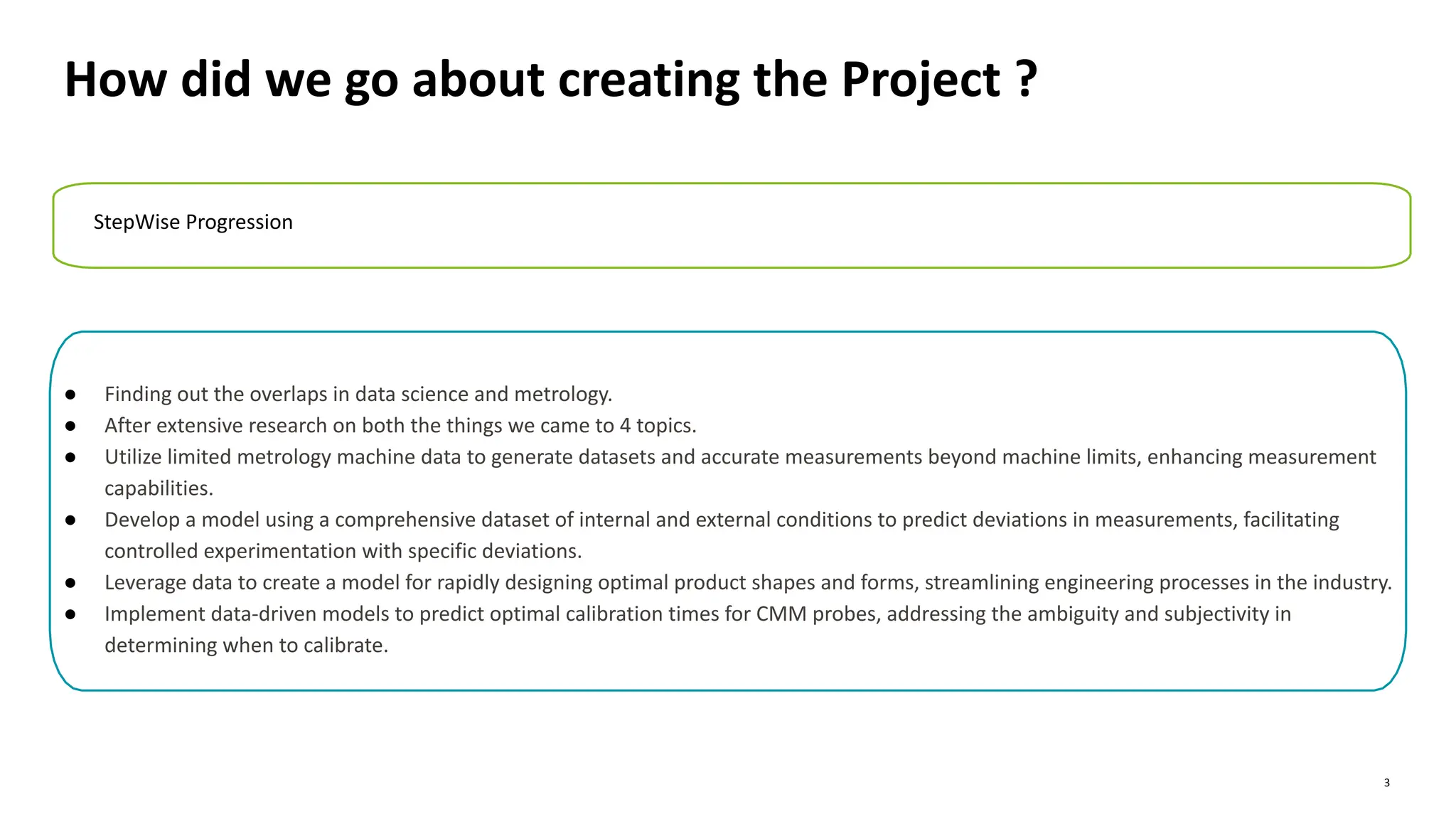

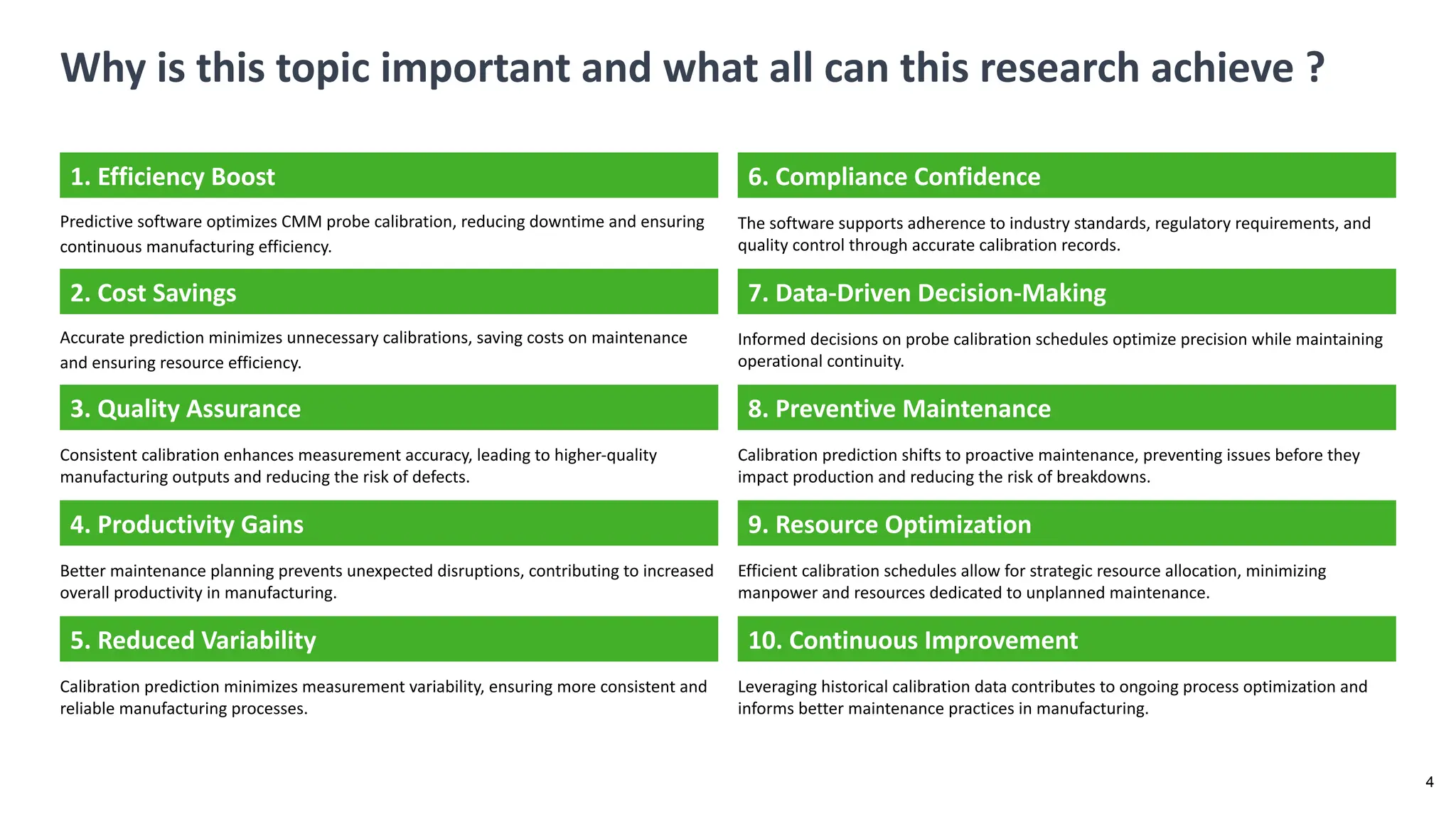

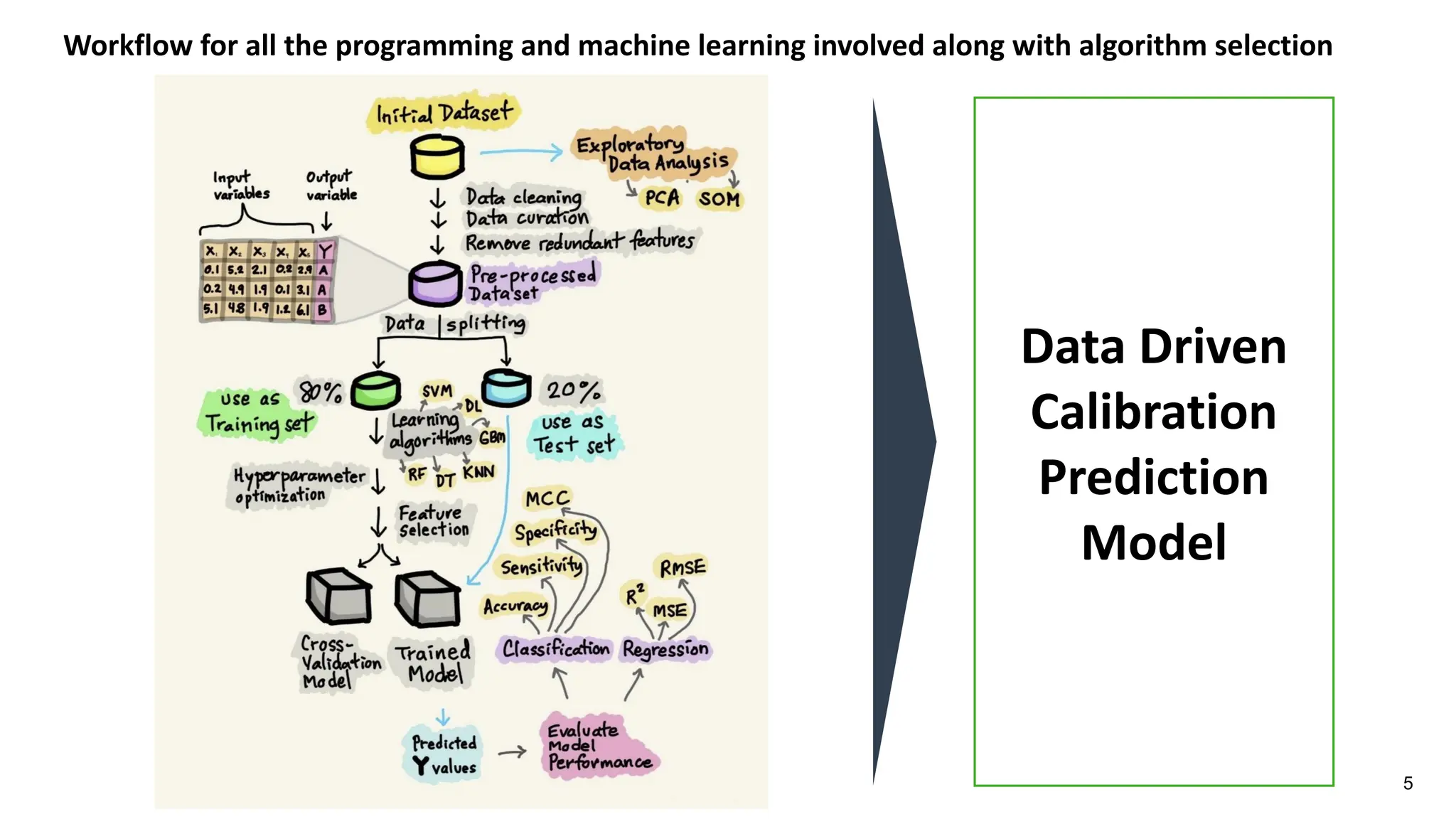

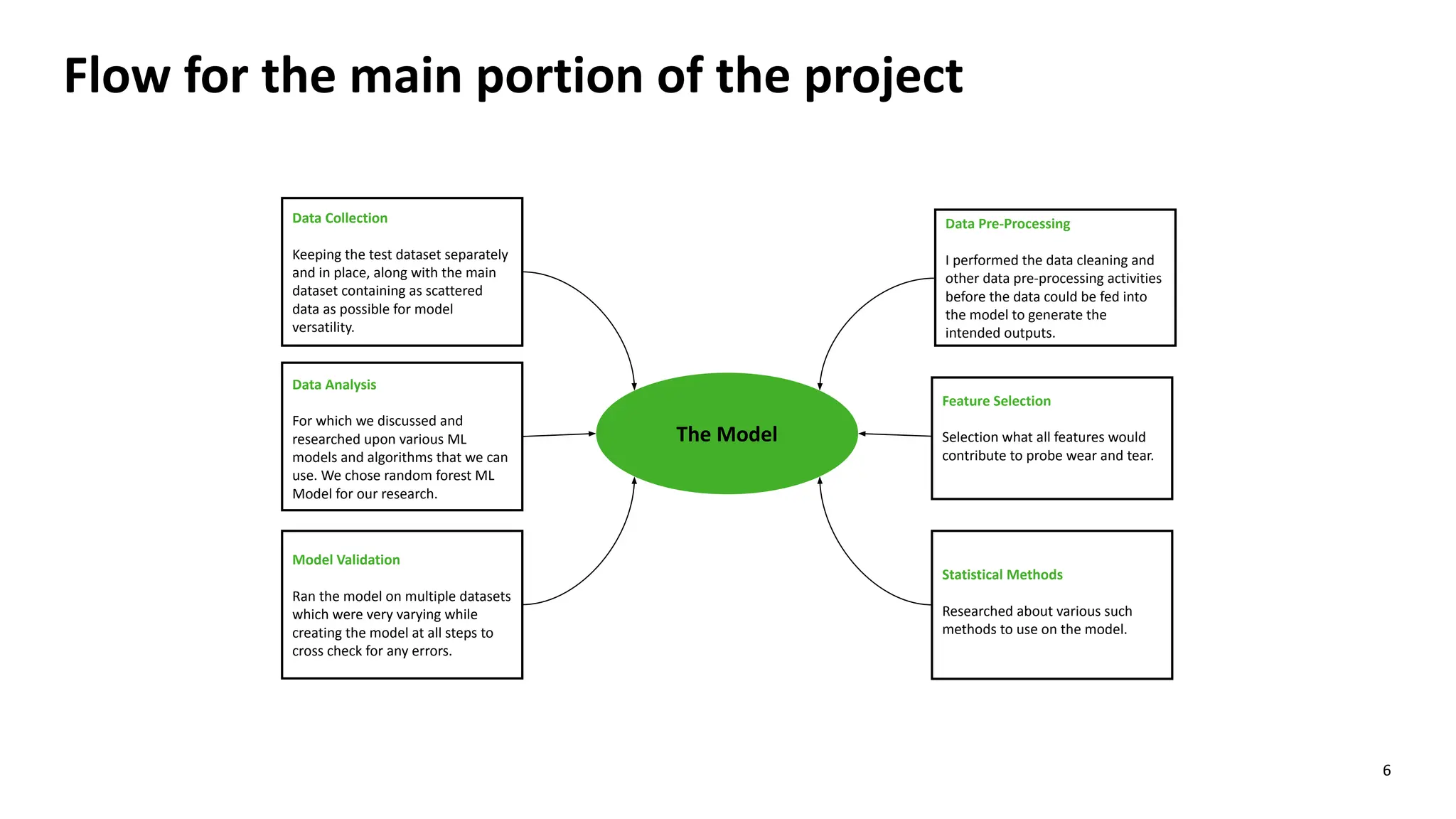

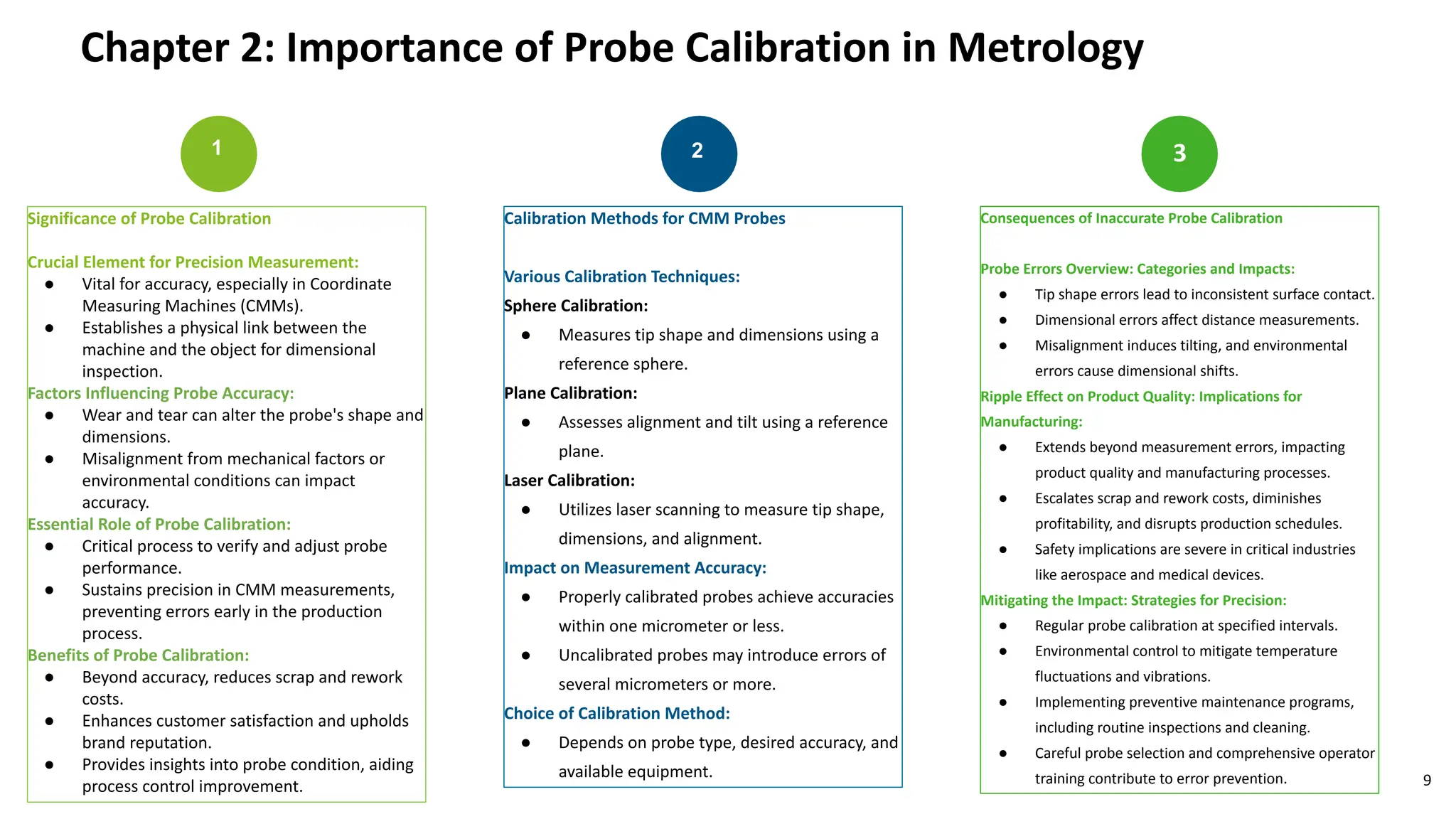

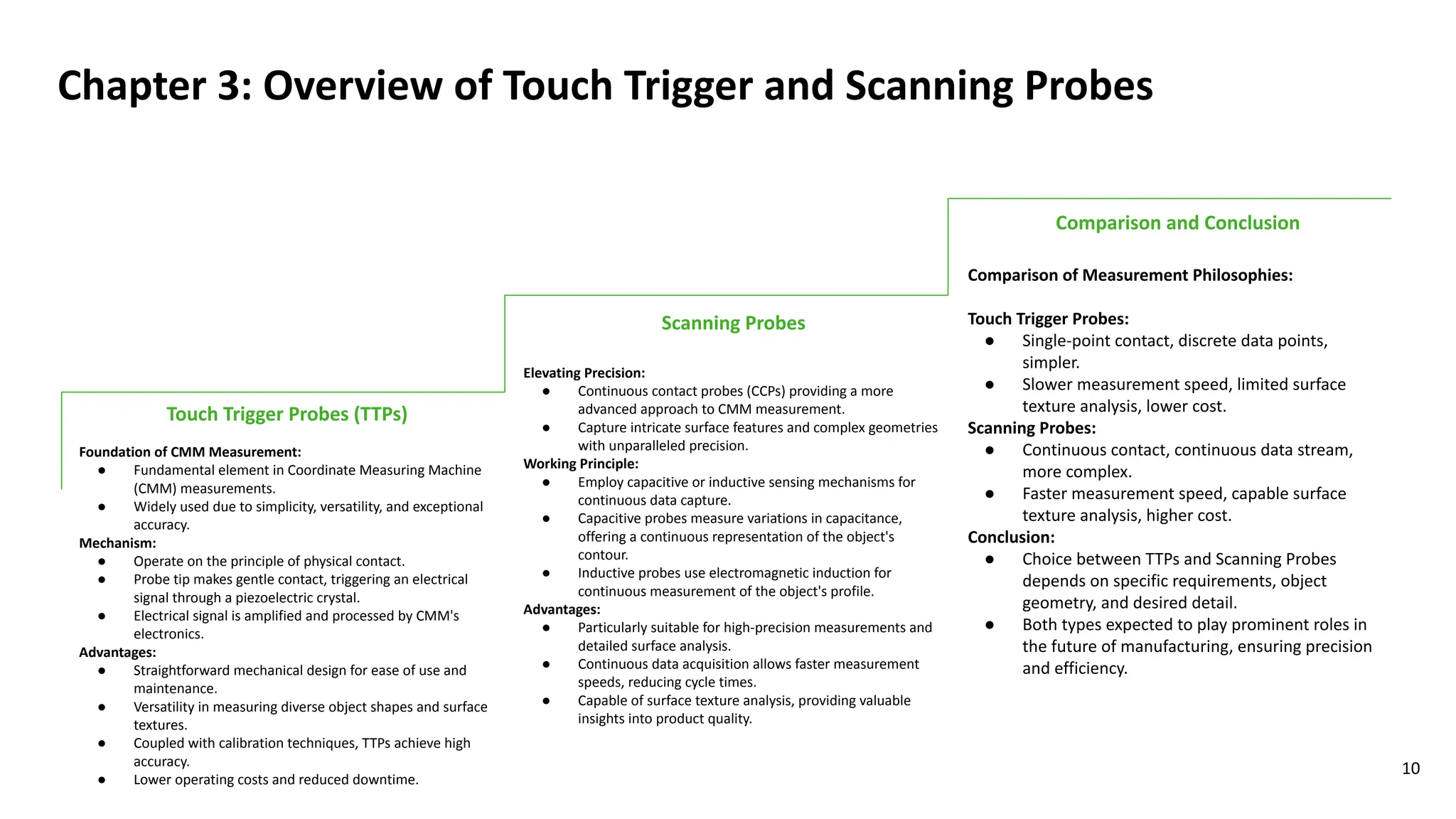

The document outlines advancements in coordinate measuring machine (CMM) technology and probe calibration for ensuring measurement accuracy in manufacturing. It discusses the importance of regular probe calibration, various calibration techniques, and factors affecting probe lifespan and maintenance, emphasizing the role of data-driven predictive modeling to improve calibration schedules and reduce costs. The findings highlight the significance of proactive maintenance and technological innovations in achieving high-quality manufacturing outcomes.