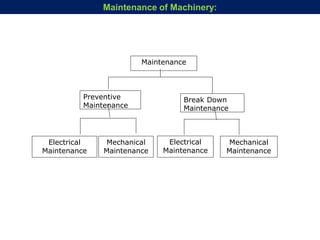

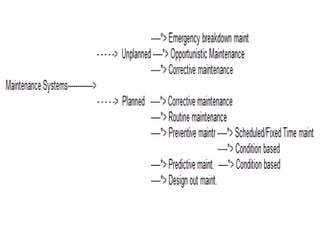

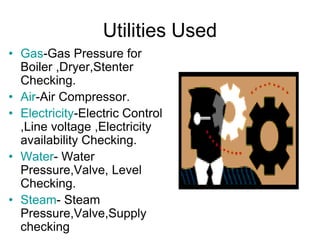

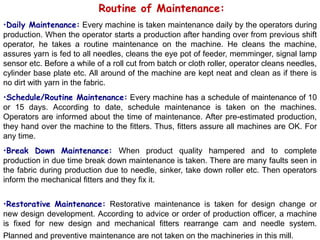

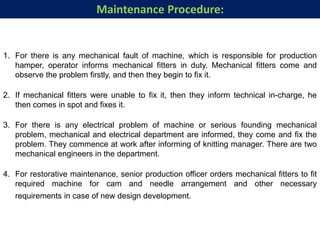

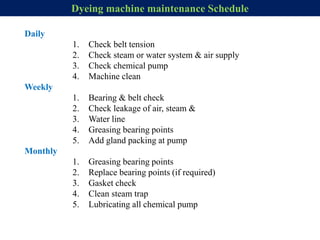

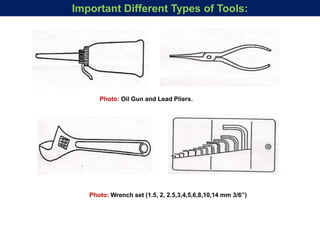

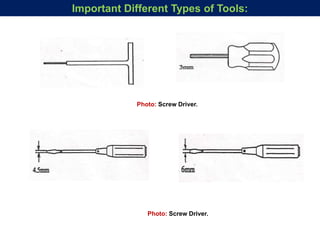

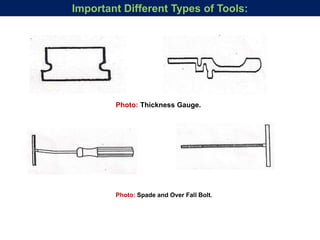

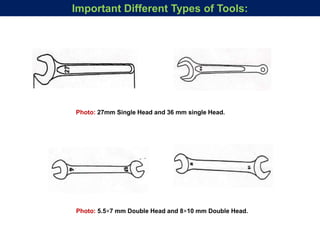

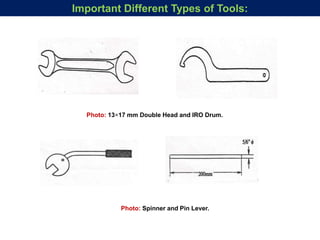

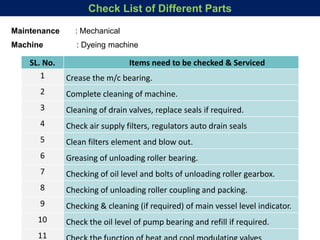

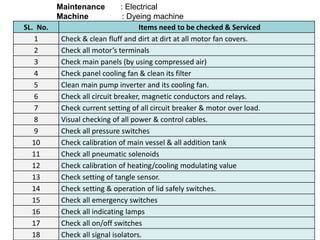

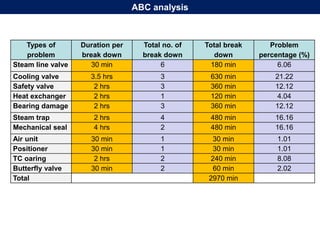

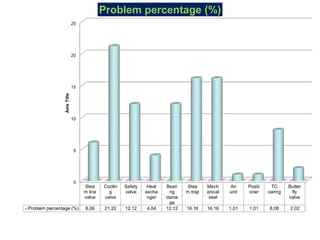

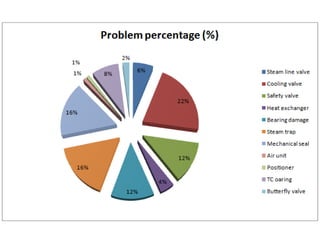

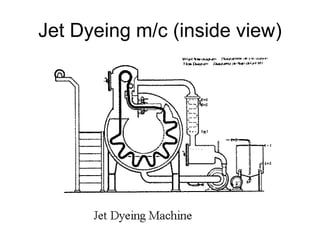

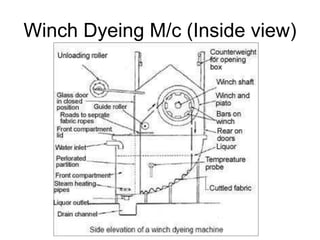

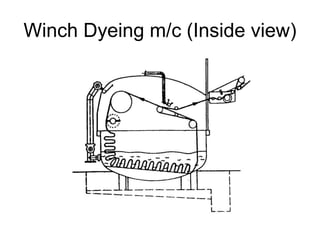

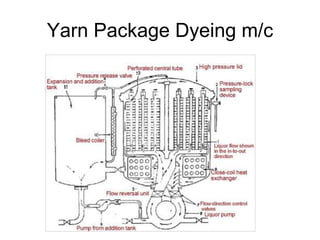

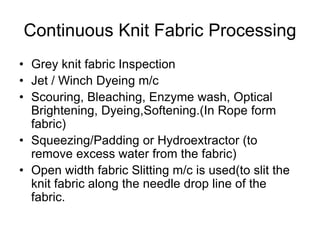

The document details maintenance practices for textile machinery at Beximco Knitting Ltd., highlighting the importance of regular upkeep to ensure operational efficiency and product quality. It outlines types of maintenance, including preventive, breakdown, and restorative maintenance, as well as scheduled routines for various machines to minimize downtime. The document also discusses the tools and processes utilized to maintain different machinery used in dyeing and knitting processes within the textile industry.