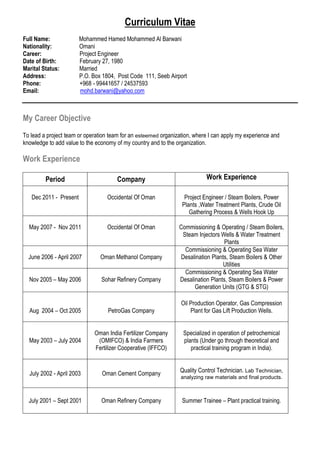

Mohammed Hamed Mohammed Al Barwani is an Omani project engineer seeking a leadership role where he can apply his experience. He has over 10 years of experience commissioning and operating utilities like steam boilers, water treatment plants, and crude oil gathering processes. He holds a BSc in engineering and has managed projects, commissioned plants, and operated facilities involving thermally enhanced oil recovery and petrochemical utilities.