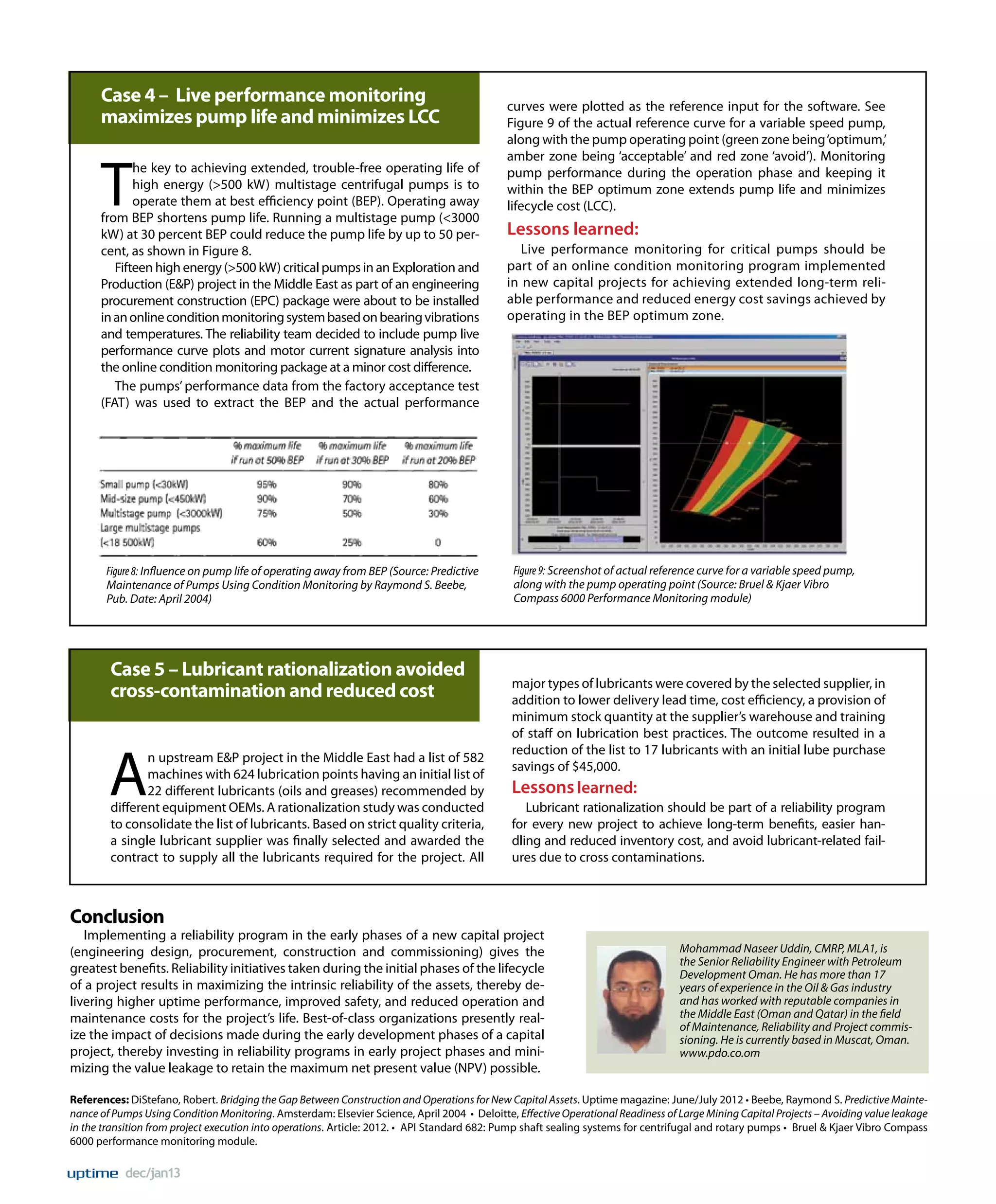

The document emphasizes the importance of implementing a reliability program early in the lifecycle of projects to avoid defects that lead to costly maintenance and downtime in industrial systems. It presents several real-life case studies from a middle east refinery that highlight how premature identification and resolution of engineering issues, such as improper installation and lack of lubrication, could have saved significant costs and improved equipment performance. Ultimately, the document advocates for greater adherence to vendor recommendations and stringent testing to enhance equipment reliability and lifecycle efficiency.