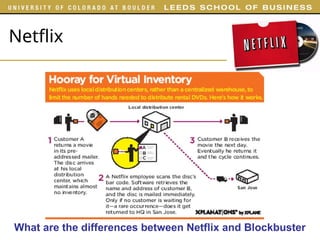

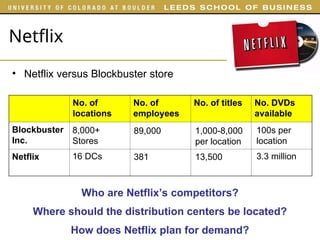

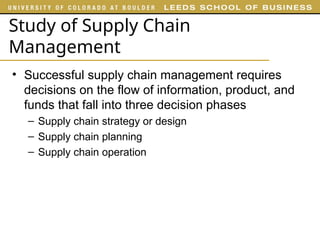

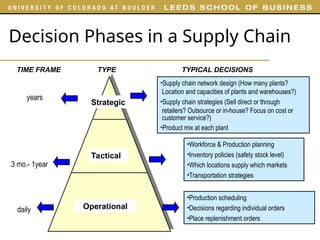

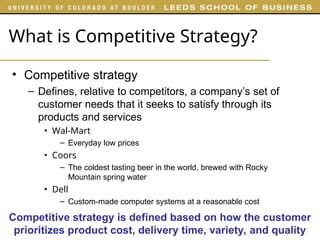

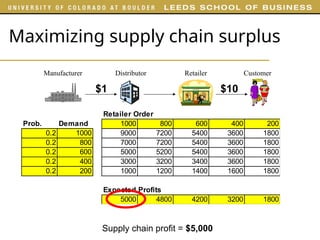

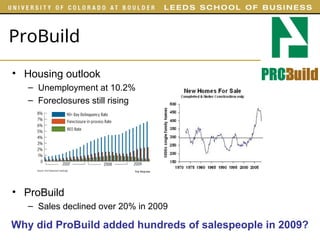

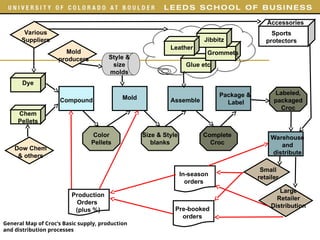

The document outlines various examples and concepts related to supply chain management, including specific case studies such as Crocs and Netflix. It discusses key decision phases in supply chain management, emphasizing the importance of aligning supply chain strategy with competitive strategy to meet customer needs effectively. Additionally, it covers challenges faced by companies like ProBuild and the impact of market conditions on supplier operations.

![Compound

Italy

Florida*

China

Mexico*

Mold

Canada*

Bosnia

China

Mexico*

Brazil*

Assemble

Denver 3rd

party

distributor

Package &

Label

Denver

Color

Pellets

Size & Style

blanks

Small

retailer

Large

Retailer

Europe

Warehouse

/ distribute

Denver

Style &

size

molds

Bosnia

China

Mexico*

Brazil*

Bosnia

China

Mexico*

Brazil*

Bosnia

China

Mexico*

Brazil*

Labeled,

packaged

Croc

Complete

Croc

Large

Retailer

Asia

Large

Retailer

South

America

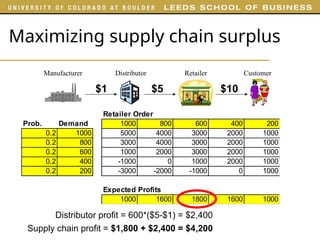

Croc’s Global Production strategy

[2]

[1]

[3]

[4]

[5]

[1] Maintain Florida plant for “Made in USA label

[2] Take advantage of tariffs, e.g., Canada to Isreal

[3] Maintain higher service component of warehousing and labeling for small retailers

[4] Minimize geographic transport by producing in region, including warehousing

[5] Move style and size molds between facilities to maximize production

[6] Use China for large volume, long-term orders from pre-season orders

[6]

*Owned by Crocs vs. outsourced](https://image.slidesharecdn.com/maximizingscmsurplus-250130102701-b6941d17/85/Maximising-Supply-Chain-Management-surplus-ppt-15-320.jpg)