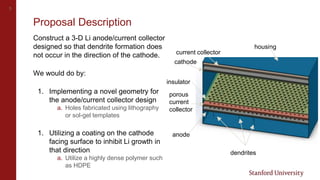

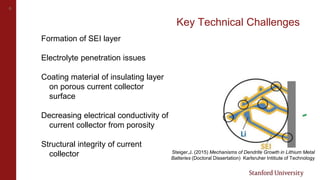

The document proposes constructing a novel 3D lithium anode/current collector design to prevent dendrite formation in rechargeable batteries. It would involve fabricating holes in the current collector using lithography and coating the cathode-facing surface with a dense polymer to inhibit lithium growth. The aims are to demonstrate prevention of dendrite formation toward the cathode and improved cyclability. Key challenges include forming a stable SEI layer, electrolyte penetration issues, and maintaining conductivity while adding porosity. Experiments will test different geometries, analyze cyclability, and image pores to monitor dendrite growth over cycles. The goal is improved grid storage and automotive battery applications.

![References

[1]: Yang, C.-P. et al. Accommodating lithium into 3D current collectors with

a submicron skeleton towards long-life lithium metal anodes. Nat.

Commun. 6:8058 doi: 10.1038/ncomms9058 (2015).

[2]: Körner, C. and Singer, R. F. (2000), Processing of Metal Foams—

Challenges and Opportunities. Adv. Eng. Mater., 2: 159–165. doi:

10.1002/(SICI)1527-2648(200004)2:4<159::AID-ADEM159>3.0.CO;2-O

[3]: Li, Z. et al. A review of lithium deposition in lithium-ion and lithium metal

secondary batteries, J. Power Sources, 254, 168-182,

http://dx.doi.org/10.1016/j.jpowsour.2013.12.099 (2014)](https://image.slidesharecdn.com/4043c08f-a2b1-4e5f-89df-a7823b9009ff-160121164624/85/MATSCI-303-Project-II-Presentation-7-320.jpg)