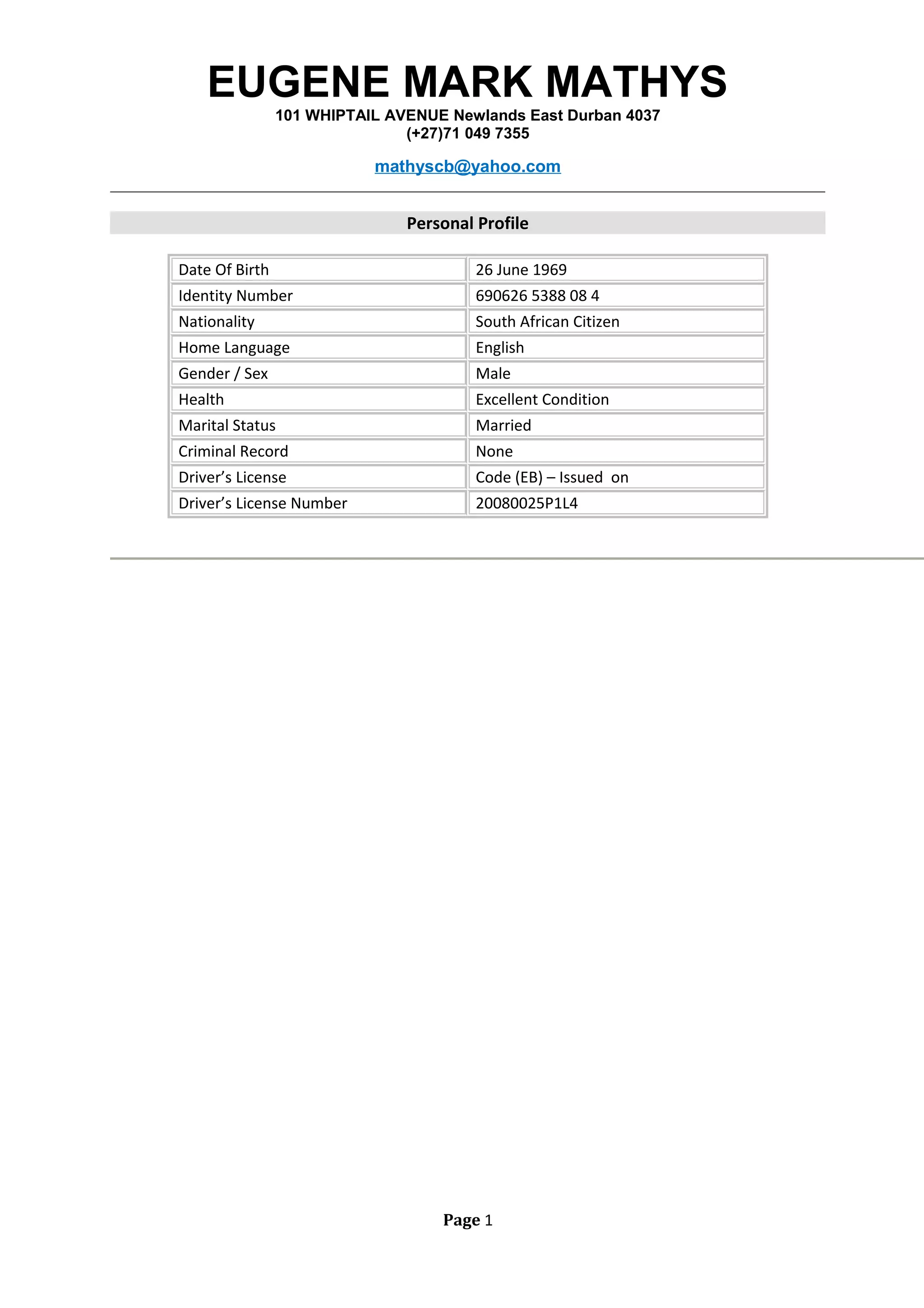

This document contains a personal profile, skills summary, employment history, and education background for Eugene Mark Mathys, a South African citizen seeking employment as a boilermaker. It details his qualifications, including an apprenticeship and technical college courses in plating and structural steel. His over 25 years of experience includes positions as a boilermaker, pipe fitter, foreman, and supervisor at various companies in South Africa. References are provided from previous employers in the engineering and construction industries.

![Key Skills

The work I do is concerned with the design, improvement and installation of integrated systems of

people, materials, equipment and energy. It draws upon specialized knowledge and skill in the

mathematical, physical and social sciences together with the principles and methods of engineering

analysis and design to specify, predict and evaluate the results to be obtained from such systems.

Therefore, with this, in my trade as a qualified boilermaker, I have acquired these skills:

Safety Awareness

Team Leader

Foreman

Supervisory Skills

Post Apprenticeship Experience Since June 1994

Team Player

Safe use and effective operation of:

• Portable Electrical Equipment

• Angle Grinders – All Sizes from [4” To 9”]

• Pencil Grinders

• Drilling Machines

• Use of Welding Machines [Electric and Diesel]

• Oxy-Acetylene Cutting Torches

• Bench Drilling Machines

• Cropper

Machinery:

• Guillotine for steel plate cutting

• hydraulic bending machine for bending plates

• Rolling machine

Tank specialist with:

• Preparation of steel plates for welds, inspections and pressure testing – re-testing.

• Pressure vessels, working with stainless steel and carbon piping and X-Ray specialists.

Accurate design layout construction of plans and drawings:

• Lobster back, square to rounds, cones

Structural steel prep:

• Accurate marking, drilling, angles and slopes, dimensions for cutting lengths.

Piping:

Fabricate and install stainless steel and carbon steel piping.

Personal achievements

Consult my References for my character and work ethic.

When I was at school, I was a top runner for school sport activities for 100m, 200m, 800m and 1500m

relay and long jump events. [1984 – 1989]

In my Matriculation year of 1988, I was elected as a prefect.

I was a Sunday school teacher and a youth leader.

Page 2](https://image.slidesharecdn.com/184774fc-e9df-4254-838a-450425394c6d-160223203824/85/mathys-eugene-cv-2-320.jpg)

![Employment Summary [Continued...]

Name Of Company GENREC (Richards Bay)

Position Held Boilermaker

Duties Performed Based at Workshop

• Fabrication: Fabrication of dredger & pontoons in the workshop.

• Constructing of templates for a specific job, as required.

• I also worked directly from drawings and also worked night shift for the contract.

• This contract consisted of one boilermaker, one assistant, and two welders.

Period of Employment February 2002 to June 2002

Name Of Company Barlow Engineering

Position Held Boilermaker / Pipe Fitter

Duties Performed Based at Huletts Refinery

• I worked unsupervised as the team leader for shutdown preparations.

• I also built screw conveyors’ & belt conveyors which were used for distribution.

• Fabrications: Structural Steel, Pipefitting, Boiler Repairs.

• Welding [Plate welding and tacking]

• Interpreting drawings from plans and specs

Period of Employment October 1997 to July 2003

Name Of Company Dorbyl Petroleum Services

Position Held Boilermaker

Duties Performed Based at S.A.P.P.I. [South African Pulp and Paper

Industry]

Maintenance work including: piping, pipe fitting, welding, repairs to cranes, installation of silos` and fabrication

of large storage tanks for Alusaf Hillside Smelter.

Period of Employment July 1994 to August 1995

Page 5](https://image.slidesharecdn.com/184774fc-e9df-4254-838a-450425394c6d-160223203824/85/mathys-eugene-cv-5-320.jpg)

![Employment Summary [Continued...]

Name Of Company Dorbyl Marine (PTY) Ltd. Now known as Dormac

Position Held Apprentice Boilermaker

Duties Performed Based at Huletts Refinery

• I worked unsupervised as the team leader for shutdown preparations.

• I also built screw conveyors’ & belt conveyors which were used for distribution.

• Fabrications: Structural Steel, Pipefitting, Boiler Repairs.

• Welding [Plate welding and tacking]

• Interpreting drawings from plans and specs

Apprenticeship Duration and completion September 1990 to June 1994

Qualified as a Boilermaker 16th

June 1994

Education Summary

Education High School

Last school attended Newlands east senior secondary school

no.1 [known as N.E.S.S.]

Highest standard passed Grade 11 in the year 1987

Subjects passed English, Afrikaans, mathematics

History, biology, physical science

Tertiary Education

Institution attended L. C. Johnson Technical College

Type of Course N1 – Platers

Subjects Passed Metal Workers Theory

Plating and Structural Steel

Technical Drawings

Mathematics

Engineering Science

Type of Course N2 – Platers

Subjects Passed Metal Workers Theory

Plating and Structural Steel

Technical Drawings

Mathematics

Engineering Science

Page 6](https://image.slidesharecdn.com/184774fc-e9df-4254-838a-450425394c6d-160223203824/85/mathys-eugene-cv-6-320.jpg)

![Additional Courses Completed

N.O.S.A. certificate course for Safety - Duration of Course: 5 days

Fire Prevention Training – SAPREF - Duration of Course: 1 day

Permit Receiver Course – SAPREF - Duration of Course: 1 day

Interests

Immigrating to Australia.

Making a better life for my children and securing their future.

I enjoy fishing. (Salt water)

To make a better life for my family and their future.

Referees

Name Employer Position Contact Number

Kreeshan Pillay Rodcon Engineering (Goss & Balfe)

GENREC (Richards Bay)

Owner - Partner –

Managing Director

031 468 3017

083 779 1121

Joe Ketley Ketley & Ketley (Rodcon Engineering) Owner – Managing Director 082 565 8525

Younis Walgee Barlow Engineering Owner / Partner Chief

Executive Officer [C.E.O.]

+27 31 468 6862

Dorbyl Petroleum Services

[Storage Tanks]

Ivan maniram /

Ash moola

Dorbyl Marine (PTY) Ltd. Now known as

Dormac

I.E.C Owner / partner

031 205 1511

031 5009762

Page 7](https://image.slidesharecdn.com/184774fc-e9df-4254-838a-450425394c6d-160223203824/85/mathys-eugene-cv-7-320.jpg)