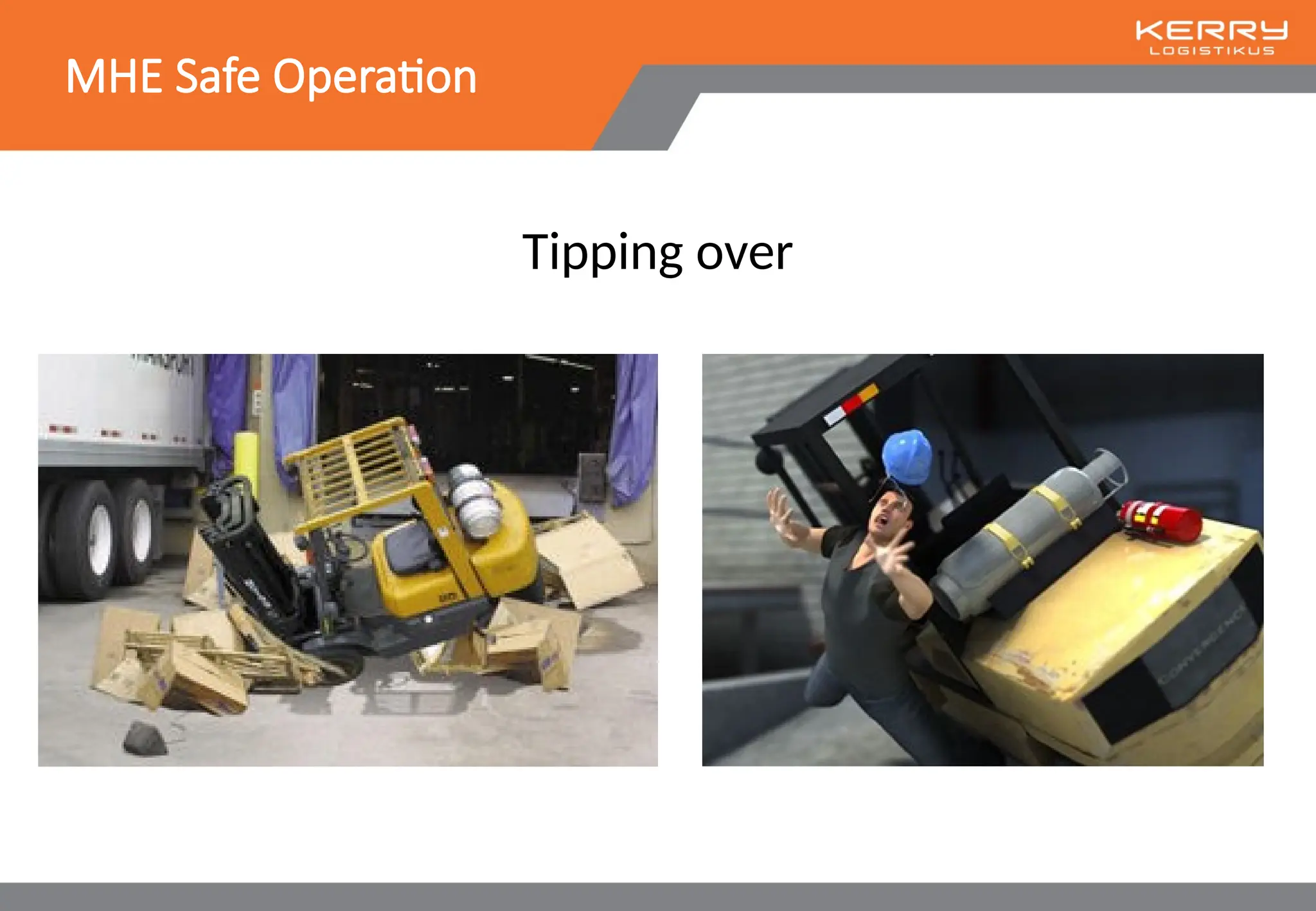

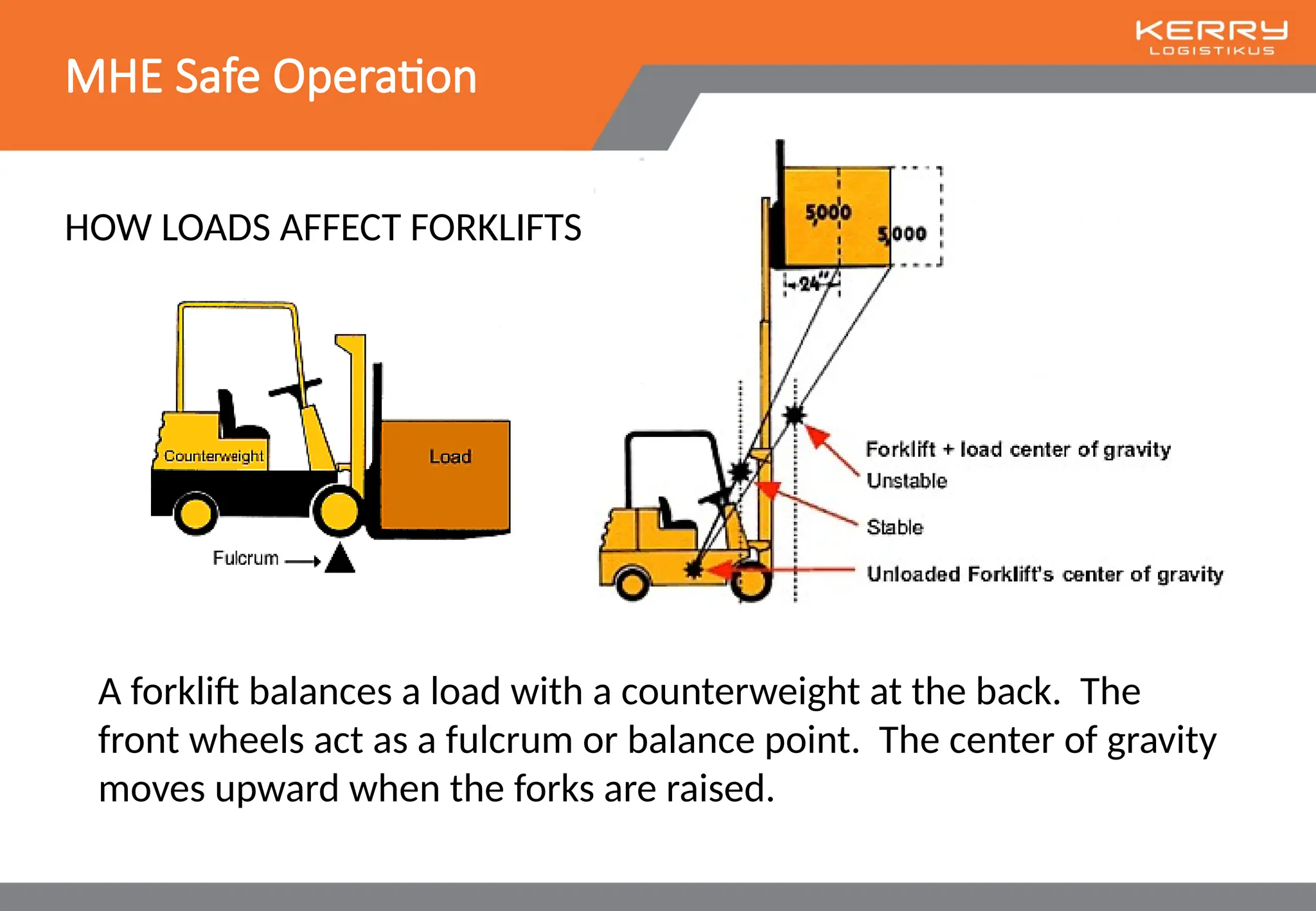

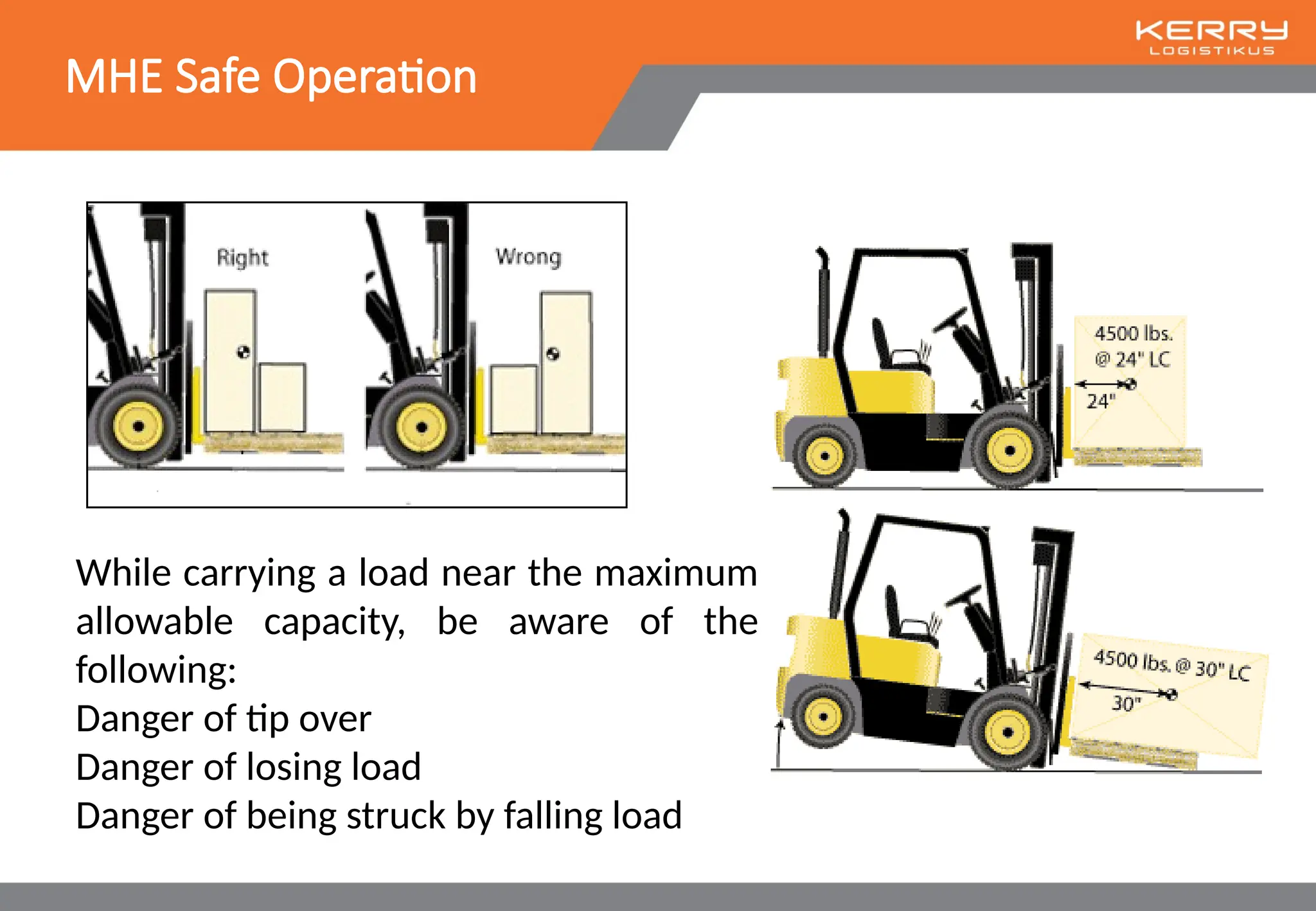

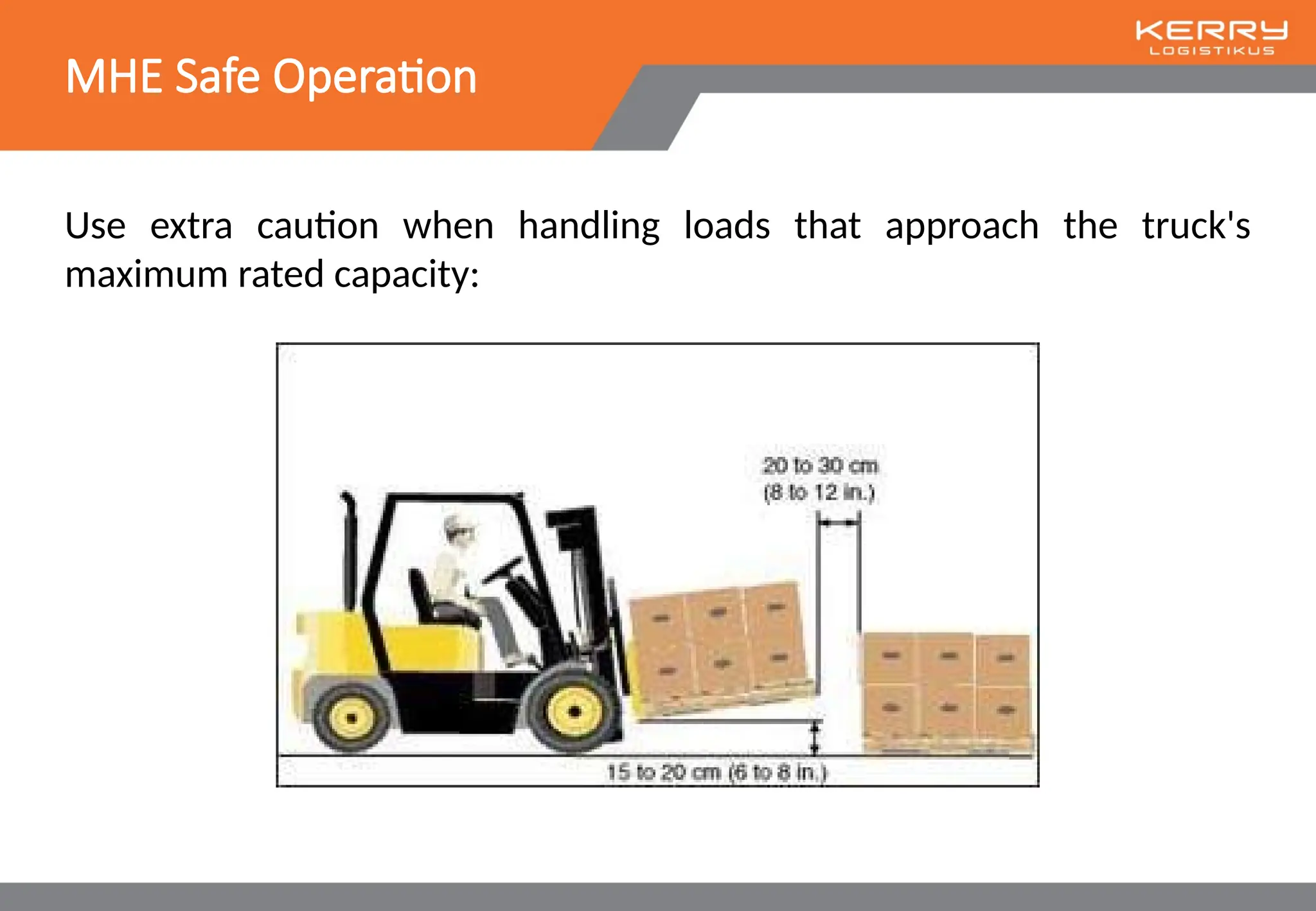

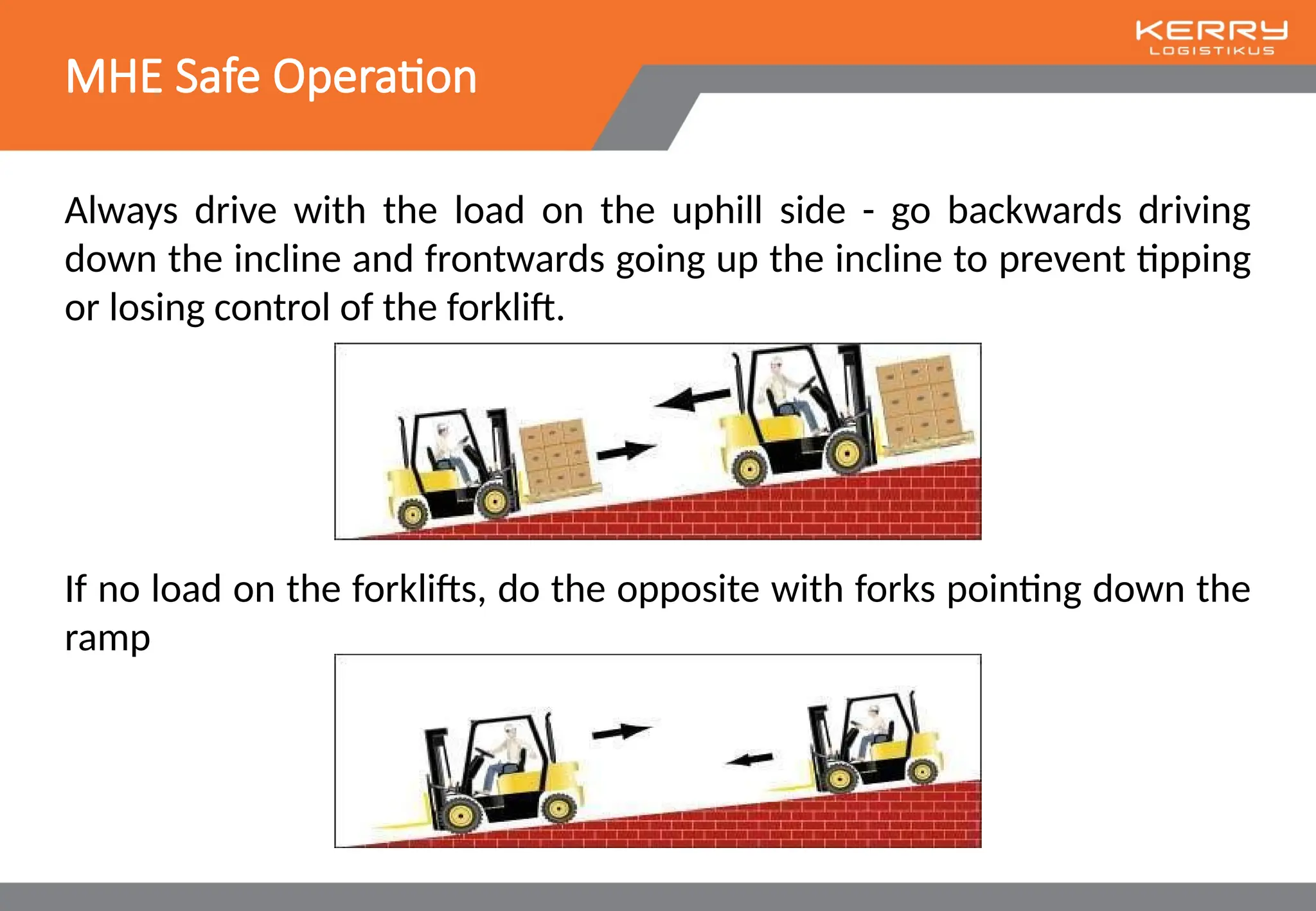

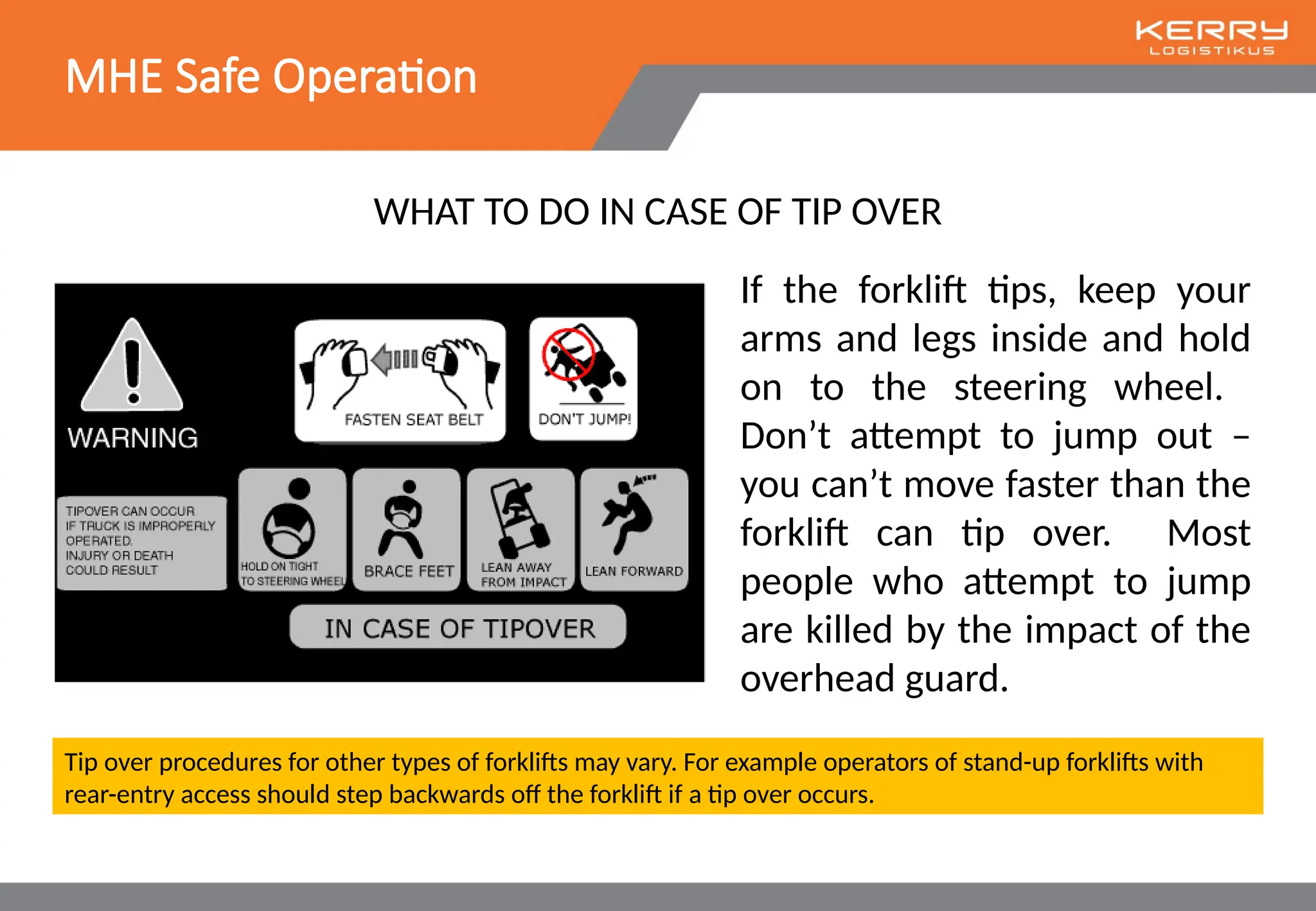

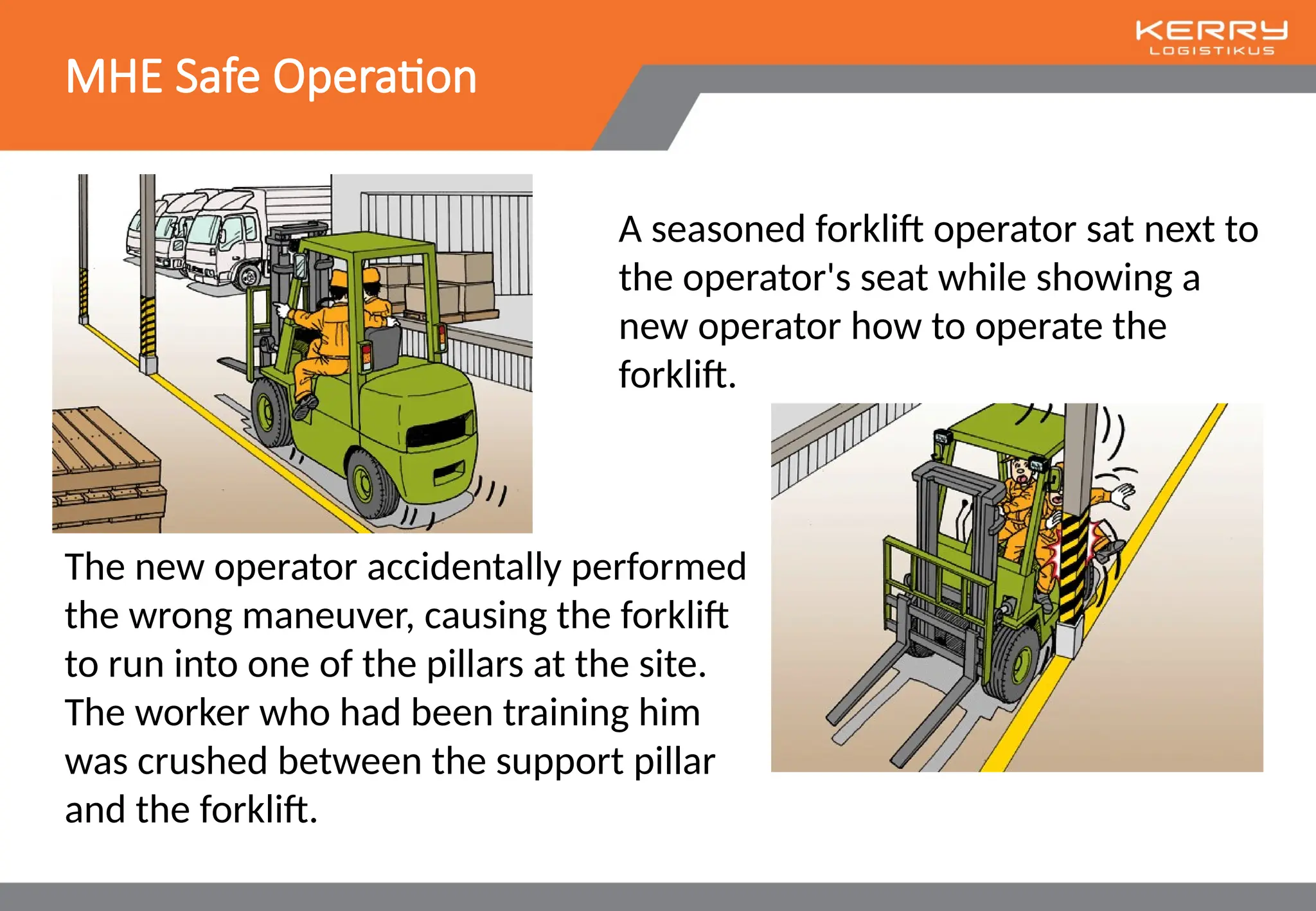

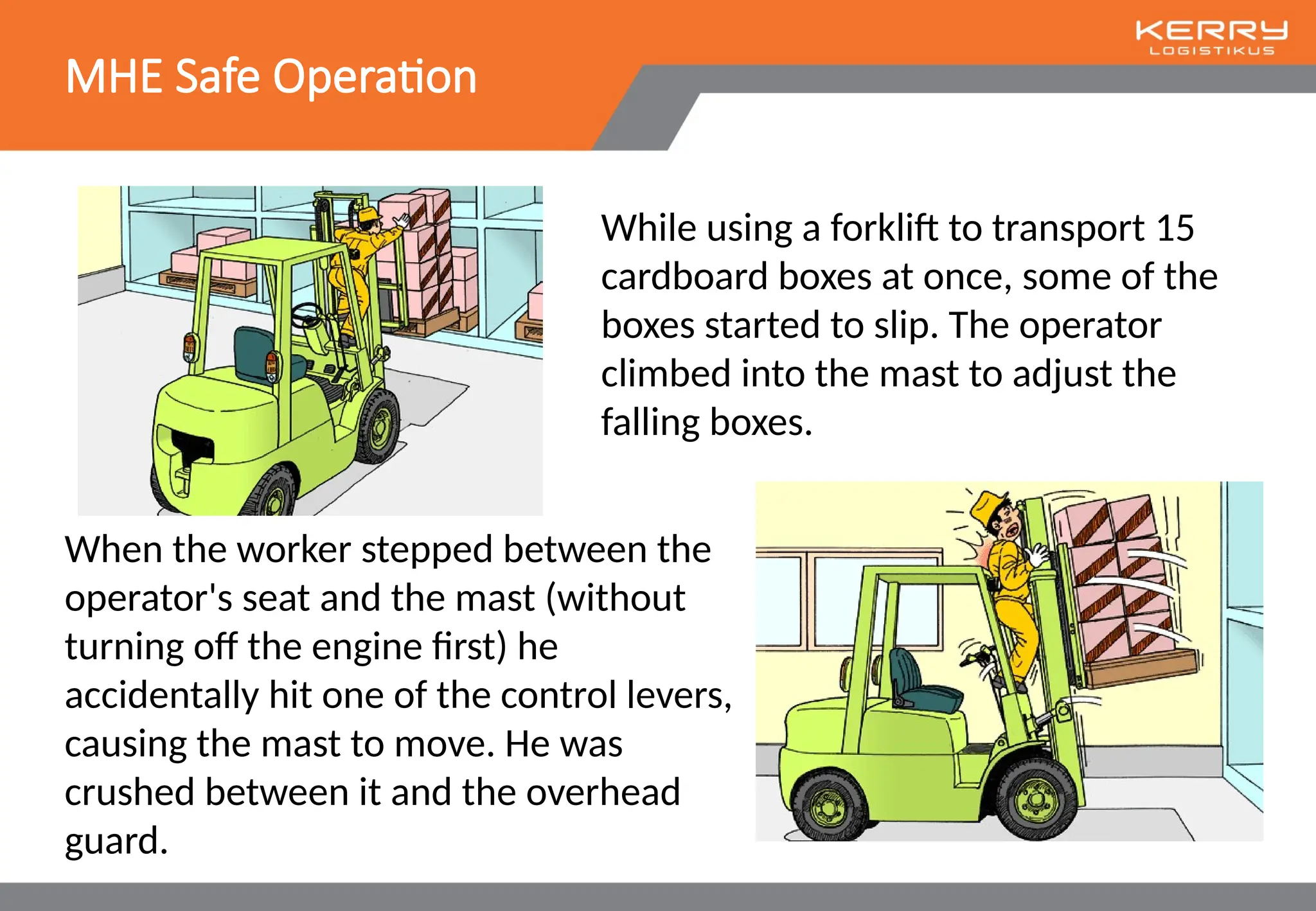

The document details safety training and incidents related to material handling equipment (MHE), particularly focusing on forklift operations. It outlines common hazards, accident statistics, and safe practices to prevent accidents, emphasizing the importance of proper training and adherence to safety protocols. Notable incidents are mentioned to highlight the risks involved and the necessity for operators to use seatbelts and follow safety guidelines.