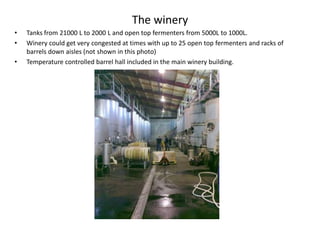

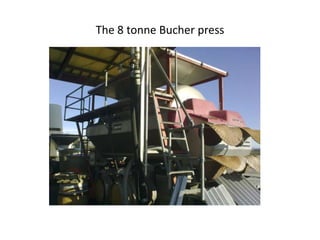

The document summarizes the 2010 vintage experience at Matariki Wines Ltd. It discusses the location of the winery and vineyards. It notes that grapes are processed from up to 15 growers, totaling just under 900 tons of fruit for the vintage. The winery has tanks from 21,000L to 2,000L and open top fermenters from 5,000L to 1,000L. The vintage began with the first fruit arriving - Pinot Gris from Auckland. Red cap management and pumpovers were a major part of the work. Bottling and a beard growing competition concluded the vintage.