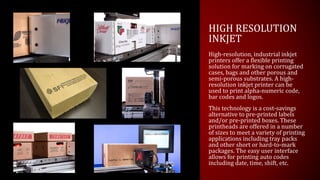

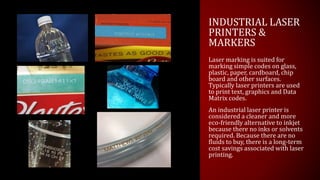

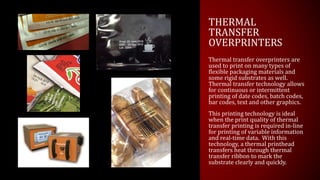

The document outlines the Product Identification Network, which consists of companies that provide marking, coding, and labeling solutions from various top manufacturers. It details various printing technologies including high-resolution inkjet, drop-on-demand inkjet, industrial laser printers, thermal transfer overprinters, and label printers, highlighting their applications and benefits. Additionally, it mentions the network members and provides links for more information and distributor locations.