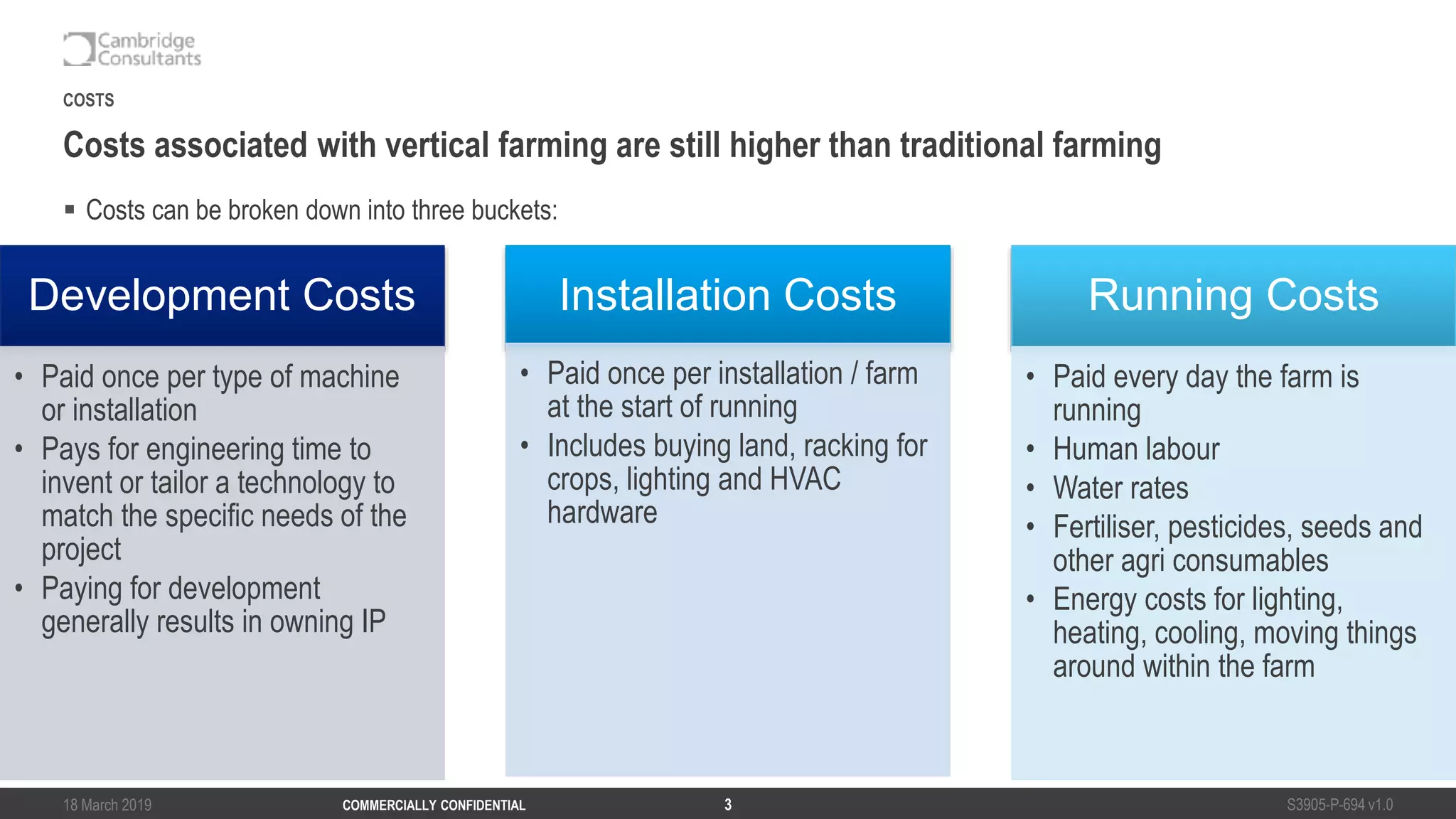

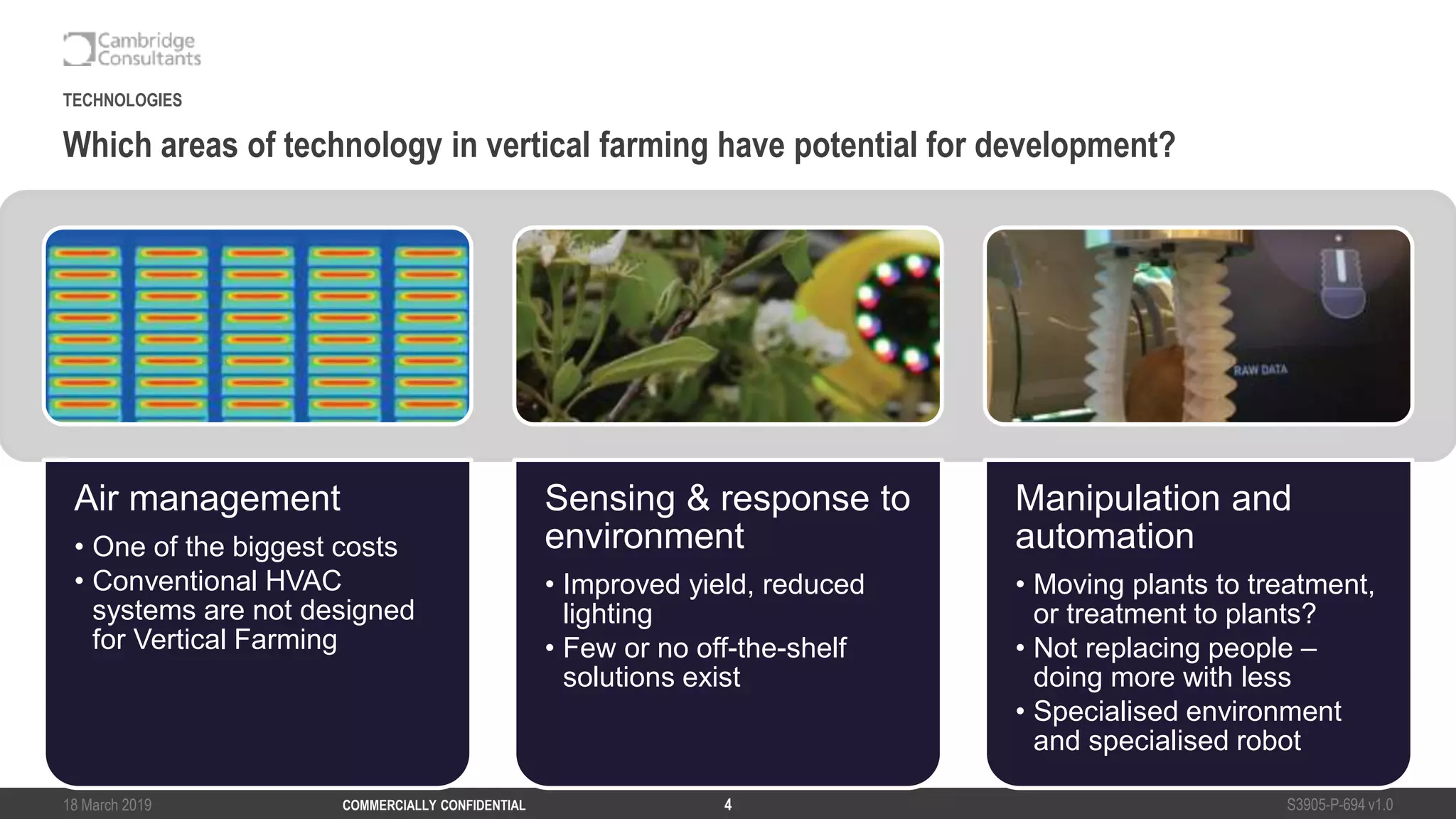

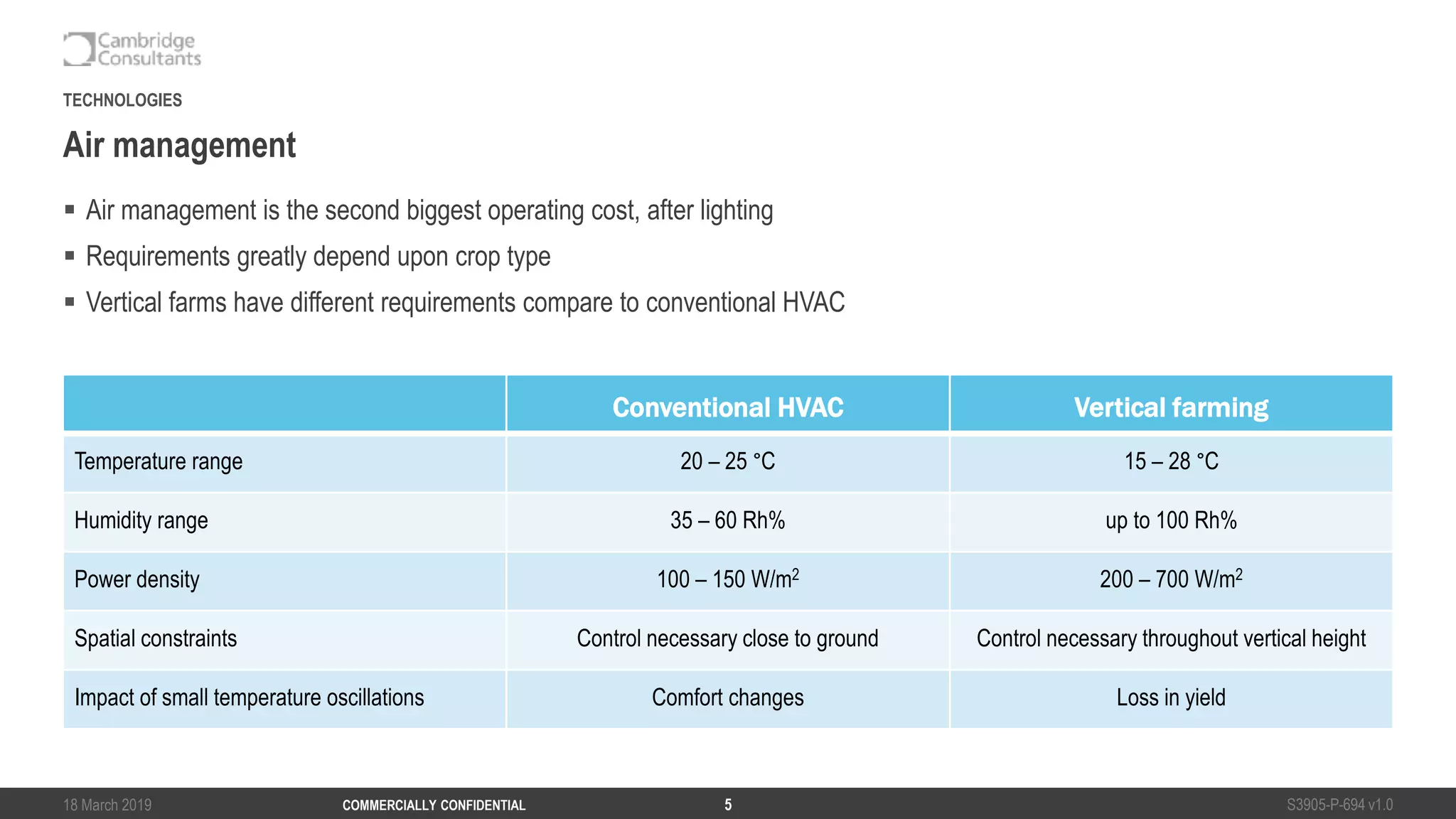

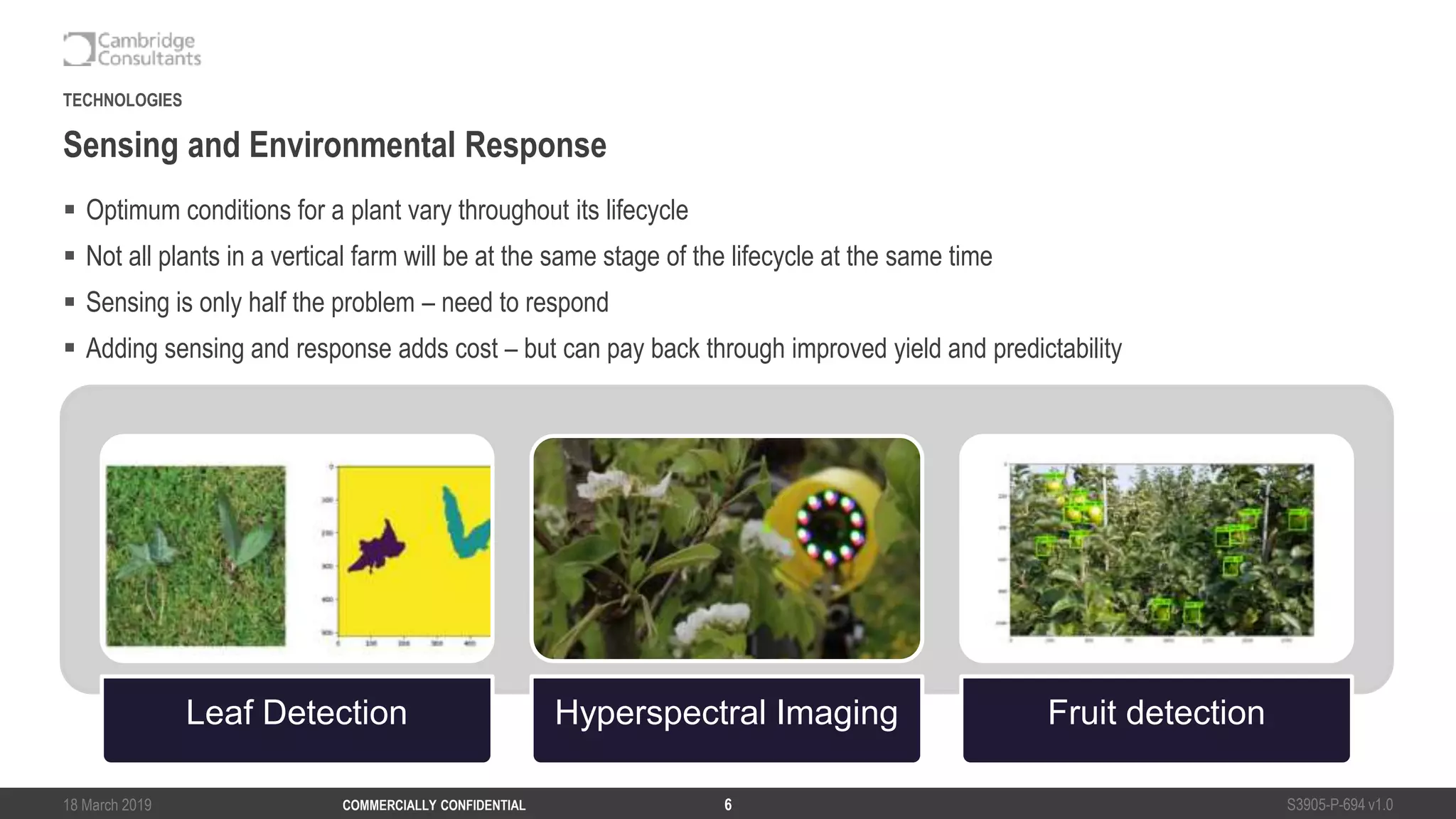

The document discusses the advantages and cost considerations of vertical farming, highlighting increased production, reduced transport costs, and sustainable practices. It outlines three types of costs associated with vertical farming: development, installation, and running costs, emphasizing the need for specialized technologies in air management and automation to reduce these costs. The conclusion stresses the importance of developing efficient technologies and possibly sharing them to achieve economic viability in vertical farming.