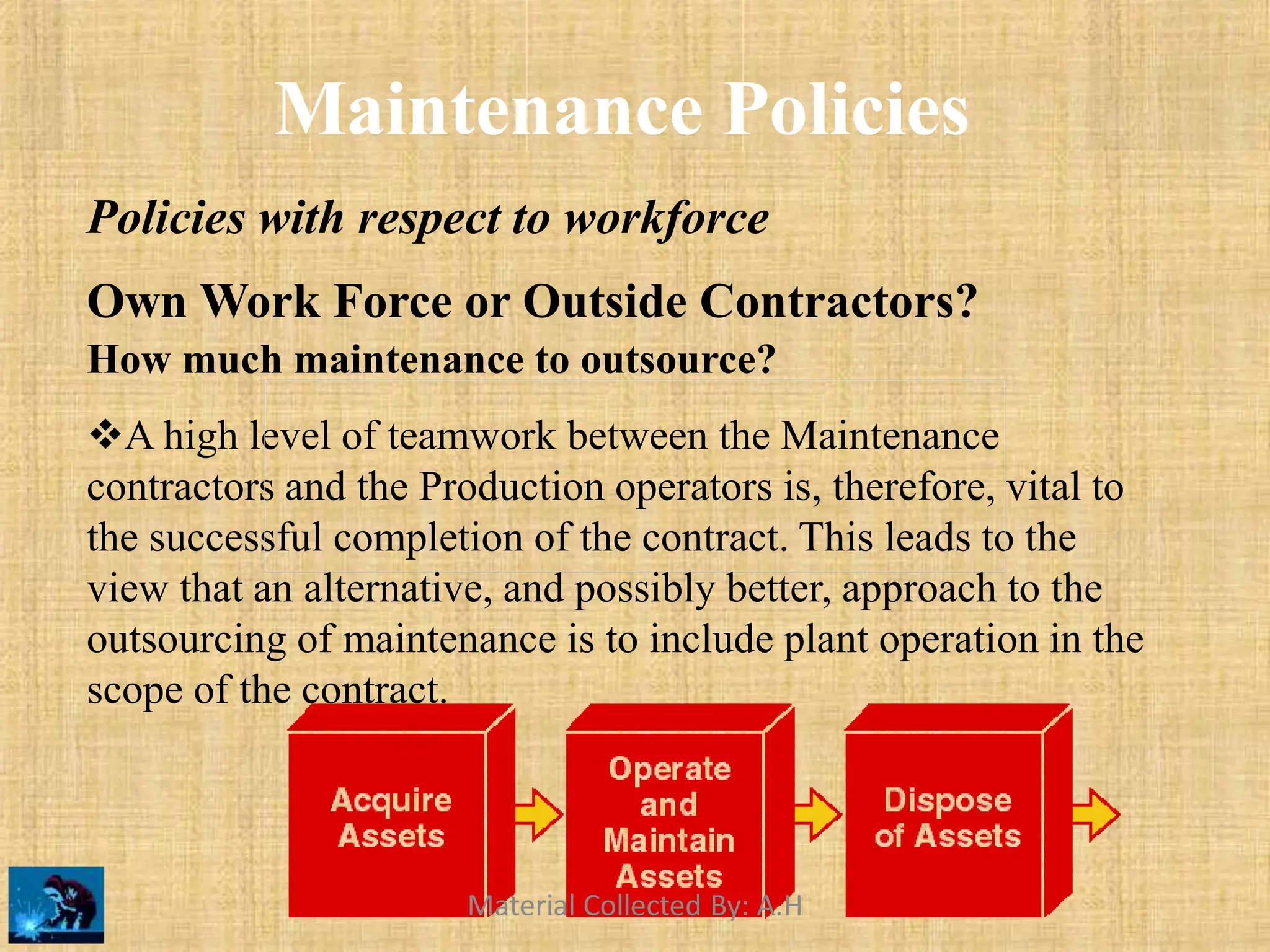

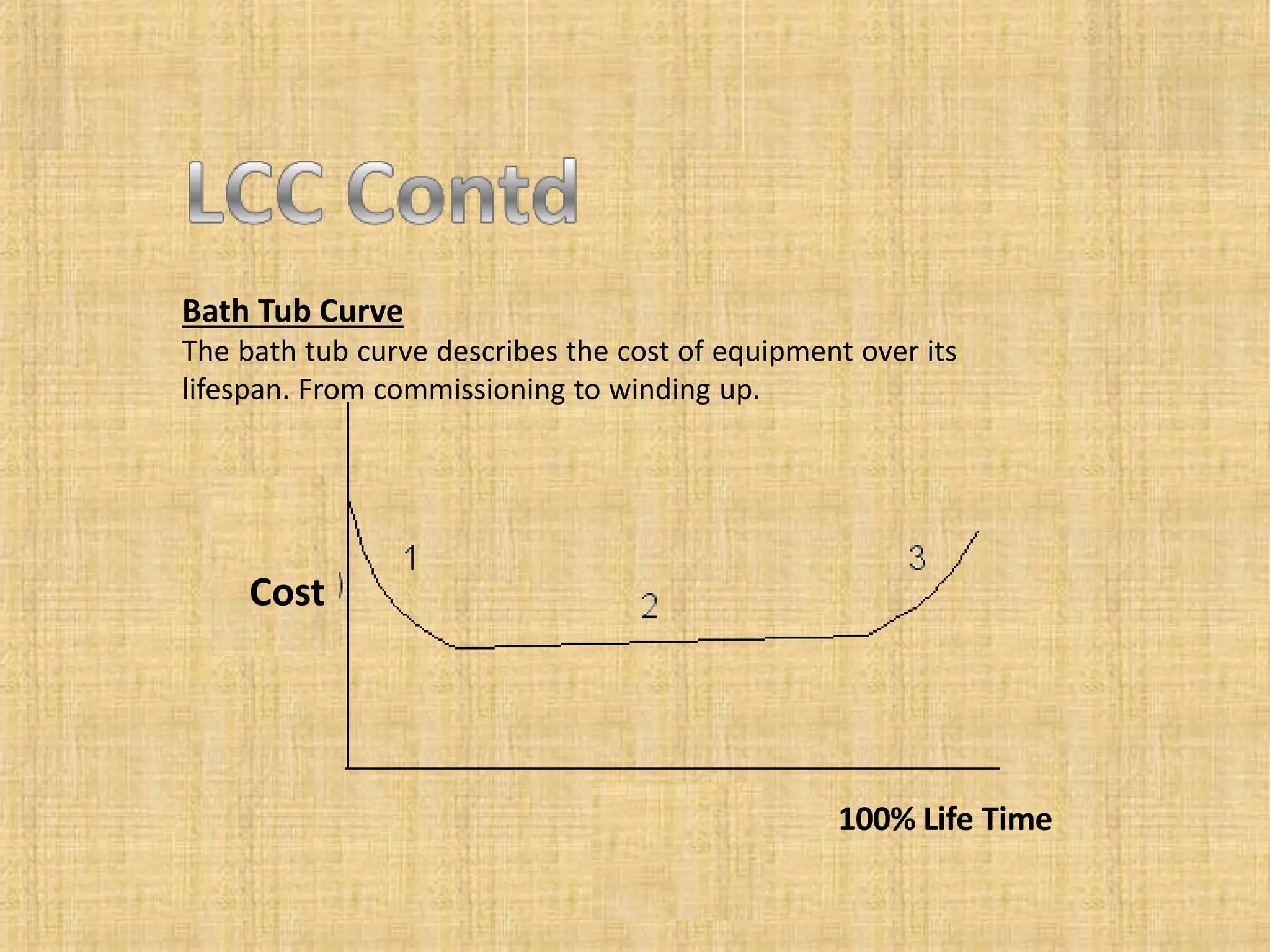

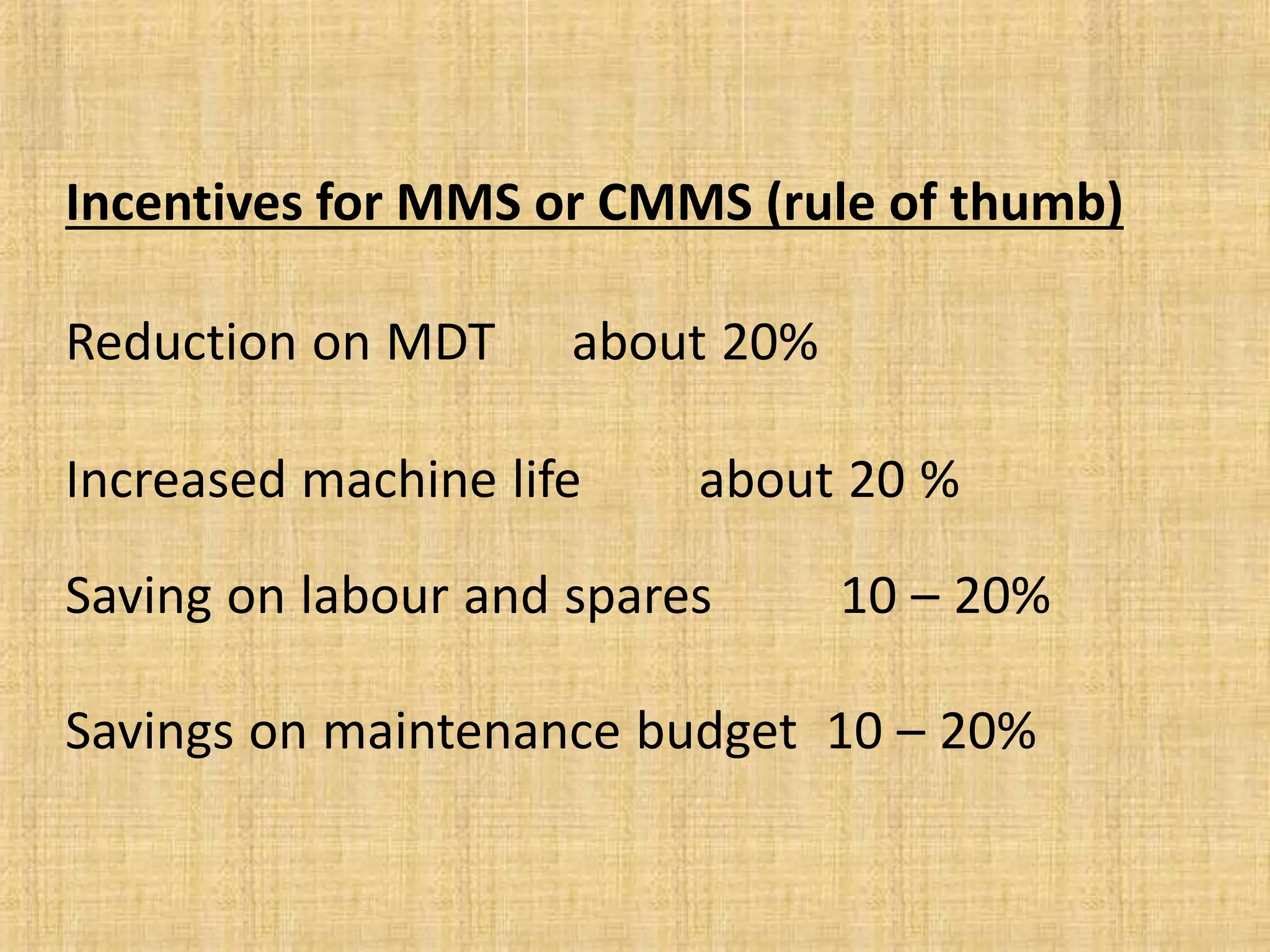

The document discusses the critical role of maintenance management in optimizing operational costs and maintaining equipment efficiency across industries. It outlines the principles of maintenance, including cost control, record keeping, preventive maintenance, and the effective organization of the maintenance department. Furthermore, it explores the decision-making process for using internal staff versus contracting out maintenance services based on strategic importance and competitive performance.