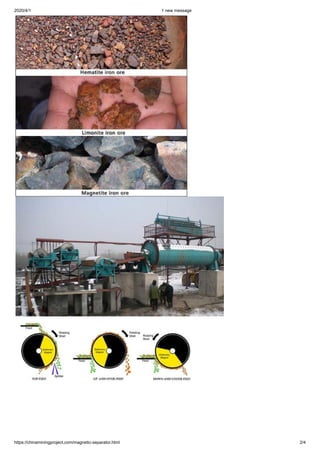

Magnetic separators are commonly used to separate magnetite iron ore. They directly separate magnetite sand or sea iron sand. For rocky magnetite, crushing and grinding is required first before magnetic separation. Magnetic separators consist of a drum where magnets are embedded to attract magnetic materials from non-magnetic tailings. For weaker magnetic ores like hematite and limonite, both magnetic separation and gravity separation are used, though gravity separation is more common due to lower costs and higher throughput. The document provides examples of iron ore beneficiation projects from 2011 that improved iron grades using magnetic separation and other methods.