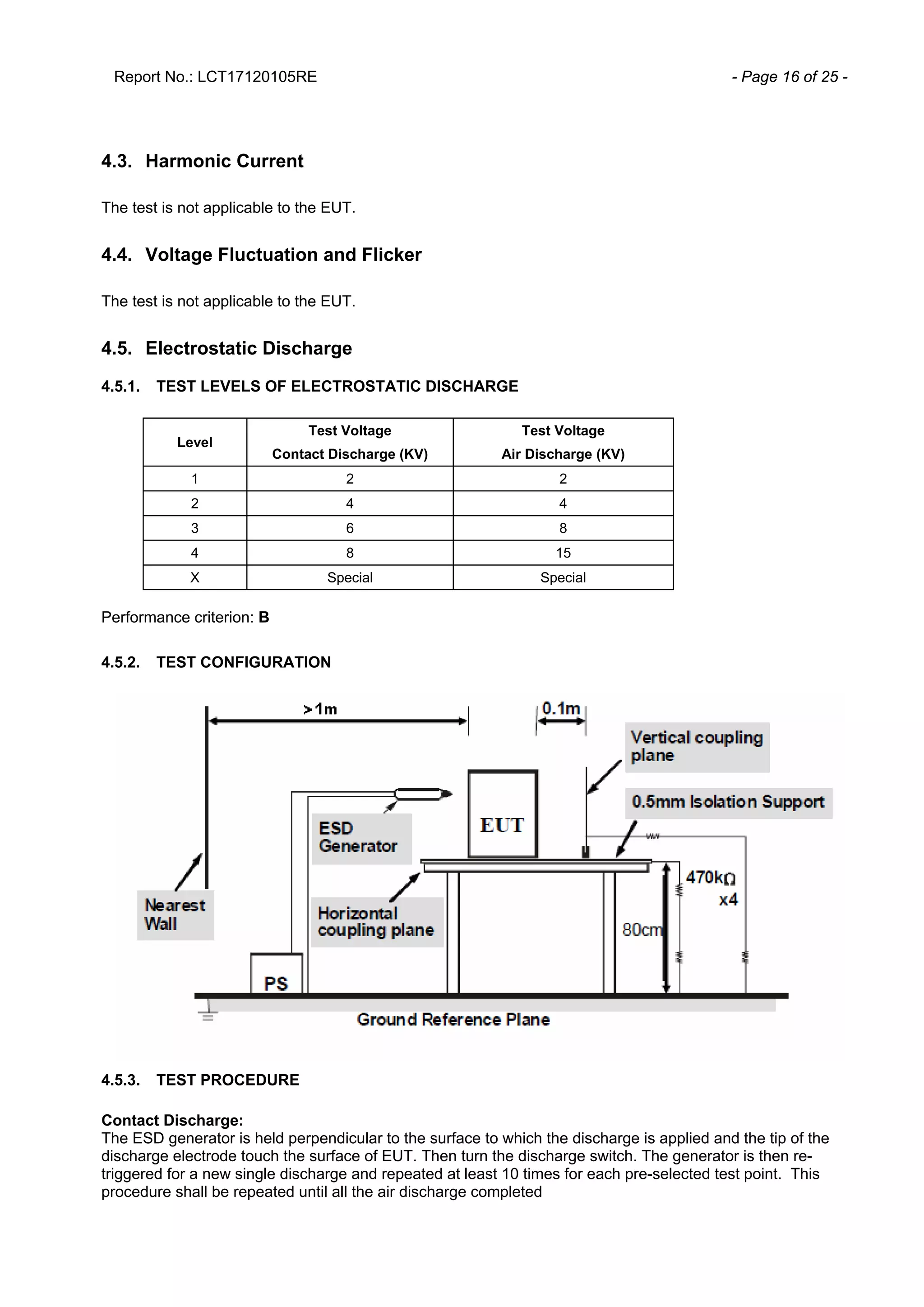

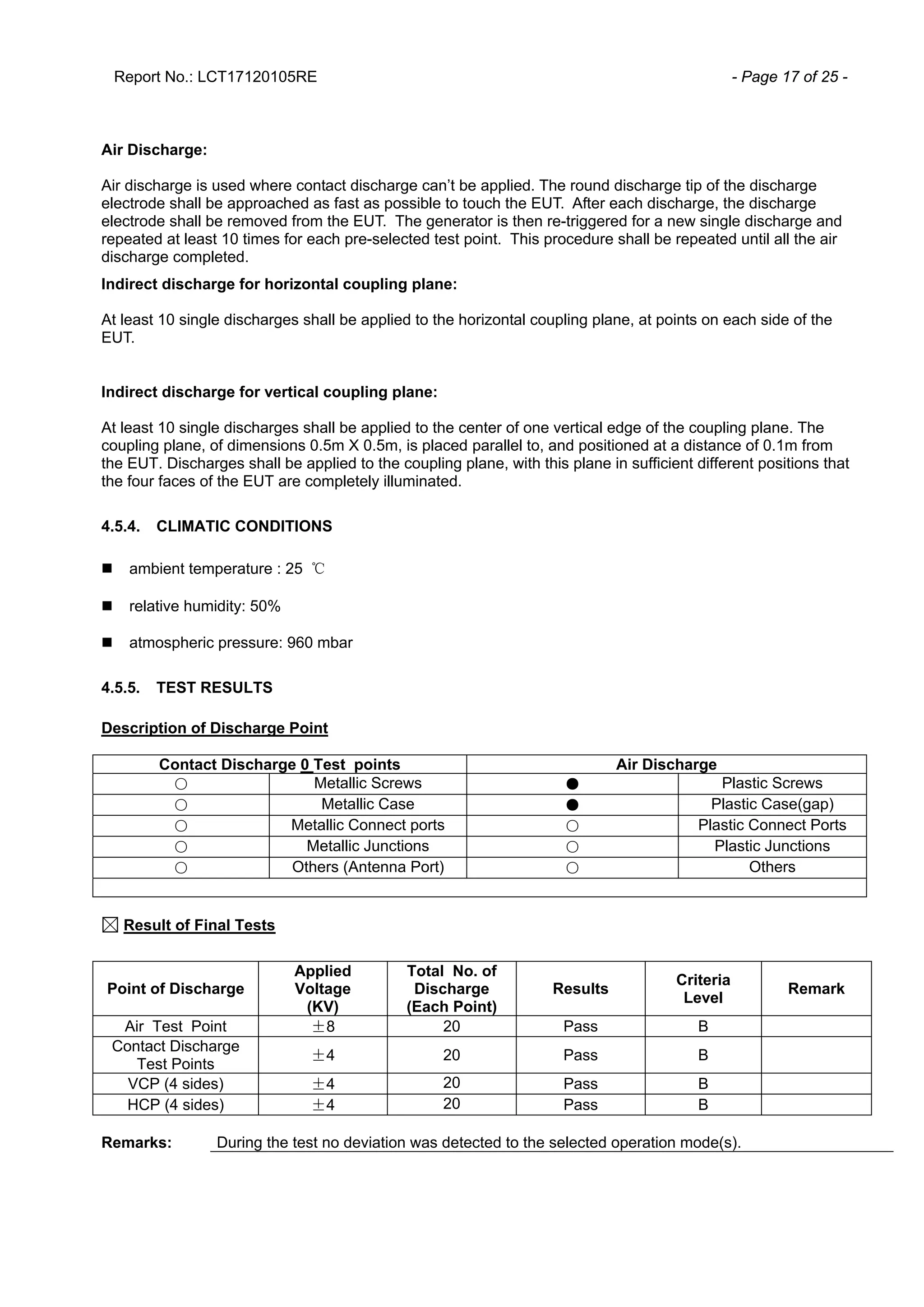

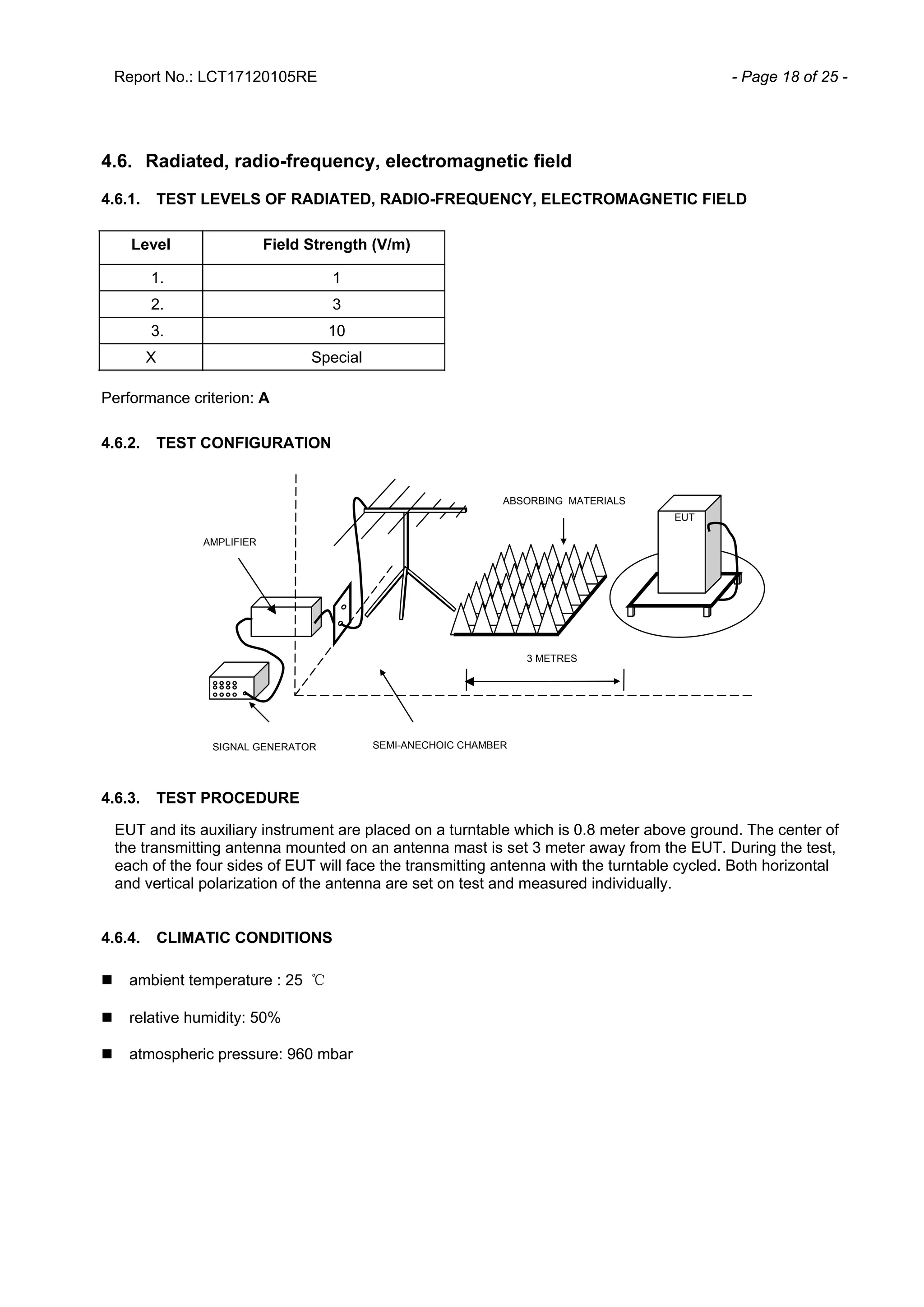

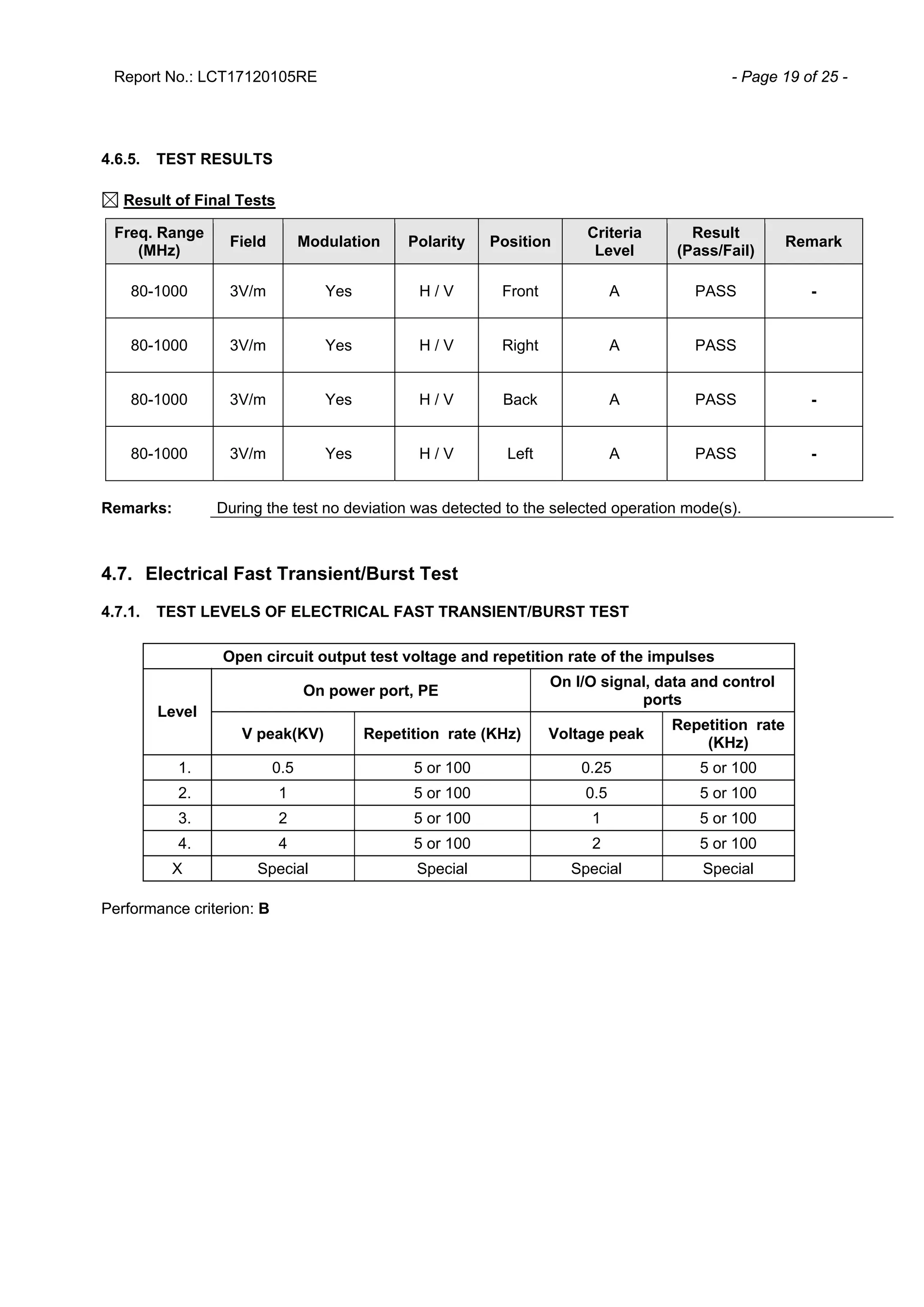

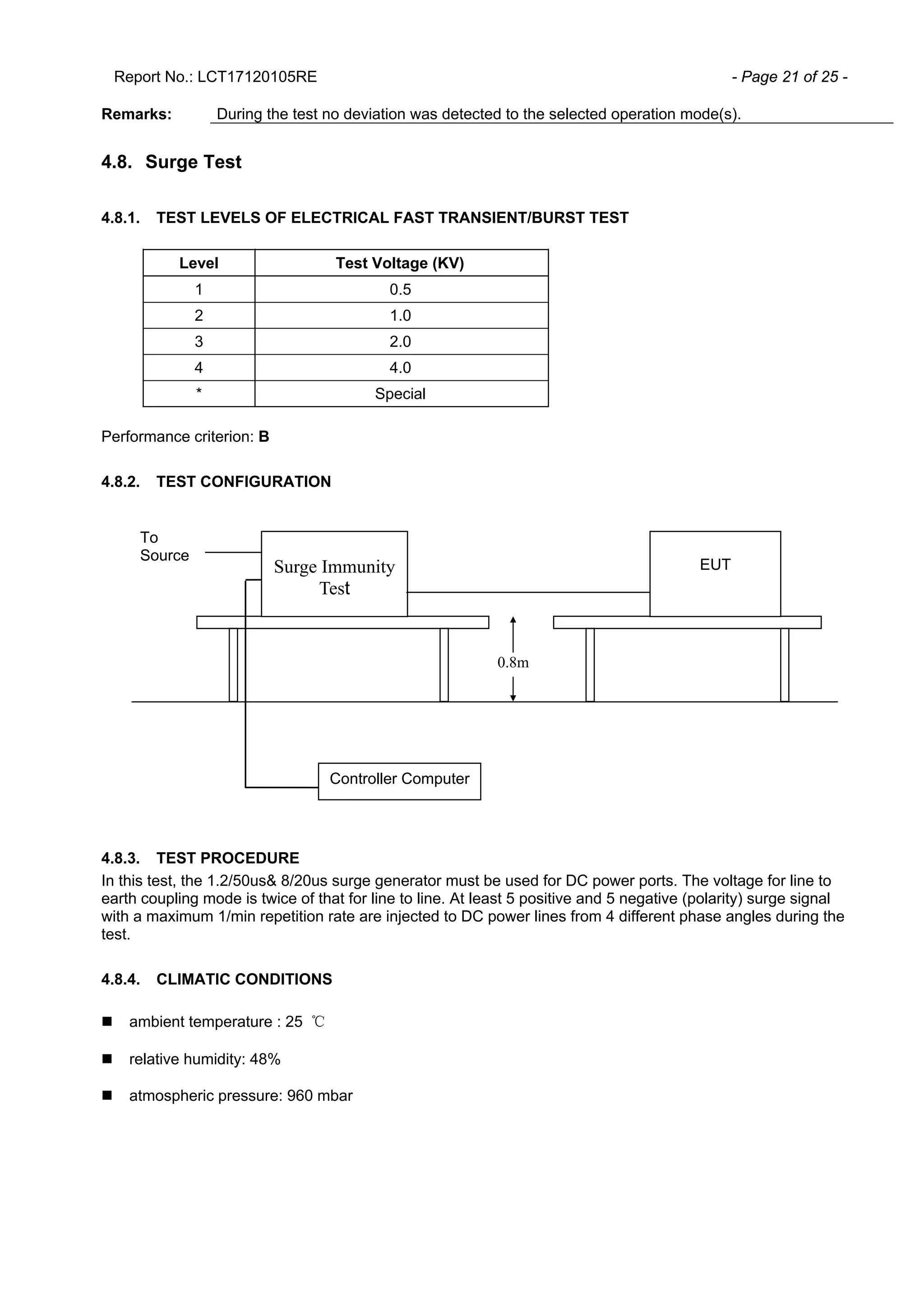

The document is a test report (no. lct17120105re) for a magnetic cable developed by Shenzhen Youcable Technology Company Limited, documenting compliance with various electromagnetic compatibility standards. Testing was conducted by Shenzhen LCT Technology Co., Ltd., with results showing that the cable passed all specified tests, including radiated emissions and immunity characteristics. The report provides details on testing conditions, equipment used, and measurement uncertainties, confirming that the equipment under test meets the required performance levels.