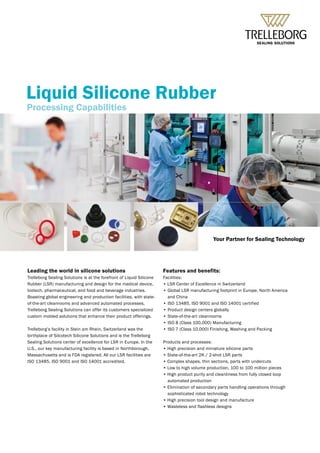

Trelleborg Sealing Solutions is a leading manufacturer of liquid silicone rubber (LSR) for medical devices, biotech, pharmaceuticals, and food and beverage industries. It has state-of-the-art facilities around the world, including a center of excellence for LSR in Switzerland. Trelleborg offers specialized custom molded silicone solutions and high precision injection molding from 100,000 to 100 million pieces. All of its LSR facilities are ISO certified.